| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Carlos Pereira | + 2087 word(s) | 2087 | 2021-05-19 05:51:33 | | | |

| 2 | Rita Xu | Meta information modification | 2087 | 2021-05-20 03:41:14 | | |

Video Upload Options

Cheese whey (CW) is nowadays recognized as a source of functional and bioactive compounds, especially proteins and peptides. However, a large proportion of the whey produced worldwide is still not valorized. This results from the fact that small and medium size dairy industries lack dimension to make the necessary investments for CW valorization. In some countries such as Portugal, Spain, Italy and Turkey, CW is employed in the production of whey cheeses. The liquid remaining after whey cheese production represents more than 90% of the original whey and is called second cheese whey (SCW). SCW is a poorly studied by-product and there is little interest in its recovery. SCW is a poorly studied by-product and there is little interest in its recovery. Some authors studied the use of SCW for conversion into biofuel and as a biotechnological substrate for fermented products while others studied its potential for the production of fermented drinks. However, half of CW and almost all SCW are not valorized for human consumption. This review presents several alternatives for the valorization of both by-products.

1. Introduction

Despite the controversy about the impact of dairy products on health, the consumption of dairy products in the world is increasing steadily. The development of new dairy products containing prebiotics and probiotics is also increasing based on their benefits for human health. Probiotic foods contain microorganisms that have therapeutic properties like antimicrobial activity, hypocholesterolemic activity, maintenance of gastrointestinal balance and anticarcinogenic activity [1]. Industry has developed a large group of new, nutritionally improved products, which have been a success on the market. Therefore, traditional dairy products have changed and dairy industries need to evolve into the new generation of dairy products with differentiated characteristics regarding health and nutritional properties [2][3].

Due to the increase in food consumption and to the stringent environmental regulations, the management of food waste and by-products is a challenge for the agri-food industries that face demanding economic costs for their treatment and/or disposal. The dairy industry annually produces millions of tons of by-products, the main component of which is cheese whey (CW), which corresponds to the net fraction remaining after milk coagulation. Around 9–10 L of whey results from the production of 1 kg of cheese and if discarded without treatment it creates a significant problem for the environment [4][5].

CW has a high Biochemical Oxygen Demand (BOD) and a high Chemical Oxygen Demand (COD) [6]. When discarded into water sources, it reduces the dissolved oxygen, and poses a major risk to aquatic life, as well as to the environment and human health [7]. As is the case of CW, second cheese whey (SCW) is considered a significant source of pollution, possessing high values of BOD and COD (ca. 50 and 80 g L−1, respectively) [8]. Lactose (35–50 g L−1) is the principal constituent responsible for the high COD values (>70%) [9]. SCW represents a considerable problem because its valorization is not a common practice and it is difficult to manage as animal feed, since most animals are not able to digest high amounts of lactose without suffering from digestive disorders [8][10]. Comparatively, the average BOD and COD values for urban wastewaters are 0.20 and 0.41 g L−1, respectively, which represents around 1/150 of the pollution charge of both by products, CW and SCW [11].

CW is nowadays recognized as a source of functional and bioactive compounds, especially proteins and peptides. However, a large proportion of the whey produced worldwide is still not valorized. This results from the fact that small and medium size dairy industries lack dimension to make the necessary investments for CW valorization [4][6].

In some countries such as Portugal, Spain, Italy and Turkey, CW is employed in the production of whey cheeses (Requeijão, Requesón, Ricotta and Lor, respectively) and other products with nutritional and medical potential [3][12][13]. Normally, these products are typically obtained from ovine, caprine, bovine or buffalo cheese whey. CW can be previously acidified, as is the case of Ricotta, followed by heating at temperatures around 85–90 °C for 20–30 min, to allow coagulation and subsequent precipitation of whey proteins and separation of whey cheese mass [1][6][8]. Whey cheese yield is quite variable depending on the origin of the whey and the process employed but, unless whey is previously concentrated, it is lower than 4%. The liquid remaining after whey cheese separation represents more than 90% of the original whey and is called second cheese whey (SCW), Sorelho in Portugal or Scotta in Italy, are the major by-product of whey cheese production. Lactose (4.8–5.0%), salts (1.0–1.13%), and proteins (0.15–0.22%) generally compose SCW resulting from bovine milk [6][9][14]. However, the protein and fat contents of SCW resulting from ovine milk can represent 1–4%.

SCW is a poorly studied by-product and there is little interest in its recovery [6]. Some authors studied the use of SCW for conversion into biofuel and as a biotechnological substrate for fermented products while others studied its potential for the production of fermented drinks [8][14][15][16]. Dried SCW protein concentrate was also evaluated for its usefulness as food ingredient, based on the functional properties of their proteins [17]. However, the available literature and research works concerning SCW are very limited.

2. Cheese By-Products

2.1. Whey

CW has a yellow-green color due to the presence of riboflavin and contains about 65 g of total solids per liter. Whey represents 85–95% of the milk volume, retains about 55% of the milk nutrients and approximately 20% of the total protein content [3]. The composition of CW depends on the origin of milk, the types of cheese manufactured (rennet or acid coagulation), and generally, on the factors that affect milk composition such as, breed, seasonal cycles, feed, and lactation phase.

This by-product can be divided in two types: sweet and acid whey, being the processing technique used that influences the type of whey. Sweet bovine whey has a pH around 6–7 [10][18] 6–10 g L−1 protein, 5–6 g L−1 fat, 46–52 g L−1 lactose and 2.5–4 g L−1 minerals and results from the production of most types of cheese or some casein products [3][19]. The first step in the manufacture of cheese (and sweet whey) is addition of rennet to milk. The rennet works by curdling the casein present in the milk leading to the formation of curd. The curd is then strained from the remaining liquid (CW). The rennet induced coagulation of casein occurs at pH 6.0–6.5 [10].

Acid whey has a pH of approximately 4.5–5.8 [10][18], 6–8 g L−1 protein, 5–6 g L−1 fat, 44–46 g L−1 lactose and 4.3–7.2 g L−1 minerals [19]. This whey results from the activity of lactobacilli or by the addition lactic acid or mineral acids used to coagulate the casein for the manufacture of most types of industrial caseins. It also results from the production of acid curdled cheeses, such as cottage cheese. Lactose content is generally lower in acid whey, but the mineral content normally exceeds that of sweet whey [18][20].

Lactose, the main solid component of CW, representing 70–75% of the total solids, is responsible for the high values for BOD and COD [3][9][21]. World production of bovine whey was estimated around 160 million tons per year [22]. The global production of cheese was expected to reach 21 million tons in 2020. This corresponds to an estimated global production of ca. 168 million tons of cheese whey [23]. About 50% of this whey is considered waste, used as animal feed, biofertilizer in irrigation systems, or discharged without treatment [21][22][24][25]. The conventional solutions for the treatment of whey include the production of dehydrated whey products such as whey powder (WP), whey protein concentrates (WPC), whey protein isolates (WPI) and powdered lactose [21].

Isolated whey proteins also have uses in the food industry due to their physic-chemical and nutritional properties, which allow them to act as emulsifiers, gelling agents, water binders and foaming/whipping agents in food systems. They are used in many different foods including soups, salad dressings, processed meat, dairy and bakery products or specific whey products such as Ricotta or other whey cheeses, as well as in fermented whey drinks [3][21][26][27].

Particular attention has been given to the benefits of CW regarding the nutritional, biological and functional value of whey proteins. More recently great attention has been given to minor components, important in human health, such as whey protein derived bioactive peptides with antihypertensive, antioxidant and antimicrobial activities, and non-digestible oligosaccharides, claimed to behave as dietary fibers and prebiotics [25][28].

The described processes for whey solids concentration include evaporation, ultrafiltration (UF), nanofiltration (NF) or reverse osmosis (RO), before dehydration by spray or freeze drying. However, these processes cannot be applied by small and medium companies as they are expensive and require large installations being the factor that limits the amount of CW valorized for human consumption [24]. Despite the fact that in several European countries, a significant amount of CW is used to obtain whey cheeses by thermal aggregation of the whey proteins only a limited amount of CW is used in the manufacture of such products [13].

The composition, as well as the high volumes produced, associated to the environmental impact of CW and SCW, are drivers for the great interest in their valorization. It should be emphasized that ovine SCW contains a protein and mineral content higher than that presented by bovine whey (Table 1). Thus, the appreciation of this by-product for possible future applications is of great interest.

Table 1. Average composition of bovine, ovine and caprine whey and of ovine second cheese whey (% w/v).

| Bovine CW | Ovine CW | Caprine CW | Ovine SCW | |

|---|---|---|---|---|

| Total solids | 6.0–7.0 | 7.6–10.5 | 7.07–10.8 | 7.1–8.3 |

| Lactose | 4.2–5.0 | 4.3–6.1 | 5.02–6.7 | 4.5–5.7 |

| Proteins | 0.7–0.9 | 1.6–1.8 | 1.2–0.63 | 0.8–1.2 |

| Fat | 0.1–0.8 | 1.2–2.5 | 0.84 | 0.2–0.4 |

| Minerals | 0.5–0.6 | 1.0–1.8 | 0.57 | 1.7–1.9 |

| pH | 5.6–6.3 | 5.3–5.9 | 6.34 | 5.5–6.3 |

(CW = Cheese whey; SCW = Second cheese whey) Adapted from [28][29][30][31].

2.2. Second Cheese Whey (Sorelho)

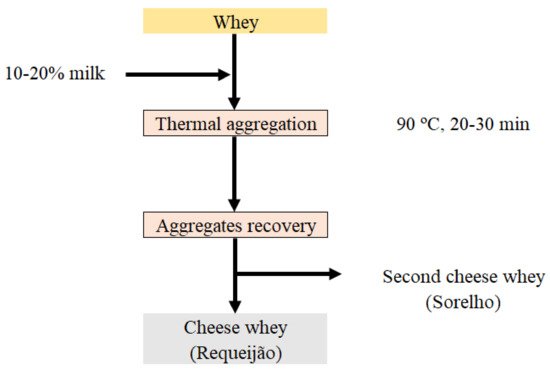

SCW is the by-product resulting from whey cheese production (e.g., Requeijão), whose manufacturing process consists basically of heat processing the whey at temperatures around 85–90 °C for 20–30 min aiming at denaturing the whey proteins [8] (Figure 1). In most cases, as happens with CW, small and medium companies are not able to valorize the SCW components for human consumption and this product is used as animal feed. Thus, the high volumes of CW (about 8 L per kg of cheese) and SCW (about 18 L per kg of whey cheese) produced remain a problem for cheese producers as they pose valuation/environmental challenges [32].

Figure 1. Scheme of whey cheese (Requeijão) manufacturing and second cheese whey (Sorelho) production.

In Italy only about 15% of CW obtained annually is used to produce Ricotta cheese generating about 1 million tons of SCW [8]. SCW is also produced in Spain, Portugal, Greece, Turkey and Romania, where it is normally used for animal feed or treated as waste.

In the past, economical and easy solutions were used by dairy industries to discard SCW such as spreading of the product on fields or elimination in rivers, lakes and ocean [33]. Nowadays, most of SCW is used as supplement feed for livestock. However, this by-product is a natural source with important compounds such as proteins mostly in the denatured state, soluble peptides, oligosaccharides, lactose, non-protein nitrogen, hydro-soluble vitamins, a variety of minerals and free amino acids [34][35]. It can be used as a good substrate in biotechnological processes to produce commercial high-value compounds [14][16][28]. SCW contains approximately 50% of the original dry matter of the whey. Lactose and minerals represent most to its dry mass, but residual fat and non-thermally precipitated nitrogen components are also present. Hence, attempts to recover some of the solid components present before the final disposal may be of interest [36]. The composition of SCW varies widely and that depends on the CW origin and processes employed to produce whey cheese. SCW resulting from bovine whey contains proteins (0.15–0.22%), salts (1.0–1.13%) and lactose (4.8–5.0%). SCW obtained from ovine whey is generally characterized by a higher protein content [6][14] and contains ca. 6.71% dry matter, 0.49% of proteins, 0.53% fat and 2.08% of minerals [15].

The mineral content of ovine SCW is quite high due to the addition of salt to the milk during cheese manufacture [9][28][34]. This by-product has acidic characteristics with pH values around 3–6 [9]. High concentrations of nutrients such as ammonium nitrogen (0.06–0.270 g L−1) and total phosphorus (0.006–0.5 g L−1) are also present in SCW [21].

Therefore, due to its composition SCW can be used for various different purposes including food formulations, nutraceuticals and biofuel products [8][28][34][37][38].

Lactose is an important ingredient in infant formula and in food processing [39]. The content of lactose in SCW is very high and its recovery may be a solution, which combined with the valorization of the nitrogen fraction, can be appealing. For lactose recuperation in CW, generally, the permeate from the UF process containing around 4–8% lactose and 0.5% salt is concentrated to 60% solids in multiple effect evaporators. Lactose is then crystallized from the concentrate, separated, and dried into lactose powder. To enhance the yield and purity, the UF permeate is also often processed by NF to partially remove the salts and to increase the lactose concentration [39]. This process can also be applied to SCW in view of its valorization.

References

- Madureira, A.; Pereira, C.; Truszkowska, K.; Gomes, A.; Pintado, M.; Malcata, F. Survival of probiotic bacteria in a whey cheese vector submitted to environmental conditions prevailing in the gastrointestinal tract. Int. Dairy J. 2005, 15, 921–927.

- Jeličić, I.; Božanić, R.; Tratnik, L. Whey based beverages-new generation of dairy products. Mljekarstvo 2008, 58, 257–274.

- Ryan, M.P.; Walsh, G. The biotechnological potential of whey. Rev. Environ. Sci. Bio Technol. 2016, 15, 479–498.

- Castelli, H.; Du Vale, L. Handbook on Cheese: Production, Chemistry and Sensory Properties; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2013.

- Jelen, P. Whey processing. Utilization and Products. In Encyclopedia of Dairy Sciences; Fuquay, J., Fox, P., McSweeney, P., Eds.; Academic Press: London, UK, 2003.

- Sommella, E.; Pepe, G.; Ventre, G.; Pagano, F.; Conte, G.M.; Ostacolo, C.; Manfra, M.; Tenore, G.C.; Russo, M.; Novellino, E. Detailed peptide profiling of “Scotta”: From a dairy waste to a source of potential health-promoting compounds. Dairy Sci. Technol. 2016, 96, 763–771.

- Yadav, J.S.S.; Yan, S.; Pilli, S.; Kumar, L.; Tyagi, R.D.; Surampalli, R.Y. Cheese whey: A potential resource to transform into bioprotein, functional/nutritional proteins and bioactive peptides. Biotechnol. Adv. 2015, 33, 756–774.

- Maragkoudakis, P.; Vendramin, V.; Bovo, B.; Treu, L.; Corich, V.; Giacomini, A. Potential use of scotta, the by-product of the ricotta cheese manufacturing process, for the production of fermented drinks. J. Dairy Res. 2016, 83, 104.

- Carvalho, F.; Prazeres, A.R.; Rivas, J. Cheese whey wastewater: Characterization and treatment. Sci. Total Environ. 2013, 445, 385–396.

- Argenta, A.B.; Scheer, A.D.P. Membrane separation processes applied to whey: A review. Food Rev. Int. 2019, 36, 1–30.

- Rama, G.R.; Kuhn, D.; Beux, S.; Maciel, M.J.; de Souza, C.F.V. Potential applications of dairy whey for the production of lactic acid bacteria cultures. Int. Dairy J. 2019, 98, 25–37.

- Pires, A.F.; Marnotes, N.G.; Bella, A.; Viegas, J.; Gomes, D.M.; Henriques, M.H.; Pereira, C.J. Use of ultrafiltrated cow’s whey for the production of whey cheese with Kefir or probiotics. J. Sci. Food Agric. 2020.

- Prazeres, A.R.; Carvalho, F.; Rivas, J. Cheese whey management: A review. J. Environ. Manag. 2012, 110, 48–68.

- Secchi, N.; Giunta, D.; Pretti, L.; García, M.R.; Roggio, T.; Mannazzu, I.; Catzeddu, P. Bioconversion of ovine scotta into lactic acid with pure and mixed cultures of lactic acid bacteria. J. Ind. Microbiol. Biotechnol. 2012, 39, 175–181.

- Pereira, C.D.; Diaz, O.; Cobos, A. Valorization of by-products from ovine cheese manufacture: Clarification by thermocalcic precipitation/microfiltration before ultrafiltration. Int. Dairy J. 2002, 12, 773–783.

- Sansonetti, S.; Curcio, S.; Calabro, V.; Iorio, G. Bio-ethanol production by fermentation of ricotta cheese whey as an effective alternative non-vegetable source. Biomass Bioenergy 2009, 33, 1687–1692.

- Díaz, O.; Pereira, C.D.; Cobos, A. Functional properties of ovine whey protein concentrates produced by membrane technology after clarification of cheese manufacture by-products. Food Hydrocoll. 2004, 18, 601–610.

- Siso, M.G. The biotechnological utilization of cheese whey: A review. Bioresour. Technol. 1996, 57, 1–11.

- Guo, M.; Wang, G. History of Whey Production and Whey Protein Manufacturing. In Whey Protein Production, Chemistry, Functionality, and Applications; Guo, M., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2019; pp. 1–12.

- Pintado, M.E.; Macedo, A.; Malcata, F. Technology, chemistry and microbiology of whey cheeses. Food Sci. Technol. Int. 2001, 7, 105–116.

- Kotoulas, A.; Agathou, D.; Triantaphyllidou, I.E.; Tatoulis, T.I.; Akratos, C.S.; Tekerlekopoulou, A.G.; Vayenas, D.V. Second Cheese Whey Treatment Using Zeolite under Continuous Flow Mode and Its Application on Wheat Growth. Water 2019, 11, 928.

- Vincenzi, A.; Maciel, M.J.; Burlani, E.; Oliveira, E.; Volpato, G.; Lehn, D.N.; de Souza, C.V. Ethanol bio-production from ricotta cheese whey by several strains of the yeast Kluyveromyces. Am. J. Food Technol. 2014, 9, 281–291.

- Carvalho, A.d.C. Estatísticas da Produção e Consumo de Leite 2015; Instituto Nacional de Estatística (INE): Lisboa, Portugal, 2015.

- Cassano, A.; Conidi, C.; Castro-Muñoz, R. Current and Future Applications of Nanofiltration in Food Processing. In Separation of Functional Molecules in Food by Membrane Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 305–348.

- Ostertag, F.; Schmidt, C.M.; Berensmeier, S.; Hinrichs, J. Development and validation of an RP-HPLC DAD method for the simultaneous quantification of minor and major whey proteins. Food Chem. 2021, 342, 128176.

- Pereira, C.; Henriques, M.; Gomes, D.; Gomez-Zavaglia, A.; de Antoni, G. Novel functional whey-based drinks with great potential in the dairy industry. Food Technol. Biotechnol. 2015, 53, 307–314.

- Piskorz, A.; Pires, A.; Marnotes, N.G.; Gomes, D.; Henriques, M.; Pereira, C.D. Valorização do Sorelho para a Produção de Molhos para Saladas e de Bebidas Lácteas Fermentadas—Parte 1; Tecnoalimentar: Porto, Portugal, 2019; pp. 26–29.

- Macedo, A.; Duarte, E.; Fragoso, R. Assessment of the performance of three ultrafiltration membranes for fractionation of ovine second cheese whey. Int. Dairy J. 2015, 48, 31–37.

- Henriques, M.; Gomes, D.; Rodrigues, D.; Pereira, C.; Gil, M. Performance of bovine and ovine liquid whey protein concentrate on functional properties of set yoghurts. Procedia Food Sci. 2011, 1, 2007–2014.

- Pintado, M.E.; da Silva, J.L.; Malcata, F.X. Comparative characterization of whey protein concentrates from ovine, caprine and bovine breeds. LWT Food Sci. Technol. 1999, 32, 231–237.

- Sanmartín, B.; Díaz, O.; Rodríguez-Turienzo, L.; Cobos, A. Composition of caprine whey protein concentrates produced by membrane technology after clarification of cheese whey. Small Rumin. Res. 2012, 105, 186–192.

- Macedo, A.; Duarte, E.; Pinho, M. The role of concentration polarization in ultrafiltration of ovine cheese whey. J. Membr. Sci. 2011, 381, 34–40.

- Tirloni, E.; Vasconi, M.; Cattaneo, P.; Moretti, V.; Bellagamba, F.; Bernardi, C.; Stella, S. A possible solution to minimise scotta as a food waste: A sports beverage. Int. J. Dairy Technol. 2020, 73, 421–428.

- Minhalma, M.; Magueijo, V.; Queiroz, D.P.; de Pinho, M.N. Optimization of “Serpa” cheese whey nanofiltration for effluent minimization and by-products recovery. J. Environ. Manag. 2007, 82, 200–206.

- Monti, L.; Donati, E.; Zambrini, A.V.; Contarini, G. Application of membrane technologies to bovine Ricotta cheese exhausted whey (scotta). Int. Dairy J. 2018, 85, 121–128.

- Pereira, C.D.; Díaz, O.; Cobos, A. Impact of ovine whey protein concentrates and clarification by-products on the yield and quality of whey cheese. Food Technol. Biotechnol. 2007, 45, 32–37.

- Zoppellari, F.; Bardi, L. Production of bioethanol from effluents of the dairy industry by Kluyveromyces marxianus. New Biotechnol. 2013, 30, 607–613.

- Lopes, A.C.A.; Eda, S.H.; Andrade, R.P.; Amorim, J.C.; Duarte, W.F. New Alcoholic Fermented Beverages—Potentials and Challenges. In Fermented Beverages; Elsevier: Amsterdam, The Netherlands, 2019; pp. 577–603.

- Chen, G.Q.; Leong, T.S.; Kentish, S.E.; Ashokkumar, M.; Martin, G.J. Membrane Separations in the Dairy Industry. In Separation of Functional Molecules in Food by Membrane Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 267–304.