Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Rafael Alvarez Gutiérrez and Version 2 by Catherine Yang.

Mosses have a large surface area of densely packed leaves that allows them to effectively trap air pollutants. This enables them to exhibit filtration efficiencies comparable to those of man-made filters. However, within the context of a circular economy, moss fibers integrated into a biocomposite matrix provide the added advantage of being reusable, facilitating the development of closed systems without waste generation.

- biocomposites

- sphagnum moss

- moss wall

- natural fibers

- air purification

- bio-binders

1. Introduction

Being exposed to ambient air pollution is a severe threat to human health causing around 4.2 million deaths every year [1][2][3][4][1,2,3,4]. Particulate matter (PM) is the main air pollutant in urban environments that causes severe health problems [2][3][5][2,3,5]. These small particles, solids or liquid aerosols, come from a variety of sources, both natural and anthropogenic, such as fossil fuel combustion, construction dust, and industrial processes [6][7][6,7]. Mainly, two types are defined based on particle diameter: PM10 are particles with a diameter of 10 µm or less and PM2.5 are particles with a diameter of 2.5 µm. These particles, especially PM2.5, can penetrate deep into the lungs, leading to severe health issues [3][5][3,5].

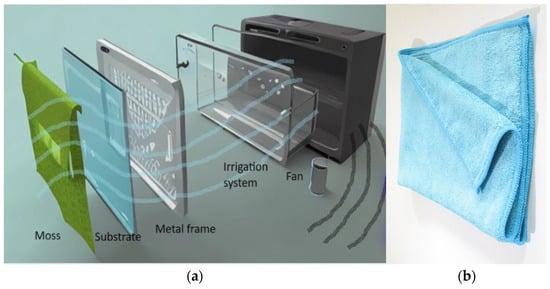

One way to combat air pollution is to address the problem at its source and reduce emissions from polluting activities. Another way is to filter polluted air using active or passive filtration technology [8][9][10][11][12][8,9,10,11,12]. Various methods and systems have been introduced to actively filter polluted outdoor air [8][11][12][8,11,12]. Among these are solutions that make use of the air-purifying properties of plants. One such method is the use of ‘moss walls’ [11][12][11,12]. These systems, illustrated in Figure 1a, draw in polluted air through ventilation fans installed inside a hollow wall that is covered with ‘moss filters’, passing the stale air through the moss and the substrate on which the moss grows. After filtering, the purified air is released back into the environment. Due to the absence of a developed root system mosses have developed a very high surface area of densely packed leaves to absorb water and nutrients compared to other plants [13][14][13,14]. This allows them to trap air pollutants, such as PM, in a very efficient way, similar to manmade filters [15]. Research performed in 2019 at the University of Antwerp has shown that the filtration efficiency of moss panels is 43.1% for PM10 and 22.8% for PM2.5 [16].

Figure 1.

(

a

) Exploded view of existing moss wall; (

b

) current substrate: synthetic microfiber cloth. The substrate is light blue in color in both images.

To use living moss as part of a filter setup in an air purification system, it needs a breathable and moisture-retaining substrate on which it can grow. Currently, in the moss wall that is the subject of this study, a synthetic microfiber cloth is used for this purpose, see Figure 1b [11][16][11,16]. However, this material is highly environmentally polluting as it contains and releases microplastics to the environment, i.e., pieces of plastic less than 5 mm in diameter, that are not degradable and are harmful to various ecosystems [17]. The exposure of microplastics to humans, whether through ingestion or inhalation, can cause potential health risks. These risks include medical conditions, such as gastrointestinal issues, chronic pulmonary diseases, fibrosis in the lungs, and an elevated risk of lung cancer [18][19][18,19].

To mitigate the entry of microplastics from the substrate of the moss wall into the environment, this study aims to lay the foundations for a bio-based alternative to microfiber cloth, utilizing excess moss from the system as a raw material. By using saturated moss from the filters and/or excess moss (after cleaning), the system will become more self-sustaining with reduced dependence on external inputs. Therefore, this solution not only addresses immediate environmental concerns but also promotes the circularity of the moss wall.