Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Taofeeq Durojaiye Moshood | + 3733 word(s) | 3733 | 2021-05-20 11:12:06 | | | |

| 2 | Peter Tang | Meta information modification | 3733 | 2021-05-21 05:52:25 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Moshood, T. Supply Chain and Digital Twins. Encyclopedia. Available online: https://encyclopedia.pub/entry/9904 (accessed on 07 February 2026).

Moshood T. Supply Chain and Digital Twins. Encyclopedia. Available at: https://encyclopedia.pub/entry/9904. Accessed February 07, 2026.

Moshood, Taofeeq. "Supply Chain and Digital Twins" Encyclopedia, https://encyclopedia.pub/entry/9904 (accessed February 07, 2026).

Moshood, T. (2021, May 20). Supply Chain and Digital Twins. In Encyclopedia. https://encyclopedia.pub/entry/9904

Moshood, Taofeeq. "Supply Chain and Digital Twins." Encyclopedia. Web. 20 May, 2021.

Copy Citation

The supply chains shaping their distribution networks become more diverse as companies respond to global markets’ stringent criteria. This is also counterproductive to the visibility of the supply chain within the company and can adversely affect the organization’s core business.

logistics

digital twins

industry 4.0

supply chain visibility

cloud computing

internet of things

manufacturing

1. Introduction

The cornerstone of an organization is a working logistics supply chain. Organizations whose core industries are based on internal and external logistics development play a crucial role in ensuring that the organization’s core business will continue without halting [1]. However, it is essential to outline the central purpose of logistics quite briefly, transporting everything from point X to Y. Based on the particular mission at hand, the methods of doing so may differ considerably. These activities are becoming more challenging for many companies as global economies impose higher consumer customization expectations. The items produced and the manufacturing lines themselves entail more complex technologies. It is becoming increasingly challenging to identify alternatives to the core businesses’ technical problems [2][3]. The method of obtaining information about the supply chain’s internal workings is becoming more complicated as distribution supply chains grow more dynamic. Any company in which the supply chain has a critical function can quickly become a concern since lacklustre accountability and exposure of the supply chain can throw clouds on outdated processes that may otherwise be rectified [4][5]. Ensuring maximum control of the supply chain not only grants access to a variety of evidence that can act as a foundation for business choices. It also offers greater capacity to adapt rapidly to developments and make fast operating decisions in real-time based on changes in demand or production [6][7].

Although the supply chain’s visibility is necessary, achieving and retaining full visibility through a supply chain network spanning the globe is a challenge bordering on the impossible without using recent digital technology developments [8][9]. The automotive business and culture as a whole are on the edge of what is sometimes referred to as “Industry 4.0” or the fourth industrial revolution [7][10]. Rapid advancement and integration to emerging technology innovations and mindsets are the core aspects of Industry 4.0. Many new technologies increasingly find further adoption and different uses within our current industrial framework [11][12]. The approaches and ideas in the context of “Industry 4.0” are situated at the interface of the disciplines of electrical engineering, business administration, computer science, business and information systems engineering, mechanical engineering, and the participating segments. The illustrated parts of Industry 4.0 result in general fields of activity, which are of particular interest for business and information systems engineering. The increasing digitalization of all manufacturing and manufacturing-supporting tools results in registering a growing amount of actor and sensor data, supporting functions of control and analysis [13]. Digital processes evolve due to the likewise increased networking of technical components. In conjunction with the increase in the digitalization of produced goods and services, they lead to completely digitalized environments [10][14]. Those are, in turn, driving forces for new technologies such as simulation, digital protection or virtual resp. Many of the innovations that make up the fourth industrial revolution are gradually utilizing innovative development, big data analytics algorithms, and sophisticated human-machine interfaces, to name only a few [15]. Four main categories can be roughly grouped into these different technologies [16]: (1) Cyber-physical constructs. (2) Platforms for the Internet of Things (IoT). (3) Computing cognitively. (4). Cloud computing.

A fascinating field of technical research within the industrial framework of Industry 4.0 is that of Digital Twins [17]. A Digital Twins is a form of cyber-physical device that uses numerous IoT sensors and produces a high-fidelity visual image of a physical asset. The abundance of data obtained by the Digital Twins is then aggregated and analyzed using machine learning algorithms to promote strategic and organizational decision-making [18]. As organizations adapt to global markets’ rigorous demands, the supply chains that constitute their logistics networks become increasingly complex. This often has a detrimental effect on the organization’s supply chain visibility, which may negatively impact the organization’s core business. This article aims to determine how organizations can improve their logistical supply chain visibility by implementing a Digital Twins—an all-encompassing virtual representation of the physical assets that constitute the logistics system.

2. Supply Chain Visibility

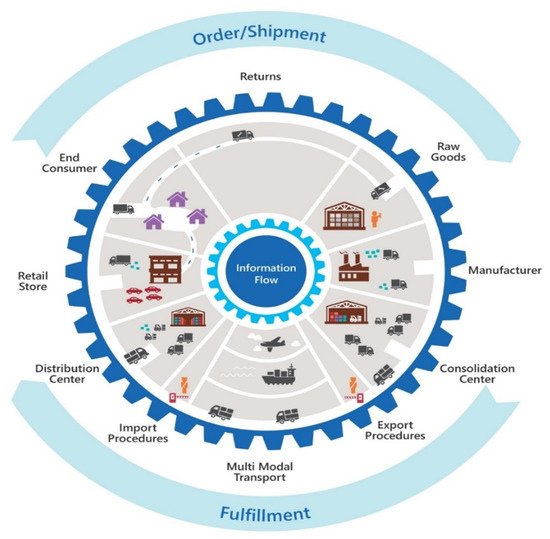

The supply chain’s visibility is part of the larger supply chain management area. A philosophy focused on developing visibility across supply chains to facilitate internal decision-making and operational efficiency. In recent years, supply chain visibility research has been squarely established in the academic limelight. Global megatrends towards globalization have raised several challenges in handling organizations’ current supply chains as they grow in line with consumer demands [6][19]. At its core, the supply chain visibility depends on ensuring that the organization provides access to reliable and current knowledge concerning the supply chains in terms of internal and external processes [20][21]. This is done by determining which supply chain operations are most significantly impacted by a lack of clarity and developing methods of gathering and exchanging appropriate data between all parties involved [6][22]. Ensuring adequate visibility in a company’s supply chain will have several beneficial consequences by optimizing predicting, preparation, arranging, and order implementation, to name a few [23][24]. With the latest technologies in the industry, such as Digital Twins, Artificial intelligence (AI), Internet of things (IoT), and Robotic Process Automation (RPA), more automation is now possible for managing end-to-end supply chain operations. Figure 1 shows supply chain visibility and control tower.

Figure 1. Supply Chain Visibility and Control Tower. Source: Reprinted with permission from [25].

Visibility necessitates a cross-divisional platform that helps in proactively managing end-to-end supply chains in real-time. A high degree of visibility is only possible when the core elements—people, technology, and process—work in tandem. Although visibility is strongly related to information sharing, it is crucial to distinguish the two since information sharing is an operation. In contrast, visibility is a likely outcome of information sharing practices [26][27][28]. The key advantages of exposure in the supply chain are the general increase in market efficiency, offering a foundation for better decision-making, both at strategic and organizational levels [29][30]. Organizations benefit from proper visibility of the supply chain at a functional level by having the capacity to reconfigure the supply chain rapidly and effectively [31]. An ability that is becoming extremely relevant in quickly changing market conditions creates a competitive advantage. In their 2010 paper, Wei and Wang suggest that four main visibility processes enable an enterprise to reorganize its supply chain in compliance with both its own requirements and external demands [23][24]. These are visibility for learning, visibility for sensing, visibility for integrating, and visibility for coordinating [21].

3. Digital Twins

Michael Grieves first proposed the idea of Digital Twins at a University of Michigan presentation on Product Lifecycle Management in 2003 [32]. NASA created the first actionable Digital Twins in 2011 as a way to forecast aircraft structural performance by examining and designed to simulate them as virtual objects. NASA scientists later described Digital Twins as “an interactive multiphysics, multiscale, probabilistic simulation of a vehicle or device that uses the highest quality physical models, sensor update fleet history, and so on, to mirror the life of its flying twin [33]. A Digital Twins is a unique, virtual representation of a physical thing that monitors and simulates both the physical state and behavior of the thing [17]. The digital copy is continually connected to the physical object(s) and updates itself to reflect real-world changes. Applied to products, machines and even entire business ecosystems, Digital Twins can reveal insights from the past, optimize the present and even predict future performance [33].

The report explains the concept and rise of Digital Twins and how it creates value [34]. The technology, which involves using digital models to better understand and manage physical assets, is already well established in some industries and has the potential to change logistics operations [18] significantly. For a graphic representation, see Figure 2.

Figure 2. Visual Representation of Digital Twins. Source: Reprinted with permission from [35].

Suppose the number of possible Digital Twins implementations increases by the day. In that case, it becomes evident that there is no existing consensus in the scientific world on what constitutes a typical Digital Twins. It may entice an organization to enthusiastically mark its current 3D-modeling systems that include asset-tracking technology as a Digital Twins. This strategy avoids diluting and underselling the complexity and future advantages of a fully-fledged Digital Twins [18]. The following list of features is a suggested description of what makes a Digital Twins interested in furthering the consensus and acting as a foundation for future scholarly endeavours. These features are based on the personal study as well as findings from scholarly works by Qi et al. [34], Lu et al. [33], Uhlemann et al. [17], and Negri et al. [18]. The below are the characteristics:

-

A Digital Twins is a virtual representation (or model) of a physical object or process.

-

The Digital Twins is continuously updated with real-time data to reflect the physical object or process’s current state and behavior.

-

The Digital Twins can help visualize and analyse the physical object or process, and by use of machine learning, further optimizations and predictions can be made.

These characteristics can be used to widely cover any possible Digital Twins implementations, from something as small as a portion of a manufacturing line to something as big as the entire city.

4. Improving Supply Chain Visibility with a Digital Twins

4.1. The Impact of Digital Twins upon Supply Chain Visibility

In order to increase the visibility of the supply chain, it soon becomes evident that providing functioning Digital Twins integrated within a company’s logistical supply chain will prove very useful [36]. Many scholars point out that the advent of modern digital technology positively impacts the supply chain’s visibility, especially those that allow for an overview of previous challenges to detect processes within the supply chain. Digital Twins are no exception to this [7][37]. It will possibly help boost all four organizational visibility factors discussed in the theoretical structure section by providing a functioning Digital Twins. In particular, a Digital Twins will dramatically improve the metrics of visibility for sensing (quickly gathering knowledge about internal and external processes) and visibility for learning (how quickly the information gathered can be processed), and this aggregated network of information can then be used to organize internal and external processes better. That said, introducing a Digital Twins is a dynamic and resource-intensive matter, and putting a Digital Twins in place does not always assure perfect visibility of the supply chain.

4.2. Visibility for Sensing and the Digital Twins

As described in the theoretical context, there are four separate areas to explore when looking at what a Digital Twins might do to increase the supply chain’s visibility. Visibility for sensing is the first type, reflecting the degree to which the enterprise can easily acquire real-time knowledge about internal and external processes and adapt to an evolving market climate. For an organization, the introduction of a Digital Twins will be tremendously helpful in this respect. The Digital Twins sensors could obtain new data types, offering more insight into the supply chain flows [38]. The Digital Twins will then identify real-time changes and alert the company about them by aggregating and interpreting the sensors’ data. Therefore, as more sensors are introduced and incorporated, the supply chain’s exposure will also begin to improve [39]. Naturally, to ensure data consistency that will cause the Digital Twins to draw assumptions that correctly mirror the fact, one must carefully consider the sensor versions. The company must also ensure that sufficient sensors are mounted for each given flow or scenario to allow the most productive use of the data obtained [7].

When it comes to optimizing supply chain visibility for internal sensing, a Digital Twins will help the company recognize improvements in demand in their supply flows more quickly [40]. With the introduction of Digital Twins to content preparation, the company will provide a more precise understanding of how many items should be ordered, resulting in a visible improvement in sensing exposure when it comes to enhancing supply chain visibility for external sensing. Using a Digital Twins in material preparation would help packaging planning gain greater visibility because packaging could be ordered alongside Digital Twins material orders [41]. This, combined with a Digital Twins that tracks packaging during the packaging period, will allow the company to be more responsive to shifts in demand for packaging. A Digital Twins may also expose the gaps in the packaging cycle, providing the packaging purchasing department with a real-time and precise picture of how demand for packaging improves [42].

4.3. Visibility to Learning and the Digital Twins

According to theory, Visibility for learning implies the extent to which new information and knowledge from both internal and external mechanisms can be obtained and absorbed by the institution. The theory notes that understanding external systems is essential for business advantage and that partners will bring new business knowledge to organizations [43]. Thus, a Digital Twins that maintains track of transport may be a potential learning opportunity to learn more about the way transport suppliers operate. In order to strengthen the supply chain for all sides, openness with commodity manufacturers may also lead to understanding more about the inner workings of their operations and whether organizations can do more [44]. However, since greater disclosure runs the risk of exposing confidential information to allies or rivals, the Digital Twins is carefully supervised and who has access to it is crucial.

Another example of how a Digital Twins can impart knowledge in increasing learning visibility is in the packaging industry [44]. As previously mentioned, having a clearer understanding of the right approaches for product repair and care can result in longer packaging lifetimes, and monitoring and tracing will assist in visualising where the black holes are in the packaging cycle. Dynamic learning involves three types of mechanisms: experience accumulation (the act of accumulating knowledge), knowledge articulation (the act of describing knowledge such that it can be communicated with others), and knowledge codification (adopting the experiences garnered and adapting the knowledge to the organization) [45]. The knowledge gathered by the Digital Twins may assist in finding the cause of an emerging issue in terms of experience accumulation. When it comes to suggesting solutions for a crisis, understanding the root cause can be incredibly helpful. When working with Digital Twins, it is also important to care about knowledge articulation. If the Digital Twins discovers new concepts, it is important to make sure that this learning is available and well-articulated for the environment to which it relates [46]. For example, once the root cause of the black hole in the packaging loop is uncovered, all of the players concerned must be made aware of this information to prepare and respond. It is important to standardise communication and ensure that relevant consumers access the material. The Digital Twins architecture must be structured to be flexible in terms of information codification [47]. If knowledge is discovered using the Twin, the company will need to make systemic or organizational improvements. In any case, the Digital Twins must be able to respond to these changes.

4.4. Visibility for Coordinating and the Digital Twins

The supply chain visibility paradigm notes that teamwork visibility shows how effective the company is at managing various aspects of its supply chain. It is essential to provide full knowledge when it comes to ensuring a higher degree of decision-making on strategic decisions that influence the supply chain. In having such results, a Digital Twins may be of great benefit [48]. For example, if a Digital Twins could better forecast or interpret the need for products or materials, it could guide financial and budgeting decision-making. Besides, a Digital Twins may help keep track of individual packaging, enabling strategic decision-making within the packaging period regarding the amount of packaging in motion [7].

Since Digital Twins can help create credible models of logistical movements, they may be a valuable tool for enhancing supply chain visibility for organizing. For example, a full Digital Twins might simulate the reorganization of logistical flows [49]. This would not only help calculate the future benefit achieved from introducing a different series of logistical flows, but it would also help predict vulnerabilities that would otherwise go unnoticed [50]. However, since a completely integrated Digital Twins is a long-term approach that does not happen immediately, it will be a long time before a company can use it as a modelling tool.

4.5. Visibility for Integrating and the Digital Twins

In order to build a strategic advantage, the theoretical paradigm decrees that visibility for integration reflects how adaptable the company is when it comes to implementing and incorporating new approaches and technology. Besides, establishing a typical supply chain identity is a critical step in terms of supply chain management as it allows a mentality that promotes the alignment of processes within the supply chain between actors [43]. Knowledge of critical processes must be exchanged between different actors to help with this, as knowing others’ core processes can lead to developments that can strengthen the supply chain. To assist with this, a Digital Twins can act as a valuable weapon, as it allows obtaining an analysis of vital internal processes within the respective supply chains. To recap the above discussion, Digital Twins are expected to have a significant effect in terms of increasing the visibility of the supply chain, as other digital solutions have been seen to be highly helpful in improving the visibility of the supply chain within organizations [51]. However, there are many problems to consider, all of which rely on maintaining technical data accuracy while still reducing and decreasing the amount of human error. The global megatrends in digital transformation and autonomous processes are expected to have enormous synergy implications concerning Digital Twins and supply chain management. It would be critical for all companies who seek to increase their visibility in the supply chain to stay updated on these developments [42].

5. The Technologies Enabling Digital Twins

5.1. Machine Learning

One of the quickest developing scientific areas today is machine learning. It incorporates components from both computer science and statistics and can be represented as a computer system that automatically enhances its efficiency over experience [52]. The terms artificial intelligence (AI) and machine learning are also used synonymously. Machine learning, though, is considered a subset of AI, which is a wider concept that covers the entire artificial intelligence area. Therefore, while machine learning is the same as AI, machine learning is not exactly the same as AI [53]. There is a wide range of implementations in which speech recognition, computer vision, language processing, and robot control are used for machine learning, just to name a few. It may be more useful for certain machine learning programs to teach the algorithm by giving it example inputs and outputs instead of manually coding it. Machine learning is now being applied progressively in several sectors, including health care, education, engineering, marketing, customer service, and logistics [52].

5.2. Internet of Things

The Internet of Things refers to all objects, often fitted with pervasive knowledge, that are connected to a network. A wide distribution network of communicative devices is generated by combining many objects for interaction through embedded systems, enabling contact between human devices and devices [54]. New standards of visibility and adaptability could be allowed to implement IoT, and efficiency could be increased in different fields, from smart homes to supply chains. In a supply chain, data obtained from various sensors in different locations could be processed and eventually informed by early alerts to human operators about any possible issues [55]. They must be fitted with sensors for IoT devices to provide any relevant data to communicate with each other. The IoT sensors come in all shapes and sizes. They are vitally important for the Digital Twins idea as they provide the knowledge with which a Digital Twins can analyse and assess the actual state of its physical twin [56].

5.3. Cloud Computing

Cloud computing is a paradigm for allowing access to computing services from a public network. The customer may access a pool of services that are owned and managed by a third party through the internet through cloud computing. Access to these properties is different from their physical location. Data storage, databases, computational capacity, and services like data analytics processing are examples of computing capabilities used in cloud computing [57]. The benefit of using a cloud is that there is no need for the customer to purchase and own costly hardware or own any computing space. The customer only pays for the cloud services they need, with the option to scale up or scale down their desired services at all times. Cloud services have three significant models: Information as a Service (IaaS), Platform as a Service (PaaS), and Software as a Service (SaaS). While cloud computing is now a common technology, it has been debated in terms of protection in some situations. The cloud also has a variety of clients using the same [7][56].

5.4. Augmented and Virtual Reality

In terms of increasing user experience, both augmented and virtual reality are becoming increasingly popular tools. Virtual reality is a technology that emulates the real world by creating a virtual world and how the user virtually experiences it [58]. This virtual world could be anything from creating a real-world high-fidelity figment to the simulation of a particular portion of the user experience. In contrast, augmented reality, rather than creating a whole new virtual world, adds a layer of information to the real world [59]. Some smartphone applications use a tangible example of everyday augmented reality, where elements are clearly visible through the phone camera that cannot be seen in the physical world [60]. In a Digital Twins context, both augmented and virtual reality can be useful tools to view and inspect the Digital Twins either on a screen (2D) or in a physical space (3D). The aforementioned technologies such as IoT, cloud computing, APIs and machine learning all provide and process the necessary data and infrastructure to create and visualize a Digital Twins in either augmented or virtual reality [61][62].

5.5. Application Programming Interface

Application Programming Interfaces allow applications such as databases, networks, and IoT sensors to interact. APIs are building blocks that are designed to be recycled by developers, so one does not have to redo the programming from scratch. A simple example of this is the Google Maps API, which can be easily combined with third-party content to view local points of interest on a Google Map. The third party would not have to schedule a completely new map in this scenario, which saves both time and money [63]. APIs help to transfer data easily from clouds, computers, and other systems, as many modern enterprises deal with cloud computing [7].

References

- Qadir, I.; Ali, A. Importance of logistics processes for customer service and firm performance: Evidence from furniture industry of pakistan. Manag. Sustain. Bus. Manag. Solutions Emerg. Econ. 2017, 22, 27–36.

- Mira, M.; Choong, Y.; Thim, C. Mediating role of port supply chain integration between involvement of human resource practices and port performance in Kingdom of Saudi Arabia. Uncertain Supply Chain Manag. 2019, 7, 507–516.

- Kovacs, G.; Kot, S. New logistics and production trends as the effect of global economy changes. Pol. J. Manag. Stud. 2016, 14, 115–126.

- Creazza, A.; Dallari, F.; Melacini, M. Evaluating logistics network configurations for a global supply chain. Supply Chain Manag. Int. J. 2010, 15, 154–164.

- Murciego, Á.L.; Jiménez-Bravo, D.; Martínez, D.P.; Román, A.V.; Lazo, G.L. Voice assistant and route optimization system for logistics companies in depopulated rural areas. Sustainability 2020, 12, 5377.

- Caridi, M.; Moretto, A.; Perego, A.; Tumino, A. The benefits of supply chain visibility: A value assessment model. Int. J. Prod. Econ. 2014, 151, 1–19.

- Blomkvist, Y.; Ullemar Loenbom, L. Improving Supply Chain Visibility within Logistics by Implementing a Digital Twin: A Case Study at Scania Logistics; KTH Royal Institute of Technology: Stockholm, Sweden, 2020.

- Tarli, M.; Masithah, S. The Effects of Supply Chain Visibility, Supply Chain Flexibility, Supplier Development and Inventory Control Toward Supply Chain Effectiveness. 2017. Available online: (accessed on 19 April 2021).

- Kot, S.; Haque, A.; Baloch, A. Supply chain management in smes: Global perspective. Montenegrin J. Econ. 2020, 16, 87–104.

- Lasi, H.; Fettke, P.D.P.; Kemper, H.-G.; Feld, D.-I.T.; Hoffmann, D.-H.M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242.

- Tjahjono, B.; Esplugues, C.; Ares, E.; Pelaez, G. What does industry 4.0 mean to supply chain? Procedia Manuf. 2017, 13, 1175–1182.

- Birkel, H.; Müller, J.M. Potentials of industry 4.0 for supply chain management within the triple bottom line of sustainability—A systematic literature review. J. Clean. Prod. 2020, 289, 125612.

- Oláh, J.; Aburumman, N.; Popp, J.; Khan, M.A.; Haddad, H.; Kitukutha, N. Impact of Industry 4.0 on Environmental Sustainability. Sustainability 2020, 12, 4674.

- Moshood, T.D.; Adeleke, A.Q.; Nawanir, G.; Ajibike, W.A.; Shittu, R.A. Emerging Challenges and Sustainability of Industry 4.0 Era in the Malaysian Construction Industry. Emerg. Chall. Sustain. Ind. 2020, 4, 1627–1634.

- Pfohl, H.-C.; Yahsi, B.; Kurnaz, T. The Impact of Industry 4.0 on the Supply Chain. In Innovations and Strategies for Logistics and Supply Chains: Technologies, Business Models and Risk Management. Proceedings of the Hamburg International Conference of Logistics (HICL); Hamburg University of Technology (TUHH): Hamburg, Germany, 2015; pp. 31–58.

- Erboz, G. How to define industry 4.0: Main pillars of industry 4.0. Manag. Trends Dev. Enterp. Glob. Era 2017, 1, 761–767.

- Uhlemann, T.H.-J.; Lehmann, C.; Steinhilper, R. The digital twin: Realizing the cyber-physical production system for industry 4.0. Procedia CIRP 2017, 61, 335–340.

- Negri, E.; Fumagalli, L.; Macchi, M. A review of the roles of Digital Twins in CPS-based production systems. Procedia Manuf. 2017, 11, 939–948.

- Li, Z.; Wu, H.; King, B.; Ben Miled, Z.; Wassick, J.; Tazelaar, J. On the Integration of Event-Based and Transaction-Based Architectures for Supply Chains. In Proceedings of the 2017 IEEE 37th International Conference on Distributed Computing Systems Workshops (ICDCSW), Atlanta, GA, USA, 5–8 June 2017; pp. 376–382.

- Francis, V. Supply chain visibility: Lost in translation? Int. J. Supply Chain Manag. 2008, 13, 180–184.

- Swift, C.; Guide, V.D.R., Jr.; Muthulingam, S. Does supply chain visibility affect operating performance? Evidence from conflict minerals disclosures. J. Oper. Manag. 2019, 65, 406–429.

- Lohmer, J.; Bugert, N.; Lasch, R. Analysis of resilience strategies and ripple effect in blockchain-coordinated supply chains: An agent-based simulation study. Int. J. Prod. Econ. 2020, 228, 107882.

- Wei, H.-L.; Wang, E.T.G. The strategic value of supply chain visibility: Increasing the ability to reconfigure. Eur. J. Inf. Syst. 2010, 19, 238–249.

- Busse, C.; Schleper, M.C.; Weilenmann, J.; Wagner, S.M. Extending the supply chain visibility boundary: Utilizing stakeholders for identifying supply chain sustainability risks. Int. J. Phys. Distrib. Logist. Manag. 2017.

- Supply Chain Control Tower Visuals (Page 2)-Line.17QQ.com. Available online: (accessed on 19 April 2021).

- Barratt, M.; Oke, A. Antecedents of supply chain visibility in retail supply chains: A resource-based theory perspective. J. Oper. Manag. 2007, 25, 1217–1233.

- Kiss, K.; Ruszaki, C.; Szűcs, A.; Koncz, G. Examining the Role of Local Products in Rural Development in the Light of Consumer Preferences—Results of a Consumer Survey from Hungary. Sustainability 2020, 12, 5473.

- Mirabelli, G.; Solina, V. Blockchain and agricultural supply chains traceability: Research trends and future challenges. Procedia Manuf. 2020, 42, 414–421.

- Wang, E.T.G.; Wei, H.-L. Interorganizational Governance Value Creation: Coordinating for Information Visibility and Flexibility in Supply Chains. Decis. Sci. 2007, 38, 647–674.

- Kimseng, T.; Javed, A.; Jeenanunta, C.; Kohda, Y. Sustaining Innovation through Joining Global Supply Chain Networks: The Case of Manufacturing Firms in Thailand. Sustainability 2020, 12, 5259.

- Christidis, K.; Devetsikiotis, M. Blockchains and Smart Contracts for the Internet of Things. IEEE Access 2016, 4, 2292–2303.

- Grieves, M. Digital twin: Manufacturing excellence through virtual factory replication. White Pap. 2014, 1, 1–7.

- Lu, Y.; Liu, C.; Wang, K.I.-K.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. Integr. Manuf. 2020, 61, 101837.

- Qi, Q.; Tao, F.; Zuo, Y.; Zhao, D. Digital twin service towards smart manufacturing. Procedia CIRP 2018, 72, 237–242.

- How Digital Twin and Analytics Improve Operations, Minimize Costs|Jacobs. Available online: (accessed on 19 April 2021).

- Mandal, S. The influence of dynamic capabilities on hospital-supplier collaboration and hospital supply chain performance. Int. J. Oper. Prod. Manag. 2017, 37, 664–684.

- Tozanlı, Ö.; Kongar, E.; Gupta, S. Evaluation of Waste Electronic Product Trade-in Strategies in Predictive Twin Disassembly Systems in the Era of Blockchain. Sustainability 2020, 12, 5416.

- Srinivasan, R.; Swink, M. An Investigation of Visibility and Flexibility as Complements to Supply Chain Analytics: An Organizational Information Processing Theory Perspective. Prod. Oper. Manag. 2018, 27, 1849–1867.

- Ivanov, D.; Dolgui, A.; Das, A.; Sokolov, B. Digital Supply Chain Twins: Managing the Ripple Effect, Resilience, and Disruption Risks by Data-Driven Optimization, Simulation, and Visibility. In Handbook of Ripple Effects in the Supply Chain; Springer: Berlin/Heidelberg, Germany, 2019; pp. 309–332.

- Fan, C.; Zhang, C.; Yahja, A.; Mostafavi, A. Disaster CityDigital Twins: A vision for integrating artificial and human intelligence for disaster management. Int. J. Inf. Manag. 2021, 56, 102049.

- Wang, J.; Ye, L.; Gao, R.X.; Li, C.; Zhang, L. Digital Twin for rotating machinery fault diagnosis in smart manufacturing. Int. J. Prod. Res. 2019, 57, 3920–3934.

- Fan, C.; Jiang, Y.; Mostafavi, A. Social Sensing in Disaster City Digital Twin: Integrated Textual–Visual–Geo Framework for Situational Awareness during Built Environment Disruptions. J. Manag. Eng. 2020, 36, 04020002.

- Shahat, E.; Hyun, C.T.; Yeom, C. City digital twin potentials: A review and research agenda. Sustainability 2021, 13, 3386.

- Xu, Y.; Sun, Y.; Liu, X.; Zheng, Y. A Digital-Twin-Assisted Fault Diagnosis Using Deep Transfer Learning. IEEE Access 2019, 7, 19990–19999.

- Elmo, D.; Stead, D. Disrupting rock engineering concepts: Is there such a thing as a rock mass digital twin and are machines capable of learning rock mechanics? In Proceedings of the 2020 International Symposium on Slope Stability in Open Pit Mining and Civil Engineering, Perth, WA, Australia, 12–14 May 2020; pp. 565–576.

- Wang, P.; Luo, M. A digital twin-based big data virtual and real fusion learning reference framework supported by industrial internet towards smart manufacturing. J. Manuf. Syst. 2021, 58, 16–32.

- Franciosa, P.; Sokolov, M.; Sinha, S.; Sun, T.; Ceglarek, D. Deep learning enhanced digital twin for Closed-Loop In-Process quality improvement. CIRP Ann. 2020, 69, 369–372.

- Wanasinghe, T.R.; Wroblewski, L.; Petersen, B.; Gosine, R.G.; James, L.A.; De Silva, O.; Mann, G.K.I.; Warrian, P.J. Digital twin for the oil and gas industry: Overview, research trends, opportunities, and challenges. IEEE Access 2020, 8, 104175–104197.

- Barricelli, B.R.; Casiraghi, E.; Gliozzo, J.; Petrini, A.; Valtolina, S. Human Digital Twins for fitness management. IEEE Access 2020, 8, 26637–26664.

- Park, K.T.; Son, Y.H.; Noh, S.D. The architectural framework of a cyber physical logistics system for digital-twin-based supply chain control. Int. J. Prod. Res. 2020, 1–22.

- Guo, D.; Zhong, R.Y.; Lin, P.; Lyu, Z.; Rong, Y.; Huang, G.Q. Digital twin-enabled Graduation Intelligent Manufacturing System for fixed-position assembly islands. Robot. Comput. Integr. Manuf. 2020, 63, 101917.

- Jordan, M.I.; Mitchell, T.M. Machine learning: Trends, perspectives, and prospects. Science 2015, 349, 255–260.

- Camerer, C.F. Artificial Intelligence and Behavioural Economics. In The Economics of Artificial Intelligence: An Agenda; University of Chicago Press: Chicago, IL, USA, 2018; pp. 587–608.

- Xia, F.; Yang, L.T.; Wang, L.; Vinel, A. Internet of Things. Int. J. Commun. Syst. 2012, 25, 1101–1102.

- Ben-Daya, M.; Hassini, E.; Bahroun, Z. Internet of Things and supply chain management: A literature review. Int. J. Prod. Res. 2019, 57, 4719–4742.

- Haße, H.; Li, B.; Weißenberg, N.; Cirullies, J.; Otto, B. Digital Twin for Real-Time Data Processing in Logistics. In Artificial Intelligence and Digital Transformation in Supply Chain Management: Innovative Approaches for Supply Chains. Proceedings of the Hamburg International Conference of Logistics (HICL); Technische Universität Hamburg: Hamburg, Germany, 2019; pp. 4–28.

- Arora, R.; Parashar, A. Secure user data in cloud computing using encryption algorithms. Int. J. Eng. Res. Appl. 2013, 3, 1922–1926.

- Jung, T.; tom Dieck, M.C. Augmented Reality and Virtual Reality; Springer: Berlin/Heidelberg, Germany, 2018.

- Olshannikova, E.; Ometov, A.; Koucheryavy, Y.; Olsson, T. Visualizing Big Data with augmented and virtual reality: Challenges and research agenda. J. Big Data 2015, 2, 1–27.

- Ge, X.; Pan, L.; Li, Q.; Mao, G.; Tu, S. Multipath Cooperative Communications Networks for Augmented and Virtual Reality Transmission. IEEE Trans. Multimed. 2017, 19, 2345–2358.

- Yang, C.-S. Maritime shipping digitalization: Blockchain-based technology applications, future improvements, and intention to use. Transp. Res. Part E Logist. Transp. Rev. 2019, 131, 108–117.

- Omollo, C.A. Disruptive Technologies in the Logistics And Supply Chain Industry: A Study on Blockchain; United States International University Africa: Nairobi, Kenya, 2019.

- Conrad, E.; Misenar, S.; Feldman, J. Domain 8: Software Development Security (Understanding, Applying, and Enforcing Software Security). In CISSP Study Guide, 3rd ed.; Syngress: Boston, MA, USA, 2016; pp. 429–477.

More

Information

Subjects:

Transportation

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.0K

Revisions:

2 times

(View History)

Update Date:

21 May 2021

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No