| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Mateja Primožič | + 3238 word(s) | 3238 | 2021-02-04 03:48:52 | | | |

| 2 | Dean Liu | -1162 word(s) | 2076 | 2021-02-19 07:54:18 | | |

Video Upload Options

Bionanotechnology, as a tool for incorporation of biological molecules into nanoartifacts, is gaining more and more importance in the field of food packaging. It offers an advanced expectation of food packaging that can ensure longer shelf life of products and safer packaging with improved food quality and traceability.

1. Introduction

In recent decades, (bio)nanotechnology has become increasingly important as an appealing technology for the food industry. Nanotechnology is a discipline composed of several fields of technology, and serves as a tool for creating, studying phenomena, or manipulating matter in nanoscale dimensions[1]. Development of novel nanomaterials makes possible to improve food quality and safety, crop growth, and monitoring environmental conditions[2]. The obtained materials have unique properties such as high surface-to-volume ratio and their other physiochemical properties such as color, solubility, strength, diffusivity, toxicity, magnetic, optical, thermodynamic properties, etc. are improved[3][5]. Therefore, nanotechnology has brought a new industrial revolution as it offers a wide range of possibilities for the development and use of structures, materials, or systems with new or improved properties in various fields such as agriculture, food and medicine, etc. Besides, it is also one of the fastest growing fields in agriculture and food sector. Bionanotechnology is a tool for integrating biological molecules into nanostructures[5]. The growing desire of consumers for quality food and awareness of a healthy lifestyle is encouraging researchers to find a way to improve food quality while least compromising nutrition product value. Therefore, new studies are focused on developing novel methods, techniques, and procedures for the purpose of processing, packaging, functionalization, and quality control implementation of food, and also the for nutraceutical products delivery system [6]. Recently, the demand for nanoparticle-based materials for the different applications e.g., food industry has increased, especially in the EU. The European nanomaterials market generated more than $2.5 million in 2015 and is expected to reach around $9 million in revenue by 2022. Many of these materials contain essential elements, some of them non-toxic[7] that can be stable at high pressures and temperatures[8][9]. The improved properties of nanomaterials have enabled and prompted the development of technologies that extend the shelf life and freshness of products, the design of methods and tools for rapid in situ analysis and the production of environmentally safe and degradable food packaging. With the use of nanotechnology, remarkable lifestyle improvements can be achieved. Nanomaterials can contribute to the development of improved products, wealth, health, and quality. Besides, this could also reduce the impact on the environment due to their nano size[10]. Nevertheless, the usage of nanotechnology in food packaging is still in the infancy stage. Nevertheless, the use of different functional nanomaterials can improve materials for packaging, the development and application of these nanomaterials is increasing presently also in the packaging industry for food increasing the shelf life and safety of packaged food[11].

Using nanotechnology, the nanoparticles can be incorporated in film to form nanofilm that could increase certain gases permeability with the aim to reduce the concentration of harmful gases, such as carbon dioxide (CO2) or oxygen (O2), which negative affect the foods shelf life and can be also used as barrier materials to prevent spoilage by microbes[12][14][13]. Since, the most widely used materials in food packaging industries are plastic polymers which are non-biodegradable and represent a serious threat to human and the environment[15], scientific research is also focused on synthesis of edible coatings and films from bionanocomposites or employed as matrixes for incorporating antimicrobial nanoparticles to prolong shelf life and enhance storage quality of fruit and vegetables[16]. With the use of biomaterials, packaging materials may be reduced and at the same time the tremendous problem of waste may be solved. Additionally, biomaterials can contribute to prolongation of the shelf life, as well as safety and quality of food during the distribution, storage and consumption period may be extended[17][18]. However, the use of biomaterials in food packaging is still very limited.

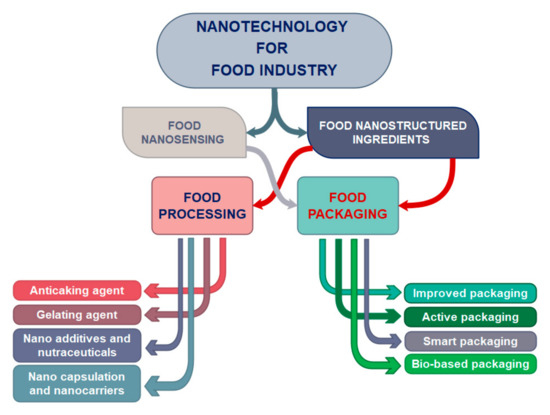

The application of nanotechnology in food industry can be divided into two major groups: food nanosensing and food nanostructured ingredients[3]. Nanostructured food ingredients cover a wide range including food processing and food packaging whereas the field of food nanosensing provides improved food quality and safety (Figure 1).

Figure 1. Application of (bio)nanotechnology in different fields of the food industry.

In the field of food processing, nanostructures and nanostructured materials can be used as: (a) food additives and carriers for smart delivery of nutrients; to improve nutritional value of food, (b) anticaking agents; to improve the consistency of food and to prevent the lump formation, (c) gelating agents; to improve the food texture and (d) nanocapsules and nanocarriers; to protect aroma, flavor and other ingredients in food. While, in the field of food nano-packaging, improved packaging, active packaging, smart packaging and bio-based packaging are considered.

2. Safety and Environmental Concerns of (Bio)Nanotechnology Implementation in Food Packaging

Nanotechnology is a rapidly developing field and nanomaterials are of significant technological and economic interest and have a huge impact on many industries especially in the food packaging industry. In general, the beneficial effects of nanocomposite materials are well recognized as opposed to the potential (eco)toxicological effects and effects of nanoparticles on human health, where less studies were performed. Their interaction with food system raises a concern about human and animal health. The use of nanomaterials in nanosensing or food packaging applications can lead to the migration of nanomaterials in the human organism. This can occur through inhalation, skin penetration or ingestion due to leaching of nanocomponents from packaging or sensing elements into the food, or by storing of packaging, nanosensors in landfills with possibility of release into the environment, air, water, and soil [19][20][21]. Some performed studies have shown the possible toxicological effects of nanoparticles on biological systems[22][23][24]. However, the toxicity seems to depend on the type and size of the nanoparticles[25]. Side effects caused by nanoparticles exposure include the formation of reactive oxygen species (ROS), protein denaturation, mitochondrial disorder, and phagocytosis dysfunction. A potential concern should be focused on the migration of nanomaterials from the packaging or the sensing element inside the packaging into the food. The most evident contact route of nanomaterials to the human body in food application is upon ingestion. Therefore, the gastrointestinal tract properties such as pH, presence of various surface-active molecules, electrolytes, digestive enzymes, gut microbiota, and mechanical forces influence the absorption of nanomaterials, which may cause changes in the properties and agglomeration state of nanoparticles [26]. The Ag migration from the various kinds of nanocomposites (plastic food containers) into food has been investigated by Echegoyer and coworkers with conclusion that in acidic food the highest level of Ag migration was detected. Besides, microwave heating increased more migration of Ag nanoparticles than a conventional oven[27]. Metal and metal oxide nanoparticles are often specified as biocompatible materials, without significant toxic effect in vivo and in vitro; however, pro-inflammatory responses and oxidative stress due to their presence were also detected[25][28][29]. In addition, the accumulation of carbon nanotube particles in living organisms and the consequent formation of ROS could classify nanotubes as potentially toxic nanomaterials. However, their toxicity is mainly conditioned by its structural modification, size distribution, surface charge and the impurities and functionalization[30][31][32]. Migration of various metal oxides such as TiO2, ZnO, SiO2, aluminum oxide, which were used in food packaging to improve mechanical, antimicrobial, light-blocking and gas barrier properties of polymers, was investigated. No significant migration of nanomaterials from packaging to food was determined[32], but additional barrier to separate food from nanocomposite is recommended. The possible migration of biopolymers also needs to be studied and taken into consideration. Ubeda and coworkers studied the migration of PLA in the form of pellets and films to food simulants was carried out. Migration tests confirmed the presence of some PLA oligomers in food simulants as well as new neo-formed oligomers formed due to the reaction processes between PLA components and food simulants[34]. Zimmermann et al. made in vitro toxicity tests and chemical composition study of 43 everyday bio-based and/or biodegradable products as well as their precursors, covering mostly food contact materials made of nine material types. 67% of the samples induced baseline toxicity, 42% oxidative stress, 23% antiandrogenicity and one sample estrogenicity. They concluded that bio-based/biodegradable materials with regards to the chemicals they contain and conventional plastics are similarly toxic[35]. However, effective guidelines and policies are required for the safer use of nanoparticles in food industry. The regulation of nanoparticles in food applications and food packaging in the USA is guided by USFDA. Food Standards Australia and New Zealand (FSANZ) is the responsible body for regulation of food additives in nano size and ingredients in Australia. The use of nanoparticles in food applications or food ingredients in EU is regulated by the European Union Novel Foods Regulation (EC 258-97). European Food Safety Authority (EFSA) prepared the re-evaluation program where a scientific opinion on the potential risks on food and feed safety (EFSA 2009), also considering nanoparticles, is drafted. Some existing restrictions and ongoing evaluation processes of nanomaterial safety are already defined (for example existing restrictions of TiO2 application in France, chitosan smaller than 100 nm is not allowed in EU for direct food contact applications etc.).

Though, additional research and investigations focused on the physico-chemical characterization, exposure assessment and toxicokinetics and toxicity of nanomaterials are needed to address the many current uncertainties and data limitations of their use in food application. The investigation should study the interaction and stability of nanomaterials in food and feed in the gastro-intestinal tract and in biological tissues. Also, the routine methods to detect, characterize and quantify nanomaterials in food contact materials, food, and feed as well as methodologies to assess toxicity including chronic exposure and carcinogenicity of nanomaterials should be developed[23]. Additionally, internationally granted protocols for the toxicity tests of nanomaterials are required for standardization of data due to their diversity.

3. Conclusions

The use of nanomaterials is increasing in diverse fields of application drastically. Current research in food packaging suggests that nanotechnology offers a variety of options in the improvement of food packaging based on functionality nanomaterials, from bio-based packaging to smart packaging. Due to the growing demand for types and varieties of exotic foods and the consequent provision of safer packaging of goods, the concept of food packaging will be increasingly advanced in the industry in the future. Nanotechnology, used for the processing of food packaging allows a remarkable improvement in packaging material properties, but further research and development are needed to better understand the role of nanotechnology in the case of food packaging materials, in particular by the advantages and disadvantages of its effect. The usage of nanotechnology in the food sector is focused on improving food quality and safety in form of the incorporation of nanoparticles in food or packaging materials. To create new food packaging functions, the use of nanotechnology enables possible improving the properties of food, such as healthier, tastier as well as improved nutritious food, when it is packaged. Additionally, by employing suitable nanomaterials, the mechanical properties, better barrier, and thermal properties of packaging materials could be improved to prolong food self-life and safety. Such material can be a surface-modified antimicrobial films from nano cellulose with incorporated both inorganic or organic antimicrobial agents with extremely good antibacterial activity against both Gram-positive and Gram-negative bacteria. The nanosensors, as intelligent packaging, could also serve to obtain visual information about the food state inside the packaging. The usage of nanoparticles as a food ingredient is more harmful than their use in food packaging applications. Active, intelligent, and bio-based packaging technologies can work synergistically to create a multi-purpose food packaging system without negative interactions between components, what present future goal of food packaging technology. Many global companies Amcor Ltd., Sonoco Products Company, BASF SE, Tetra Laval International S.A., Honeywell International Inc., and Chevron Phillips Chemical Company, LLC, among others already produce nanotechnology-based packaging materials that extend shelf life and improve food safety. The upcoming trends in the nanotechnology application in food packaging sector are expected to be at the forefront in the coming decade, with dominance in the field of blockchain application .

With more intensive development of sustainable or green food packaging, the impact of packaging on the environment could be drastically reduced, through the use of edible or biodegradable materials, plant extracts and bionanomaterials. Besides the human health aspects, the carbon, energy, water, and land footprints need to be taken into consideration when the creation of new food packaging materials is in progress to avoid regrettable substitutions to already existing ones.

References

- Luttge, R. Chapter 4—Nanotechnology. In Microfabrication for Industrial Applications; Luttge, R., Ed.; Micro and Nano Technologies; William Andrew Publishing: Boston, MA, USA, 2011; pp. 91–146. ISBN 978-0-8155-1582-1.

- He, X.; Deng, H.; Hwang, H. The current application of nanotechnology in food and agriculture. J. Food Drug Anal. 2019, 27, 1–21.

- Singh, T.; Shukla, S.; Kumar, P.; Wahla, V.; Bajpai, V.K.; Rather, I.A. Application of nanotechnology in food science: Perception and overview. Front. Microbiol. 2017, 8.

- Ramsden, J.J. Chapter 11—Bionanotechnology. In Nanotechnology, 2nd ed.; Ramsden, J.J., Ed.; Micro and Nano Technologies; William Andrew Publishing: Oxford, UK, 2016; pp. 263–278. ISBN 978-0-323-39311-9.

- Dasgupta, N.; Ranjan, S.; Mundekkad, D.; Ramalingam, C.; Shanker, R.; Kumar, A. Nanotechnology in agro-food: From field to plate. Food Res. Int. 2015, 69, 381–400.

- Roselli, M.; Finamore, A.; Garaguso, I.; Britti, M.S.; Mengheri, E. Zinc oxide protects cultured enterocytes from the damage induced by Escherichia coli. J. Nutr. 2003, 133, 4077–4082.

- Mohamadian, N.; Ghorbani, H.; Wood, D.A.; Khoshmardan, M.A. A hybrid nanocomposite of poly(styrene-methyl methacrylate- acrylic acid)/clay as a novel rheology-improvement additive for drilling fluids. J. Polym. Res. 2019, 26, 33.

- Samadi, A.; Klingberg, H.; Jauffred, L.; Kjær, A.; Bendix, P.M.; Oddershede, L.B. Platinum nanoparticles: A non-toxic, effective and thermally stable alternative plasmonic material for cancer therapy and bioengineering. Nanoscale 2018, 10, 9097–9107.

- Kuswandi, B.; Moradi, M. Improvement of food packaging based on functional nanomaterial. In Nanotechnology: Applications in Energy, Drug and Food; Siddiquee, S., Melvin, G.J.H., Rahman, M.M., Eds.; Springer: Cham, Switzerland, 2019; pp. 309–344. ISBN 978-3-319-99602-8.

- Kuswandi, B.; Wicaksono, Y.; Jayus; Abdullah, A.; Heng, L.Y.; Ahmad, M. Smart packaging: Sensors for monitoring of food quality and safety. Sens. Instrum. Food Qual. 2011, 5, 137–146.

- Joye, I.J.; Davidov-Pardo, G.; McClements, D.J. Nanotechnology in food processing. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016; pp. 49–55. ISBN 978-0-12-384953-3.

- Yoksan, R.; Chirachanchai, S. Silver nanoparticle-loaded chitosan-starch based films: Fabrication and evaluation of tensile, barrier and antimicrobial properties. Mater. Sci. Eng. C 2010, 30, 891–897.

- Khare, S.; Williams, K.; Gokulan, K. Nanotechnology. In Encyclopedia of Food Microbiology, 2nd ed.; Batt, C.A., Tortorello, M.L., Eds.; Academic Press: Oxford, UK, 2014; pp. 893–900. ISBN 978-0-12-384733-1.

- Thompson, R.C.; Moore, C.J.; vom Saal, F.S.; Swan, S.H. Plastics, the environment and human health: Current consensus and future trends. Philos. Trans. R Soc. B 2009, 364, 2153–2166.

- Xing, Y.; Li, W.; Wang, Q.; Li, X.; Xu, Q.; Guo, X.; Bi, X.; Liu, X.; Shui, Y.; Lin, H.; et al. Antimicrobial nanoparticles incorporated in edible coatings and films for the preservation of fruits and vegetables. Molecules 2019, 24, 1695.

- Calva-Estrada, S.J.; Jimenez-Fernandez, M.; Lugo-Cervantes, E. Protein-based films: Advances in the development of biomaterials applicable to food packaging. Food Eng. Rev. 2019, 11, 78–92.

- Kuswandi, B. Environmental friendly food nano-packaging. Environ. Chem. Lett. 2017, 15, 205–221.

- He, X.; Hwang, H.-M. Nanotechnology in food science: Functionality, applicability, and safety assessment. J. Food Drug Anal. 2016, 24, 671–681.

- Xia, Y.; Rubino, M.; Auras, R. Release of nanoclay and surfactant from polymer—Clay nanocomposites into a food simulant. Environ. Sci. Technol. 2014, 48, 13617–13624.

- Han, W.; Yu, Y.; Li, N.; Wang, L. Application and safety assessment for nano-composite materials in food packaging. Chin. Sci. Bull. 2011, 56, 1216–1225.

- Oberdörster, G.; Stone, V.; Donaldson, K. Toxicology of nanoparticles: A historical perspective. Nanotoxicology 2007, 1, 2–25.

- Bahadar, H.; Maqbool, F.; Niaz, K.; Abdollahi, M. Toxicity of nanoparticles and an overview of current experimental models. Iran Biomed. J. 2016, 20, 1–11.

- Brandelli, A. The interaction of nanostructured antimicrobials with biological systems: Cellular uptake, trafficking and potential toxicity. Food Sci. Hum. Wellness 2020, 9, 8–20.

- Mauricio, M.D.; Guerra-Ojeda, S.; Marchio, P.; Valles, S.L.; Aldasoro, M.; Escribano-Lopez, I.; Herance, J.R.; Rocha, M.; Vila, J.M.; Victor, V.M. Nanoparticles in medicine: A focus on vascular oxidative stress. Oxid. Med. Cell Longev. 2018, 2018.

- McClements, D.J.; Xiao, H. Is nano safe in foods? Establishing the factors impacting the gastrointestinal fate and toxicity of organic and inorganic food-grade nanoparticles. NPJ Sci. Food 2017, 1, 6.

- Echegoyen, Y.; Nerín, C. Nanoparticle release from nano-silver antimicrobial food containers. Food Chem. Toxicol. 2013, 62, 16–22.

- Vass, I.Z.; Deák, Z.; Paul, K.; Kovács, S.; Vass, I. Interaction of nanoparticles with biological systems. Acta Biol. Szeged. 2015, 59, 225–245.

- Kumar, V.; Sharma, M.; Khare, T.; Wani, S.H. Chapter 17—Impact of nanoparticles on oxidative stress and responsive antioxidative defense in plants. In Nanomaterials in Plants, Algae, and Microorganisms; Tripathi, D.K., Ahmad, P., Sharma, S., Chauhan, D.K., Dubey, N.K., Eds.; Academic Press: Cambridge, MA, USA, 2018; pp. 393–406. ISBN 978-0-12-811487-2.

- Mohanta, D.; Patnaik, S.; Sood, S.; Das, N. Carbon nanotubes: Evaluation of toxicity at biointerfaces. J. Pharm. Anal. 2019, 9, 293–300.

- Kobayashi, N.; Izumi, H.; Morimoto, Y. Review of toxicity studies of carbon nanotubes. J. Occup. Health 2017, 59, 394–407.

- Francis, A.P.; Devasena, T. Toxicity of carbon nanotubes: A review. Toxicol. Ind. Health 2018, 34, 200–210.

- Garcia, C.V.; Shin, G.H.; Kim, J.T. Metal oxide-based nanocomposites in food packaging: Applications, migration, and regulations. Trends Food Sci. Technol. 2018, 82, 21–31.

- Ubeda, S.; Aznar, M.; Alfaro, P.; Nerín, C. Migration of oligomers from a food contact biopolymer based on polylactic acid (PLA) and polyester. Anal. Bioanal. Chem. 2019, 411, 3521–3532.

- Zimmermann, L.; Dombrowski, A.; Völker, C.; Wagner, M. Are bioplastics and plant-based materials safer than conventional plastics? In vitro toxicity and chemical composition. Environ. Int. 2020, 145, 106066.

- Zimmermann, L.; Dombrowski, A.; Völker, C.; Wagner, M. Are bioplastics and plant-based materials safer than conventional plastics? In vitro toxicity and chemical composition. Environ. Int. 2020, 145, 106066.