| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Victoria Nahum | + 1672 word(s) | 1672 | 2021-02-18 04:49:17 | | | |

| 2 | Bruce Ren | -22 word(s) | 1650 | 2021-03-01 04:25:44 | | |

Video Upload Options

Health food has become a prominent force in the market place, influencing many food industries to focus on numerous bioactive compounds to reap benefits from its properties. Use of these natural compounds in food matrices has several limitations. Most of the food bio-additives are sensitive compounds that may quickly decompose in both food and within the gastrointestinal tract. Since most of these bioactives are highly or partially lipophilic molecules, they possess very low water solubility and insufficient dispersibility, leading to poor bioavailability. Thus, various methods of microencapsulation of large number of food bioactives have been studied. For encapsulation of hydrophobic compounds several lipid carriers and lipid platforms have been studied, including emulsions, microemulsions, micelles, liposomes, and lipid nano- and microparticles. Solid lipid particles (SLP) are a promising delivery system, can both deliver bioactive compounds, reduce their degradation, and permit slow and sustained release. Solid lipid particles have important advantages compared to other polymer carriers in light of their simple production technology, including scale up ability, higher loading capacity, extremely high biocompatibility, and usually low cost. This delivery system provides improved stability, solubility in various matrixes, bioavailability, and targeting properties.

1. Food Additives

Food additives are substances incorporated in foods to improve production, processing, storage or packaging, to increase or maintain nutritional values, to maintain or improve safety, freshness, and taste, as well as texture and appearance [1]. Production and use of new additives decidedly multiplied during the 20th century because of the increased number of industrial foods. Almost all newly invented products, such as snacks, low-calorie, and ready-to-eat foods could not have been possible without food additives. There is also a growing demand for the incorporation of active nutritional ingredients in food for health reasons, as depicted in following table (Table 1).

Table 1. Bioactive additives for health demand [1].

|

Anti-Ageing |

Digestive Health |

Immunity |

Cognitive Health |

Energy |

|

Herbs/Botanicals |

Probiotics |

Herbs/Botanicals |

Omega-3 |

Vitamins |

|

Antioxidants |

Herbs/Botanicals |

Probiotics |

Herbs/Botanicals |

CoQ10 |

|

Omega-3 |

Enzymes |

Antioxidants |

Antioxidants |

Herbs/Botanicals |

|

Vitamin C |

Fiber |

Vitamin C |

Ginger |

Proteins |

|

Vitamin E |

Omega-3 |

Beta-sitosterol |

Lecithin |

Guarana |

Business Insight Survey 2008, Market interest [2].

Food additives can be categorized [3] as preservatives, nutritional additives, flavoring agents, coloring agents, etc. Some can belong to more than one category. Food preservatives are compounds with antioxidant or antimicrobial properties. Antioxidants supplements allow to delay or prevent decomposition of foods due to oxidation during industrial processing, packaging, or storing. Compounds for this purpose include, among others, Ascorbic acid (AA) as an oxygen scavenger, and Butylated hydroxyanisole (BHA) or Butylated hydroxytoluene (BHT) as free radical scavengers. Antimicrobial agents such as benzoic acid, natamycin, nitrates, sorbic acid, parabens, and others inhibit growth of bacteria or other microorganisms in foods. Nutritional additives are usually added to enrich various foods with dietary supplements [4]. For example, vitamins are added to many foods to rise their nutritional value. For example, Vitamin A and D supplements can be added to dairy and cereal products. Vitamins B are added to flour, pasta, cereals, and baked goods. Vitamin C is added to fruit beverages, cereals, and dairy products. Probiotics, as well, are an example of an additive commonly added to dairy products to enrich the gastrointestinal flora with essential microbes. Fatty acids, minerals, and dietary fibers are other examples of nutritional additives used to enrich food products. Various texturizing agents are added during food production to supply the desired consistency of a product. Our perception of product quality is often heavily influenced by its color. Therefore, colorants are added to create a standard product with an attractive color. These coloring agents can be divided into two categories: natural or synthetic. Natural colorants can originate from plants (e.g., strawberry (red), grape (blue), paprika (red/orange)), from animal or mineral sources, while artificial food colorants are usually petroleum-based chemical compounds (e.g., Brilliant Blue FCF, Indigotine, Fast Green FCF, Allura Red AC, Erythrosine, and Tartrazine). The largest group of food additives, with more than 1200 different compounds that can create flavor or replenish flavors lost or diminished in processing is Flavoring agents. They can be only one chemical or a mixture of several chemicals drawn from natural or synthetic sources.

2. Encapsulation of Phytochemicals and Food Additives

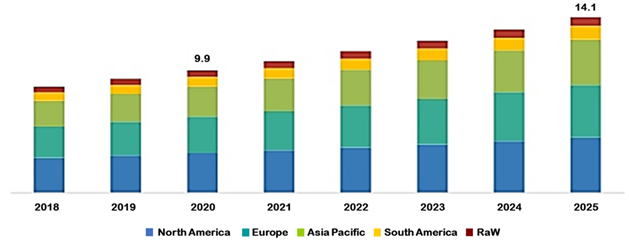

For health concerns the food industry avails itself of increasingly more natural substances as food bio-additives. Due to processing and gastrointestinal conditions, there is a growing demand to initiate new processes and technologies suitable for their protection [5], since these materials are commonly recognized as highly sensitive to the environment, like heat, light, oxygen, and moisture. One proposed tool that can ensure improved bioavailability, stability, and delivery of these materials is microencapsulation [6], that can potentially prevent interaction with the food matrix and convert the applied ingredients into the easily handled, free-flowing, and dispersible powders. Taste masking is another aim of encapsulation. Essential fatty acids, for example, are highly valuable for health, however they have an unpleasant taste that can become a negative factor when overgoing oxidation process. This problem can be avoided by encapsulation in suitable vehicles. Pre-cooked food, for example, represents a large part of our consumption. Recomposed powders, long-term storage period, and the need for innovation have deeply changed the management of the products [7]. As mentioned previously, microencapsulation offers sustained and controlled release that can be prompted by different factors such as dissolution, temperature, pressure, pH, and enzymes, depending on wall material [8]. The global food encapsulation market was estimated to account for US $9.9 billion in 2020 and is projected to surpass US $14 billion by 2025, (Figure 1) [9]. This market is mainly driven by the rising request for encapsulated flavor and colorants. High demand for fortified and functional foods among consumers has caused a rise in demand for food additive encapsulation. Manufactures, therefore, have been adopting this technology at a high rate.

Figure 1. Projection of food encapsulation market.

3. Examples of Microencapsulation of Bioactives in Foods

Microencapsulation is a process in which small particles or droplets of a core material are coated or embedded into a homogeneous or heterogeneous matrix to create small capsules. Microcapsules are extremely small (1–1000 µm) and can have numerous morphologies. Food microcapsules, in particular, are small particles containing an active food additive (core) surrounded by a coating or shell. The shell material can comprise a variety of food grade polymers, carbohydrates, fats, and waxes that function as a barrier between the bioactives and the surrounding environment. Encapsulation of flavors, lipids, and carotenoids among other ingredients had recently attracted much attention by food industry [10]. l-Menthol, for example, has been encapsulated in a carrier mixture of maltodextrin and gum Arabic. Flavors such as oregano, citronella, and marjoram have been encapsulated using skimmed milk powder and whey protein concentrate [11]. Flavor-loaded microcapsules can release the active material at a perfect time to produce the maximum effect for the consumer. Microencapsulated fish oil (an oil rich in omega-3 polyunsaturated fatty acids) powder with hidden taste and prolonged shelf life has been successfully manufactured and introduced into numerous food products. Lycopene, a molecule believed to decrease the risk of prostate cancer, has been successfully microencapsulated using a carrier consisting of gelatin and sucrose [12]. Another use of microencapsulation is to reduce degradation of carotenoids in foods, thereby preventing decreased product quality in nutritional properties and coloration [11]. Specific applications of microencapsulation are [13]: baby foods, baked products, chewing gum, flavored waters, leavening agents, nutrition bars, and yogurt. Taste-masked microcapsules containing caffeine for food and sports nutrition industries have been produced for gels or chews to avoid typical unpleasant taste [14]. Microencapsulation has also been used to improve water spreading and bioavailability of hydrophobic materials, such as coenzyme Q10 or carotenoids [15][16].

4. Microencapsulation of Phytochemicals and Food Additives Using Polysaccharides and Proteins

Guidelines for food additives are more severe than for pharmaceuticals. Many carrier materials are not “generally recognized as safe” (GRAS) and have not been certified for food applications. Therefore, natural materials were used mostly for encapsulation in the food industry. Polysaccharides are the most broadly used natural polymers in food applications. These natural carbohydrate polymers originate from different sources, e.g., plants, animals, algae, and microbes. Starch is one of the most abundant polysaccharides in plants. Frequently used starches and its derivatives include amylose, amylopectin, dextrins, cyclodextrines, maltodextrins, syrups, polydextrose, and cellulose. Another group of natural polysaccharides enjoying wide food applications is gums, due to their exceptional functionalities, non-toxicity, biodegradability, biocompatibility, and safety for human nutrition. Gums possess an excellent ability to incorporate flavors, nutraceutical compounds, phenolic compounds, and antioxidants. Other polysaccharides utilized for encapsulation are carrageenans and alginates (from marine sources), dextran, chitosan, xanthan, and gellan (from microbial and animal sources). Proteins are also suitable for encapsulation since they are GRAS materials as well as they possess high nutritional values [17]. Proteins are found to be an effective vehicle for bioactive compounds, fats, oils, fatty acids, and flavors The most frequently used animal proteins in encapsulation are casein, gelatin, collagen, whey protein, while plant-derived proteins are soy protein, zein, and gliadin.

5. Solid lipid Microencapsulation

Solid lipid micro- and nanoparticles, also called Lipospheres, are drug-loaded solid lipid spheres decorated with phospholipids and surfactants, used to deliver active agents [18][19][20][21]. The presence of lipids can instantaneously increase the dispersibility of hydrophobic additives leading to improved absorption, and thus to increased bioavailability. The difference between solid lipid particles and oil-in-water (o/w) emulsions is that their lipid carrier is composed of a solid lipid (solid at room temperature) [22]. The added materials (core) remain incorporated inside a solid lipid phase, usually stabilized by surfactant molecules [23]. The solid state of Solid Lipid Microparticles (SLM) provides clear advantages over the liquid state, encouraging increasing interest in their development. Lipid microparticles can be an advantageous alternative to polymeric particles in light of several visible advantages of this delivering system. Amongst them, facility of large-scale production, relatively low cost, and low toxicity. In addition to solubilization and better dispersion of the active ingredient, SLM can provide extended release of active agent, to mask the undesirable taste and protect against degradation inside the GI tract [24].

References

- Overview of Food Ingredients, Additives & Colors, FDA. Available online: https://www.fda.gov (accessed on 9 February 2021).

- Augustin, M.A.; Sanguansri, L. Introduction to microencapsulation of functional ingredients in food products—short course on micro- and nano-encapsulation of functional ingredients in food products. In Proceedings of the World Congress on Oils & Fats and 31st Lectureship Series, Rosario, Argentina, 31 October–4 November 2015.

- Branen, A.L.; Davidson, P.M.; Salminen, S.; Thorngate, J.H., III. Food Additives, 2nd ed.; CRC Press.: Boca Raton, FL, USA, 2001.

- Encyclopedia Britannica. Available online: https://www.britannica.com/topic/food-additive (accessed on 9 February 2021).

- Gaonkar, A.; Vasisht, N.; Khare, A.; Sobel, R. Microencapsulation in the Food Industry, 1st ed.; Academic Press: Cambridge, MA, USA; Elsevier: Amsterdam, The Netherlands, 2014.

- Nedovica, V.; Kalusevica, A.; Manojlovicb, V.; Levica, S.; Bugarskib, B. An overview of encapsulation technologies for food applications. Procedia Food Sci. 2011, 1, 1806–1815.

- Poncelet, D.; Picot, A.; El Mafadi, S. Encapsulation: An essential technology for functional food applications. Innov. Food Technol. 2011 32-34. Available online: www.innovationsfood.com (accessed on 9 February 2021).

- James, H.P.; John, R.; Alex, A.; Anoop, K.R. Smart polymers for the controlled delivery of drugs—A concise overview. Acta Pharm. Sin. B 2014, 4, 120–127.

- Food Encapsulation Market by Shell Material (Polysaccharides, Emulsifiers, Lipids, Proteins), Technology (Microencapsula-tion, Nanoencapsulation, Hybrid encapsulation), Application, Method, Core Phase, and Region—Global Forecast to 2025. Available online: https://www.marketsandmarkets.com/Market-Reports/food-encapsulation-advanced-technologies-and-global-market-68.html (accessed on 9 February 2021).

- Gharsallaoui, A. Ingredients: Microencapsulation of Food Ingredients: Still a Field to be Explored? Available online: https://www.newfoodmagazine.com/ (accessed on 9 February 2021).

- Gharsallaoui, A.; Roudaut, G.; Chambin, O.; Voilley, A.; Saurel, R. Applications of spray-drying in microencapsulation of food ingredients: An overview. Food Res. Int. 2007, 40, 1107–1121.

- Shu, B.; Yu, W.; Zhao, Y.; Liu, X. Study on microencapsulation of lycopene by spray-drying. J. Food Eng. 2006, 76, 664–669.

- Poncelet, D. Microencapsulation: Fundamentals, Methods and Applications. In Surface Chemistry in Biomedical and Environ-mental Science; Springer: Heidelberg, The Netherlands, 2006, pp. 23–34.

- Pimparade, M.B.; Morott, J.T.; Park, J.B.; Kulkarni, V.I.; Majumdar, S.; Murthy, S.N.; Lian, Z.; Pinto, E.; Bi, V.; Durig, T.; Murthy. R.; Shivakumar, H.N.; Vanaja, K.; Kumar, P.C.; Repka, M.A. et al. Development of taste masked caffeine citrate formulations utilizing hot melt extrusion technology and in vitro-in vivo evaluations. Int. J. Pharm. 2015, 487, 167–176.

- Zhao, X.-H.; Tang, C.-H. Spray-drying microencapsulation of CoQ10 in olive oil for enhanced water dispersion, stability and bioaccessibility: Influence of type of emulsifiers and/or wall materials. Food Hydrocoll. 2016, 61, 20–30.

- Polyakov, N.E.; Kispert, L.D. Water soluble biocompatible vesicles based on polysaccharides and oligosaccharides inclusion complexes for carotenoid delivery. Carbohydr. Polym. 2015, 128, 207–219.

- Shishir, M.R.I., Xie, L., Sun, C., Zheng, X., Chen, W. Advances in micro and nano-encapsulation of bioactive compounds us-ing biopolymer and lipid-based transporters. Trends in Food Science & Technology 2018, 78, 34–60.

- Domb, A.J. Lipsopheres for Controlled Delivery Substances. U.S. Patent 5,188,837A, 13 November 1989.

- Domb, A.J. Long-acting injectable oxytetracycline-liposphere formulations. Int. J. Pharm. 1995, 124, 271–278.

- Masters, D.B.; Domb, A.J. Liposphere local anesthetic timed-release for perineural site application. Pharm. Res. 1998, 15, 1038–1045.

- Bekerman, T.; Golenser, J.; Domb, A. Cyclosporin nanoparticulate lipospheres for oral administration. J. Pharm. Sci. 2004, 93, 1264–1270.

- Cazado, C.P.S.; de Pinho, S.C. Effect of different stress conditions on the stability of quercetin-loaded lipid microparticles produced with babacu (Orbignya speciosa) oil: Evaluation of their potential use in food applications. Food Sci. Technol. Cam-pinas 2016, 36, 9–17.

- Ezhilarasi, P.N.; Muthukumar, S.P.; Anandharamakrishnan, C. Solid lipid nanoparticle enhances bioavailability of hy-droxycitric acid compared to a microparticle delivery system. RSC Adv. 2016, 6, 53784–53793.

- Albertinia, B.; Bertonia, S.; Perissuttib, B.; Passerinia, N. An investigation into the release behavior of solid lipid micropar-ticles in different simulated gastrointestinal fluids. Colloids Surf. B 2019, 173, 276–285.