| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Isaac Nongwe Beas | + 1533 word(s) | 1533 | 2021-02-25 10:04:39 | | | |

| 2 | Karina Chen | Meta information modification | 1533 | 2021-04-09 09:29:35 | | |

Video Upload Options

Demand for food packaging is on the rise as a result of increasing global demand for food due to population growth. Most of the food packaging are used on-the-go and are single-use plastics that are disposed of within a short space of time. The bulk of this plastic waste has found its way into the environment contaminating land, water and the food chain. The food industry is encouraged to reduce, reuse and recycle packaging materials.

1. Packaging

In the modern world, goods' packaging is essential from their inception through their processing and handling right up to their life cycle. In developed countries, packaging accounts for about 2% of the gross national product, and most packaging materials are used in the food industry [1]. In the year 2000, the global packaging market was at USD 383 billion and is expected to reach USD 980 billion in 2020 [2]. Materials used in packaging serve to preserve, protect, merchandise, market and cost-effectively distribute foods to the satisfaction of industry and consumers and minimise the negative impact on the environment [3][4].

Packaging solutions are a product of years of design improvements where some developments were by unintended luck. In the early years, humans would consume food at the source, and the societies were self-sufficient and only made or caught what they used, and thus, packaging materials were not needed [5]. When the need for packaging came, nature provided the first materials for packaging in hollowed logs, woven grasses and animal organs [5][6]. Newer materials with unique shapes were used for specific needs as civilisation developed; these materials included ceramics, glass, metal and paper [6]. Packaging materials can be either rigid or flexible. Rigid packaging includes bottles, jars, cans and tins, whilst flexible packaging includes plastic films, papers, foil, cloth and sacks.

1.1. Types of Packaging

There are three types of packaging, namely primary, secondary and tertiary [7][8][9][10];

- Primary packaging is in direct contact with products and will be handled by the consumer.

- Secondary packaging groups individual units (primary packages) together for transportation and can be designed to be shelf-ready to display primary packaging for advertisement in retail outlets.

- Tertiary packaging is for the storage and handling of secondary packaged products.

1.2. Plastic Packaging

The packaging industry requires lightweight materials to reduce the amount used to package a product, reducing product weight for transportation cost savings and reducing the amount of end-of-life packaging waste material. Plastics have managed to fulfil this role very well and have remained unchallenged. For example, one study by Marsh [11] revealed that the replacement of glass bottles with plastic bottles for beverage packaging in airlines resulted in savings of over USD 1 million in fuel costs due to the weight loss.

Fossil fuels are the main raw material used in the manufacture of plastics. In 2009, up to 8% of world oil was channelled towards their production, with 50% of it serving as feedstock and the other 50% as fuel for the conversion process [12]. In 2019, 10 years later, 10% of global oil production was used for plastic production, with 40% dedicated to making single-use plastics [13]. Plastics consumption's annual growth shows that the estimated global plastic consumption by 2050 will be standing at 500 million tonnes, of which single-use products will be the major consumer [14][15]. The most used polymers for packaging are thermoplastic, accounting for 84% of the plastic market share [16]. The following Table 1 shows some uses of thermoplastics in the packaging of food.

Table 1. Food packaging application from thermoplastics. Adapted from [17].

|

Thermoplastic Material |

Abbreviation |

Packaging Application |

|

Polyethylene Terephthalate |

PET |

Water/juice/soft drink bottles Food jars Microwavable containers Plastic films |

|

Polypropylene |

PP |

Drinking bottles Bottles for milk Food containers |

|

Polyvinyl chloride |

PVC |

Plastic bags Frozen foods stretch films Container lid |

|

Polystyrene |

PS |

Take away clamshells Meat trays Bottle caps Straws |

|

Low-density polyethylene |

LDPE |

Disposal cups Plates Spoon Bread bags |

|

High-density polyethylene |

HDPE |

Custom packages Grocery bags Water/milk/juice containers Cereal and snack liners |

Petroleum-based polymers, which include polypropylene (PP), polystyrene (PS), polyvinylchloride (PVC), polyethylene (PE) and polyethylene terephthalate (PET), have been used extensively for packaging as a result of their lightweight, good mechanical performance, good barrier properties among many other properties [17][18][19]. Many of these end up in landfills, where they take centuries before they degrade [20]. They are responsible for a great amount of environmental pollution as they are nonbiodegradable [21].

The packaging industry has begun using recyclable plastics in their designs to reduce waste disposed into the environment. However, recyclers must maintain contaminants in the reformed plastic to sufficiently low levels acceptable for the intended use of the resulting packaging [6]. This has proved difficult, time-consuming and costly since the collected plastic waste consists of different plastic types that have to be sorted and separated. After which, the plastic wastes may have to be washed clean to remove the different contaminated residues from products they were packaging [22]. Additionally, plastic additives such as the popular phthalates are persistent in recycled plastic and continue posing health problems. They have low molecular weight and can easily migrate from plastics into packaged food or water [23].

2. Food Packaging Waste

There are high amounts of food packaging waste entering the environment, causing pollution. Snack food packaging is one good long term case of a visually irritating example of environmental pollution [24]. Most food packaging plastics culminate in waste streams within a short time after purchase, especially for single-use packaging applications used in short-lived goods [23]. This is due to an increase in on-the-go consumption of food and drinks driving the growth of single-use plastic packaging [25][26]. In some locations, the challenge of low availability of bins can increase littering [27]. Many food packaging plastics easily end up in open spaces as litter, municipal waste, landfills and even in oceans, whilst a few can be recycled. This is due to the human throw away culture [28] which is more prevalent in developing countries. After consuming, when consumers purchase food-on-the-go, they often throw away the packaging at any location where they finished eating or drinking the packaged food. This culture can also be linked to social trends and individual behaviours, which can be quite complex. Waste collection systems are seemingly failing to deal with waste resulting from this culture. Poor waste management systems also compound this problem or nonexistence of enforcements or absence of substitute materials [17].

Globally, there are low recycling rates for single-use plastic packaging materials. Only 14% of plastic packaging is collected for recycling, and only 5% of it being successfully recycled into new plastic [29][30]. The common single-use plastic packaging waste materials polluting the environment in quantity include drinking bottles, bottle caps, food wrappers, grocery bags, lids, straws, stirrers and foam take away containers [31]. The food industry is encouraged to adopt the reduce, reuse and recycle waste control options rather than adopt the easy direct disposal method. This waste disposed of in landfills results in methane gas creation, a greenhouse gas that surpasses carbon dioxide by more than 2000% in causing global warming [32].

Global plastic waste generated in 2015 had packaging contributing about 50% [33]. This figure has remained high, with food packaging estimated to be more than a third of the world total packaging market [34]. The food packaging industry's 12% annual growth raises more environmental concerns, including greenhouse gases and greater carbon footprints [35]. Annually, Europe alone produces 23 million tonnes of plastic packaging, and current projections will see 92 million tonnes by the year 2050 [36]. The European Union has championed amendments to packaging waste to demand that 75% of it be recycled by 2030. A comparative lifecycle study investigating the extent of recycling that can yield favourable impacts on the environment has been done [37]. Results showed that recycling could greatly reduce the environmental burdens posed by food packaging waste. Therefore, to deal with food packaging waste, there is a need for integrated waste management schemes that can sustainably control waste generation without compromising society's needs and environment.

3. Plastic Waste Disposal

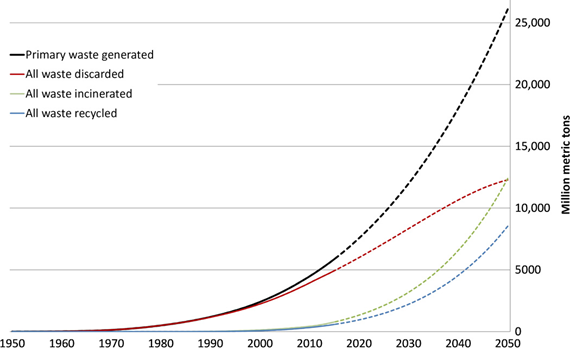

After their use, products made from plastic can be disposed of, recycled or incinerated. Up to 1980, almost all plastic waste was discarded as recycling and incineration were negligible [38]. Incineration as a method for plastic waste management started growing from 1980, and in 1990, recycling started to be appreciated. In 2015, approximately 6300 million tonnes of cumulative plastic waste had been generated, and about 9% was recycled, 12% was incinerated, and 79% was accumulated in landfills or the natural environment [39]. From these three routes of plastic waste disposal, incineration was the only permanent route of eliminating the waste, and this thermal treatment involves combustion.

Most synthetic plastics disposed of in nature have a very unreasonably slow degradation process that takes long periods spanning hundreds to thousands of years. When plastics are thrown away by consumers, some are blown off by wind to cover more area, and rains wash away some even to find their way into water bodies. Plastics are one of the biggest pollutants of oceans. Living creatures like sea animals, birds and livestock have even been affected by the plastic waste dumped in water bodies and land. Figure 1 displays the cumulative plastic waste generated and disposal.

Figure 1. Generation and discarding of plastic waste [39] (https://creativecommons.org/licenses/by-nc/4.0/).

The solid lines show historical data from 1950 to 2015, whilst dashed lines show projections up to the year 2050 based on historical trends. Following these projections, environmental pollution with plastic waste is set to rise to alarming levels. Pollution from plastics is a global challenge requiring a complete paradigm shift on producing, using, and disposing of plastics [40].

References

- Robertson, G.L. Food Packaging: Principles and Practice; CRC Press: Boca Raton, FL, USA, 2016.

- Sydow, Z.; Bieńczak, K. The overview on the use of natural fibers reinforced composites for food packaging. J. Nat. Fibers 2018, 16, 1189–1200.

- Marsh, K.; Bugusu, B. Food packaging—Roles, materials, and environmental issues. J. Food Sci. 2007, 72, R39–R55.

- Robertson, G.L. Definitions, Functions, Attributes and Environments of Food Packaging. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2018.

- Welt, B. A Brief History of Packaging. Institute of Food and Agricultural Sciences, Document ABE321; University of Florida: Gainesville, FL, USA, 2005; Available online: https://ufdc.ufl.edu/IR00001524/00001 (accessed on 25 November 2020).

- Raheem, D. Application of plastics and paper as food packaging materials—An overview. Emir. J. Food Agric. 2013, 25, 177–188.

- Nurul Fazita, M.; Jayaraman, K.; Bhattacharyya, D.; Mohamad Haafiz, M.; Saurabh, C.K.; Hussin, M.H.; HPS, A.K. Green composites made of bamboo fabric and poly (lactic) acid for packaging applications—A review. Materials 2016, 9, 435.

- Ashok, A.; Rejeesh, C.; Renjith, R. Biodegradable polymers for sustainable packaging applications: A review. IJBB 2016, 1, 11.

- Kumar, M.S.; Yaakob, Z. Biobased materials in food packaging applications. Handb. Bioplast. Biocompos. Eng. Appl. 2011, 81, 121–159.

- Wikström, F.; Williams, H.; Verghese, K.; Clune, S. The influence of packaging attributes on consumer behaviour in food-packaging life cycle assessment studies—A neglected topic. J. Clean. Prod. 2014, 73, 100–108.

- Marsh, K.S. Polymer and Plastic Packaging. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016.

- Andrady, A.L.; Neal, M.A. Applications and societal benefits of plastics. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 1977–1984.

- Jefferson, M. Whither Plastics?—Petrochemicals, plastics and sustainability in a garbage-riddled world. Energy Res. Soc. Sci. 2019, 56, 101229.

- Sardon, H.; Dove, A.P. Plastics recycling with a difference. Science 2018, 360, 380–381.

- Wang, W.; Themelis, N.J.; Sun, K.; Bourtsalas, A.C.; Huang, Q.; Zhang, Y.; Wu, Z. Current influence of China’s ban on plastic waste imports. Waste Dispos. Sustain. Energy 2019, 1, 67–78.

- Narancic, T.; O’Connor, K.E. Plastic waste as a global challenge: Are biodegradable plastics the answer to the plastic waste problem? Microbiology 2019, 165, 129–137.

- Kumar, G.M.; Irshad, A.; Raghunath, B.; Rajarajan, G. Waste management in food packaging industry. In Integrated Waste Management in India; Springer: Heidelberg/Berlin, Germany, 2016; pp. 265–277.

- Biron, M. Thermoplastics and Thermoplastic Composites; William Andrew: Norwich, NY, USA, 2018.

- Williams, K.S. Plastic Packaging: Not a Throw-away Resource. In Issues in Environmental Science and Technology: Waste as a Resource; The Royal Society for Chemistry: Cambridge, UK, 2013; pp. 83–109.

- Hu, B. Biopolymer-based lightweight materials for packaging applications. In Lightweight Materials from Biopolymers and Biofibers; ACS Publications: Washington, DC, USA, 2014; pp. 239–255.

- Porta, R.; Sabbah, M.; Di Pierro, P. Biopolymers as Food Packaging Materials. Int. J. Mol. Sci. 2020, 21, 4942.

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58.

- Pivnenko, K.; Eriksen, M.K.; Martín-Fernández, J.A.; Eriksson, E.; Astrup, T.F. Recycling of plastic waste: Presence of phthalates in plastics from households and industry. Waste Manag. 2016, 54, 44–52.

- Brown, D. Plastics packaging of food products: The environmental dimension. Trends Food Sci. Technol. 1993, 4, 294–300.

- European Commission. A European Strategy for Plastics in a Circular Economy; European Commission: Brussels, Belgium, 2018.

- Lau, W.W.; Shiran, Y.; Bailey, R.M.; Cook, E.; Stuchtey, M.R.; Koskella, J.; Velis, C.A.; Godfrey, L.; Boucher, J.; Murphy, M.B. Evaluating scenarios toward zero plastic pollution. Science 2020, 369, 1455–1461.

- Thompson, R.C.; Moore, C.J.; Vom Saal, F.S.; Swan, S.H. Plastics, the environment and human health: Current consensus and future trends. Philos. Trans. R. Soc. B: Biol. Sci. 2009, 364, 2153–2166.

- McDermott, K.L. Plastic Pollution and the Global Throwaway Culture: Environmental Injustices of Single-Use Plastic. 2016. Available online: https://www.semanticscholar.org/paper/Plastic-Pollution-and-the-Global-Throwaway-Culture%3A-McDermott/1f5739852233d4c162994a919f058251b8196418?p2df (accessed on 25 November 2020).

- Dauvergne, P. Why is the global governance of plastic failing the oceans? Glob. Environ. Chang. 2018, 51, 22–31.

- Hahladakis, J.N.; Iacovidou, E. Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity? Sci. Total Environ. 2018, 630, 1394–1400.

- Chitaka, T.Y.; Russo, V.; von Blottnitz, H. In pursuit of environmentally friendly straws: A comparative life cycle assessment of five straw material options in South Africa. Int. J. Life Cycle Assess. 2020, 25, 1818–1832.

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422.

- UNEP. SINGLE-USE PLASTICS: A Roadmap for Sustainability; UNEP: Nairobi, Kenya, 2018.

- Nemat, B.; Razzaghi, M.; Bolton, K.; Rousta, K. The role of food packaging design in consumer recycling behavior—A literature review. Sustainability 2019, 11, 4350.

- Kumar, N.; Kaur, P.; Bhatia, S. Advances in bio-nanocomposite materials for food packaging: A review. Nutr. Food Sci. 2017, 47, 591–606.

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The next generation of sustainable food packaging to preserve our environment in a circular economy context. Front. Nutr. 2018, 5, 121.

- Toniolo, S.; Mazzi, A.; Niero, M.; Zuliani, F.; Scipioni, A. Comparative LCA to evaluate how much recycling is environmentally favourable for food packaging. Resour. Conserv. Recycl. 2013, 77, 61–68.

- Ritchie, H.; Roser, M. Plastic Pollution. Available online: https://ourworldindata.org/plastic-pollution (accessed on 13 July 2020).

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782.

- de Kock, L.; Sadan, Z.; Arp, R.; Upadhyaya, P. A circular economy response to plastic pollution: Current policy landscape and consumer perception. S. Afr. J. Sci. 2020, 116, 1–2.