You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 1 by Di Chen and Version 3 by Conner Chen.

The matrix of edible oils is complex, and it is necessary to perform efficient sample preparation to extract the target components before detection [16,17,18]. Sample preparation generally includes steps such as sample collection, extraction, purification, and concentration.

- edible oils

- phthalic acid esters

- sample preparation methods

1. Sample Preparation Methods

The matrix of edible oils is complex, and it is necessary to perform efficient sample preparation to extract the target components before detection [1][2][3][16,17,18]. Sample preparation generally includes steps such as sample collection, extraction, purification, and concentration. At present, the sample preparation methods for detecting PAEs in edible oils mainly include liquid-based extraction techniques [4][5][6][7][19,20,21,22], gel permeation chromatography (GPC) [8][9][23,24], sorptive-based extraction techniques [10][11][12][25,26,27], and QuEChERS (quick, easy, cheap, effective, rugged, and safe) [13][14][15][28,29,30].

2. Liquid-Based Extraction Techniques

Liquid-liquid extraction (LLE) is a traditional method for sample preparation. It transfers target analytes from the sample solution to the extractant based on the different distribution coefficients of the target analytes in two immiscible or slightly soluble solvents. For the extraction of PAEs from edible oils, the commonly used extraction solvents are mainly nonpolar solvents such as n-hexane, isooctane, and dichloromethane. Table 12 summarizes the methods for analyzing PAEs in edible oils by LLE combined with appropriate determination techniques.

Table 12.

Applications of LLE-based methods for extracting PAEs in edible oil samples.

| Sample Amount | Analytes | Solvent Usage | Sample Preparation | Detection | LODs | Ref. |

|---|---|---|---|---|---|---|

| 0.1 g | 12 PAEs (DMP etc.) | Extraction solvent: 900 µL of n-hexane saturated acetonitrile | LLE | LC-HRMS | 0.02–0.35 mg/kg | [4][19] |

| 0.5 g | 17 PAEs (DMP etc.) | Extraction solvent: 40 mL of hexane-saturated acetonitrile | LLE | GC-MS/MS | 0.1–4.0 µg/kg | [7][22] |

| 2 g | 10 PAEs (DMP etc.) | Extraction solvent: 5 mL of acetonitrile | LLE | LC-MS/MS | 1–9 µg/L | [5][20] |

| 50 g | DEP | Extraction solvent: 75 mL of a mixture of hexane and acetone (1:1, v/v) | LLE | GNP-rt-IPCR | 1.06 pg/L | [6][21] |

| 1 g | PA (hydrolysate of total PAEs) | Extraction solvent: 600 µL of TBP | LPME | LC-MS/MS | 1.0 µmol/kg | [16][31] |

| 5 mL | o-PA, m-PA, p-PA | Extraction solvent: 34 µL of ammoniacal buffer | AA-LPME | LC-DAD | 0.11–0.29 ng/mL | [17][32] |

| 0.5 mL | 5 PAEs (DMP etc.) | For AALLE, extraction solvent: 1 mL of DMSO;For DLLME, dispersive solvent: DMSO (from AALLE); extraction solvent: 0.45 mL of chloroform | AALLE and DLLME | GC-FID/GC-MS | 0.007–0.023 µg/L | [18][33] |

AA-LPME: air-assisted liquid-phase microextraction; DAD: diode array detector; DLLME: dispersed liquid-liquid microextraction; DMP: dimethyl phthalate; DMSO: dimethyl sulfoxide; DEP: diethyl phthalate; FID: flame ionization detector; GC: gas chromatography; GNP-rt-IPCR: gold nanoparticles improved real-time immuno-Polymerase Chain Reaction; HRMS: high-resolution mass spectrometry; MS: mass spectrum; PA: phthalic acid; TBP: Tributyl phosphate.

LLE is simple to perform and does not require expensive instruments, making it widely used in the detection of PAEs [4][5][6][7][19,20,21,22]. However, traditional LLE is not environmentally friendly because it often results in the formation of emulsions and consumes large volumes of organic solvents during the extraction process. Zhou et al. used hexane-saturated acetonitrile (ACN) to extract PAEs from edible oils. The entire extraction process took more than 15 min, with a high consumption of over 40 mL of hexane-saturated acetonitrile and approximately 0.5 g of vegetable oils [7][22].

With the development of the new concept of green chemistry, the advantages of microextraction technology have become prominent [19][34]. Compared with traditional extraction methods, microextraction technology consumes lower amounts of organic solvents and is more environmentally friendly [20][21][22][35,36,37]. Liquid-phase microextraction (LPME) is a miniaturized extraction technology developed on the basis of LLE. Since the introduction of LPME in 1996 [23][38], this technology has been widely used in the analysis of various samples as a new approach for sample preparation [17][24][25][32,39,40]. In recent years, various modes have been derived from LPME, among which dispersed liquid–liquid microextraction (DLLME) has been widely used for the extraction of PAEs in edible oils. The DLLME system is a ternary solvent system composed of samples, dispersants, and extractants. During DLLME, a mixture of extractant and dispersant is quickly injected into the sample solution through a syringe. Under the action of the dispersant, the extractant that was originally immiscible with the sample solution forms small droplets. The droplets are dispersed in the extractant, thus increasing the contact area between the extraction phase and the sample, shortening the extraction time. Currently, these extraction technologies are often combined with auxiliary means, such as ultrasonic-assisted extraction [26][41] and air-assisted extraction [17][18][25][26][32,33,40,41], for the extraction of PAEs in edible oils. These auxiliary methods can further reduce the consumption of organic solvents and effectively improve the extraction efficiency. Khoshmaram et al. used air-assisted liquid–liquid extraction (AA-LLE) coupled with DLLME for the extraction and preconcentration of some PAEs from edible oils prior to their detection by gas chromatography (GC). The entire extraction process only required about 10 min, with the low consumption of 1 mL of dimethyl sulfoxide and 0.45 mL of chloroform as the extractant and 0.5 mL of edible oils [18][33].

Extraction technologies based on traditional LLE generally use organic solvents as extractants, which are harmful to the operator and the environment. Farajzadeh et al. used an alkaline aqueous solution instead of organic solvents and proposed an organic-solvent-free AA-LPME method to extract and preconcentrate phthalic acid residues from edible oil samples. They combined this technology with liquid chromatography (LC)-diode array detector (DAD) to detect three types of phthalic acids (o-phthalic acid, m-phthalic acid, and p-phthalic acid) in edible oil samples, and the method showed low limits of detection (LODs) of 0.11–0.29 ng/mL and high extraction recoveries of 81–97%. Moreover, they compared this method with other dispersive methods, including ultrasound-assisted dispersive liquid–liquid microextraction (USA-DLLME), manual shaking-liquid-phase microextraction (MSh-LPME), and vortex-assisted liquid–liquid microextraction (VA-LLME). Under the same conditions, the amounts of time required by USA-DLLME, MSh-LPME, and VA-LLME were 12, 5, and 4 min, respectively, with the consumption of 5 mL of oil samples and 34 µL of the ammoniacal buffer. At the same time, the LODs for all the analytes were improved when using the proposed method compared with those of other methods [17][32]. This demonstrates that the organic-solvent-free AA-LPME method proposed above has the advantages of being more rapid, efficient, and sensitive. Most importantly, the application of an aqueous extractive phase instead of organic extraction solvents makes traditional LLE technology more environmentally friendly. Given that phthalic acid is the main hydrolysate of PAEs, it will be a good choice to adopt the method proposed above to indirectly determine the contents of PAEs in edible oils.

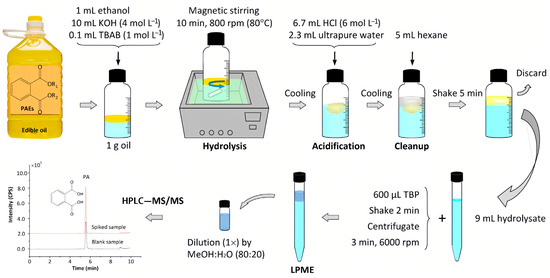

In addition, there are various PAE plasticizers in edible oils, some of which are still unknown due to the lack of corresponding standard compounds. Therefore, establishing a suitable method to determine all of the PAEs in edible oils is challenging. Liu et al. [16][31] and Xie et al. [26][41] used phase transfer catalyst to accelerate the oil/water biphasic base hydrolysis of PAEs; PAEs were hydrolyzed into phthalic acid, and the total contents of PAEs were indirectly measured by determining phthalic acid (Figure 2). This method provided new ideas for measuring the total contents of PAEs in edible oils.

3. Gel Permeation Chromatography

GPC uses a porous gel as the stationary phase. Based on the spatial size effect of the gel pores, molecules of different sizes elute from large to small in order, thus achieving the goal of separating the target analyte. GPC has the characteristics of high purification efficiency, reusability, wide applicability, and a high degree of automation. GPC is suitable for separating substances with significant differences in molecular size. The matrix of edible oil samples is complex and rich in a large amount of macromolecular interfering substances. Therefore, using GPC to remove macromolecular substances to purify small-molecule PAEs is a good method. In the pretreatment process of edible oil samples, macromolecular substances such as oils and pigments are first leached out, while small-molecule substances such as PAEs are leached out later, thus achieving effective purification.

Li et al. used GPC to extract 15 kinds of PAEs from edible oils with a glass chromatography column filled with a Bio-Beads (S-X3) filler. Then, the contents of the extracted solution were detected by GC-mass spectrometry (MS). The experimental results showed that the LODs of the 15 kinds of PAEs were between 0.001 and 2.000 µg/L, the average standard addition recoveries of three concentrations were in the range of 70.50–112.00%, and the average deviations (n = 6) were in the range of 1.59–7.54%. This indicated that GPC had a good purification ability for oil samples [8][23]. The application of the fully automatic purification and concentration of the GPC system greatly simplified the extraction process, enabling unattended and reliable operation [27][42]. However, GPC also has many shortcomings. In 2018, Li et al. found that in sesame oil, PAEs had a significant overlap with the matrix, and the interference of the matrix after the GPC approach was difficult to compensate for [9][24]. Moreover, conventional GPC technology consumes large volumes of solvents and has high costs. The GPC system itself has a PAE background value, which makes the quantification of trace PAEs difficult to achieve [9][24]. Therefore, in recent years, for the determination of PAEs in edible oils, GPC technology has gradually been replaced by other technologies, such as solid-phase extraction (SPE) and LLE.

4. Sorptive-Based Extraction Techniques

SPE is by far one of the most common sample preparation methods for the determination of PAEs [28][43]. When a complex sample solution passes through the extraction column, the sorbent will selectively retain the target substance and some of the interferents through polar, hydrophobic, or ion exchange interactions. Next, the extraction column is washed to remove interferents adsorbed by the sorbent, followed by choosing another solvent to elute the target analyte, thus achieving the purpose of separating, purifying, and enriching the target compound [29][30][44,45]. Compared with traditional LLE method, SPE has the advantages of avoiding emulsification phenomena, being easy to automate, and achieving efficient purification [10][11][12][25,26,27]. There have been many new reports on the extraction of PAEs in edible oils using SPE combined with various measurement methods.

The development of SPE technology mainly depends on the innovation of the sorbents. For the extraction and purification of PAEs in edible oils, traditional sorbents for SPE mainly include C18 [31][46], primary secondary amine (PSA) [28][32][33][43,47,48], and Florisil® [34][35][49,50]. However, conventional SPE sorbents exhibit low adsorption and selectivity. Chen et al. invented novel molecularly imprinted polymers of PAEs by atom transfer radical polymerization to replace traditional SPE sorbents. They successfully detected 10 PAEs in edible oils using molecularly imprinted solid-phase extraction (MISPE) combined with GC and a flame ionization detector (FID). The LODs of this method were 0.10–0.25 μg/mL, and the recoveries of the spiked samples were 82.5–101.4%. The extraction effectiveness of MISPE for PAEs was compared with that of commercial SPE columns, and the results indicated that the performance of MISPE was better than those of C18-SPE, PSA-SPE, PAE-SPE, and silica SPE under optimized extraction conditions [36][53].

Solid-phase microextraction (SPME) pretreatment method was developed on the basis of SPE. It is a new sample pretreatment technology that integrates sampling, extraction, enrichment, and injection into one step [37][60]. In SPME, the sorbent is coated onto a matrix material such as quartz fibers to extract, enrich, and concentrate the target compounds. Once the extraction process is finished, the fibers undergo desorption using either thermal desorption or liquid desorption methods. Subsequently, the target compounds are detected [38][61]. The entire process is easy to perform, time-saving, and solvent-free [39][62]. In SPME, the performance of the coating materials is the most critical factor in improving the extraction efficiency [40][63]. Therefore, similar to SPE, the development of SPME technology also mainly depends on the innovation of the coating materials. To date, various coating materials have been developed for SPME to extract PAEs from edible oils, such as metal-organic framework deep eutectic solvent/molecularly imprinted polymers (MOF-DES/MIPs) [41][3], polydimethylsiloxane/divinylbenzene (PDMS/DVB) fiber and polyethylene glycol (PEG) fiber [42][58], materials institute lavoisier-88(Fe)/graphene oxide (MIL-88(Fe)/GO)-coated fibers [43][54], graphene/polyvinylchloride (G/PVC) nanocomposite [44][57], and divinylbenzene–carboxen–polydimethylsiloxane (DVB/CAR/PDMS) [45][56].

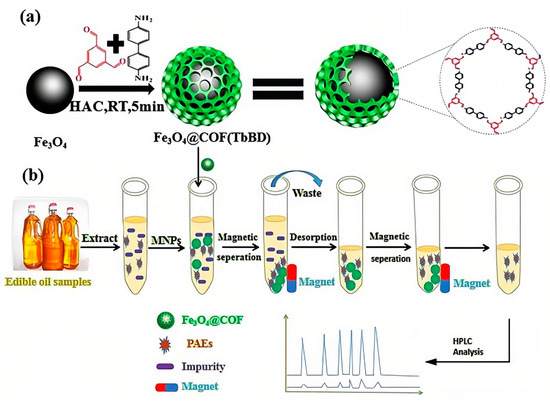

Magnetic solid-phase extraction (MSPE), which uses magnetic materials as sorbents and utilizes an external magnetic field to conveniently and quickly separate the adsorbent and analyte from the solution during the purification process, has also received great interest for achieving separation operation more easily [46][64]. Zhao et al. fabricated new magnetic covalent organic framework nanospheres named Fe3O4@covalent organic framework (1,3,5-triformylbenzene-benzidine) (Fe3O4@COF(TbBD)) as the magnetic sorbent and combined them with LC-DAD to achieve the extraction and detection of seven PAEs in edible vegetable oils (Figure 23). Under optimal conditions, the proposed method possessed a high sensitivity with LODs of 0.55–0.95 µg/kg and limits of quantification (LOQs) of 1.80–3.10 µg/kg, as well as satisfactory recoveries of 80.2–102.9% [47][4].

5. QuEChERS

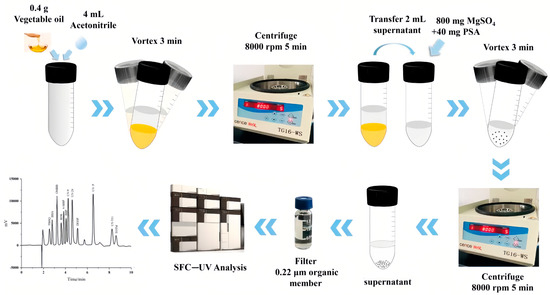

QuEChERS was first proposed by Anastassuades et al. in 2003 [13][28] and has received significant attention for its advantages such as its simplicity, low solvent consumption, and flexibility. In recent years, QuEChERS has gradually become a new trend for the detection of trace organic matter in foods, with a wide range of applications in the detection of plasticizers. This method consists of two major steps: LLE with ACN (acetonitrile) and subsequent purification by dispersive solid-phase extraction (DSPE). As shown in Figure 34, Gan et al. successfully applied QuEChERS followed by supercritical fluid chromatography (SFC) and UV detector for the qualitative and quantitative analysis of 12 chemical additives (including three plasticizers: BBP, DEHP, and trioctyl trimellitate (TOTM)) in various edible vegetable oils [14][29]. In detail, they performed LLE with 0.4 g of edible vegetable oils and 4 mL of ACN, followed by salting-out with anhydrous magnesium sulfate. After DSPE with the sorbent, the supernatant was analyzed by SFC. In this process, they used ultracentrifugation to help with the purification.

Figure 34. Schematic diagram of the QuEChERS-SFC method for the determination of PAEs in edible oils [14].

In addition to SFC, QuEChERS is usually combined with other detection technologies, such as GC-MS/MS [15][48][30,65] and LC-DAD [49][66], to detect plasticizers in edible oils. All these methods have achieved satisfactory results. Although QuEChERS has been able to meet the extraction requirements for most of the tested samples, further removal of lipids from edible oils for more accurate detection of the target analytes is still of great significance. Sun et al. combined QuEChERS with freezing-lipid precision to further remove the lipids in the edible oil sample during the process of extracting PAEs, thus preventing the lipids from affecting the performance of the instrument [48][65]. The results showed that the extraction solution without freezing-lipid precipitation was turbid due to the dispersion of lipids in it, while the extraction solution after freezing-lipid precipitation was significantly clearer, and a large amount of lipids was deposited at the bottom of the glass centrifuge bottle. The effective removal of lipids would further improve the accuracy of detection and reduce the pollution of lipids on the instrument. As an emerging technology, QuEChERS will have an increasingly wider application in the pretreatment of edible oil samples.