The electrospun nanofiber membrane has a unique structure and biological function similar to the extracellular matrix (ECM), and is considered an advanced wound dressing. They have significant potential in encapsulating and delivering active substances that promote wound healing.

1. Introduction

Skin is the largest important organ of the human body and the first barrier against external pathogens

[1]. However, external mechanical forces, surgical operations, burns, chemical injuries, and ulcers from certain chronic diseases can cause varying degrees of damage to the skin

[2]. Wound healing is a complicated and dynamic process of tissue regeneration, mainly composed of four stages: hemostasis, inflammation, proliferation, and remodeling

[3]. Although the skin can undergo a certain degree of spontaneous repair, bacterial infection has always been the main reason hindering wound healing. For an infected wound, it will not only disrupt the normal healing process, but also cause the wound tissue to be deformed, causing great pain to the patient

[4].

Wound dressings play an essential role in wound healing management. They protect the wound from external risk factors, and speed up the healing process

[5]. On the basis of the mechanism of wound healing, an ideal wound dressing ought to have the accompanying attributes: (1) absorb excess exudate; (2) protect the wound from microbial infection; (3) maintain a moist healing environment at the wound site; (4) facilitate gas exchange; (5) non-toxic, biocompatible, and degradable; (6) does not adhere to the wound, easy to replace and remove; (7) promote angiogenesis and tissue regeneration

[6][7][8][6,7,8]. Different wound needs should be integrated when choosing wound dressings. So far, the common dressings on the market mainly include film

[9], foam

[10], sponge

[11], hydrogel

[12][13][12,13], and nanofiber membrane

[14][15][14,15]. Among these materials, the unique structure of the small pore size and high porosity of the nanofiber membrane can protect the wound from pathogen infection and ensure the free transportation of gas and liquid molecules. At the same time, a large amount of research has been carried out, combining the adjustable characteristics of physical and mechanical properties to make it stand out among biomaterials

[16][17][16,17].

So far, methods such as drawing

[18], self-assembly

[19], phase separation

[20] and template synthesis

[21] have been used to prepare nanofibers. However, they have disadvantages such as high cost, time-consuming and low efficiency. Therefore, simple and practical electrospinning technology is widely used to manufacture fibers with diameters in the nanometer or micrometer range

[22]. Electrospun nanofiber membranes represent a new class of materials. Because of their high surface-to-volume ratio, high microporosity and versatility, they can be used in various biomedical applications

[23], such as tissue engineering scaffolds

[24][25][24,25], drug delivery

[26][27][28][26,27,28] and wound dressings

[29][30][29,30]. Nanofiber wound dressings prepared by electrospinning technology have many advantages. First, the structure and biological function are similar to the natural extracellular matrix (ECM), which provides an ideal microenvironment for cell adhesion, proliferation, migration and differentiation

[31][32][31,32]. Secondly, the polymer matrix used for electrospinning can simultaneously combine the biocompatibility of natural polymers and the reliable mechanical strength of synthetic polymers

[33]. Furthermore, the nanofiber membrane’s wide surface area and porous structure can be effectively loaded with various biologically active ingredients, including antibacterial drugs, inorganic nanoparticles, vitamins, growth factors and Chinese herbal extracts. The rate and time of drug release are controlled by adjusting the fiber structure and morphological size, thereby promoting effective healing of the wound site

[34]. Therefore, electrospun nanofibers show great potential in the preparation of advanced bioactive wound dressings.

2. Wound and Wound Dressing

2.1. Wounds Classification

Wounds are defined as skin deformities or tissue discontinuities brought about by physical or thermal injury, or underlying ailments

[35]. Given the nature and duration of the healing process, wounds are usually divided into acute and chronic types

[36]. Acute wounds mainly include mechanical injuries, chemical injuries, surface burns and surgical wounds, etc. The healing process follows the normal wound healing cycle

[37][38][39][37,38,39]. However, chronic wounds refer to those cannot go through an orderly healing process and have been open for more than one month. The causes of chronic wounds vary, and are mainly related to certain specific diseases (such as diabetes). They are notorious for the terrible incidence of ulcers, and they are susceptible to infection by inflammatory bacteria that affect wound repair

[40][41][40,41]. Globally, chronic wounds impose a heavy burden on patients and healthcare systems

[42].

2.2. Types of Wound Dressing

In 1962, Dr. Jorge Winter of the University of London put forward the “moist healing environment theory” first, and related studies confirmed that a moist environment will speed up the wound healing process

[43]. In recent years, the theory of moist healing has received extensive consideration. The U.S. Food and Drug Administration (FDA) pointed out in an industry guide issued in August 2000 that one of the standard methods of wound treatment is to maintain a moist environment on the wound surface

[44]. With the in-depth study of wound healing, the types of wound treatment and dressings are constantly improving and developing

[45]. Wound dressings are classified into traditional wound dressing, modern wound dressing and bioactive wound dressing according to their functional properties and wound origin.

Table 1 classifies and summarizes wound dressings based on their functions.

Table 1. Types of wound dressing.

|

Nature

|

Category

|

Advantages

|

Disadvantages

|

Ref.

|

|

Traditional

wound dressing

|

Gauze, lint, bandage

|

Easy to use and economical

|

1. Dry, unable to maintain a moist healing environment

2. Adhering to the wound site is difficult to remove

|

[46]

|

|

Modern wound dressing

|

Film

|

1. Transparent, can observe wound changes

2. Form a bacterial barrier

3. Gas and water vapor permeability

|

1. Absorptive capacity is not strong

2. Obstruct the regeneration of epithelial tissue

|

[47]

|

|

Foam

|

1. High water absorption performance to maintain the moist environment of the wound

2. Change the dressing without damage

|

1. Weak adhesion

2. Completely opaque

|

[48]

|

|

Hydrocolloid

|

1. Stimulate tissue autolysis and debridement

2. The closed structure blocks the invasion of external bacteria

|

1. Poor degradability

2. Produce a special smell

|

[49]

|

|

Hydrogel

|

1. Ability to replenish water and maintain a humid environment

2. Comfortable and easy to replace

|

1. No adhesion, low mechanical strength

2. High water content, limited absorption capacity, not suitable for wounds with high exudate

|

[50]

|

|

Alginate

|

1. Non-toxic, fast hemostasis

2. Good air permeability

3. Biodegradation

|

Not suitable for dry wounds

|

[51]

|

|

Bioactive wound dressing

|

Drug-loaded dressing, antibacterial dressing

|

1. Good biocompatibility

2. Anti-inflammatory and antibacterial

3. Promote the growth of cells and tissues

|

Induce immune response

|

[52]

|

3. Electrospinning Technology

Electrospinning technology, as a superfine fiber preparation technology, has experienced hundreds of years of development

[53][63]. The electrostatic spinning device is mainly composed of four parts: a high-voltage generator, a fluid driver, a spinneret and a collection device

[54][64]. In the electrospinning process, the initial electrospinning fluid gradually changes its morphology after the voltage is applied, until it reaches the critical voltage shape into a Taylor cone. When the liquid jet stretches over a certain distance, it enters the bending and whiplash stage. With the solvent volatilization, the jet is stretched to micrometers or even tens of nanometers, finally solidified and deposited on the collector to form nanofiber

[55][56][65,66]. On the basis of this principle, the electrospinning process can be adjusted by system parameters (polymer type, molecular weight, viscosity, conductivity of the solution, surface tension), process parameters (voltage, flow rate, receiving distance) and environmental parameters (humidity, temperature) to change the morphology and size of nanofibers

[57][58][67,68]. As a simple, top-down one-step preparation method, electrospinning technology produces nanofibers with small pore size, high porosity and a structure similar to ECM. Therefore, it has received extensive attention from researchers and used to prepare functionalized nanofibers for applications in biomedicine and other fields

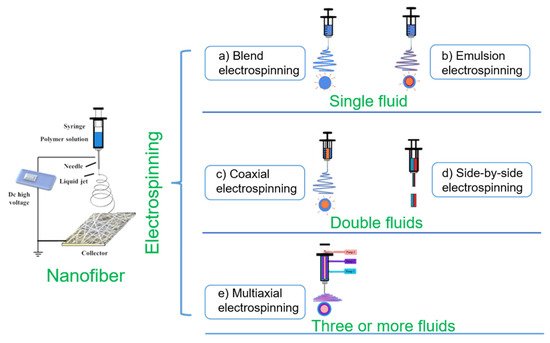

[59][60][61][69,70,71]. At the same time, the electrospinning technology is continuously upgraded and optimized. As shown in

Figure 1, it has gradually developed into single fluid electrospinning (blend electrospinning and emulsion electrospinning), double-fluid electrospinning (coaxial electrospinning and side-by-side electrospinning) and multifluid electrospinning (triaxial electrospinning and other multifluid electrospinning).

Figure 1. Process classification of electrospinning technology (adapted from [62], with permission from MDPI, 2021). Process classification of electrospinning technology (adapted from [72], with permission from MDPI, 2021).

4. Electrospun Nanofibers in Wound Dressing

Nanofibers prepared by electrospinning technology show excellent properties in promoting wound healing. Their microstructure is highly fitted to the human body ECM structure, which is conducive to cell growth, proliferation and adhesion

[31][63][31,98]. At the same time, the high permeability and absorption rate can absorb the exudate formed on the wound surface and maintain a moist healing environment. In addition, the large surface area benefits loading and transporting bioactive ingredients such as drugs and growth factors

[34][64][34,99]. Therefore, electrospun nanofiber materials are considered to be the ideal choice for wound dressings.

4.1. Polymer in Electrospun Wound Dressing

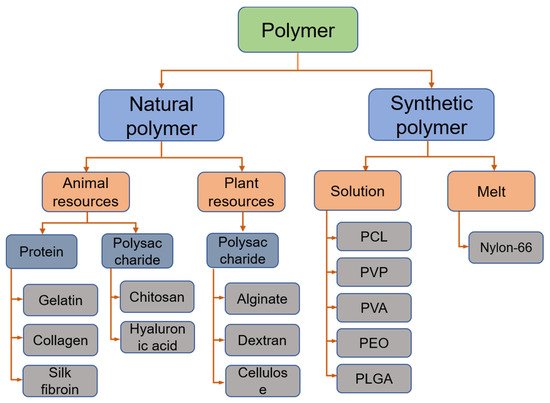

At present, there are hundreds of polymers that can be successfully used to prepare drug carriers by electrospinning. In related research on electrospinning wound dressings, both natural and synthetic polymers have been widely used.

Figure 2 simply classifies and summarizes the common polymers in electrospun wound dressings.

Figure 2.

Common polymers used in electrospun wound dressings.

4.2. Bioactive Ingredients in Electrospun Wound Dressing

Another important advantage of electrospinning to prepare nanofiber wound dressings is that it can load a variety of biologically active ingredients to prepare functionalized products. At present, to improve the antibacterial properties of dressings, commonly used active substances include antibiotic drugs (ciprofloxacin (CIP), curcumin, metronidazole, tetracycline, gentamicin and diclofenac), inorganic nanoparticles (nanosilver particles (AgNP), ZnO, titanium dioxide (TiO

2), cerium oxide (CeO

2)), natural substances (honey, essential oils, chitosan) and growth factors

[65][66][67][68][120,121,122,123].

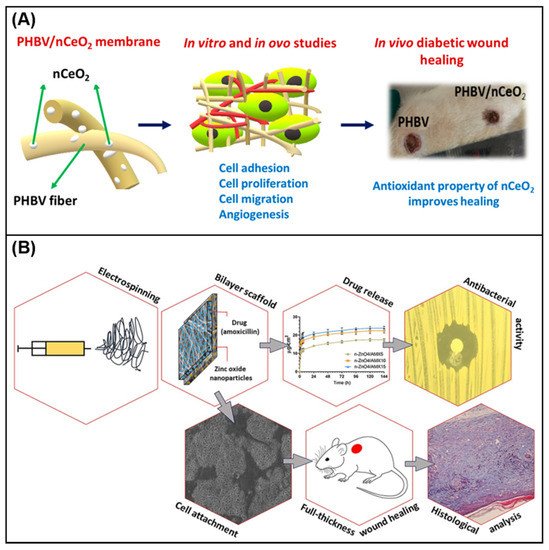

Augustine et al.

[69][124] reported the development of a new type of nCeO

2, which contains electrospun poly (3-hydroxybutyrate-co-3-hydroxy valerate) (PHBV) membrane. In vivo wound healing studies in diabetic rats confirmed that PHBV membranes mixed with 1% nCeO

2 showed perfect cell compatibility, and could be used as promising biomaterials to treat diabetic wound healing (

Figure 3A). Yang et al.

[70][125] used the side-by-side electrospinning process to prepare Janus nanofibers containing CIP and AgNP as the polymer matrix, and studied their effects on wound healing. The antibacterial effect in the process provides a new idea for the preparation of new antibacterial wound dressings. Jafari et al.

[71][126] prepared a bilayer nanofiber scaffold based on PCL and gelatin. The top layer contains amoxicillin, and the bottom layer contains n-ZnO to accelerate wound healing. In vitro release test showed the sustained release of amoxicillin. Analysis of wound healing in rats showed that the scaffold improved the shrinkage rate of the wound, enhanced the deposition of collagen and reduced the formation of scars. All results and findings indicate that prefabricated stents can be a promising alternative method for treating skin injuries.

Figure 3B shows the characterization analysis of the prepared bilayer nanofiber scaffold.

Table 2 summarizes the common polymers and active substances in electrospinning wound dressings.

Figure 3. (

A) PHBV/nCeO

2 nanofiber membrane in cell adhesion, migration and wound healing research

[69][124]; (

B) the electrospun antibacterial bilayer nanofiber scaffold is used to promote the various characterization analysis of the full-thickness skin defect healing in mice

[71][126].

Table 2. The latest literature on polymer materials and bioactive ingredients used in electrospinning to promote skin wound healing.

|

Scaffold Material

|

Additional Polymer

|

Bioactive Ingredients

|

Solvent

|

Electrospinning Technique

|

Highlights

|

Ref.

|

|

Gelatin

|

CA

|

Berberine

|

HFP

|

Blend

|

Has strong antibacterial activity and is suitable for the management and treatment of diabetic foot ulcer

|

[72][127]

|

|

CA/PVP

|

Gentamicin

|

Acetic acid, ethanol

|

Bi-layer

|

Thermal stability, wettability characteristics and antibacterial activity

|

[73][128]

|

|

Collagen

|

EC/PLA

|

Silver sulfadiazine

|

Chloroform, ethanol

|

Blend

|

The antibacterial performance showed inhibitory activity against Bacillus (9.71 ± 1.15 mm) and E. coli (12.46 ± 1.31 mm), promoted cell proliferation and adhesion

|

[74][129]

|

|

Zein/PCL

|

n-ZnO, aloe vera

|

Chloroform, ethanol

|

Blend

|

The developed nanofibers revealed good cell compatibility

|

[75][130]

|

|

CS

|

PCL

|

Lidocaine hydrochloride, mupirocin

|

HFIP, DCM

|

Dual

|

Have the functions of promoting hemostasis, antibacterial, and drug release.

|

[76][131]

|

|

PEO/CNC

|

Acacia extract

|

Acetic acid

|

Blend

|

A continuous release of natural acacia extract from nanofibers occurred during 24 h

|

[77][132]

|

|

SF

|

PLGA

|

Artemisinin

|

HFIP

|

Blend

|

The fabricated membrane shows anti-inflammatory properties without cytotoxicity

|

[78][133]

|

|

PCL/PVA

|

Curcumin

|

Formic acid, dichloromethane

|

Blend

|

Accelerate wound healing in diabetic mice

|

[79][134]

|

|

Alginate

|

PVA/CS

|

Dexpanthenol

|

Acetic acid

|

Coaxial

|

Not only is it non-toxic to fibroblasts, but it also has a certain effect on cell attachment and morphology

|

[80][135]

|

|

PVA

|

Cardamom extract

|

Distilled water

|

Blend

|

Have good biocompatibility and antibacterial properties

|

[81][136]

|

|

PVP

|

EC

|

CIP, AgNP

|

Ethanol, acetic acid, acetone

|

Side-by-side

|

Janus fiber has good bactericidal activity

|

[70][125]

|

|

PLA/PEO/Collagen

|

Cefazolin

|

DCM, DMF, HFIP, ethanol

|

Coaxial

|

Antibacterial studies on wounds show that they can effectively inhibit the growth of microorganisms.

|

[82][137]

|

|

PCL

|

CS

|

Aloe vera

|

Acetic acid

|

Blend

|

Have good antibacterial properties and biocompatibility

|

[83][138]

|

|

CS

|

Curcumin

|

Ethanol, acetic acid

|

Blend

|

Shows antibacterial, anti-oxidant and wound healing capabilities

|

[84][139]

|

|

Gelatin

|

Oregano oil

|

HFIP

|

Blend

|

Good biocompatibility and antibacterial activity

|

[85][140]

|

|

/

|

Urtica dioica, n-ZnO

|

DMF, DCM

|

Blend

|

The hybrid scaffold shows high antibacterial activity and cell viability

|

[86][141]

|

|

Gelatin

|

Clove essential oil

|

Glacial acetic acid

|

Blend

|

Antibacterial activity

|

[87][142]

|

|

PVA

|

CS/Starch

|

/

|

Double-distilled water, acetic acid

|

Blend

|

Proper tensile strength and elongation, excellent biocompatibility and antibacterial activity

|

[88][143]

|

|

CS

|

/

|

Acetic acid

|

Blend

|

Good physical and chemical properties, biocompatibility and antibacterial properties

|

[89][144]

|

|

PEO

|

CS

|

Vancomycin

|

Acetic acid

|

Blend

|

Antibacterial effects against S. aureus

|

[90][145]

|

|

CS

|

Teicoplanin

|

Acetic acid

|

Dual

|

Wound closure was significantly improved

|

[91][146]

|

HFP: Hexafluoropropylene, EC: Ethylcellulose, PLA: Polylactic acid, HFIP: 1,1,1,3,3,3-hexafluoro-2-propanol, DCM: Dichloromethane, PEO: Polyethene oxide, CNC: Cellulose nanocrystals, DMF: N,N-dimethylformamide.

4.3. In Situ Electrospinning in Wound Dressing

Compared with ordinary electrospinning, in situ electrospinning is more convenient and comfortable to use, and can better cover wounds. Simultaneously, dressings can be customized according to patient needs

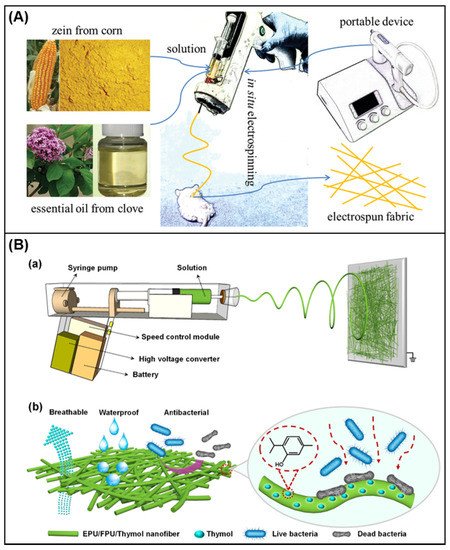

[92][147]. Qin et al.

[93][148] used a portable electrospinning device to prepare electrospun Zein/Clove essential oil nanofiber. In vitro experiments have observed good biocompatibility and antibacterial effects. In the mouse wound model, it can be observed that the prepared Zein/CEO nanofiber membrane promotes wound healing.

Figure 4A shows the diagram of its preparation. Yue et al.

[94][149] used ethanol-soluble polyurethane (EPU) and Fluorinated polyurethane (FPU) as polymer carriers and used a customized electrospinning device to prepare thymol-loaded nanofiber membranes (

Figure 4B(a)). The results indicate that the membrane has good breathable, waterproof performance and excellent antibacterial activity (

Figure 4B(b)), providing a promising strategy for developing portable electrospinning devices.

Figure 4. (

A) In situ electrospinning process

[93][148]; (

B)

[94][149] (

a) schematic diagram of portable electrospinning device and preparation of EPU/FPU/thymol nanofiber; (

b) schematic diagram of the breathable, waterproof and antibacterial functions of EPU/FPU/Thymol nanofiber.

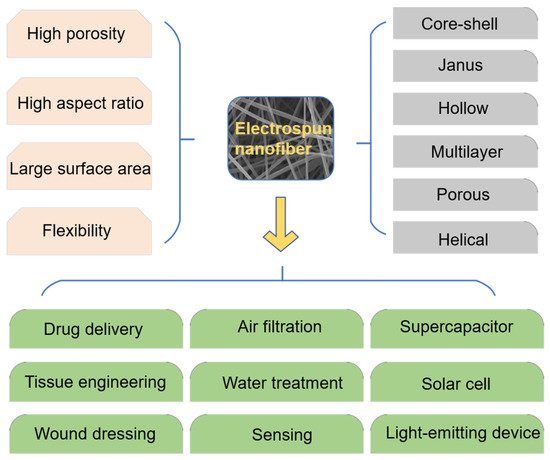

4.4. Application of Electrospinning Technology in Other Fields

In recent years, the advantages of electrospinning have attracted more and more attention. With the continuous research of related scholars, the application of electrospinning nanofibers has become more and more extensive. In addition to playing a role in the field of biomedicine (drug delivery

[95][96][97][150,151,152], tissue engineering

[98][153] and wound dressings), it also plays a pivotal position in environmental protection (air filtration, water treatment), energy and chemical industries (light-emitting device, solar cell and supercapacitor) and other fields

[99][100][154,155]. Fiber materials with unique structures and characteristics arranged by electrospinning have been generally utilized in different fields (

Figure 5). Combining the structural advantages of the materials with the properties of the materials will be the focus of future research.

Figure 5.

Structure, performance and application of electrospun nanofiber.