Dielectric elastomers (DEs) are a class of electroactive polymers (EAPs) widely used as active elements in soft transducers (actuators, sensors and generators)

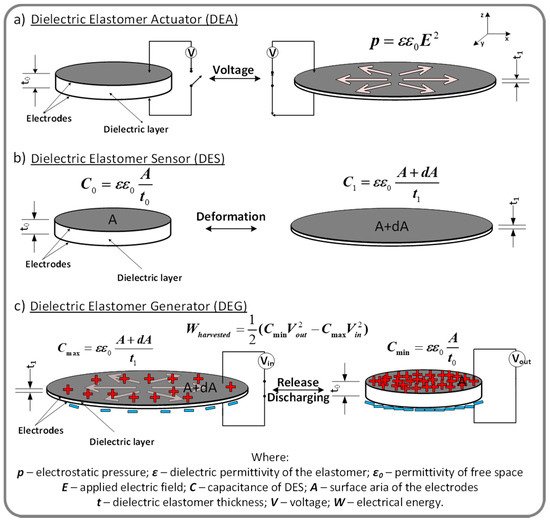

[1]. Such a transducer consists in principle of a highly deformable dielectric elastomer film sandwiched between compliant electrodes. When a voltage is applied to the electrodes, the electrostatic force squeezes the dielectric elastomer film expanding it laterally due to the elastomer incompressibility (dielectric elastomer actuator, a)

[2]. Two mechanisms underlie the electrical action, Maxwell stress (caused by coulombian interaction between oppositely charged electrodes) and electrostriction (based on small displacements of dipoles from their equilibrium positions under an applied electric field

[3]. However, although it occurs in all dielectrics, in the case of dielectric elastomers, the electrostriction contribution is low, often being ignored, especially in the case of non-polar polymers such as silicones

[4].

Figure 1. The principle of operation of dielectric elastomer transducers (DETs) as: (a) actuators (DEA); (b) sensor (DES); (c) generator (DEG).

Dielectric elastomers can also be used for measuring mechanical deformations, such as pressure, strain, shear and torsion acting as soft capacitive sensors (dielectric elastomer sensor, b)

[5][6]. Another important functionality of DEs, is their ability to work as generators by converting mechanical to electrical energy (c)

[7].

Since the discovery of the basic principles in 1990 and the first application of electroactive elastomers in the field of robotics, followed by the first use of DEGs for wave energy conversion (WEC) in 2001 and the first fully elastomeric WEC in 2012

[8] to the present, the field is constantly expanding and developing. The electromechanical transducers based on dielectric elastomers (DETs) show many benefits in comparison with traditional piezoelectric, magnetic, pneumatic or hydraulic transducers that are in general bulky, rigid, expensive and often unsuitable due to their incompatibility with soft or complex-shaped objects. The thin, homogeneous, soft and flexible polymer film is the key to the low voltage operation of multilayer DETs to qualify as artificial muscles.

Although such DETs are of interest for a growing number of applications (adjustable optics, microfluidics, soft robotics and haptic devices)

[9][10][11][12][13] and technically feasible, there are still some challenges to be addressed: rapid and reproducible production of elastomeric membranes, the ability to self-repair defects of a certain level, realization and deposition of extensible electrodes, ensuring their good compliance with the dielectric film, et cetera

[14]. Thus, although the dielectric is the active element of a DEG, the electrodes are also at the core of the device’s performance: they must be conductive, soft and sustain large deformations while remaining conductive, and they must also be able to do so for millions of cycles. The main requirements for dielectric elastomers consist mainly of large actuation strain, low modulus and low elastic losses, high dielectric strength, fast response, low weight, low costs, recyclability, et cetera

[15].

2.Electromechanically Active Silicone Elastomers

Of the types of elastomers tested for DETs purpose over time, only silicones and acrylics have proven to be competitive. Silicones meet most of these requirements, being primarily highly compliant and capable of large deformations due to their high flexibility

[16], having shear modulus values between 100 kPa and 3 MPa, and low loss tangent, tan σ << 0.001

[17]. In addition, they can operate in a wide temperature range, are easy to handle and process in the form of films of different thicknesses

[18][19]. Silicones also have advantages in terms of resistance to the environment (humidity, ozone, oxygen, sunlight, marine environment, etc.) and weathering (), but they have the drawback that they are not biodegradable, while recycling processes are complicated

[20].

Table 1. Important weather resistances of main classes of dielectric elastomers; where: E—excellent; G—Good; F—Fair; P—Poor

[21][22].

| Properties |

Elastomer Type |

| Silicone |

Acrylic |

Polyurethane |

Natural Rubber |

| Atmospheric ageing resistance |

E |

E |

F |

P |

| Oxidation resistance |

E |

E |

E |

G |

| Heat resistance |

E |

E |

F–G |

F–G |

| Low temperature flexibility |

E |

P |

F |

E |

| Moisture resistance |

E |

F |

G |

G–E |

Based on the above and due to their appropriate mechanical properties (low modulus and high elongation), silicones are among the most used polymers in DETs. Their properties can be easily tuned by the preparation strategy: proper choice of the molecular mass and microstructure of the polymer matrix; adding of more or less active fillers, whether these are incorporated in the polymeric matrix (

ex situ) or generated

in situ; crosslinking mode (through the side or ending functional groups) or mechanism (condensation, radicalic or by hydrosilylation). Thus, it was possible to improve the performance of silicone elastomers by manipulating parameters, such as the molecular weight of the polymer and the crosslinking pattern, without other additions or chemical changes. Polydimethylsiloxanes with molecular weights from several tens of thousands to over one million Da have been obtained

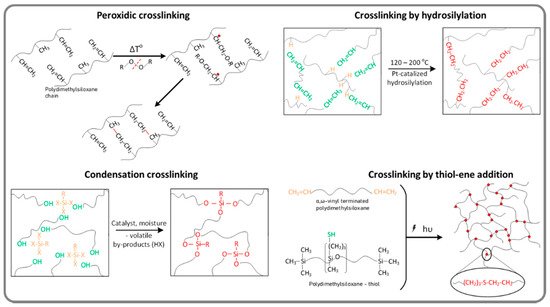

[23]. They were crosslinked by different chemical pathways: peroxide, condensation, hydrosilylation, dehydrocoupling and thiol-ene addition ()

[24] obtaining soft to ultra-soft silicones, with Young’s moduli generally less than 0.1 MPa and elongation at break of over 1000%, and good values for elastic recovery and stress decay

[23].

Figure 2. Approaches for increasing the performance of dielectric elastomers using different cross-linking pathways: peroxide, condensation, hydrosilylation, dehydrocoupling, thiol-ene addition

[24].

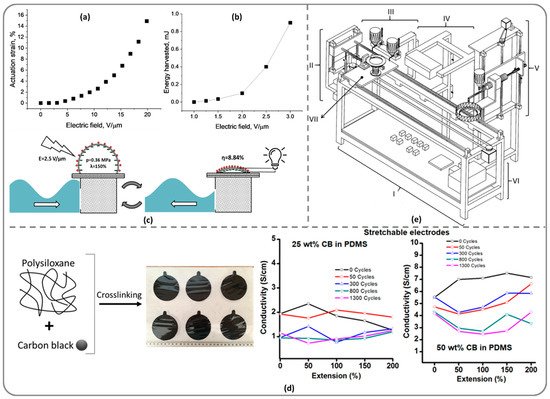

By properly designing polysiloxanes in terms of structure, molecular weight and crosslinking pattern, it was found that a silicone elastomer based on PDMS (

Mw = 80,000 Da) containing 8.4 mol.% vinyl groups crosslinked by thiol-ene addition with a PDMS (

Mw = 35,000 Da) containing 16.5 mol.% SH group along the chain, without other additions, incorporated in a DEA developed a lateral actuation of 15% when applying an electric field E = 20 MV/m (3a)

[24]. A DEG built from three circular layers of common silicone with a diameter of 120 mm and coaxial circular stretchable electrodes of 60 mm diameter also based on silicone but embedding 25 wt.% carbon black was able, at 200% strain, to harvest almost 1 mJ (b)

[25]. An energy harvesting efficiency of η = 8.84% was achieved with a DEG based on silicone filled with 2 wt.% TiO

2 nanotubes and carbon black electrodes (c)

[26]. By incorporating carbon black

[27] or carbon nanotubes within the PDMS matrix, stretchable electrodes were obtained, several conductivity performances of these being showed in d.

Figure 3. Own performances obtained with dielectric silicone elastomer transducers: (

a) actuation showed by a DEA with single-layer silicone film based on PDMS (Mw = 80,000 Da) containing 8.4% vinyl groups crosslinked by thiol-ene addition with a PDMS with Mw = 35,000 Da containing 16.5% SH group along the chain

[24]; (

b) energy harvesting with a DEG based on three layers of silicone elastomer and stretchable electrodes also based on silicone embedding 25 wt% carbon black

[25]; (

c) energy collected with a DEG based on silicone filled with 2 wt% TiO

2 nanotubes and carbon black electrode

[26]; (

d) conductivity performances of stretchable electrodes based on PDMS incorporating 25 wt% carbon black within the PDMS matrix

[27]; (

e) automatic installation for stacked DET manufacturing (block I—stainless steel rigid skeleton, block II—automatic drop of the circular mask, block III—two spray guns that allow the deposition of the electrode solution and the silane, block IV—UV lamp, block V—polymer dispenser, block VI—electronic parts, block VII—left-right mobile rotating disc on stainless steel plate)

[28].

However, silicones suffer from low value of dielectric permittivity, requiring relatively high electric fields (E > 100 MV/m) on the electrodes for actuation

[29][30][31][32]. Therefore, significant efforts are being made to improve this parameter. One of the ways to improve the performance of silicone elastomers in terms of dielectric permittivity against the background of their other properties of interest is to attach polar groups

[33]. This can be done on monomers (silanes or cyclosiloxanes) or by post-functionalization of polymers containing certain reactive groups, generally Si-H, Si-CH = CH

2 or RX (R: alkyl, X: NH

2, halogen, SH) by hydrosilylation, thiol-ene addition or substitution reactions. While some of these groups are themselves of interest due to polarity, their modification can lead to more complex structures. Thus, groups such as cyan, epoxy, benzaldehyde, dispersed Red1 (DR1)

[34], acetate, carboxyl and chloride

[35] were attached to increase the dielectric permittivity of silicones and indeed this effect has been achieved, and more. Although they have very good dielectric properties, polar silicones most often show weak mechanical properties due to phase separation, which limit their applicability in electromechanical devices. An alternative solution has been considered, polysiloxanes carrying CN-propyl or Cl-propyl groups were processed as submicron particles stabilized by either full organic

[36] or a specially designed siloxane surfactant

[37], cross-linked within the formed particles and used as fillers in a high molecular weight polydimethylsiloxane matrix

[36][37]. Soft elastomers with Young’s moduli of 0.12–0.5 MPa, depending on the filler’s structure, dielectric strength up to 63 MV/m and dielectric permittivity up to 4.7 at 10

4 Hz were obtained. High apparent piezoelectric coefficient (

d33) was measured by piezoresponse force microscopy (PFM) without poling, at ambient temperature, while variation of

d33 with stretching was observed, in correlation with morphological aspects

[36]. Elastomeric composites with improved mechanical properties (higher elongation and tensile strength) and electromechanical response (higher

actuation) were obtained. Polyazomethine (PAZ) submicron particles (either containing siloxane moieties, or not) have also been used as fillers for silicone-based composites

[38]. Polar particles were obtained by polycondensation reactions performed in organic solvents in the presence of an amphiphilic siloxane oligomer. Elastomers with increased dielectric permittivity relative to pure polydimethylsiloxane elastomer, excellent stretchability with elongations in excess of 500% and up to 800% and low Young’s moduli were obtained by this approach.

Much research has also been done on the preparation of elastomeric silicone composites by incorporation in a silicone matrix with different parameters (molecular weight, functionality, degree of crosslinking, etc.) of other active fillers capable of increasing its dielectric permittivity. Fillers of different types were tested with this aim. For example, ceramic fillers (BaTiO

3 [39][40][41], TiO

2 [26]) having different morphologies and inorganic ones (

in situ generated silica

[42]) were used. Studies have shown that the success of such an approach depends primarily on the degree of dispersion and compatibility of the filler with the matrix. For this, an adequate surface treatment is required, which also ensures a reasonable dielectric strength for the resulting material. In the case of the use of BaTiO

3 having different morphologies, the particles with high aspect ratio were found to be more adequate, an addition of only 5 wt.% BaTiO

3 leading to an increase of about three times of the relative dielectric permittivity compared to the value measured for the silicone matrix

[40]. The electromechanical sensitivity and actuation strain, calculated from mechanical and dielectric data, proved to be the highest in the case of acicular particles, also being high compared to those reported in the literature (electromechanical sensitivity, β ~ 400 MPa

−1 and lateral actuation strain Sx ~ 23%), thus promise for a good effective electromechanical response exists

[40]. TiO

2 nanotubes were first properly treated on the surface with hexamethyldisilazane and incorporation (5 wt.%) in the silicone matrix led to a dielectric elastomer with dielectric permittivity of 7.7 at 0.1 Hz and dielectric strength of 60 MV/m. A synergy between the increased dielectric permittivity and a low Young’s modulus reflected a good electromechanical response of the composites, resulting in 8.84% efficiency for 400 V input voltage and 150% balloon-like elongation (c)

[26].

Besides the ceramic particles, less studied materials as permittivity enhancers for PDMS are metal (Mn, Fe, Cr) complexes of salen-type Schiff bases with tetramethyldisiloxane spacers

[43]. The resulted composites showed a slight decrease of elastic properties but an increase in dielectric permittivity of up to 100%, while the electromechanical sensitivity was almost double compared with the reference sample. Cu-, Co-, and Ni-atranes

[44] or a 1D coordination polymer

[45], were also tested as fillers for silicones. While in the latter case, a dielectric permittivity value of 4.6 was obtained at a load of 3 wt.% filler, regardless of the frequency, in the first case, remarkably high values were registered for dielectric permittivity but, unfortunately, also for dielectric loss, which makes these composites fall more into the semiconductor field. Iron oxide nanoparticles are another category of inorganic fillers studied as permittivity enhancers for polysiloxanes

[46][47]. Spherical ferrihydrite and nanorods of goethite were prepared and subsequently incorporated into the PDMS matrix

[47]. The nanocomposites prepared with spherical nanoparticles showed permittivity values up to 5 at 1 kHz and electromechanical sensitivity comparable to that of composites with ceramic fillers.

The dielectric permittivity of polysiloxanes can also be increased by incorporating conductive fillers at concentrations below the percolation threshold. There are two strategies of using these fillers as permittivity enhancers, either the concentration of the filler is kept below the percolation threshold or the fillers are coated with surfactants or other materials to avoid this phenomenon. Composites based on silicones and conductive fillers are also being studied as compliant electrodes. Considering that the carbon black particles represent the cheapest powder that can be used as a conductive filler, a rubber electrode was fabricated by incorporating 25 wt.% of carbon black into a high molecular weight PDMS

[25][27]. The electrical conductivity was about 0.1 S·cm

−1 at 150% strain, remaining almost unchanged even after a few hundred stretching cycles (d). By increasing the carbon black load to 50%, the conductivity increases considerably but the cyclic operation performance decreases. An automatic installation for the alternating deposition of rubbery dielectric and electrode layers for obtaining stacked DETs has been patented

[28] (3e). This consists of several blocks (I–VII), which allows obtaining the alternating deposition of dielectric and electrode layers as a stacked DET

[47]. A stainless-steel rigid block (I) sustains all other blocks, while a mobile block (VII), that mainly consists of a rotating disc, moves horizontally in four steps to obtain two consecutive sacrificial layers, two electrodes and one active layer, as follows. In the first step, a silane solution is sprayed with a gun on the rotating disc from block VII, under block III. In the second step, a certain amount of polymer is poured on the disc after block VII moves under block V and spin-coated to obtain the desired thickness. The UV crosslinking of the thin polymer layer occurs under block IV in the third step. The first electrode is obtained by moving block VII beside block II and under block III. At this step, the fourth, a circular mask drops on the rotating disc, the disc rotates with the mask and simultaneously the electrode solution is sprayed with a gun onto the disc. The mask allows obtaining the circular shape of the electrode. These steps are repeated to obtain the active layer, the second electrode and the final sacrificial layer. Several performances obtained with such formulations and arrays are showed in .