| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Jamal Deen | + 1108 word(s) | 1108 | 2021-03-08 09:48:45 | | | |

| 2 | Lily Guo | Meta information modification | 1108 | 2021-03-19 05:08:55 | | | | |

| 3 | Catherine Yang | Meta information modification | 1108 | 2021-09-28 11:18:10 | | |

Video Upload Options

Smart packaging of fresh produce is an emerging technology targeting the reduction of waste and the preservation of consumer health and safety. Smart packaging systems also help to prolong the shelf life of perishable foods during transport and mass storage, which are difficult to regulate. The use of these ever-progressing technologies in the packaging of fruits has the potential to result in many positive consequences, including improved fruit quality, reduced waste, higher consumer confidence and associated improved public health.

1. Introduction

Present civilization has an extreme urgency of innovation in the field of food production, storage, and distribution to solve hunger problems that still afflict several parts of the world. Food production is rapidly growing with the help of science and technology due to increased demand. However, there is a large disparity between the different countries where there are constant food shortages and some other countries where food is wasted at an alarming rate [1]. Despite the differences, all societies have a common need for better methods of preventing unnecessary food spoilage. Also, the global food market has a higher than ever demand to deliver fresher, higher quality food at a reasonable cost [2]. With a global population of 7.6 billion producing over 1.3 billion tonnes of food wastage, and a projected population of 9.6 billion by 2050 [3], current food processing practices and technologies must be assessed and improved.

Fruits and vegetables are living biological bodies, having a respiratory system that continues during their living processes and even after harvest. By respiration, fruits and vegetables take in oxygen and give out carbon dioxide. Therefore, the handling and packaging of fruits are key toward maintaining their freshness until they reach the consumer’s table. One of the major sources of premature spoilage in perishable fruits is during transport and storage. This is a key issue for fresh fruits, which gets very little quality monitoring after it has been harvested, treated, and packed. Fruits are necessary parts of the human diet, as they contain vitamins, minerals, antioxidants, fiber, and many other essential nutrients [4]. Most countries suggest daily servings of fruits and vegetables in their dietary recommendation guides, emphasizing the importance of accessibility to good quality produce [5]. The health and safety of the consumers are also important factors in the consideration of fruits quality. Many harmful microorganisms can infect fresh produce, especially through poor handling and processing practices. A majority of these pathogens are picked up during transport and storage and due to faulty packaging techniques [6]. Due to the potential severity of these hazards, regulations on fresh fruits are stringent, particularly in the developed countries. Resellers take precautionary measures such as disposing of food that has passed its “best before” date, which the United States Department of Agriculture states is not a true indicator of spoiled food [7]. Products are often still viable after this date, meaning that large amounts of unsold food are unnecessarily discarded [8].

Conventional packaging aims to limit the harmful environmental exposure of fruits and fruit products, but it is often not enough. It is difficult to monitor and retain the peak level of quality during all stages of food processing. In most cases, the fruit may not have warning about problems before it is too late. To address this need in produce processing, along with other food-processing innovations, freshness sensors and smart packaging system for fruit monitoring have emerged. Fruit freshness sensors or indicators can sense and inform the status of a fruit’s quality, such as freshness, ripeness, leak, microbial pathogens, and emitted gases, correlated to the safety of the food being consumed. Therefore, the freshness sensors can be defined as the on-package sensors or indicators that can sense the freshness of the food associated to the environment inside or outside of the package and advise about the quality and safety of the food [9]. On the other hand, smart packaging systems offer methods for both passive and active packaging solutions. Embedded with sensor technology that can detect changes in fruits’ health and environmental conditions that impact quality, intelligent packaging allows for the use of real-time monitoring until the product is delivered to the customer. In fact, smart packaging systems can be further applied to create response systems that can mitigate spoilage conditions and prolong the shelf-life of perishable items. While still in its early stages, the numerous opportunities for the applications of smart packaging technology in spoilage prevention for fruits is a key motivator for further research and development [2].

There have been many studies on the use of freshness sensors and smart packaging systems in food and beverage industries [6], as well as their applications in water quality monitoring [10][11][12]. A few studies also focused on freshness monitoring and controlled packaging of meat and animal products [4][9][13]. However, there has been very limited studies that focused on the freshness monitoring and sensing of fruits and fruit products. In fact, many of these studies focused on the freshness of produces [14][15][16][17], with less attention to fruits and fruit products. The high spoilage rate of fruits and the increased instances of diseases outbreaks related to fruits demands a comprehensive study on the state-of-the-art technologies and future research trends on freshness monitoring and smart packaging of fruits inside a package. Freshness sensors and smart packaging systems for fruit monitoring can also have great potential in terms of the presence of emerging contaminants such as plastic micropollutants migrating from the plastic packages [18]. Also, a comprehensive review on the freshness sensors and smart systems technologies for fruits monitoring will illustrate current challenges and outlook for the technology roadmaps towards the possibility of further commercial use of smart packaging in the fruits packaging industry.

2. Smart Packaging Systems for Fruit Freshness

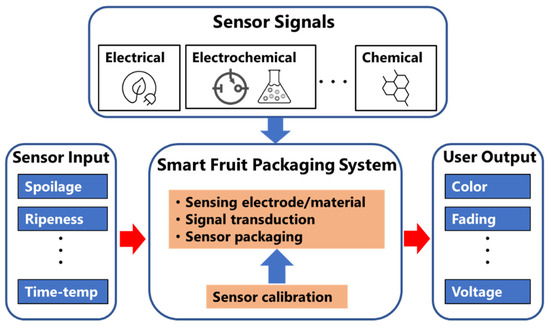

Freshness sensors or indicators can sense and inform about the quality of fruits in terms of their freshness level, ripeness, or firmness. Therefore, fruit freshness sensors are on-package indicators that monitors the environment inside or outside the package and allow consumers to make informed decisions about the quality of the fruits [19]. On the other hand, smart packaging and/or sensors refer to an embedded system, which is a combination of electronics and electrochemical/electro-optical sensors that are near packaged fruits, allowing continuous monitoring of the quality of packaged fruits once the package leave the plant until it reaches to consumers, as illustrated in Figure 1. The use of freshness sensors in fruits’ packaging vastly depends on the type of fruits and the fruits physiology. Therefore, a general classification and understanding of the fruit’s physiology is important when designing and implementing freshness sensors and smart packaging systems, as discussed in the following subsections.

Figure 1. Schematic diagram illustrating the details of a smart fruit packaging system.

References

- Ishangulyyev, R.; Kim, S.; Lee, S. Understanding Food Loss and Waste—Why Are We Losing and Wasting Food? Foods 2019, 8, 297.

- Nicoletti, M.; Serrone, P. Del Intelligent and Smart Packaging. In Future Foods; InTech: London, UK, 2017.

- Morone, P.; Koutinas, A.; Gathergood, N.; Arshadi, M.; Matharu, A. Food waste: Challenges and opportunities for enhancing the emerging bio-economy. J. Clean. Prod. 2019, 221, 10–16.

- Mohebi, E.; Marquez, L. Intelligent packaging in meat industry: An overview of existing solutions. J. Food Sci. Technol. 2015, 52, 3947–3964.

- Slavin, J.L.; Loyd, B. Health Benefits of Fruits and Vegetables. Adv. Nutr. 2012, 3, 506–516.

- Top 3 Consumer Demands Driving Produce Packaging Trends. Available online: (accessed on 6 December 2020).

- The Maryland–National Capital Park and Planning Commission. Reduce, Recover, Recycle—Food Waste in Prince George’s County, MD; The Maryland–National Capital Park and Planning Commission: Adelphi, MD, USA, April 2019. Available online: (accessed on 6 December 2020).

- Food Safety Education. Available online: (accessed on 6 December 2020).

- Kuswandi, B. Freshness Sensors for Food Packaging. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–11. ISBN 9780081005965.

- Alam, A.U.; Clyne, D.; Jin, H.; Hu, N.-X.; Deen, M.J. Fully Integrated, Simple, and Low-Cost Electrochemical Sensor Array for in Situ Water Quality Monitoring. ACS Sens. 2020, 5, 412–422.

- Alam, A.U.; Howlader, M.M.R.; Hu, N.-X.; Deen, M.J. Electrochemical sensing of lead in drinking water using β-cyclodextrin-modified MWCNTs. Sens. Actuators B Chem. 2019, 296, 126632.

- Qin, Y.; Alam, A.U.; Pan, S.; Howlader, M.M.R.; Ghosh, R.; Hu, N.-X.; Jin, H.; Dong, S.; Chen, C.-H.; Deen, M.J. Integrated water quality monitoring system with pH, free chlorine, and temperature sensors. Sens. Actuators B Chem. 2018, 255, 781–790.

- Alam, A.U.; Qin, Y.; Howlader, M.M.R.; Hu, N.-X.; Deen, M.J. Electrochemical sensing of acetaminophen using multi-walled carbon nanotube and β-cyclodextrin. Sens. Actuators B Chem. 2018, 254, 896–909.

- Beaudry, R.M. Effect of O2 and CO2 partial pressure on selected phenomena affecting fruit and vegetable quality. Postharvest Biol. Technol. 1999, 15, 293–303.

- Li, Z.G.; Liu, Y.; Dong, J.G.; Xu, R.-J.; Zhu, M.-Z. Effect of low oxygen and high carbon dioxide on the levels of ethylene and 1-aminocyclopropane-1-carboxylic acid in ripening apple fruits. J. Plant Growth Regul. 1983, 2, 81–87.

- Shirazi, A.; Cameron, A.C. Controlling Relative Humidity in Modified Atmosphere Packages of Tomato Fruit. HortScience 1992, 27, 336–339.

- Mehyar, G.F.; Han, J.H. Active Packaging for Fresh-Cut Fruits and Vegetables. In Modified Atmosphere Packaging for Fresh-Cut Fruits and Vegetables; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; pp. 267–283.

- Alam, A.U.; Deen, M.J. Bisphenol A Electrochemical Sensor Using Graphene Oxide and β-Cyclodextrin-Functionalized Multi-Walled Carbon Nanotubes. Anal. Chem. 2020.

- Kuswandi, B.; Wicaksono, Y.; Jayus; Abdullah, A.; Heng, L.Y.; Ahmad, M. Smart packaging: Sensors for monitoring of food quality and safety. Sens. Instrum. Food Qual. Saf. 2011, 5, 137–146.