| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Oliver Schierz | + 390 word(s) | 390 | 2021-04-19 07:43:50 | | | |

| 2 | Vicky Zhou | Meta information modification | 390 | 2021-04-28 03:06:07 | | | | |

| 3 | Vicky Zhou | + 1 word(s) | 391 | 2021-04-28 03:07:00 | | | | |

| 4 | Vicky Zhou | Meta information modification | 391 | 2021-04-29 05:20:01 | | |

Video Upload Options

Polyoxymethylene (POM) is a material able to provide tooth-colored esthetics and that is suitable for fabrication of frameworks for removable dental prostheses. POM can be characterized as both polyethers (-C-O-) as well as polyacetals (-O-C-O-).

1. Introduction

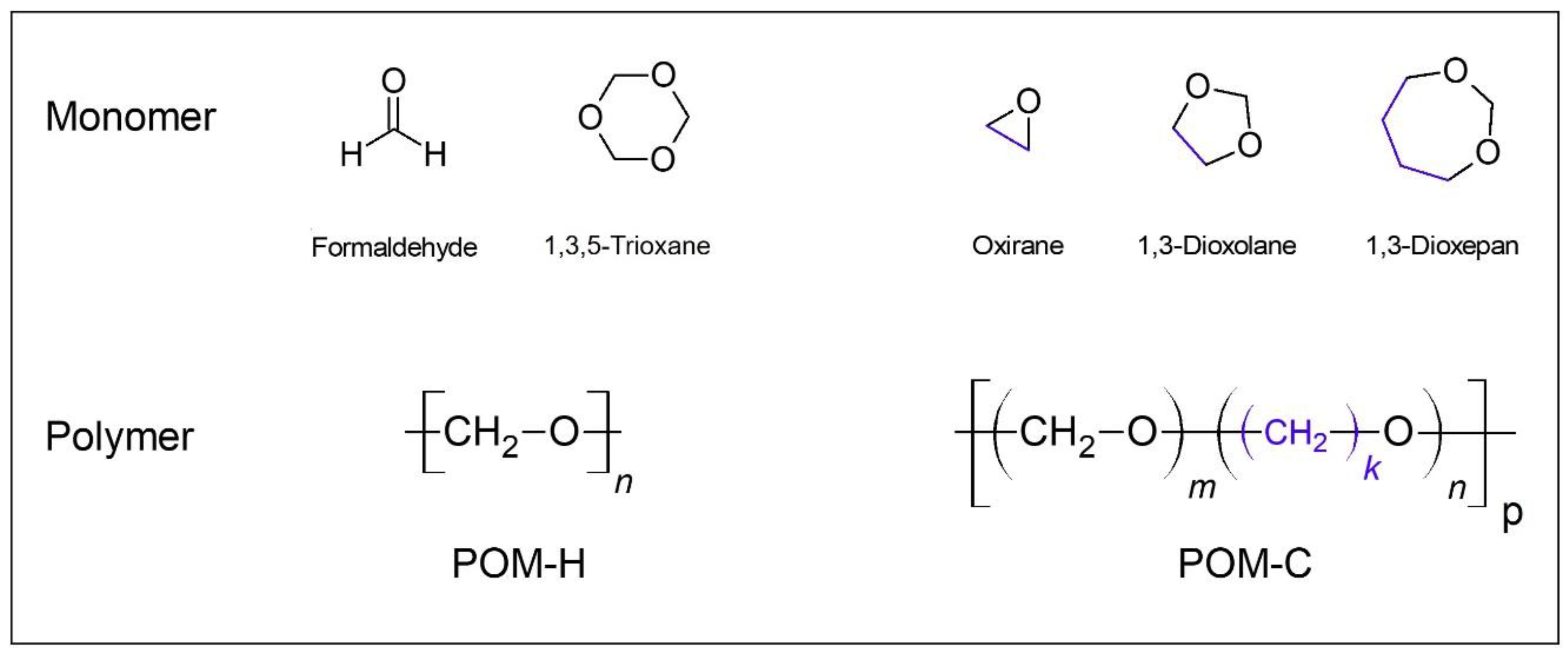

Polyoxymethylene (POM) is a material able to provide tooth-colored esthetics and that is suitable for fabrication of frameworks for removable dental prostheses (RDPs). POM can be characterized as both polyethers (-C-O-) as well as polyacetals (-O-C-O-) [1]. Two formulations of POM are available: the polyoxymethylen homopolymer (POM-H) and copolymer (POM-C). POM-H can be fabricated either from formaldehyde monomers or from trioxane monomers [1]. POM-H is a highly crystalline thermoplastic material with a helical structure [1][2]. For the formulation of POM-C, small amounts of other cyclic ethers (-C-O-) featuring additional methylene groups are added (Figure 1) [3][4]. The additional methylene groups result in higher thermal and hydrolytic stability, which improves its resistancy against polymer chain degradation [5].

Figure 1. Structural formulas of POM-H, POM-C, and corresponding monomers, additional methylene groups (blue).

2. Application

Due to its excellent properties, POM is industrially used as a constructional material, e.g., for the manufacturing of gear wheels, housing parts, and bearings [2][5]. The favorable mechanical properties include high strength, stiffness, hardness, impact strength, low coefficient of friction, high wear resistance, and dimensional stability [2][5][6]. In addition, POM is featured by high chemical resistance, low water absorption, und high biocompatibility [7][8]. The melting point of POM ranges around 175 °C. For thermoplastic manufacturing techniques, injection moulding is the most frequently employed process [8]. By using subtractive manufacturing, artefacts due to smearing can arise due to excessive cutting temperature levels [9]. Additive manufacturing methods such as powder bed fusion have rarely been investigated [6]. Recent literature revealed that POM can also be processed via selective laser sintering [7]. Regarding the optical appearance, POM is characterized by even surfaces and an intrinsic whiteness. The latter is based on its crystallinity [6][7]; however, POM can also be colored [10]. All in all, favorable properties of POM are advantageous for medical application [3][7] and the CAD/CAM-techniques pave the way for application in dentistry (overview see Table 1).

Table 1. Advantages and Disadvantages of polyoxymethylene as material for removable dentures.

| Advantages | Disadvantages |

|---|---|

| Tooth-colored, available in different shades | Opaque |

| Break-proof due to high impact strength | Flexible |

| Smooth surface | Low chemical interaction with other materials |

| Non known allergies | Limited wear resistance |

| Color stability | |

| Customizable color |

References

- Uchida, T.; Tadokoro, H. Structural studies of polyethers. IV. Structure analysis of the polyoxymethylene molecule by three-dimensional fourier syntheses. J. Polym. Sci. A-2 Polym. Phys. 1967, 5, 63–81.

- Samyn, P.; van Driessche, I.; Schoukens, G. Thermal and spectroscopic analysis of worn polyoxymethylene surfaces and wear debris explaining degradation and polymerisation mechanisms. J. Polym. Res. 2007, 14, 411–422.

- Eschbach, L. Nonresorbable polymers in bone surgery. Injury 2000, 31, D22–D27.

- Klein, R.; Schüll, C.; Berger-Nicoletti, E.; Haubs, M.; Kurz, K.; Frey, H. ABA Triblock Copolymers Based on Linear Poly(oxymethylene) and Hyperbranched Poly(glycerol): Combining Polyacetals and Polyethers. Macromolecules 2013, 46, 8845–8852.

- Bergmann, W. Werkstofftechnik. Mit 4 Tabellen: Grundlagen, 7th ed.; Carl Hanser: Munich, Germany, 2013.

- Dechet, M.A.; Baumeister, I.; Schmidt, J. Development of Polyoxymethylene Particles via the Solution-Dissolution Process and Application to the Powder Bed Fusion of Polymers. Materials 2020, 13, 1535.

- Wendel, B.; Rietzel, D.; Kühnlein, F.; Feulner, R.; Hülder, G.; Schmachtenberg, E. Additive Processing of Polymers. Macromol. Mater. Eng. 2008, 293, 799–809.

- Domininghaus, H.; Elsner, P.; Eyerer, P.; Hirth, T. Kunststoffe. Eigenschaften und Anwendungen, 8th ed.; Springer: Berlin/Heidelberg, Germany, 2012; ISBN 9783642161728.

- Rubio, J.C.C.; Panzera, T.H.; Scarpa, F. Machining behaviour of three high-performance engineering plastics. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 28–37.

- Kaiser, W. Kunststoffchemie für Ingenieure. Von der Synthese bis zur Anwendung, 5th ed.; Carl Hanser: Munich, Germany, 2021.