Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Eleni Vrochidou and Version 2 by Camila Xu.

An end effector is a peripheral device attached to a robot’s wrist, enabling interaction during a task. For harvesting robots, the end effector is considered the contact point between the robot and the product to be harvested. Robotic systems have been designed to cover labor shortage, to increase the speed of harvesting, and to improve the efficiency of harvesting.

- end effector

- manipulation

- harvesting robots

1. Introduction

As the human population increases, moving towards sustainable agricultural management becomes ever harder. In the next decades, human population is expected to grow by 40% to 9.7 billion by the year 2050 [1], calling for double fruit production. The worldwide agricultural area is expected to double as well. Nevertheless, agriculture employment is expected to decrease in half by the year 2050, resulting in a shortage of 5 million harvesters. Hence, more than 10% of fruits worldwide cannot be harvested; the latter is equal to the European Union’s annual consumption [2].

Harvesting is a seasonal, low-paid, repetitive, and labor-intensive work with meagre professional prospects. Experienced harvesters are retiring, whereas younger people are not interested in replacing them. Labor shortages result in harvest delays. However, a fruit harvested with several days of delay deteriorates in quality and may lose up to 80% of its market value. As a result, worldwide growers lose up to an estimated USD 30 billion a year in potential sales from fruits that cannot be harvested [3].

For this reason, crop management has significantly changed over the last decades. More specifically, ground and aerial robots have been introduced in agriculture, demonstrating their potential to meet the rising food demand, by automating traditionally manual agricultural operations [4], including harvest. Thus, robotic systems have been designed to cover labor shortage, to increase the speed of harvesting, and to improve the efficiency of harvesting.

In traditional manual harvesting, the harvester uses his/her hands to remove leaves or branches, to grasp the fruit, and to detach it from the plant by pulling it away, sometimes using a cutting tool. Efficient manual harvesting requires experienced skills; an inexperienced harvester may unintentionally harm the plants. However, the kinematics of human hands and body, sense of touch, and muscular strength give inherent grasping abilities to humans and a major degree of quick adaptation to different crop shapes and textures for applying a suitable detachment force. However, human skills are only limited by tiredness. On the other hand, a robotic system can harvest continuously, accurately, and tirelessly with consistency. For this reason, researchers try to emulate human harvesting skills, resulting in kinematic models for the movement of robotic arms and the design of sophisticated end effectors with appropriate sensors for crops’ manipulation [5][6][5,6].

An end effector is a peripheral device attached to a robot’s wrist, enabling interaction during a task. For harvesting robots, the end effector is considered the contact point between the robot and the product to be harvested. If not designed effectively, an end effector could damage the crop and deteriorate the overall performance of the harvesting system. The diversity of the crops requires that each harvesting system possess an end effector according to the specifications of the harvested crop. Toward the latter end, this work provides a detailed summary of state-of-the-art robotic end effectors for harvesting applications. Requirements for the detachment of harvesting products, different types of end effectors, and sensory control strategies are also discussed.

2. End Effectors in Agricultural Robotic Harvesting Systems

Once a fruit is detected and located, the challenge is to pick it without damaging the fruit or the crop. Typically, fruits are difficult to reach due to many unstructured obstacles that interfere with the harvesting system, such as branches and leaves. An effective harvesting system must balance between speed and efficiency. Bulk harvesting approaches, such as limp or branch shaking systems, are used in harvesting [7][14] and report a lower harvesting cycle, that is, harvesting time per fruit. However, such techniques are not appropriate for soft or for sensitive fruits. To ensure superior quality and high market value, most fruits need individualized harvesting mechanisms. A key component of any harvesting mechanism is a harvesting end effector that detaches a fruit from a tree. It is common for end effectors to be customized based on the harvested crop. However, the design can be adapted to other crops of the same fruit size or can be adjusted to different fruits with minor readjustments. In all cases, a manipulation system in harvesting applications has to fulfill specific requirements. The most important of these requirements include: (1) operational characteristics: adaptation to various shapes, not causing damage to the harvesting product, consistency, and high precision of operations, and (2) technical characteristics: high activation speed, low maintenance, low weight, and low energy consumption [8][15]. The design of the end effector needs to comply with the aforementioned requirements, and it is an essential aspect for effective harvesting. Finally, a specialized end-effector control unit is used to provide a standardized software and hardware interface. In what follows, first, fruit detachment methods are reviewed to underline the requirements of an effective end effector. Second, the most common types of end effectors that meet the harvesting requirements are summarized. Third, additional sensors for agricultural end effectors are discussed, as well as operating requirements. Basic agricultural end effector development principles are also proposed.2.1. Detachment Methods

The most common detachment method is grasping and pulling [9][16]. Simply grasping and pulling a fruit away from the crop results in breaking the stem and cutting it free from the plant. However, pulling away places extreme force on the fruit, which may damage it and cause plant shaking. Shaking will cause all fruits on the tree to swing. The latter may cause three additional problems: (1) movement of the fruits that had been detected by the vision system from their original position and hence failure of the manipulation system to grasp them, but the latter can be resolved by recalculating the location of the fruits when a fruit is removed; (2) detachment or brushing of nearby fruits due to shaking of the tree; and (3) possible detachment of the stem from the plant, instead of the fruit alone. The part of the remaining stem can damage (e.g., pierce/scratch) the rest of the fruits during their collection, storage, and/or transport. In order to deal with fruit damage due to unnecessary detachment pulling force, grasping from the stem and pulling has been applied [10][17]. Stem grasping is an intact alternative method, which does not require the fruit to be grasped directly; therefore, it does not typically damage the harvested fruit. The end effector grasps the stem of the fruit and detaches it from the tree. However, the shaking of the tree remains. To overcome this problem, end effectors able to cut the fruit stem were designed. Therefore, it could be either direct contact grasping of the fruit and simultaneous cutting of the stem [11][18] or grasping from the stem and cutting it [12][19]. The second may be a fully intact method, yet it is more challenging, since the detection of a small stem is more demanding, due to dense foliage and occlusions in in-field applications, than the detection of an entire fruit. One solution to overcome this difficulty and still reduce the exerted force from the stem is to rotate the fruit before pulling it from the tree [13][20]. Rotation before pulling is a traditional technique of manual harvesting. The stem folds at the fruit–stem interface, which facilitates the breaking of the stem at its contact point with the fruit. Suction detachment methods are also common. Suction, when applied alone, is similar to grasping. However, due to the applied suction force, it could wound the fruit at the point of contact and pierce or injure the fruit skin. Therefore, vacuum is used auxiliary to another detachment method, usually with grasping [14][21]. Vacuum pressure can facilitate the fruit to expose and approach the grasping end effector by removing and releasing it from the foliage.2.2. End-Effector Types

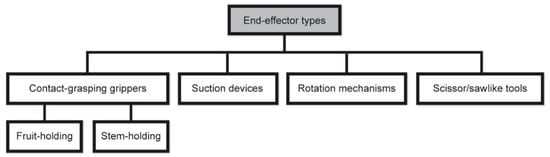

End effectors consist of a gripper or a tool. Grippers provide temporary direct contact with the product to be grasped, from either the fruit body or the stem. Vacuums, which are properly constructed suction devices, are considered types of grippers; however, no actual grasping takes place (indirect harvesting). In this work, suction devices will be considered separately, while grippers will exclusively be considered devices that make actual direct grasping. The identified four end-effector types in this work are illustrated in Figure 13. End effectors of the above categories can be combined. Therefore, an end effector mounted on a harvesting system may detach the fruit by combining grasping and rotation, grasping and suction, grasping and cutting, suction and cutting, and so on.

Figure 13.

The four identified end-effector types considered in this work.

2.3. Additional Sensors

Human grasping integrates inherent sensory abilities, enabling stable, flexible, and adaptive grasping. Robotic end effectors attempt to imitate the skills of human hands by using tactile and visual sensors, so as to insert touch and visual perception to the designed end effectors. When sensors interfere between an end effector and the harvested product, useful information can be acquired toward optimizing the functionality of the end effector regarding the specific harvested product. Sensors can add intelligence to an end effector [17][31]. End-effector sensors related to grasping operations can be divided into four broader categories [18][12]: (1) switching sensors, (2) tactile sensors, (3) visual sensors, and (4) measuring sensors, as detailed in the following. Switching sensors supply a trigger signal (binary on/off) for the mechanical system when a particular status for the gripper is monitored (open/close), and they have been used extensively with mechanical grippers [17][31]. Proximity [19][34], reed [20][35], touch [21][36], and Hall effect switches [22][37] belong in this category. Tactile sensors [23][38] are able to detect the properties of objects through physical contact. Mechanical properties can therefore be measured, such as pressure, grasping force, torque, slipping, vibration, humidity, and temperature. In harvesting end effectors, the focus is on contact force and torques. Tactile sensors placed on the fingertips of grippers can detect applied forces and torques so as to monitor deformations on the structure of the end effector while grasping. The most common forms of tactile sensors are piezoresistive, capacitive, and optical [23][38]. Contact with an object returns a digital imprint that can be interpreted as information regarding contour characteristics, dimensions, position, or orientation of the grasped fruit. Visual sensors are the most important contactless sensors for robotic manipulating systems. Visual sensors can detect obstacles, sense structures, determine grasping points, locate objects, and so on. Monocular and stereoscopic cameras have been reported in the literature, mounted on robotic end effectors to provide visual feedback to the manipulation system [24][39]. More specifically, stereoscopic cameras provide 3D information of the surroundings and, therefore, are considered more appropriate for harvesting applications in order to recognize and accurately locate the harvesting application points. Measuring sensors are used to measure the distance between the end-effector tool and the target object, the dimensions of the grasped object, or the status of the end effector in terms of speed, acceleration, force, torque, and so on. For distance measurements, ultrasonic, microwave, and laser triangulation sensors are used [25][40]. For status measurements are employed Hall effect sensors, acceleration sensors, force–torque sensors, and so on [26][41]. Multiple sensors can be fused at hardware and/or software levels so as to provide a set of possible outcomes. In all cases, since the act of grasping is a function of time, sensory data acquisition and fusion need to be temporally dynamic [27][42]. The integration of multiple sensors could result in more dexterous handling of objects through the analysis of acquired information between the end effector and the object, which could support real-time decision making. Therefore, sensors combined with the respective control strategies could make an end effector more “intelligent”. End-effector functions, which can be monitored or be controlled, are the gripping force and movement, speed, position, and orientation of the object, forces, and movement during manipulation, identification of contact point, and so on. Extensive details regarding end-effector control strategies can be found in [18][28][29][12,26,43].2.4. Operating Requirements for Agricultural End Effectors

End effectors in robotic systems used in agricultural harvesting may be (a) commercially available multifinger grippers suitable for harvesting a particular agricultural product, (b) integrated devices that have a control mechanism and the required elements (e.g., fingers) for harvesting, or a combination of mechanism elements and a simultaneous or two-step cutting system. In all those cases, depending on the features of the agricultural product (fruit or vegetable), such as its dimensions, weight, difficulty of detachment, and degree of sensitivity, the end effectors should be properly designed by considering a number of different features always combined with the robotic system (e.g., robotic arm) on which they are mounted [30][7]. Those features include:-

The maximum load they can lift. This load ranges from a few tens of grams up to a few kilograms depending on the weight of the fruit. It should be clarified that it is not enough to consider only the end effector’s load capacity, but also the robotic system’s load capacity on which the end effector is mounted on. In addition, depending on how the product is detached (e.g., suction, rotation, or cut), this maximum load should be increased so that the additional forces required for the fruit’s detachment could be applied for the final detachment of the harvested product from a branch on which it is usually connected [31][44].

-

The power exerted by the mechanism. To hold the product before it is removed from the branch, an appropriate force should be applied, which should not deform the product. In this case, depending on the product, the end effector may have sensors that control the applied force or have properly configured fingers with soft interior surfaces for holding smoothly agricultural products. In the former case, continuous control of the applied forces with the help of appropriate algorithms is required, whereas in the latter case, no sensors are often required, and end effectors have smaller control problems [16][32][8,45].

-

The type of movement to perform a particular task. In most cases of end effectors for the harvesting of agricultural products, the movement of the gripper is limited to opening and closing operations. However, the trajectory of the robotic system should be properly planned so that the end effector can approach, catch, and hold the product and remove it from the branch, for example, by moving towards a specific direction and orientation and by employing a rotational movement until the product is detached or cut off with the help of an appropriate cutting mechanism [34][47].

-

The type of actuators required. Most end effectors are based on electric actuators that permit accurate control. The required power is small (some watts or a few dozens of watts), so it could be provided by the moving robotic system on which they are mounted. However, in recent years, implementations with soft actuators have appeared that allow the handling of sensitive products with much higher safety and less manufacturing costs. These actuators mainly operate with air and only limited by the accuracy of their movement and control [35][48].

-

The time of action completing a movement to harvest a product. The end effector, depending on its complexity (e.g., use of sensors, control software, etc.) requires some time to complete a processing cycle of holding and detaching the harvested fruit from the crop. This picking time concerns: (a) the time to detect the fruit with the help of a detection system, which in most cases is a vision system with one camera (monocular), stereoscopic camera, or 3D camera; (b) the design of the trajectory that the robotic system should follow toward the desired goal; (c) the navigation to the desired goal; (d) the time required to grasp the product; (e) the detachment of the fruit from the branch; and (f) the transfer of the harvested product to a predetermined collection location. The grasping time of an end effector may be in the range of a few tenths of a second to a few seconds [30][7].

-

The characteristics of contact with the product. Depending on the type of product, as mentioned above, the final configuration of the fingers of the end effector should be carefully determined. If the product is very sensitive, such as a strawberry, then the fingers should have soft surfaces and additional force or pressure sensors to regulate the holding force. If the product has medium hardness, such as an apple, then the use of only soft surfaces on the fingers (and control of the power with the current in the actuator–electric grippers) is generally sufficient to hold without damaging the product. To hold a product from the stem and detach it with an appropriate stem-cutting mechanism, such as in grape harvest, no sensors or control approaches are required [36][10].

-

The tolerances and accuracy of the system. The end effector and the robotic navigation system towards the desired goal should at all times have the required precision so that the target could be detected and approached accurately. If the robotic system does not have the required accuracy by construction, then accuracy improvement techniques should be developed and applied as the end effector approaches the final target, for example, with the sensory feedback of a vision system mounted on the end effector and a visual servoing application [37][49].

2.5. Basic Agricultural End-Effector Development Principles

Identifying principles for an end-effector design is expected to lead to more effective prototypes. In what follows, basic principles, from conceptual design to the final prototype manufacturing, are proposed in four basic steps, including (1) research and requirements, (2) design, (3) prototype development, and (4) testing.2.5.1. Research and Requirements

Research and requirements include a literature review on traditional harvesting and selective harvesting techniques on already-existing automation, extraction of the functional and nonfunctional requirements, and evaluation of the system based on these requirements.-

Bibliography. Research in the bibliography is the first step toward effective end-effector development. First, traditional manual harvesting and selective harvesting methods need to be reviewed. Selective harvesting is the segmented picking of a fruit at harvest based on different yield or quality criteria in order to exploit any observed variations [38][50]. By studying the human hand patterns, imitation detachment techniques and appropriate tools could be developed. Research on automation and end effectors used can also provide useful insights; a detailed design and evaluation of end-effector systems could be used as a guide for system development, modification, or improvement toward enhancing performance.

-

Functional and nonfunctional requirements. According to the study of the bibliography, the system requirements need to be extracted. System requirements that need to be addressed, summarized in Section 3.4, include the maximum payload, grip force, geometry, and dimensions of the end effector in relation to the harvesting product, type of harvesting movement, type of actuators, picking time, detachment method, definition of product contact surface, material selection, tolerance, and accuracy of the system.

-

Evaluation based on requirements. Evaluation of the development process and cost estimation is essential after specifying the operational requirements so as to ensure that the proposed design idea is feasible to fabricate and cost-effective.

2.5.2. Design

Based on the identified requirements, an end-effector system design, in terms of both hardware and software, follows.-

Hardware design. The study and selection of all hardware components and materials takes place, such as plastics, metals, motors, cutters, and all the remaining necessary mechanical components, sensors, batteries, and so on. The design of necessary components with the help of known computer-aided design (CAD) software applications (AutoCAD, SolidWorks, FreeCAD, etc.) follows. The way that the hardware will be connected, installed, and assembled and the design of appropriate driving and control electronic circuits for all devices (schematic and printed circuit board (PCB) design) are also included. Energy and payload requirements also need to be considered.

-

Software design. For effective control of the end-effector system, driving algorithms, navigation, and control strategies based on software engineering principles need to be developed. Unified Modeling Language (UML) diagrams could be used for the visual representation of the system design. Effective data—as well as knowledge—representations should also be considered.

-

System simulation. End-effector manufacturers try hard to realize true system performance until it is too late in the design process; mechanical and electrical subsystems need to be validated against the identified requirements. However, testing and validation of the entire system is usually delayed, leading to potential redesign or changes to the initial design of the end effector, which is costly, time-consuming, and risky. In order to improve engineering efficiency and reduce product development challenges, early system design validation is considered necessary, enabled by simulation. In this phase, if the appropriate software tools exist (for example, Robot Operating System (ROS), Gazebo simulation suite), a virtual model of the end-effector system can be constructed (e.g., a Unified Robot Description Format (URDF) file), and the operation of the end effector can be evaluated in a simulation environment. In ROS, with the help of the Gazebo simulation environment, an important number of parameters can be tested. For example, in the simulated environment, simulated sensors’ values can be read, and simulated actuators can change their state depending on sensor values. Contacts, forces implemented, torques, pressures, light variation, and so on, as responses of sensors, change the state as well as the behavior of the end effector. However, if an extensive analysis of the end-effector operation is required, more specific simulation applications are adopted. For example, Adams and Simulia multibody dynamic simulation environments can evaluate and manage the complex interactions of a system, including motion, structures, actuation, and controls, to better optimize product designs for performance and safety.

2.5.3. Prototype Development

Prototype device development includes the detailed development of a simple first prototype device hardware as well as the development of the appropriate software application system, as a result of the previous analysis and design.2.5.4. Testing

After the end-effector prototype development and system integration, the whole system testing follows:-

Testing of the prototype system. The evaluation of fabrication time and estimation of the final cost of the prototype is required. The testing of the effectiveness of the prototype through an experimental procedure; recording of material behavior, applied forces, payload, pressure control, energy requirements, sensory feedback, control algorithm performance, and so on; and measurement of selected performance metrics (damage rate, picking time, etc.).

-

Optimization and fine-tuning. Optimization of the design of the end effector, re-experimentation and measurement of performance metrics, decision on an acceptable minimum/maximum performance for the prototype so as to be considered potentially viable are suggested. If the required changes are significant, then a new full cycle is repeated (design, prototype development, and testing).

-

Alternative designs and comparison. Prototype development, evaluation, and optimization of alternative end-effector designs toward comparison and final selection.