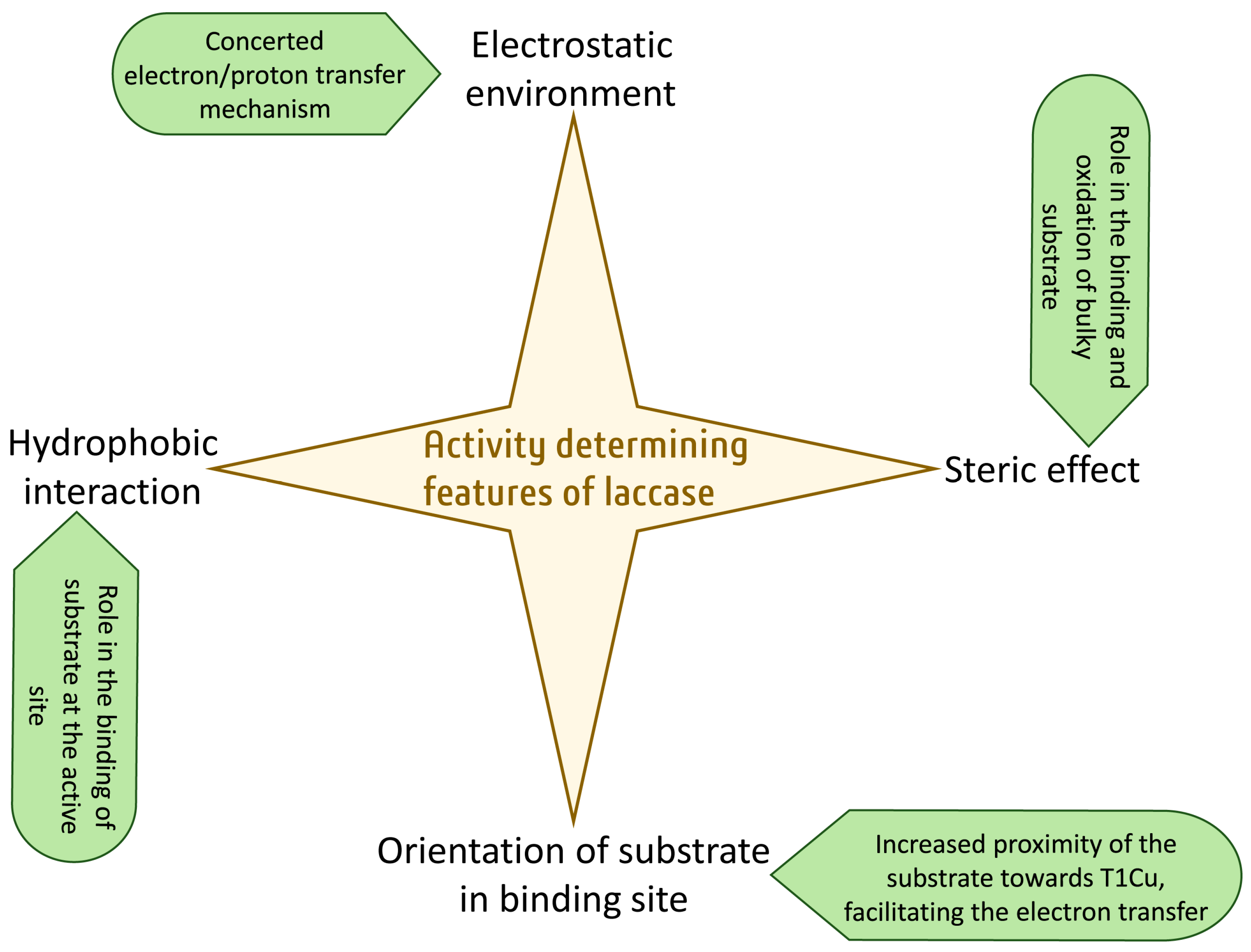

Laccase, one of the metalloproteins, belongs to the multicopper oxidase family. It oxidizes a wide range of substrates and generates water as a sole by-product. The engineering of laccase is important to broaden their industrial and environmental applications. The general assumption is that the low redox potential of laccases is the principal obstacle, as evidenced by their low activity towards certain substrates. Therefore, the primary goal of engineering laccases is to improve their oxidation capability, thereby increasing their redox potential. Even though some of the determinants of laccase are known, it is still not entirely clear how to enhance its redox potential. However, the laccase active site has additional characteristics that regulate the enzymes’ activity and specificity. These include the electrostatic and hydrophobic environment of the substrate binding pocket, the steric effect at the substrate binding site, and the orientation of the binding substrate with respect to the T1 site of the laccase.

- laccases

- rational engineering

- electrostatic environment

- hydrophobic environment

1. Introduction

2. An Overview of the Laccase Structure

2.1. Overall Structure of the Laccase

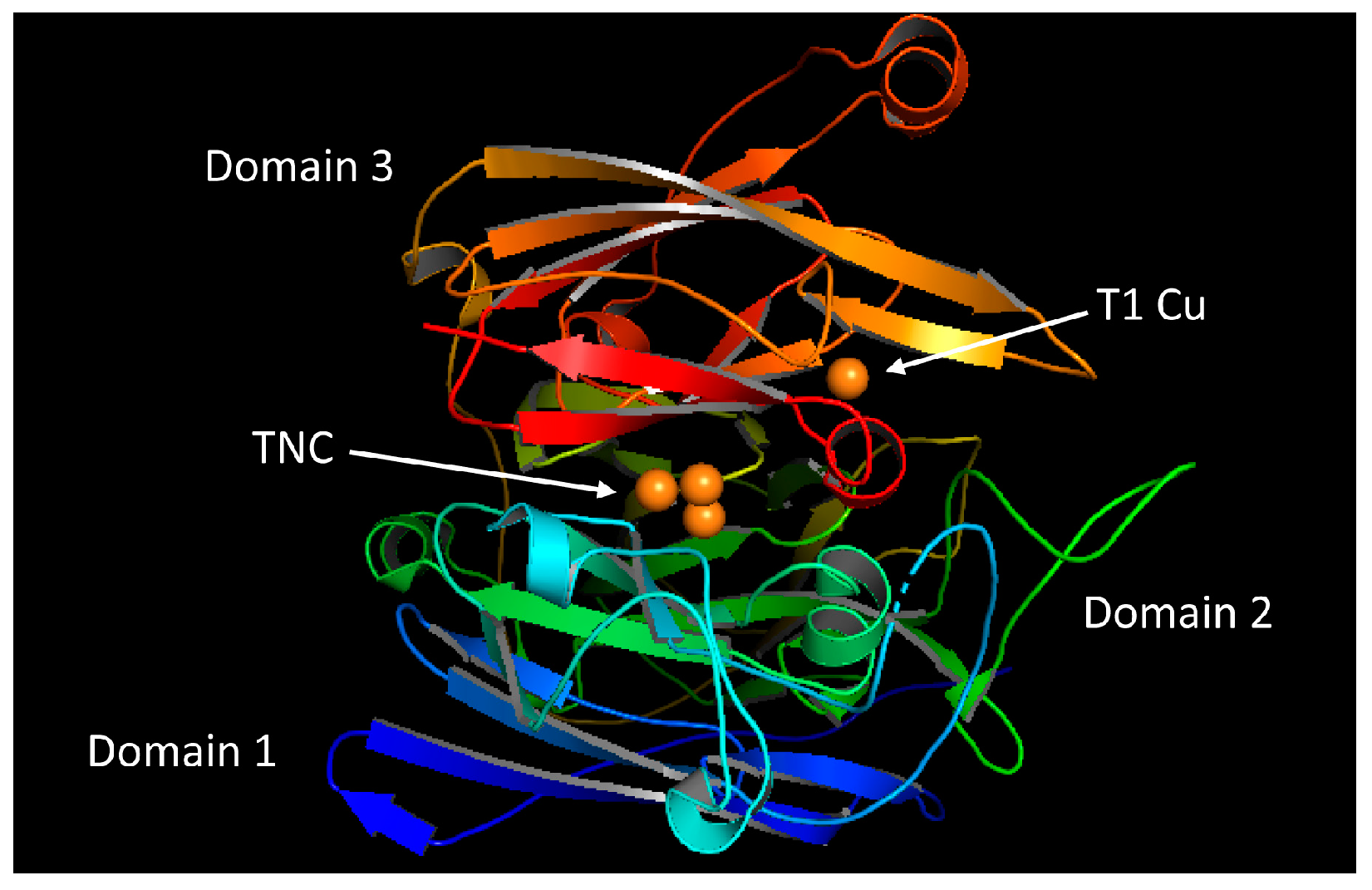

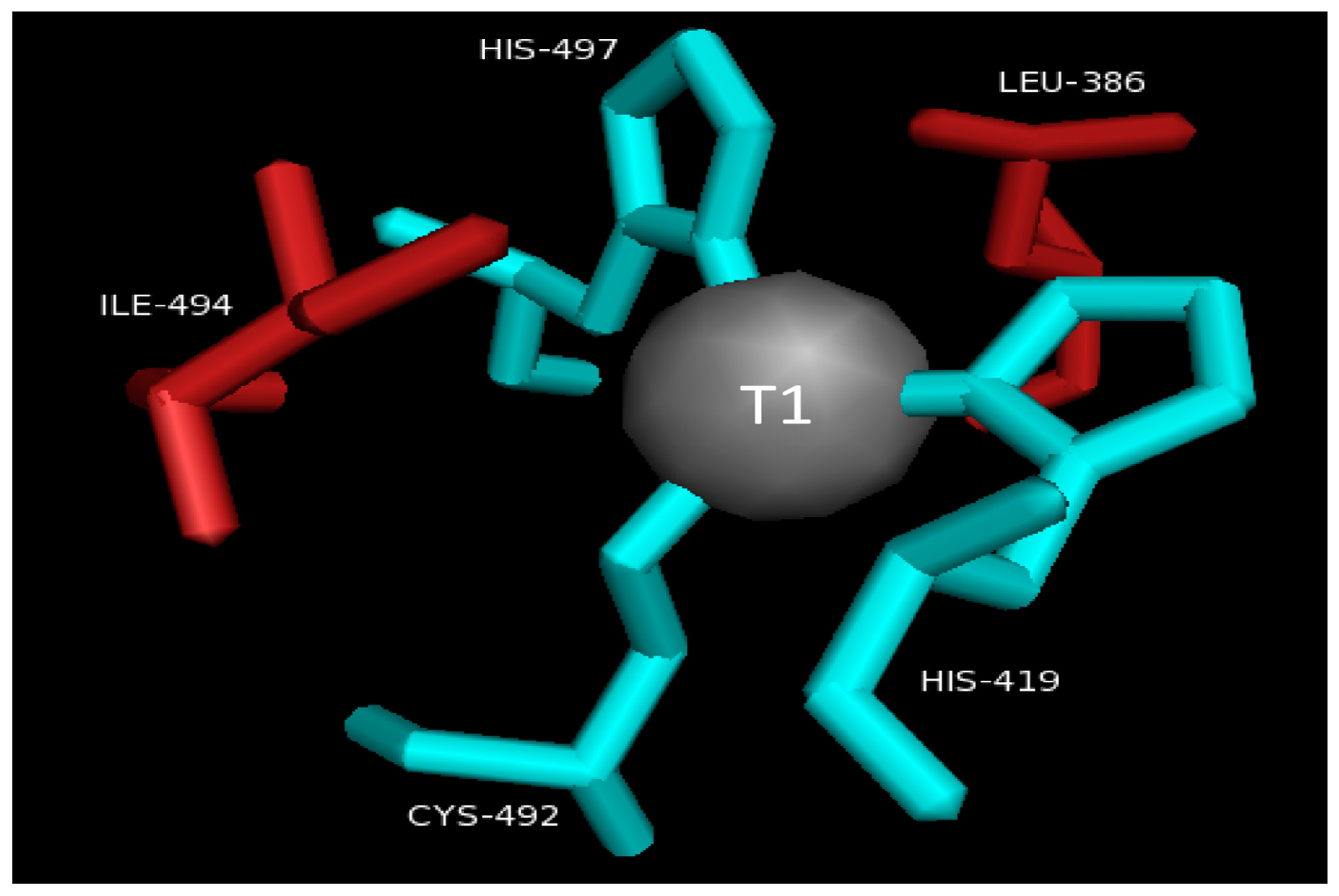

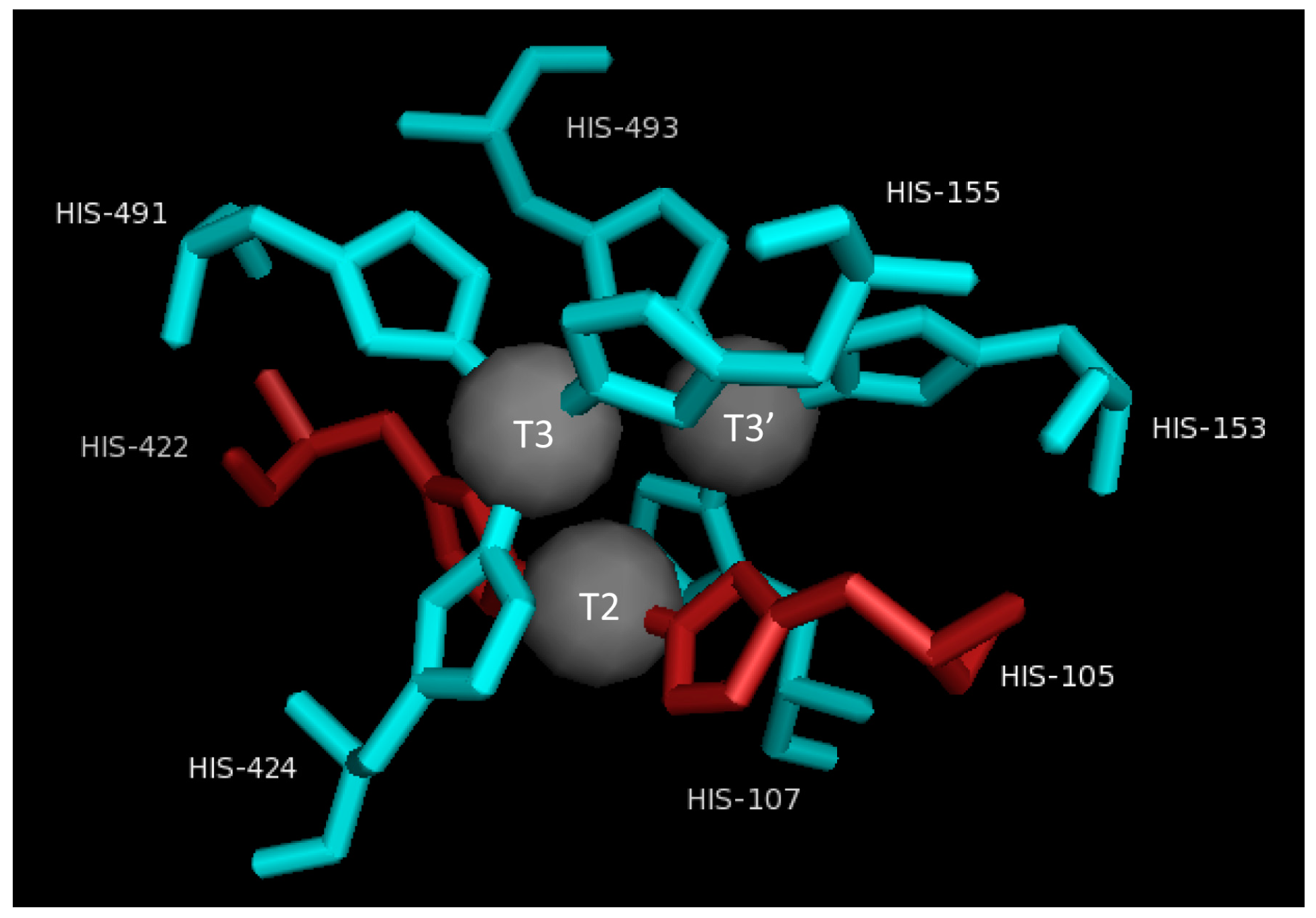

Laccases exhibit a peculiar fold that consists of three cupredoxin domains, and their active site consists of four copper atoms. These atoms are categorized as type 1 copper (T1Cu) in the T1 site (mononuclear copper center) and a cluster of type 2 and type 3 coppers (T2Cu, T3Cu, and T3’Cu) in the T2/T3 site (trinuclear copper center) as shown in the Figure 1. The distinctive absorbance of the T1 copper site has been found somewhere around 610 nm. This site is responsible for the blue color of the enzyme. The T2 copper cannot be identified by spectrophotometry; however, it generates a distinctive EPR signal [2,37,38][2][18][19]. The absorbance peak can be seen at 330 nm, which is due to the diamagnetic nature of the T3 copper site [39][20]. Their optical and electro paramagnetic resonance characteristics serve as the main criteria for this classification [2,26,40][2][21][22]. For some laccases, it has been reported that T1 is the primary site where electrons are accepted from reduced substrates. In addition, the catalytic efficiency (kcat/Km) is influenced by the redox potential of the T1 copper site [2,20,41][2][23][24]. Mononuclear and trinuclear copper centers are localized in the third domain and in between the first and third domains, respectively (Figure 1) [42,43][25][26]. The substrate binding pocket is located near the mononuclear copper center and is constituted by the residues of the second and third domains [28,35][27][28].

2.2. T1 Site

2.2. T1 Site

2.3. T2/T3 Site

3. Characteristics That Determine Activity Other Than the Redox Potential

3.1. Electrostatic Environment of the Enzyme Pocket

3.2. Steric Hindrance Due to Bulky Structures

3.3. Orientation of Substrate in Binding Site

The crucial element affecting how quickly the substrate oxidizes is the substrate’s orientation in the laccase’s substrate binding pocket. Various site-directed mutagenesis studies have been conducted, which support the importance of the substrate’s orientation in the binding site. Substitution of V148L has resulted in an increased activity of mutant laccase compared to the parental enzyme. The presence of the aromatic ring of Y208 in the vicinity of the leucine side chain may have changed the loop (204–208) conformation at the substrate binding site containing the conserved D205, which interacts with the binding substrate. Conformational changes may have resulted in a favorable orientation of D205 towards the binding substrate, which has increased the reducing substrate’s oxidation, thus increasing the activity of the mutant [67][37]. Mutation of M168G at the putative substrate binding site of a small low-redox-potential laccase from Streptomyces coelicolor resulted in improved kcat (fourfold increase) and Km (tenfold lower), which consequently resulted in around a 40-fold improvement in kcat/Km over the WT enzyme.3.4. Hydrophobic Environment of the Enzyme Pocket

The hydrophobic milieu of the substrate-binding pocket also plays a crucial role in determining the activity of the laccase [52][32]. The hydrophobic interaction between the xylidine and laccase through the hydrophobic amino acids that delimit the enzyme’s substrate binding pocket is considered the initial stage of the catalytic pathway [74][38]. Increased hydrophobic interactions caused by L386W/G417L mutations in Bacillus subtilis CotA-laccase were also reported to be responsible for increased enzyme activity [75][39]. Chen et al. also described that hydrophobic forces are essential for the interaction of laccase with lignin/lignin model compounds [76][40]. The activity of the double mutant (L386W/G417L) of Bacillus pumilus CotA-laccase for the decolorization of dyes was enhanced due to increased hydrophobic interactions between the redox mediator 2,2′-azino-bis(3-ethylbenzothiazoline-6-sulfonic acid) and the catalytic residues [77][41]. It was also observed that hydrophobic interactions are crucial in maintaining the favorable orientation of the substrate at the binding site [72,78][42][43]. The residues F162, L164, F265, F332, and F337 in TvL offer great hydrophobic binding to the subjected substrate to retain it close to the T1 site. The duration of residence of the substrate’s active pose is exploited, which facilitates electron transfer to T1.4. Conclusions

Engineering laccases is of great interest because of their broad range of functions, including industrial and environmental applications. Therefore, the number of laccases has been engineered to increase/enhance their activity and selectivity. But engineering the enzymes with rational methods has always been an appealing approach to saving time and effort. The most logical point that is usually considered for the rational engineering of laccase is to increase the redox potential of T1Cu at the active site. However, increasing the redox potential is a difficult task, as knowledge about increasing the redox potential of T1Cu effectively is still in its infancy. However, there are some other determinants at the active site of laccase that control its activity and can be engineered efficiently (Figure 74). The electrostatic environment at the active site of laccase aids in concerted electron/proton transfer during the oxidation of the substrate. Another feature that regulates the activity of laccase is the steric effect, i.e., whether the substrate is able to find its way to the substrate binding pocket or not. Sometimes, the size of the substrate is so bulky that it is not able to reach the substrate binding site and hence affects the activity. This can be addressed by widening the substrate binding pocket of the laccase. Proper orientation of the bound substrate towards the T1Cu is also very important in determining the activity of laccase. If the bound substrate is more buried towards the T1Cu of the laccase, it facilitates electron transfer from the substrate to T1Cu and hence increases the oxidizing ability of the laccase. Last but not least, the hydrophobic environment at the substrate binding site plays an important role in the binding of the substrate with the enzyme, as the affinity of the enzyme for the substrate is an important feature of enzyme catalysis. Therefore, improving binding affinity of enzyme to the substrate will results in an increased activity. Although a number of features of the active site of the laccase that determine its oxidizing ability have been discovered, extensive research is still required to explore to what extent these features are specific to controlling the activity of the laccase. Moreover, these discussed features should be extensively targeted to engineer the laccases rationally.

References

- Janusz, G.; Pawlik, A.; Swiderska-Burek, U.; Polak, J.; Sulej, J.; Jarosz-Wilkolazka, A.; Paszczynski, A. Laccase Properties, Physiological Functions, and Evolution. Int. J. Mol. Sci. 2020, 21, 966.

- Solomon, E.I.; Sundaram, U.M.; Machonkin, T.E. Multicopper Oxidases and Oxygenases. Chem. Rev. 1996, 96, 2563–2606.

- Kumar, A.; Ahlawat, S.; Mohan, H.; Sharma, K.K. Stabilization-destabilization and redox properties of laccases from medicinal mushroom Ganoderma lucidum and human pathogen Yersinia enterocolitica. Int. J. Biol. Macromol. 2021, 167, 369–381.

- Solomon, E.I.; Chen, P.; Metz, M.; Lee, S.K.; Palmer, A.E. Oxygen Binding, Activation, and Reduction to Water by Copper Proteins. Angew. Chem. Int. Ed. 2001, 40, 4570–4590.

- Bassanini, I.; Ferrandi, E.E.; Riva, S.; Monti, D. Biocatalysis with laccases: An updated overview. Catalysts 2020, 11, 26.

- Ayodeji, F.D.; Shava, B.; Iqbal, H.M.N.; Ashraf, S.S.; Cui, J.D.; Franco, M.; Bilal, M. Biocatalytic Versatilities and Biotechnological Prospects of Laccase for a Sustainable Industry. Catal. Lett. 2023, 153, 1932–1956.

- Cambria, M.T.; Gullotto, D.; Garavaglia, S.; Cambria, A. In silico study of structural determinants modulating the redox potential of Rigidoporus lignosus and other fungal laccases. J. Biomol. Struct. Dyn. 2012, 30, 89–101.

- Chappell, H.A.; Milliken, A.; Farmer, C.; Wendland, N.; Coward, L.; Gregory, D.J.; Johnson, C.M. Efficient remediation of 17α-ethinylestradiol by Lentinula edodes (shiitake) laccase. Biocatal. Agric. Biotechnol. 2017, 10, 64–68.

- Cardullo, N.; Muccilli, V.; Tringali, C. Laccase-mediated synthesis of bioactive natural products and their analogues. RSC Chem. Biol. 2022, 3, 614–647.

- Witayakran, S.; Ragauskas, A.J. Synthetic Applications of Laccase in Green Chemistry. Adv.Synth. Catal. 2009, 351, 1187–1209.

- Chen, Z.; Oh, W.D.; Yap, P.S. Recent advances in the utilization of immobilized laccase for the degradation of phenolic compounds in aqueous solutions: A review. Chemosphere 2022, 307, 135824.

- Mayolo-Deloisa, K.; Gonzalez-Gonzalez, M.; Rito-Palomares, M. Laccases in Food Industry: Bioprocessing, Potential Industrial and Biotechnological Applications. Front. Bioeng. Biotechnol. 2020, 8, 222.

- Stanzione, I.; Pezzella, C.; Giardina, P.; Sannia, G.; Piscitelli, A. Beyond natural laccases: Extension of their potential applications by protein engineering. Appl. Microbiol. Biotechnol. 2020, 104, 915–924.

- Backes, E.; Kato, C.G.; Corre, R.C.G.; Moreira, R.D.P.M.; Peralta, R.A.; Barros, L.; Ferreira, I.C.F.R.; Zanin, G.M.; Bracht, A.; Peralta, R.M. Laccases in food processing: Current status, bottlenecks and perspectives. Trends Food Sci. Technol. 2021, 115, 445–460.

- Minussi, R.C.; Pastore, G.M.; Duran, N. Potential applications of laccase in the food industry. Trends Food Sci. Technol. 2002, 13, 205–216.

- Hussain, A.; Bilal, M.; Rafeeq, H.; Jabeen, Z.; Afsheen, N.; Sher, F.; Kumar, V.; Bharagava, R.N.; Ferreira, L.F.R.; Iqbal, H.M. Role of laccase in the pulp and paper industry. In Nanotechnology in Paper and Wood Engineering; Elsevier: Faisalabad, Pakistan, 2022; pp. 35–60.

- Unuofin, J.O.; Falade, A.O.; Aladekoyi, O.J. Applications of microbial laccases in bioremediation of environmental pollutants: Potential issues, challenges, and prospects. Bioremediat. Environ. Sustain. 2021, 519–540.

- Leontievsky, A.A.; Vares, T.; Lankinen, P.; Shergill, J.K.; Pozdnyakova, N.N.; Myasoedova, N.M.; Kalkkinen, N.; Golovleva, L.A.; Cammack, R.; Thurston, C.F.; et al. Blue and yellow laccases of ligninolytic fungi. FEMS Microbiol. Lett. 1997, 156, 9–14.

- Koroljova-Skorobogat’ko, O.V.; Stepanova, E.V.; Gavrilova, V.P.; Morozova, O.V.; Lubimova, N.V.; Dzchafarova, A.N.; Jaropolov, A.I.; Makower, A. Purification and characterization of the constitutive form of laccase from the basidiomycete Coriolus hirsutus and effect of inducers on laccase synthesis. Biotechnol. Appl. Biochem. 1998, 28, 47–54.

- Shin, K.S.; Lee, Y.J. Purification and characterization of a new member of the laccase family from the white-rot basidiomycete Coriolus hirsutus. Arch. Biochem. Biophys. 2000, 384, 109–115.

- Jiang, Q.; Cui, Z.; Wei, R.; Nie, K.; Xu, H.; Liu, L. Feasible Cluster Model Method for Simulating the Redox Potentials of Laccase CueO and Its Variant. Front. Bioeng. Biotechnol. 2022, 10, 957694.

- Mate, D.M.; Alcalde, M. Laccase engineering: From rational design to directed evolution. Biotechnol. Adv. 2015, 33, 25–40.

- Xu, F.; Shin, W.S.; Brown, S.H.; Wahleithner, J.A.; Sundaram, U.M.; Solomon, E.I. A study of a series of recombinant fungal laccases and bilirubin oxidase that exhibit significant differences in redox potential, substrate specificity, and stability. Biochim. Biophys. Acta 1996, 1292, 303–311.

- Yaropolov, A.I.; Skorobogatko, O.V.; Vartanov, S.S.; Varfolomeyev, S.D. Laccase—Properties, Catalytic Mechanism, and Applicability. Appl. Biochem. 1994, 49, 257–280.

- Gabdulkhakov, A.; Kolyadenko, I.; Kostareva, O.; Mikhaylina, A.; Oliveira, P.; Tamagnini, P.; Lisov, A.; Tishchenko, S. Investigations of Accessibility of T2/T3 Copper Center of Two-Domain Laccase from Streptomyces griseoflavus Ac-993. Int. J. Mol. Sci. 2019, 20, 3184.

- Giardina, P.; Faraco, V.; Pezzella, C.; Piscitelli, A.; Vanhulle, S.; Sannia, G. Laccases: A never-ending story. Cell. Mol. Life Sci. 2010, 67, 369–385.

- Camarero, S.; Pardo, I.; Canas, A.I.; Molina, P.; Record, E.; Martinez, A.T.; Martinez, M.J.; Alcalde, M. Engineering platforms for directed evolution of Laccase from Pycnoporus cinnabarinus. Appl. Environ. Microbiol. 2012, 78, 1370–1384.

- Arregui, L.; Ayala, M.; Gomez-Gil, X.; Gutierrez-Soto, G.; Hernandez-Luna, C.E.; Herrera de Los Santos, M.; Levin, L.; Rojo-Dominguez, A.; Romero-Martinez, D.; Saparrat, M.C.N.; et al. Laccases: Structure, function, and potential application in water bioremediation. Microb. Cell Factories 2019, 18, 200.

- Jones, S.M.; Solomon, E.I. Electron transfer and reaction mechanism of laccases. Cell. Mol. Life Sci. 2015, 72, 869–883.

- Serrano-Posada, H.; Centeno-Leija, S.; Rojas-Trejo, S.P.; Rodríguez-Almazán, C.; Stojanoff, V.; Rudiño-Piñera, E. X-ray-induced catalytic active-site reduction of a multicopper oxidase: Structural insights into the proton-relay mechanism and O2-reduction states. Acta Crystallogr. Sect. D Biol. Crystallogr. 2015, 71, 2396–2411.

- Xu, F.; Berka, R.M.; Wahleithner, J.A.; Nelson, B.A.; Shuster, J.R.; Brown, S.H.; Palmer, A.E.; Solomon, E.I. Site-directed mutations in fungal laccase: Effect on redox potential, activity and pH profile. Biochem. J. 1998, 334 Pt 1, 63–70.

- Bertrand, T.; Jolivalt, C.; Briozzo, P.; Caminade, E.; Joly, N.; Madzak, C.; Mougin, C. Crystal structure of a four-copper laccase complexed with an arylamine: Insights into substrate recognition and correlation with kinetics. Biochemistry 2002, 41, 7325–7333.

- Autore, F.; Del Vecchio, C.; Fraternali, F.; Giardina, P.; Sannia, G.; Faraco, V. Molecular determinants of peculiar properties of a Pleurotus ostreatus laccase: Analysis by site-directed mutagenesis. Enzym. Microb. Technol. 2009, 45, 507–513.

- Loi, M.; Glazunova, O.; Fedorova, T.; Logrieco, A.F.; Mule, G. Fungal Laccases: The Forefront of Enzymes for Sustainability. J. Fungi 2021, 7, 1048.

- Rochefort, D.; Leech, D.; Bourbonnais, R. Electron transfer mediator systems for bleaching of paper pulp. Green Chem. 2004, 6, 14–24.

- Prasad, N.K.; Vindal, V.; Narayana, S.L.; Ramakrishna, V.; Kunal, S.P.; Srinivas, M. In silico analysis of Pycnoporus cinnabarinus laccase active site with toxic industrial dyes. J. Mol. Model. 2012, 18, 2013–2019.

- Miele, A.; Giardina, P.; Notomista, E.; Piscitelli, A.; Sannia, G.; Faraco, V. A semi-rational approach to engineering laccase enzymes. Mol. Biotechnol. 2010, 46, 149–156.

- Cambria, M.T.; Di Marino, D.; Falconi, M.; Garavaglia, S.; Cambria, A. Docking Simulation and Competitive Experiments Validate the Interaction Between the 2,5-Xylidine Inhibitor and Rigidoporus lignosus Laccase. J. Biomol. 2010, 27, 501–509.

- Gupta, N.; Lee, F.S.; Farinas, E.T. Laboratory evolution of laccase for substrate specificity. J. Mol. Catal. B Enzym. 2010, 62, 230–234.

- Chen, M.; Zeng, G.M.; Lai, C.; Li, J.; Xu, P.; Wu, H.P. Molecular basis of laccase bound to lignin: Insight from comparative studies on the interaction of Trametes versicolor laccase with various lignin model compounds. RSC Adv. 2015, 5, 52307–52313.

- Chen, Y.; Luo, Q.; Zhou, W.; Xie, Z.; Cai, Y.J.; Liao, X.R.; Guan, Z.B. Improving the catalytic efficiency of Bacillus pumilus CotA-laccase by site-directed mutagenesis. Appl. Microbiol. Biotechnol. 2017, 101, 1935–1944.

- Mehra, R.; Meyer, A.S.; Kepp, K.P. Molecular dynamics derived life times of active substrate binding poses explain KM of laccase mutants. RSC Adv. 2018, 8, 36915–36926.

- Kyomuhimbo, H.D.; Brink, H.G. Applications and immobilization strategies of the copper-centred laccase enzyme; a review. Heliyon 2023, 9, e13156.