Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Camila Xu and Version 1 by Markos Petousis.

Strain rate is a parameter related with dynamic loading phenomena, which are common in industrial applications.

- strain rate sensitivity

- tensile properties

- polycarbonate (PC)

- thermoplastic polyurethane (TPU)

1. Introduction

Strain rate is a parameter related with dynamic loading phenomena, which are common in industrial applications [31,32][1][2]. Strain rate sensitivity is a measure that has been widely studied for polymers processed through many manufacturing technologies [33][3]. On the other hand, not enough research exists in the literature regarding the strain rate sensitivity of polymers processed through AM technologies and especially the FFF technology [33,34][3][4]. Strain rate sensitivity is an important parameter for end-use applications when polymers are FFF processed. Studying the behavior change due to the strain rate could provide information for fail-safe mechanisms and other dynamic analysis properties [35][5], such as the energy absorbed in crashes etc. [36][6].

A recent study provided critical information for the strain rate sensitivity of several different polymers processed with the FFF technology [33][3]. The increasing demand for FFF manufactured parts with engineering grade polymers such as polycarbonate (PC) and thermoplastic polyurethane (TPU) has further increased the necessity for a study on the strain rate sensitivity of these polymers, which has not been reported before in literature. PC is a well-known high mechanical performance polymer [37][7], widely used in many applications which require strong dynamical properties, such as automotive [38][8], medical [39,40,41,42][9][10][11][12] and optics [43][13] applications. In AM, PC applications are still limited in the literature, with research mainly related to acoustic applications [44][14] and heat pipes [45][15]. TPU is also an elastic material, employed in many industrial and other environmental parts [46,47][16][17]. Indicative applications of TPU material are in mechanical seals [48,49][18][19] or more advanced applications, such as flexible electronics [50][20], force sensors [51][21], pneumatic actuators [52][22] and pharmaceutical applications [53][23]. TPU thermal properties in 3D printing have also been reported [54,55][24][25].

The strain rate of these materials has been studied either for homopolymers or for composites [38[8][26][27],56,57], but not for parts built with AM technology. The manufacturing of parts through FFF technology requires the extrusion of melted-state polymer in shells, infills and, of course, in consecutive layers [10][28]. The interlayer and throughout layer fusion are prone to a wide range of process settings, such as number of shells, layer height, infill percentage, infill geometry pattern, extrusion temperature, extrusion speed etc. [58,59][29][30]. As mentioned above, AM built parts have an anisotropic behavior. These parameters are among others, responsible for the anisotropic behavior of the parts manufactured with the FFF process [19][31]. This anisotropy can create unpredicted behavior, especially when dynamic stresses are applied to AM processed parts.

2. Tensile Properties

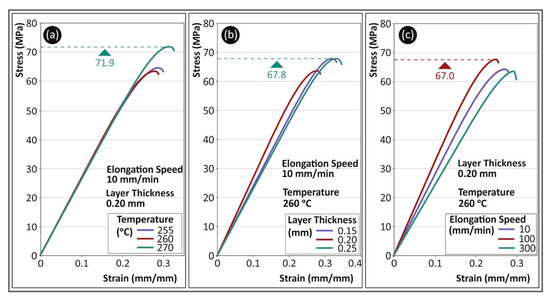

Figure 31 shows representative graphs from the tensile tests conducted during the present study. Specifically, in Figure 31a, typical stress (MPa) to strain (mm/mm) curves are shown for PC material for the 10 mm/min strain rate. The layer thickness of the specimens, in this case, was 0.2 mm and curves shown are for the three different 3D printing temperatures studied in this work (one graph per temperature). Through this comparison, it can be observed that increasing the 3D printing temperature to 270 °C improved the mechanical performance of the material, probably due to increased inter and intra layer fusion. In Figure 31b, PC stress (MPa) to strain (mm/mm) typical curves for the different layer thicknesses studied are shown for the elongation speed of 10 mm/min and 3D printing temperature of 260 °C. The figure shows that varying the layer height had little effect on the strength of the specimen, as the difference was less than 10%. This difference could be plausibly attributed to the anisotropy of the process followed (AM). Figure 31c shows the effect of the strain rate on the PC polymer, at three different elongation speeds (10 mm/min, 100 mm/min and 300 mm/min), for specimens built with a 0.20 mm layer thickness at 260 °C. As it is shown, the strain rate had an effect on the typical stress to strain curve of the PC polymer, although the maximum strength developed on the specimens was similar in the three cases shown.

Figure 31. Stress (MPa) to strain (mm/mm) typical curves for PC material for (a) different 3D printing temperatures, (b) different layer thicknesses and (c) different elongation speeds.

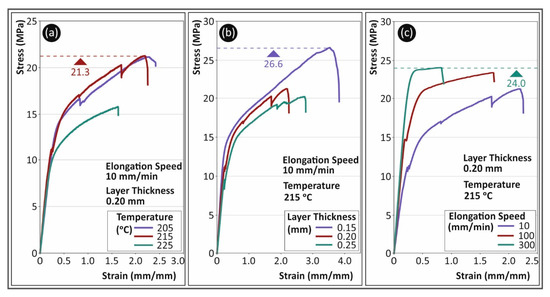

Figure 42. Stress (MPa) to strain (mm/mm) typical curves for TPU material for (a) different 3D printing temperatures, (b) different layer thicknesses and (c) different elongation speeds.

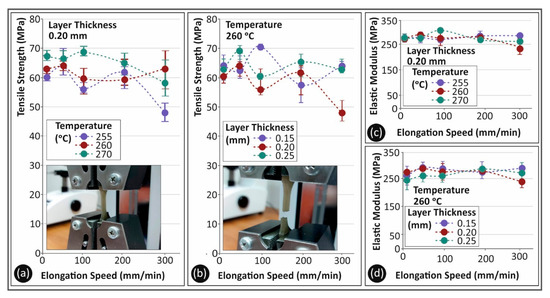

Figure 53. (a,b) Average tensile strength (MPa) and (c,d) average tensile elastic modulus (MPa) to elongation speeds (mm/min) for PC material as follows: (a,c) 3D printing temperatures; (b,d) layer heights.

References

- Siviour, C.R. High strain rate characterization of polymers. AIP Conf. Proc. 2017, 1793, 8–13.

- Rohbeck, N.; Ramachandramoorthy, R.; Casari, D.; Schürch, P.; Edwards, T.E.J.; Schilinsky, L.; Philippe, L.; Schwiedrzik, J.; Michler, J. Effect of high strain rates and temperature on the micromechanical properties of 3D-printed polymer structures made by two-photon lithography. Mater. Des. 2020, 195, 1–9.

- Vidakis, N.; Petousis, M.; Velidakis, E.; Liebscher, M.; Mechtcherine, V.; Tzounis, L. On the strain rate sensitivity of fused filament fabrication (Fff) processed pla, abs, petg, pa6, and pp thermoplastic polymers. Polymers 2020, 12, 2924.

- Vairis, A.; Petousis, M.; Vidakis, N.; Savvakis, K. On the Strain Rate Sensitivity of Abs and Abs Plus Fused Deposition Modelling Parts. J. Mater. Eng. Perform. 2016, 25, 3558–3565.

- Hosur, M.V.; Alexander, J.; Jeelani, S.; Vaidya, U.K.; Mayer, A. High strain compression response of affordable woven carbon/epoxy composites. J. Reinf. Plast. Compos. 2003, 22, 271–296.

- Mirmomeni, M.; Heidarpour, A.; Zhao, X.L.; Packer, J.A. Effect of elevated temperature on the mechanical properties of high-strain-rate-induced partially damaged concrete and CFSTs. Int. J. Impact Eng. 2017, 110, 346–358.

- Bhadeshia, H.K.D.H. Additive manufacturing. Mater. Sci. Technol. 2016, 32, 615–616.

- Krausz, T.; Serban, D.A.; Negru, R.M.; Radu, A.G.; Marsavina, L. The effect of strain rate and temperature on the mechanical properties of polycarbonate composites. Mater. Today Proc. 2020, 45, 4211–4215.

- Lv, D.; Li, P.; Zhou, L.; Wang, R.; Chen, H.; Li, X.; Zhao, Y.; Wang, J.; Huang, N. Synthesis, evaluation of phospholipid biomimetic polycarbonate for potential cardiovascular stents coating. React. Funct. Polym. 2021, 163, 104897.

- Park, S.J.; Lee, J.E.; Lee, H.B.; Park, J.; Lee, N.K.; Son, Y.; Park, S.H. 3D printing of bio-based polycarbonate and its potential applications in ecofriendly indoor manufacturing. Addit. Manuf. 2020, 31, 100974.

- Kalkal, A.; Kumar, S.; Kumar, P.; Pradhan, R.; Willander, M.; Packirisamy, G.; Kumar, S.; Malhotra, B.D. Recent advances in 3D printing technologies for wearable (bio)sensors. Addit. Manuf. 2021, 46, 102088.

- Hacioglu, F.; Tayfun, U.; Ozdemir, T.; Tincer, T. Characterization of carbon fiber and glass fiber reinforced polycarbonate composites and their behavior under gamma irradiation. Prog. Nucl. Energy 2021, 134, 103665.

- Mishra, V.; Sharma, R.; Khatri, N.; Garg, H.; Karar, V.; Khan, G.S.; Sarepaka, R.V. Processing of Polycarbonate by Ultra-Precision Machining for Optical Applications. Mater. Today Proc. 2018, 5, 25130–25138.

- Liu, Z.; Zhan, J.; Fard, M.; Davy, J.L. Acoustic properties of a porous polycarbonate material produced by additive manufacturing. Mater. Lett. 2016, 181, 296–299.

- Arai, T.; Kawaji, M. Thermal performance and flow characteristics in additive manufactured polycarbonate pulsating heat pipes with Novec 7000. Appl. Therm. Eng. 2021, 197, 117273.

- Gul, J.Z.; Sajid, M.; Choi, K.H. 3D printed highly flexible strain sensor based on TPU-graphene composite for feedback from high speed robotic applications. J. Mater. Chem. C 2019, 7, 4692–4701.

- Mistry, P.; Chhabra, R.; Muke, S.; Narvekar, A.; Sathaye, S.; Jain, R.; Dandekar, P. Fabrication and characterization of starch-TPU based nanofibers for wound healing applications. Mater. Sci. Eng. C 2021, 119, 111316.

- Wang, C.; Hausberger, A.; Berer, M.; Pinter, G.; Grün, F.; Schwarz, T. An investigation of fretting behavior of thermoplastic polyurethane for mechanical seal application. Polym. Test. 2018, 72, 271–284.

- Xiao, X.; Wang, J.; Cai, D.; Lou, L.; Xiao, F. A novel application of thermoplastic polyurethane/waste rubber powder blend for waterproof seal layer in high-speed railway. Transp. Geotech. 2021, 27, 100503.

- Choi, J.; Moon, D.S.; Jang, J.U.; Yin, W.B.; Lee, B.; Lee, K.J. Synthesis of highly functionalized thermoplastic polyurethanes and their potential applications. Polymer (Guildf.) 2017, 116, 287–294.

- Kim, K.; Park, J.; Suh, J.-h.; Kim, M.; Jeong, Y.; Park, I. 3D printing of multiaxial force sensors using carbon nanotube (CNT)/thermoplastic polyurethane (TPU) filaments. Sens. Actuators A Phys. 2017, 263, 493–500.

- Hohimer, C.J.; Petrossian, G.; Ameli, A.; Mo, C.; Pötschke, P. 3D printed conductive thermoplastic polyurethane/carbon nanotube composites for capacitive and piezoresistive sensing in soft pneumatic actuators. Addit. Manuf. 2020, 34, 101281.

- Verstraete, G.; Samaro, A.; Grymonpré, W.; Vanhoorne, V.; Van Snick, B.; Boone, M.N.; Hellemans, T.; Van Hoorebeke, L.; Remon, J.P.; Vervaet, C. 3D printing of high drug loaded dosage forms using thermoplastic polyurethanes. Int. J. Pharm. 2018, 536, 318–325.

- Kang, K.S.; Jee, C.; Bae, J.H.; Jung, H.J.; Huh, P.H. Heat capacity variables of thermoplastic polyurethane for high-quality 3D printing resolution and their characteristics. Mater. Lett. 2019, 257, 126698.

- Liu, J.; Li, W.; Guo, Y.; Zhang, H.; Zhang, Z. Improved thermal conductivity of thermoplastic polyurethane via aligned boron nitride platelets assisted by 3D printing. Compos. Part. A Appl. Sci. Manuf. 2019, 120, 140–146.

- Wilberforce, S.; Hashemi, S. Effect of fibre concentration, strain rate and weldline on mechanical properties of injection-moulded short glass fibre reinforced thermoplastic polyurethane. J. Mater. Sci. 2009, 44, 1333–1343.

- Walley, S.M.; Field, J.E. Strain Rate Sensitivity of Polymers in Compression from Low to High Rates. DYMAT J. 1994, 1, 211–227.

- Vidakis, N.; Petousis, M.; Velidakis, E.; Mountakis, N.; Tzounis, L.; Liebscher, M.; Grammatikos, S.A. Enhanced mechanical, thermal and antimicrobial properties of additively manufactured polylactic acid with optimized nano silica content. Nanomaterials 2021, 11, 1012.

- Johnson, G.A.; French, J.J. Evaluation of Infill Effect on Mechanical Properties of Consumer 3D Printing Materials. Adv. Technol. Innov. 2018, 3, 179–184.

- Fernandes, J.; Deus, A.M.; Reis, L.; Vaz, M.F.; Leite, M. Study of the influence of 3D printing parameters on the mechanical properties of PLA. Proc. Int. Conf. Prog. Addit. Manuf. 2018, 547–552.

- Vidakis, N.; Petousis, M.; Tzounis, L.; Maniadi, A.; Velidakis, E.; Mountakis, N.; Papageorgiou, D.; Liebscher, M.; Mechtcherine, V. Sustainable Additive Manufacturing: Mechanical Response of Polypropylene over Multiple Recycling Processes. Sustainability 2020, 13, 159.

More