| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Foram Dave | + 1665 word(s) | 1665 | 2021-03-15 09:26:35 |

Video Upload Options

Laser Transmission Welding of Polymers is a joining technique frequently selected by contemporary researchers to weld two thermoplastic surfaces.

1. Introduction

Laser Transmission Welding (LTW) is one of the smart manufacturing techniques of Industry 4.0. It is a versatile technique used to join polymeric components with varying thickness and configuration using a laser source. Various factors influence the weld strength during LTW, such as the inter-diffusion phenomenon leading to microstructural changes, carbon black (size, shape, structure, thermal conductivity, dispersion, distribution, etc.) in the laser absorptive part, nucleating agent in the laser transmissive part and its processing conditions. Among the laser parameters, laser power, scanning speed and clamping pressure are considered to be the most critical. There are various innovative ideas, such as incorporating metal as an absorber in the laser absorptive part, hybrid carbon black (CB), dual clamping device, and an increasing number of scans and patterns. LTW has excellent potential in polymer joining applications. The challenges include the cost-effectiveness, innovative ideas to provide state-of-the-art design and fabrication of complex products in a wide range of applications.

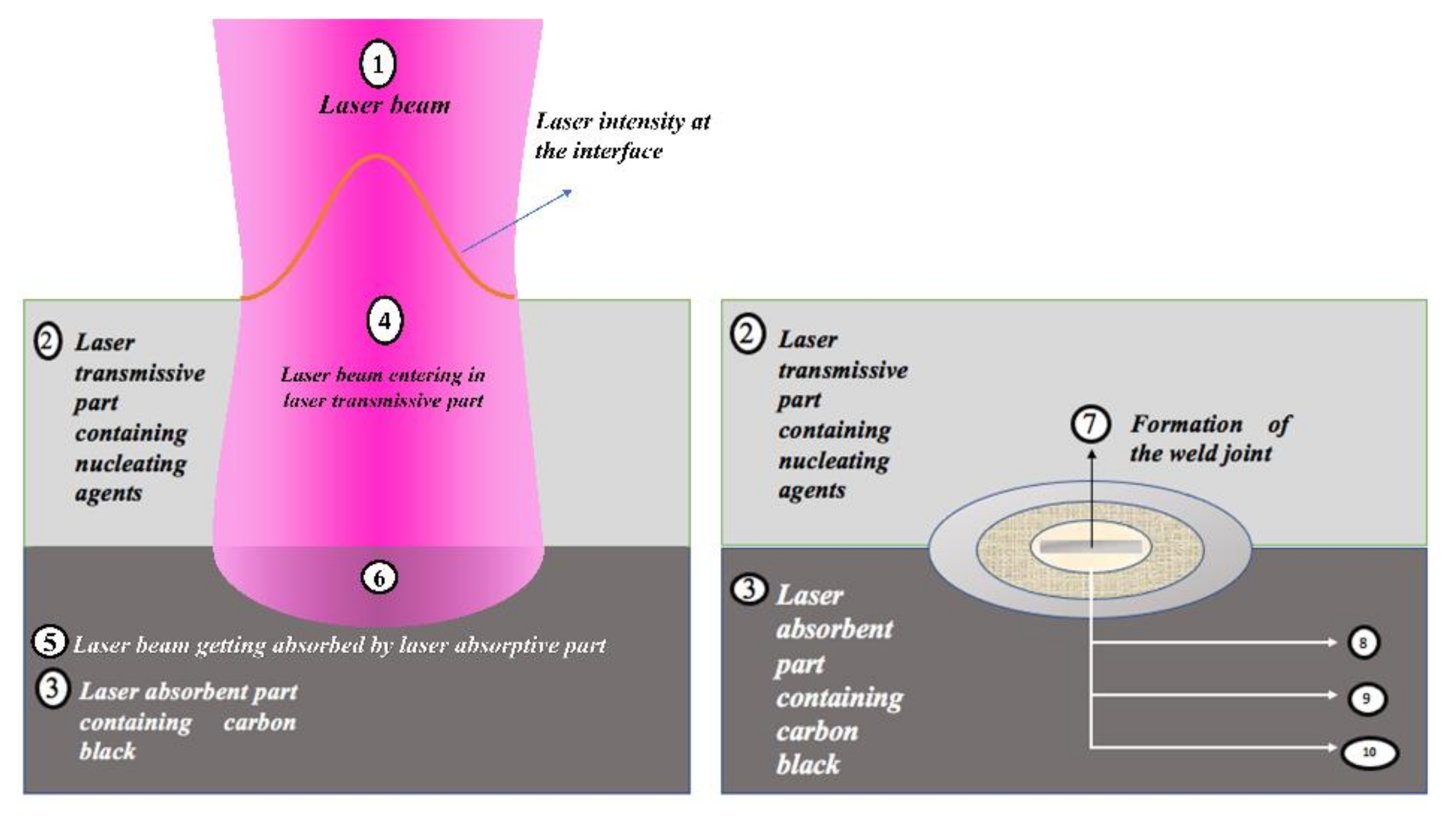

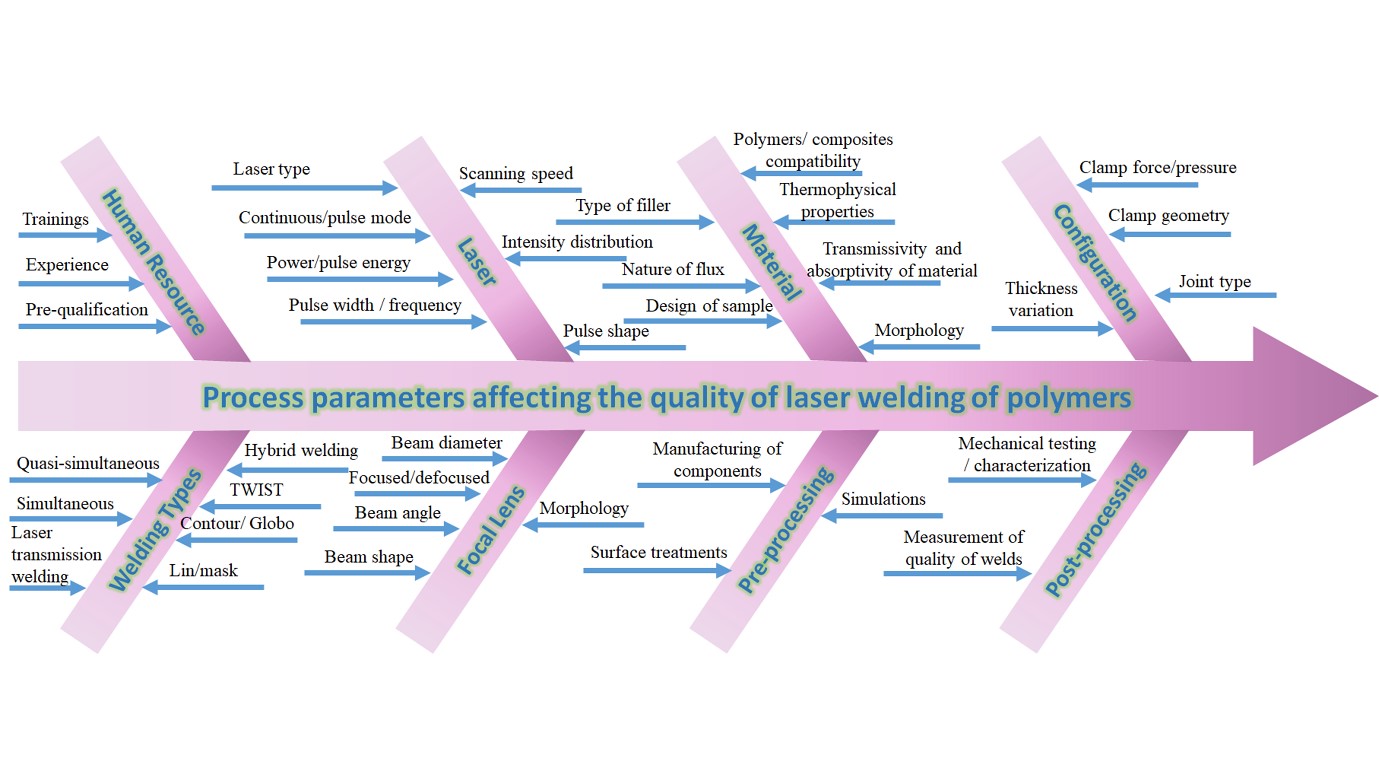

Diode laser welding results in a cleaner and stronger joints[1]. The diode LTW consists of two polymer parts where the beam passes through the laser transmissive (LT) polymer and dissipates heat in the laser absorptive (LA) layer, resulting in the joining of two surfaces as a result of melting and inter-diffusion of polymer chains [2]. Several factors are influencing the quality of the weld, as shown in Figure 1. Therefore, it is essential to have the optimised laser welding process to save time and other resources used in the manufacturing process.

Figure 1. Ishikawa diagram representing the various factors influencing on quality of laser welding of polymers. Authors’ self-created diagram.

2. Laser Transmission Welding

LTW of polymers is a joining technique frequently selected by contemporary researchers to weld two thermoplastic surfaces, as illustrated in Figure 2. It avoids the generation of byproduct or particle release, unlike adhesive bonding [3]. Diode laser for LTW is mostly considered due to its capability to encapsulate sensitive electronic housings without any damage than other techniques such as ultrasonic welding. Furthermore, LTW is a non-contact and non-contaminant process involving an optically transparent part (LT) for a given laser to pass through and an absorbing surface (LA) that melts and forms a hermetic sealing [4][5][6][7][8]. Preferential deposition of energy is required in the interfacial zone, which eventually becomes the weld zone. The surrounding area of the weld zone, which is affected by residual heat, is considered the heat-affected zone (HAZ). When the laser beam is emitted from the laser and reaches the polymer, it undergoes recrystallisation for the laser generating the continuous wave. The morphology developed after recrystallisation depends upon its initial morphological structure formed during polymer processing. Hence, it becomes essential to understand changes taking place in SC polymers due to thermal history, spherulite formation, etc., during the fabrication process. Processing techniques such as extrusion and moulding involve crystallisation during the operation when the polymer undergoes shear stress of the crystallising volume. It is essential to understand the role of this shear stress in controlling nucleation. This helps to relate the spherulitic structure or polymer morphology to various structures found in industrial products [9]. In LTW, there is no vibration of the components, and therefore, the welding of materials from thin sheets (~0.01 mm) to thick plates (~50 mm) with high performance, good flexibility, and low distortion can easily be achieved [10].

Figure 2. Lap joint and interaction of the laser beam during the LTW process.

Overlap joint assembly is the most basic configuration for LTW of polymers, as shown in Figure 2 [11][12][13]. The laser energy transmitted through LT is converted into heat with the help of LA, which melts the material. The clamping mechanism is used to make the layers in intimate contact, and in this way, heat is conducted through LA to LT [14]. After interdiffusion of the material, the joint is created, and this welding technique is used in almost all thermoplastics. The laser-welded products, specifically continuous reinforced thermoplastic composites [10], provide a good stiffness and strength level besides other properties like chemical resistance [15]. However, to achieve a strong joint or weld integrity, it is highly essential to understand the laser process parameters’ specifications and capability, factors leading to weld defects, welding mechanism, and the materials’ properties [16]. The contribution of laser power in the laser welding process is found to be 58% (statistically more significant than other parameters), followed by focal distance (31%) and scanning speed (11%) [15].

The ultimate goal for any industry is to increase productivity with a minimum scrap rate. Different types of lasers are used with increased laser power and scanning speeds [11]. Applying simulation, mathematical modelling [17][18][19], optimisation [20], monitoring and adaptive control of LTW processes [21] for industrial products are some of the recent advancements made in this field. Besides, in most industrial applications, polymers are used as composite materials due to their better thermo-mechanical properties. For instance, CB filler incorporated into polymer matrix imparts valuable properties such as reinforcement, tensile strength, tensile modulus, flexural strength and flexural modulus [22]. These properties depend upon the type of CB (shape, size, surface area, surface activity, aggregate structure, etc.), dispersion and distribution of the filler and filler-polymer interactions [23]. There is a need to focus on compounding ingredients, especially CB and salient processing parameters on the polymer morphology, which ultimately controls the laser energy and amount of melting along with the prominent laser welding parameters. Understanding the melting and inter-diffusion phenomena during the formation of the weld joint is significantly essential. Hence, this article highlights the current status of the LTW of SC polymers and their composites. It also includes discussing the importance of CB dispersion to the laser-welded product performance and its economic aspects. The diode laser transmission welded SC polymers are to be characterised and analysed to understand the pre and post-processing techniques (Table 1).

Table 1. List of LTW pre-and post-processing techniques for the analysis of SC polymers

|

Type of Characterisation |

Techniques |

Analysis |

|

Rheology |

Melt flow index (MFI) |

Ease of flow of the polymer melt |

|

Thermal Characterisation |

Differential scanning calorimetry (DSC) [24] |

Phase transformation, Glass transition (Tg), crystallisation temperature (Tc) and melt temperature (Tm) |

|

Thermo-gravimetric analysis (TGA) |

Material degradation temperature |

|

|

Morphological Analysis |

X-ray diffraction (XRD) [25] |

Phase information, crystallographic information, residual strain |

|

Transmission electron microscopy (TEM) [26] |

Grain size, microstructure, orientation, diffraction pattern |

|

|

Scanning electron microscopy (SEM) [16] and field emission (FE) [27] |

Microstructure, topography, grain size, fracture analysis, Weld defects: voids, cracks, porosity, etc. |

|

|

Optical microscope [28] |

|

|

|

Electron probe X-ray micro analyser (EPMA) [29] |

Elemental analysis in the weld zone |

|

|

Attenuated total reflectance Fourier Transform Infrared Spectroscopy (FT-IR: ATR) and Raman Spectroscopy [30] |

Vibrational analysis, Chemical structure, polymer degradation, structural fingerprints |

|

|

Wavelength-energy dispersive X-ray spectrometric analysis (WDS, EDS) [31] |

Elemental analysis |

|

|

Electron back scattering diffraction (EBSD) |

Orientation and size of the grain |

|

|

Mechanical Testing |

Micro-hardness measurement |

|

|

Universal Testing Machine (UTM) [36] |

Lap-shear test, |

|

|

Microtome [3] |

Slicing thin samples |

3. Effect of Carbon Black (CB)

In the LTW of polymers, CB plays a vital role in the absorbing partner [37]. Due to the unequal distributions of CB or improper dispersions of CB, the absorption of the laser beam is unequal/preferential on the absorbing surface, which is in contact with the LT. Various hypotheses are formulated. One of them is a polymer matrix containing more CB that will absorb more laser energy. Due to the presence of CB, the melting point of the polymer is reached faster as it has greater heat-absorbing properties. This material surface melts first and in higher volume as compared to the polymer matrix having lesser CB content. Hence, there is an unequal melting of the surface resulting in an unequal weld width. To increase the penetration depth and hence the weld strength, the carbon content needs to be decreased but with high laser power. However, high laser power can lead to degradation of the polymer [38]. CB also affects the crystallisation of isotactic PP as a filler in the composite. The nature of nucleation and crystalline growth mechanism of PP changes with the CB content and the crystallisation temperature (Tc) [39].

The polymer formulation and its processing, as well as the methodology of material production, affect the transmission properties. In this, the granules are either compounded with CB or it is added during the injection moulding in an extruder. Studies have shown that the laser light transmitted through the thermoplastics are a function of thickness [40] and the laser incidence angle. There is a decrease in the transmission rate with an increase in the laser angle of incidence [41]. Transmission of laser energy in polymer reduces due to an increase of crystallinity and large spherulites [42]. Apart from CB’s content, the size and distribution of the particles also impact the polymer properties. Compared to other fillers, CB is cheaper, and hence, it has gained industrial importance. However, there are certain products where black colouration is not preferred. Special pigmentations have been developed to weld non-black polymer which can absorb the laser beam [43]. However, these non-black pigments are unable to weld micro parts and micro-structured parts. Further studies are needed for micro-welding parts containing non-black pigments.

LTW is an expensive technique as compared to other joining methods considering the capital equipment investment. However, the overall cost per assembled sample (successful delivery and selling), makes LTW the most cost-effective industry technique. The surfaces to be welded should be clean and requires a good fit-up. For welding non-pigmented materials, some absorbent form will be needed for the laser beam at the joint interface, which adds an extra complication to the process [44]. There are various challenges and areas for optimisation such as fixture designing for welded product testing, obtaining high ingress protection ratings, for welded products etc. Regardless of the significant work progress already carried out in the laser field, integrating the various available technologies is complex and challenging to achieve. The consumer businesses which have taken advantage of the connective technology can be scrutinised to get an idea of how the laser welding of composites could unlock the potential of Industry 4.0. Hence, the effective implementation of Industry 4.0 technologies is challenging and still a subject of research.

References

- Brown, M.S.; Arnold, C.B.; Jones, I.; Kiss, Z.; Czigány, T.; Frick, T.; Anto ´ nczak, A.J.; Ste¸pak, B.D.; Szustakiewicz, K.; Wójcik, M.R.; et al. Numerical Model of CO2 Laser Welding of Thermoplastic Polymers. J. Laser Appl. 2007, 32, 022004.

- Asséko, A.C.A.; Cosson, B.; Schmidt, F.; Le Maoult, Y.; Lafranche, E. Laser Transmission Welding of Composites-Part A: Thermo-Physical and Optical Characterization of Materials. Infrared Phys. Technol. 2015, 72, 293–299.

- Aden, M.; Liviany, F.; Olowinsky, A. Joint Strength for Laser TransmissionWelding of Thermoplastics: A Simulation Approach. Int. Polym. Process. 2013, 28, 79–83.

- Acherjee, B.; Kuar, A.S.; Mitra, S.; Misra, D. Application of Grey-Based Taguchi Method for Simultaneous Optimisation of Multiple Quality Characteristics in Laser TransmissionWelding Process of Thermoplastics. Int. J. Adv. Manuf. Technol. 2011, 56, 995–1006.

- Acherjee, B.; Kuar, A.S.; Mitra, S.; Misra, D.; Acharyya, S. Experimental Investigation on Laser TransmissionWelding of PMMA to ABS via Response Surface Modeling. Opt. Laser Technol. 2012, 44, 1372–1383.

- Chen, Z.; Huang, Y.; Han, F.; Tang, D. Numerical and Experimental Investigation on Laser TransmissionWelding of Fiberglass-Doped PP and ABS. J. Manuf. Process. 2018, 31, 1–8.

- Coelho, J.P.; Abreu, M.A.; Pires, M.C. High-Speed Laser Welding of Plastic Films. Opt. Lasers Eng. 2000, 34, 385–395.

- Prabhakaran, R.; Kontopoulou, M.; Zak, G.; Bates, P.J.; Baylis, B.K. Contour Laser—Laser-Transmission Welding of Glass Reinforced Nylon 6. J. Thermoplast. Compos. Mater. 2006, 19, 427–439.

- Clark, E.S.; Garber, C.A. Effect of Industrial Processing on the Morphology of Crystalline Polymers. Int. J. Polym. Mater. 1971, 1, 31–45.

- Cosson, B.; Deléglise, M.; Knapp,W. Numerical Analysis of Thermoplastic Composites LaserWelding Using Ray Tracing Method. Compos. Part B Eng. 2015, 68, 85–91.

- Juhl, T.B.; de Claville Christiansen, J.; Jensen, E.A. Mechanical Testing of Polystyrene/Polystyrene Laser Welds. Polym. Test. 2013, 32, 475–481.

- Sapuan, S.M.; Haniffah, W.H.; AL-Oqla, F.M.; Nukman, Y.; Enamul Hoque, M.; Sanyang, M.L. Effects of Reinforcing Elements on the Performance of Laser Transmission Welding Process in Polymer Composites: A Systematic Review. Int. J. Perform. Eng. 2016, 12, 535–550.

- Mayboudi, L.S.; Birk, A.M.; Zak, G.; Bates, P.J. Laser TransmissionWelding of a Lap-Joint: Thermal Imaging Observations and Three-Dimensional Finite Element Modeling. J. Heat Transf. 2007, 129, 1177–1186.

- Zoubeir, T.; Elhem, G. Numerical Study of Laser Diode Transmission Welding of a Polypropylene Mini-Tank: Temperature Field and Residual Stresses Distribution. Polym. Test. 2011, 30, 23–34.

- Jaeschke, P.; Herzog, D.; Haferkamp, H.; Peters, C.; Herrmann, A.S. Laser Transmission Welding of High-Performance Polymers and Reinforced Composites—A Fundamental Study. J. Reinf. Plast. Compos. 2010, 29, 3083–3094.

- Rodríguez-Vidal, E.; Quintana, I.; Gadea, C. Laser Transmission Welding of ABS: Effect of CNTs Concentration and Process Parameters on Material Integrity and Weld Formation. Opt. Laser Technol. 2014, 57, 194–201.

- Hopmann, C.; Kreimeier, S. Modelling the Heating Process in Simultaneous Laser Transmission Welding of Semicrystalline Polymers. J. Polym. 2016, 2016, 1–10.

- Sooriyapiragasam, S.K.; Hopmann, C. Modeling of the Heating Process during the Laser TransmissionWelding of Thermoplastics and Calculation of the Resulting Stress Distribution. Weld. World 2016, 60, 777–791.

- Coluccelli, N. Nonsequential Modeling of Laser Diode Stacks Using Zemax: Simulation, Optimization, and Experimental Validation. Appl. Opt. 2010, 49, 4237–4245.

- Flock, D.; Sickert, M.; Haberstroh, E. Temperature Measurement in Laser TransmissionWelding of Plastics. Int. Polym. Sci. Technol. 2013, 40, 704–708.

- Purtonen, T.; Kalliosaari, A.; Salminen, A. Monitoring and Adaptive Control of Laser Processes. Phys. Procedia 2014, 56, 1218–1231. .

- Ojha, S.; Acharya, S.K.; Raghavendra, G. Mechanical Properties of Natural Carbon Black Reinforced Polymer Composites. J. Appl. Polym. Sci. 2014, 132, 1–7.

- Thomassin, J.M.; Jérôme, C.; Pardoen, T.; Bailly, C.; Huynen, I.; Detrembleur, C. Polymer/Carbon Based Composites as Electromagnetic Interference (EMI) Shielding Materials. Mater. Sci. Eng. R Rep. 2013, 74, 211–232.

- Juhl, T.B.; Bach, D.; Larson, R.G.; Christiansen, J.D.; Jensen, E.A. Predicting the Laser Weldability of Dissimilar Polymers. Polymer 2013, 54, 3891–3897.

- Ramachandramoorthy, R.; Mousavand, T.; Hubert, P. Laser Transmission Welding of Thermoplastic Tubes and Plates Using Laser Refraction; McGill University: Montreal, QC, Canada, 2011.

- Verma, P.; Verma, M.; Gupta, A.; Chauhan, S.S.; Malik, R.S.; Choudhary, V. Multi Walled Carbon Nanotubes Induced Viscoelastic Response of Polypropylene Copolymer Nanocomposites: Effect of Filler Loading on Rheological Percolation. Polym. Test. 2016, 55, 1–9.

- Pawar, S.M.; Moholkar, A.V.; Kim, I.K.; Shin, S.W.; Moon, J.H.; Rhee, J.I.; Kim, J.H. Effect of Laser Incident Energy on the Structural, Morphological and Optical Properties of Cu2ZnSnS4 (CZTS) Thin Films. Curr. Appl. Phys. 2010, 10, 565–569.

- Rodríguez-Vidal, E.; Quintana, I.; Etxarri, J.; Azkorbebeitia, U.; Otaduy, D.; González, F.; Moreno, F. Optical Design and Development of a Fiber Coupled High-Power Diode Laser System for Laser TransmissionWelding of Plastics. Opt. Eng. 2012, 51, 124301.

- Takayama, Y.; Nomoto, R.; Nakajima, H.; Ohkubo, C. Comparison of Joint Designs for LaserWelding of Cast Metal Plates and Wrought Wires. Odontology 2013, 101, 34–42.

- Saerens, L.; Dierickx, L.; Lenain, B.; Vervaet, C.; Remon, J.P.; Beer, T. De Raman Spectroscopy for the In-Line Polymer-Drug Quantification and Solid State Characterization during a Pharmaceutical Hot-Melt Extrusion Process. Eur. J. Pharm. Biopharm. 2011, 77, 158–163.

- O’Hara, D. Combination wavelength and energy dispersive X-ray spectrometer. US Patent 005912940A, 15 June 1999.

- Amitay-Sadovsky, E.;Wagner, H.D. Hardness and Young’s Modulus of Transcrystalline Polypropylene by Vickers and Knoop Microindentation. J. Polym. Sci. Part B Polym. Phys. 1999, 37, 523–530.

- Lopez, J. Microhardness Testing of Plastics: Literature Review. Polym. Test. 1993, 12, 437–458.

- Martin, B.; Pereña, J.M.; Pastor, J.M.; De Saja, J.A. Microindentation Hardness and Dynamic Mechanical Moduli in Polypropylene near the Glass Transition. J. Mater. Sci. Lett. 1986, 5, 1027–1028.

- Lorenzo, V.; Pereña, J.M.; Fatou, J.G. Vickers Microhardness Related to Mechanical Properties of Polypropylene. J. Mater. Sci. Lett. 1989, 8, 1455–1457.

- Acherjee, B.; Kuar, A.S.; Mitra, S.; Misra, D. Selection of Process Parameters for Optimising the Weld Strength in Laser Transmission Welding of Acrylics. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 1529–1536.

- Haberstroh, E.; Lützeler, R. Influence of Carbon Black Pigmentation on the Laser Beam Welding of Plastics Micro Parts. J. Polym. Eng. 2001, 21, 119–130.

- Zhan, X.; Zhang, D.; Wei, Y.; Wang, Y. Research on the Microstructure and Properties of Laser-MIG Hybrid Welded Joint of Invar Alloy. Opt. Laser Technol. 2017, 97, 124–136.

- Mucha, M.; Marszalek, J.; Fidrych, A. Crystallization of Isotactic Polypropylene Containing Carbon Black as a Filler. Polymer 2000, 41, 4137–4142.

- Xu, X.F.; Parkinson, A.; Bates, P.J.; Zak, G. Effect of Part Thickness, Glass Fiber and Crystallinity on Light Scattering during Laser Transmission Welding of Thermoplastics. Opt. Laser Technol. 2015, 75, 123–131.

- Azhikannickal, E.; Bates, P.J.; Zak, G. Laser Light Transmission through Thermoplastics as a Function of Thickness and Laser Incidence Angle: Experimental and Modeling. J. Manuf. Sci. Eng. Trans. ASME 2012, 134, 1–7.

- Haferkamp, H.; Von Busse, A.; Barcikowski, S.; Bunte, J.Welding of Polymer andWood Composites Using Laser Radiation. In Proceedings of the ICALEO 2003—22nd International Congress on Applications of Lasers & Electro-Optics, Jacksonville, FL, USA, 13–16 October 2003; p. 605.

- Haberstroh, E.; Hoffmann, W. Laser Transmission Welding of Transparent Plastics Parts in Micro Technology. 4M Network of Excellence. 2007. Available online: http://www.4m-net.org/files/papers/4M2007/364065/PID364065.pdf (accessed on 22 February 2021).

- Jones, I. Laser Welding for Plastic Components. Assem. Autom. 2002, 22, 129–135.