| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Milivoj Radojčin | + 2751 word(s) | 2751 | 2021-01-27 07:55:29 | | | |

| 2 | Catherine Yang | Meta information modification | 2751 | 2021-02-19 09:14:46 | | |

Video Upload Options

Drying is one of the oldest methods for food preservation that removes the water from fruit and makes it available for consumption throughout the year. Dried fruits can be produced by small- and large-scale processors, which makes them a very popular food among consumers and food manufacturers. The most frequent uses of drying technology include osmotic dehydration, vacuum drying, freeze-drying, and different combinations of other drying technologies. However, drying may provoke undesirable changes with respect to physiochemical, sensory, nutritional, and microbiological quality. The energy efficiency of drying processes and the quality of dried fruits are crucial factors in fruit drying. Recent research shows that innovative technologies such as ultrasound, pulsed electric field, or high pressure may be used as a pretreatment or in combination with traditional drying technologies for process intensification. This could result in quality improvements of dried fruits and enhanced efficiency and capacity of the production process, with a positive impact on environmental and economic benefits.

1. Introduction

Fresh fruits have high moisture contents as they are classified as highly perishable commodities; therefore, storage at refrigerated temperatures and controlled humid conditions is required [1]. Fruits are rich sources of nutrients, including vitamins, minerals, dietary fibers, phenolics, carotenoids, etc., that are useful for human health. Drying is an alternative method for the preservation of the nutritional value of fruits, which increases their relative concentration, extends their shelf life, and minimizes packaging, handling, and transportation costs [2]. In addition, drying is an alternative to expensive postharvest management and selling surpluses of fruits on the market. The drying of fruits by conventional methods, such as sun drying or open-air drying, can degrade quality and food safety. Numerous disadvantages of these technologies led to the development of new drying technologies, such as oven drying, microwaving, vacuuming, as well as infrared, freeze, and different hybrid drying, which are being used successfully for different kinds of fruits [3][4][5]. Each drying technique depends on various factors, such as the required type of product, size, level of ripeness, structure, color, aroma, chemical composition, nutritional composition, together with expected final quality, availability of a dryer, and costs.

Fruits are commonly subjected to various chemical and/or physical pretreatments prior to thermal drying to shorten the drying time, reduce energy consumption and preserve the quality of products. By modifying the properties of fruit tissue, pretreatments could increase the drying rate, inhibit the bio-enzymes, and minimize possible deterioration reactions during drying and subsequent storage [6]. Therefore, each product needs to be dried by using appropriate pre-and post-processing steps, such as osmotic dehydration, blanching, soaking, or by the use of innovative approaches, e.g., ultrasound, pulsed electric field, high hydrostatic pressure, cold plasma, or other treatments to add satisfactory value after drying [7][8].

2. Unconventional/Emerging Drying Intensification Technologies

Many different strategies can be applied in order to enhance the drying process and/or to improve dried food properties. These strategies usually consider the modification of drying parameters or material properties. The approach that is based on changing the parameters of drying, such as temperature, flow rate, and humidity, is usually sufficient to enhance the first period of drying, which is governed by external mass transfer resistance. In turn, intensification of the second stage of drying can usually be achieved by the introduction of a pretreatment step that will change the material properties, for example, its dimensions or integrity of the cellular structure. A reduction in dimensions, which can intensify drying kinetics to a great extent, is not always possible. The rupture of cellular structure can be thermally achieved, e.g., blanching [9][10]. Additionally, this can be done by non-thermal methods such as high hydrostatic pressure (HHP), cold plasma (CP), ultrasound, or pulsed electric field (PEF) treatment [11]. Non-thermal treatments, in principle, allow better preservation of thermo-sensitive compounds and are linked with lower energy consumption in comparison to thermal-based technologies.

2.1. Ultrasound

Ultrasound (US) can be described as a cyclic sound pressure with a frequency that is inaudible to humans (>20 kHz). In food processing, ultrasound can be used for the enactment of traditional technologies or to replace them. Ultrasound can be utilized either as low-frequency but high-energy or as high-frequency but low-energy assays. The first one is usually associated with the facilitation of different unit operations such as extraction, freezing and thawing, emulsification, and homogenization or drying, while the second one is mainly associated with control, analytical and diagnostic procedures [12]. The application of low-frequency but high-intensity ultrasound causes different phenomena depending on the type of medium where they propagate. The application of ultrasound in the fluid systems results in cavitation and microstreaming, which intensifies mass and heat transfer but can also lead to the formation of free radicals and reactive oxygen species. Cavitation bubbles that are collapsing may also erode and degrade the surface or structure of the materials that they contact [13][14]. When ultrasound propagates through solid-like material, for instance, food matrix, cyclic compression, and expansion of material can occur—such behavior is called sponge effect and it can lead to the formation of micro-channels, which facilitate mass transfer between the treated material and its surroundings [15][16]. Ultrasound can be applied using direct and contact methods or indirectly using ultrasound baths [17]. In the case of drying, ultrasound can be used not only prior to drying, but also during the process [18].

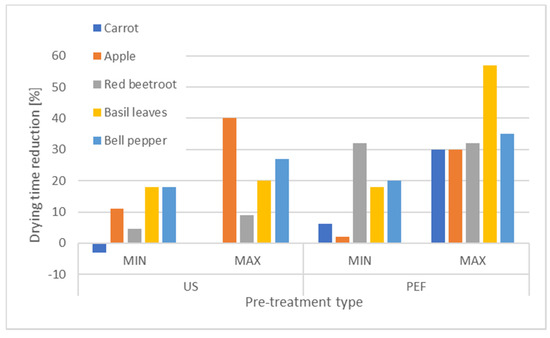

The literature about the effect of US on drying kinetics is ambiguous and the effects of pretreatment depend strongly on the food matrix (Figure 1). There are reports that indicate that sonication can reduce the drying time of apples by 11–40% in comparison to untreated material [19][20], and there are articles that demonstrate that US pretreatment has no effect on process course or that it can even extend drying, as it was reported for carrots [21].

Figure 1. Minimum (MIN) and maximum (MAX) air-drying time reductions for different food matrices as reported in the scientific literature for pulsed electric field (PEF) and ultrasound (US) pretreatment.

Moreover, drying kinetics seem to depend not only on the type of raw material but also on the parameters of US. The influence of sonication time is one of the most studied issues. It was found that the relation between the time of sonication and drying reduction is not linear. For instance, the sonication of 20 min of apple tissue reduced air drying better than the treatment of 30 min [20]. Similar findings were reported for other raw materials, such as pineapples or parsley leaves [21][22].

The possibility of process intensification by sonication was also exemplified by other drying methods, such as microwave-assisted air drying or vacuum drying. It has been demonstrated that microwave and ultrasound-assisted air drying reduced processing time by 79% in comparison to traditional, convection processes. In addition, samples produced with the assistance of US exhibited higher porosity and better reconstitution properties than untreated material [23].

The vacuum drying of nectarine with sonication was 50% shorter than the control process, plus US treated samples demonstrated higher retention of phenols and smaller changes in color. The authors of this study stated that there is a synergistic effect of vacuum drying and ultrasound treatment [24]. The positive addition of ultrasound during drying on rehydration and color retention was also demonstrated for purple-fleshed potatoes [25].

2.2. Pulsed Electric Fields

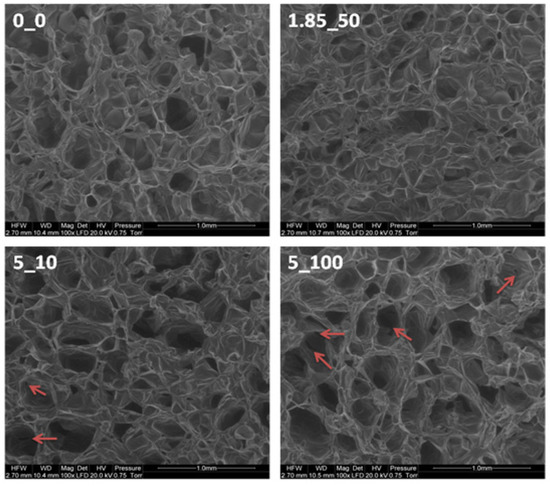

Pulsed electric field (PEF) is an electron-based technology since it involves electric fields for its application. PEF treatment of food depends on the exposition of material into short-lasting pulses characterized by high electric field intensity that varies from 0.1 to 50 kVcm−1, depending on the desired technological effect [26][27]. PEF treatment results in a rupture of cell membrane continuity due to a phenomenon and a process of electroporation [28]. The electroporation can be irreversible or reversible depending on the induced transmembrane potential of the cell that is treated, which in turn depends on many different factors. Among them are the cell diameter and external electric field, which are the most important [29]. Figure 2 presents the SEM images of apple tissue treated by PEF at different parameters with indicated ruptures in cellular structure.

Figure 2. SEM images of untreated (0_0) and PEF treated (1.85_50—E = 1.85 kV cm−1, n = 50 pulses; 5_10—E = 5 kV cm−1, n = 10 pulses; 5_100—E = 5 kV cm−1, n = 100 pulses) fresh apple tissue. Red arrows indicate the damages and ruptures in cell structure. Magnification of × 100. E—electric field intensity of applied PEF [kV cm−1]; n—number of pulses. Source: own elaboration, unpublished data.

The majority of PEF applications in food processing involves irreversible electroporation. Such PEF treatment can be used to enhance extraction, juice pressing, freezing, osmotic dehydration, or drying [30]. However, there are some data that demonstrated that reversible electroporation could also be applied for the improvement of drying [31]. It is worth noting that the effectiveness of PEF treatment has been proved on an industrial scale for winemaking, juice preservation or potato processing [32][33][34].

As a contrast to ultrasound, the vast majority of scientific publications show that PEF pretreatment facilitates mass transfer during drying. Drying reduction by PEF prior to water removal varies from 2% to 57% in comparison to untreated material, as it was reported for apples and basil leaves, respectively (Figure 3). The effect of PEF on drying depends on many different factors that are related to the material properties and processing parameters: electric field intensity, energy input, number of pulses, pulse width, and geometry or drying methods [35].

For instance, the intensification of drying depends on the cell disintegration index (CDI) of the material (which varies from 0 to 1, for untreated and hypothetical totally disintegrated samples). Here, the effective water diffusion coefficient of apples subjected to air-drying was equal to 1.044, 1.090, and 1.252 m2 s−1, for untreated samples, samples with CDI = 0.33 and with CDI = 0.88, respectively [36].

A higher water diffusion coefficient of PEF pretreated samples was also reported by Ostermeier et al. [37] for the two-step convective drying of onion tissue. Further, PEF treatment was also characterized by 14.5% higher pyruvic acid content and a 47% higher rehydration coefficient.

The exposition of the material to PEF treatment was also demonstrated as an efficient method for freeze-drying improvements. Wu et al. [38] reported that the application of 30 pulses at an electric field intensity of 1 kV cm−1 reduced the freeze-drying time by 22.5% in comparison to untreated apples. The higher reduction in freeze-drying time of 31.5%, as compared to intact material, was reported for potatoes treated by 45 pulses at 1.5 kV cm−1. A very interesting approach for the utilization of PEF in the freeze-drying process was demonstrated by Lammerskitten et al. [39]. In this case, the authors did not freeze the apple slices before freeze-drying using a freezer, rather the freezing occurred inside the freeze-drying chamber as a result of a pressure drop during the initial phases of freeze-drying. Such treated material kept its original shape (low drying shrinkage) and it was characterized by a high crunchiness index, high porosity, and had similar chemical properties to the untreated material [40]. Similar findings were also reported by Fauster et al. [41] for freeze-dried strawberries and bell peppers. Some of the research papers indicated that PEF can also improve vacuum drying, similar to how it improves air and freeze-drying. As it has been reported by Liu et al. [42], PEF pretreatment of carrots reduced vacuum drying time by 33–55% and improved the retention of carotenoids.

Although the number of publications in the field of PEF and drying is growing, the research should also focus on the combination of PEF with other unconventional drying methods, such as infrared drying or microwave vacuum drying. Although some of the drying techniques in combination with PEF are well tested, optimization studies, using advanced experimental planning methods, are needed. Such an approach could address the questions related to the potential modification of drying parameters, such as temperature, in order to get the best possible quality and economic outcomes. Moreover, there is a gap in knowledge about the effectiveness of PEF pretreatment before drying for pilot and industrial-scale processes enhancement and the sustainability aspects of its utilization.

2.3. High Hydrostatic Pressure

High hydrostatic pressure (high pressure processing, HHP, HPP) is one of the oldest and most popular non-thermal food processing methods. However, it is used mainly for preservation purposes since it inactivates microorganisms but keeps low molecular weight substances (like vitamins) intact. HHP is also used on an industrial scale. It has been reported that in 2015, more than 300 units of HHP were operating all over the world [43]. The utilization of HHP, like PEF or US, can also modify the cell membrane permeability, and thus it can enhance water transfer during dehydration processes [44]. HHP pretreatment has been demonstrated to reduce the drying time of vegetables such as carrots, green beans, and potatoes [45] or fruits such as apples [46][47] and pineapples [48]. This method has also been demonstrated as effective in the intensification of drying of ginger—processes preceded by HHP treatment (10 min, 100–400 MPa) were characterized by much higher moisture diffusivity (2.84–6.09 × 10−9 m2 s−1) than the reference operation (2.03–4.87 × 10−9 m2 s−1). Moreover, HHP pretreatment also increased the extractability of oleoresin and 6-gingerol from dried material [49]. HHP pretreatment has also been reported to increase the antioxidant activity of osmodehydrated strawberries [50]. However, the effect of HHP treatment applied prior to drying depends on the quality changes of dried material and depends strongly on matrix type. It has been reported that HHP may result in undesirable color changes like the darkening of tissue, as it has been reported in the case of garlic [51]. One of the main drawbacks of HHP treatment is the cost of the processing and batch (or quasi-continuous) operating mode. Some studies report the costs of HHP to be three times higher than the costs of PEF treatment [52].

2.4. Cold Plasma

Plasma is considered as a fourth, quasi-neutral, like gas, state of matter. It is, in fact, an ionized gas which is a mixture of anions and cations, electrons, free radicals, molecules in an excited state, and non-ionized molecules [53]. The presence of very active chemical molecules, such as free radicals or reactive oxygen species, makes plasma a potential tool for the decontamination of food and food contact surfaces. Indeed, most of the literature data about possible plasma utilization in food processing deal with preservation and microbial quality [54]. However, plasma application can also modify the surface properties of materials subjected for treatment, like some of the polymers [55]. The modification of the surface by cold plasma treatment was also reported for food products, such as black pepper seeds [56]. Recently, cold plasma has been reported as a pretreatment method for drying enhancement. Such an approach is related to the aforementioned possibility of modification of the surface and structure by plasma application by the physical and chemical processes—plasma can etch large cavities into the structure of the material, which facilitates subsequent moisture removal during drying [57]. The time of wolfberry drying was reduced by 50% when processes were preceded by cold plasma treatment. Moreover, the plasma-treated dried material exhibited better reconstitution properties and higher retention of phenolics in comparison to the untreated material. The authors of this study stated that in addition to the alteration of the surface, the cellular structure was disintegrated as well due to cold plasma treatment [58]. The acceleration of drying by cold plasma treatment has also been reported for shitake mushroom [59] or corn kernel [60] drying. Nevertheless, the data about the impact of plasma radiation of food before drying are limited, but the method seems to be very promising, especially for the facilitation of drying of peel containing raw materials such as chili pepper [61]. Moreover, since plasma consists of very reactive chemical molecules, research should also focus on the chemical property changes and safety aspects of such treated food. Another important issue related to the utilization of this method is the possibility of its scale-up ability.

3. Conclusions

Drying provides extended shelf life, reduced transportation costs, and minimized losses for various foods, and it is an indispensable part of the food processing industry around the world. Recent literature is focused on applying advanced technologies for drying intensification to improve conventional drying performances with respect to product quality and energy savings. Combinations of drying methods/hybrid drying and advanced pretreatments are useful for optimal results for both product quality and environmental impacts. Therefore, the right selection of drying methods and mathematical optimizations (modeling) of the process can reduce energy consumption, operational costs and provide superior quality products. Thermal drying techniques, such as hot air, have significant adverse effects on shrinkage, color, and textural properties, but they are economic. Furthermore, microwaves due to the volumetric effect increase drying rate and reduce drying time and energy consumption, with the final quality close to hot air drying. Introducing vacuuming during drying will cause the avoidance of thermal and oxidative stress, with positive repercussions on product quality. In conclusion, combinations of advanced and conventional techniques have the potential to overcome inherited disadvantages of single technologies, while improving the economic outlook of food manufacturing.

References

- Orsat, V.; Changrue, V.; Raghavan, G.S.V. Microwave drying of fruits and vegetables. Stewart Postharvest Rev. 2006, 2, 1–7.

- Ratti, C. Advances in Food Dehydration. In Dehydration of Foods; Araya-Farias, M., Ratti, C., Eds.; CRC Press: Boca Raton, FL, USA, 2009.

- Mercer, D.G. An Introduction to the Dehydration and Drying of Fruits and Vegetables; University of Guelph: Guelph, ON, Canada, 2014; p. 166.

- Chua, K.J.; Chou, S.K. Low-cost drying methods for developing countries. Trends Food Sci. Tech. 2003, 14, 519–528.

- Çoklar, H.; Akbulut, M. Effect of sun, oven and freeze-drying on anthocyanins, phenolic compounds and antioxidant activity of black grape (Ekşikara) (Vitis vinifera L.). S. Afr. J. Enol. Vitic. 2017, 38, 264–272.

- Deng, L.-Z.; Mujumdar, A.S.; Zhang, Q.; Yang, X.-H.; Wang, J.; Zheng, Z.-A.; Gao, Z.-J.; Xiao, H.-W. Chemical and physical pretreatments of fruits and vegetables: Effects on drying characteristics and quality attributes–a comprehensive review. Crit. Rev. Food Sci. 2017, 59, 1408–1432.

- Mujumdar, A.S.; Devahastin, S. Fundamental principles of drying. In Guide to Industrial Drying; Mujumdar, A.S., Ed.; Universiti Kebangsaan Malaysia: Hyderabad, India, 2008.

- Chen, X.D.; Mujumdar, A.S. Food Processing; Blackwell Publishing: West Sussex, UK, 2008.

- Sobukola, O.P.; Dairo, O.U.; Odunewu, A.V. Convective hot air drying of blanched yam slices. Int. J. Food Sci. Technol. 2008, 43, 1233–1238.

- Doymaz, İ. Influence of blanching and slice thickness on drying characteristics of leek slices. Chem. Eng. Process. 2008, 47, 41–47.

- Witrowa-Rajchert, D.; Wiktor, A.; Sledz, M.; Nowacka, M. Selected emerging technologies to enhance the drying process: A review. Dry. Technol. 2014, 32, 1386–1396.

- Tao, Y.; Sun, D.-W. Enhancement of food processes by ultrasound: A review. Crit. Rev. Food Sci. 2014, 55, 570–594.

- Ashokkumar, M. Applications of ultrasound in food and bioprocessing. Ultrason. Sonochem. 2015, 25, 17–23.

- Wu, J.; Nyborg, W.L. Ultrasound, cavitation bubbles and their interaction with cells. Adv. Drug Deliv. Rev. 2008, 60, 1103–1116.

- de la Fuente-Blanco, S.; de Sarabia, E.R.-F.; Acosta-Aparicio, V.M.; Blanco-Blanco, A.; Gallego-Juárez, J.A. Food drying process by power ultrasound. Ultrasonics 2006, 44, e523–e527.

- Miano, A.C.; Ibarz, A.; Augusto, P.E.D. Mechanisms for improving mass transfer in food with ultrasound technology: Describing the phenomena in two model cases. Ultrason. Sonochem. 2016, 29, 413–419.

- Gere, A.; Radványi, D.; Héberger, K. Which insect species can best be proposed for human consumption? Innov. Food Sci. Emerg. 2019, 52, 358–367.

- Musielak, G.; Mierzwa, D.; Kroehnke, J. Food drying enhancement by ultrasound–A review. Trends Food Sci. Tech. 2016, 56, 126–141.

- Magalhães, M.L.; Cartaxo, S.J.M.; Gallão, M.I.; García-Pérez, J.V.; Cárcel, J.A.; Rodrigues, S.; Fernandes, F.A.N. Drying intensification combining ultrasound pre-treatment and ultrasound-assisted air drying. J. Food Eng. 2017, 215, 72–77.

- Nowacka, M.; Wiktor, A.; Śledź, M.; Jurek, N.; Witrowa-Rajchert, D. Drying of ultrasound pretreated apple and its selected physical properties. J. Food Eng. 2012, 113, 427–433.

- Nowacka, M.; Wedzik, M. Effect of ultrasound treatment on microstructure, colour and carotenoid content in fresh and dried carrot tissue. Appl. Acoust. 2016, 103, 163–171.

- Śledź, M.; Nowak, P.; Witrowa-Rajchert, D. Drying of parsley leaves pre-treated by ultrasound. ZPPNR 2014, 579, 91–99.

- Szadzińska, J.; Łechtańska, J.; Pashminehazar, R.; Kharaghani, A.; Tsotsas, E. Microwave- and ultrasound-assisted convective drying of raspberries: Drying kinetics and microstructural changes. Dry. Technol. 2018, 37, 1–12.

- da Silva, E.S.; Brandão, S.C.R.; da Silva, A.L.; da Silva, J.H.F.; Coêlho, A.C.D.; Azoubel, P.M. Ultrasound-assisted vacuum drying of nectarine. J. Food Eng. 2019, 246, 119–124.

- Liu, Y.; Sun, Y.; Yu, H.; Yin, Y.; Li, X.; Duan, X. Hot air drying of purple-fleshed sweet potato with contact ultrasound assistance. Dry. Technol. 2016, 35, 564–576.

- Timmermans, R.A.H.; Mastwijk, H.C.; Berendsen, L.B.J.M.; Nederhoff, A.L.; Matser, A.M.; Van Boekel, M.A.J.S.; Groot, M.N. Moderate intensity Pulsed Electric Fields (PEF) as alternative mild preservation technology for fruit juice. Int. J Food Microbiol. 2019, 298, 63–73.

- Kayalvizhi, V.; Pushpa, A.J.S.; Sangeetha, G.; Antony, U. Effect of pulsed electric field (PEF) treatment on sugarcane juice. J. Food Sci. Technol. 2016, 53, 1371–1379.

- Weaver, J.C.; Chizmadzhev, Y.A. Theory of electroporation: A review. Bioelectrochem. Bioenerg. 1996, 41, 135–160.

- Kotnik, T.; Frey, W.; Sack, M.; Meglič, S.H.; Peterka, M.; Miklavčič, D. Electroporation-based applications in biotechnology. Trends Biotechnol. 2015, 33, 480–488.

- Barba, F.J.; Parniakov, O.; Pereira, S.A.; Wiktor, A.; Grimi, N.; Boussetta, N.; Saraiva, J.A.; Raso, J.; Martin-Belloso, O.; Witrowa-Rajchert, D.; et al. Current applications and new opportunities for the use of pulsed electric fields in food science and industry. Food Res. Int. 2015, 77, 773–798.

- Thamkaew, G.; Galindo, F.G. Influence of pulsed and moderate electric field protocols on the reversible permeabilization and drying of Thai basil leaves. Innov. Food Sci. Emerg. 2020, 64, 102430.

- Maza, M.; Álvarez, I.; Raso, J. Thermal and Non-Thermal Physical Methods for Improving Polyphenol Extraction in Red Winemaking. Beverages 2019, 5, 47.

- Min, S.; Jin, Z.T.; Zhang, Q.H. Commercial scale pulsed electric field processing of tomato juice. J. Agric. Food Chem. 2003, 51, 3338–3344.

- Fauster, T.; Schlossnikl, D.; Rath, F.; Ostermeier, R.; Teufel, F.; Toepfl, S.; Jaeger, H. Impact of pulsed electric field (PEF) pretreatment on process performance of industrial French fries production. J. Food Eng. 2018, 235, 16–22.

- Wiktor, A.; Singh, A.P.; Parniakov, O.; Mykhailyk, V.; Mandal, R.; Witrowa-Rajchert, D. PEF as an alternative tool to prevent thermolabile compound degradation during dehydration processes. In Pulsed Electric Fields to Obtain Healthier and Sustainable Food for Tomorrow; Barba, F., Parniakov, O., Wiktor, A., Eds.; Academic Press: London, UK, 2020; pp. 155–202.

- Wiktor, A.; Nowacka, M.; Dadan, M.; Rybak, K.; Lojkowski, W.; Chudoba, T.; Witrowa-Rajchert, D. The effect of pulsed electric field on drying kinetics, color, and microstructure of carrot. Dry. Technol. 2015, 34, 1286–1296.

- Ostermeier, R.; Parniakov, O.; Töpfl, S.; Jäger, H. Applicability of pulsed electric field (PEF) pre-treatment for a convective two-step drying process. Foods 2020, 9, 512.

- Wu, Y.; Guo, Y.; Zhang, D. Study of the effect of high-pulsed electric field treatment on vacuum freeze-drying of apples. Dry. Technol. 2011, 29, 1714–1720.

- Lammerskitten, A.; Mykhailyk, V.; Wiktor, A.; Toepfl, S.; Nowacka, M.; Bialik, M.; Czyżewski, J.; Witrowa-Rajchert, D.; Parniakov, O. Impact of pulsed electric fields on physical properties of freeze-dried apple tissue. Innov. Food Sci. Emerg. 2019, 57, 57.

- Lammerskitten, A.; Wiktor, A.; Siemer, C.; Toepfl, S.; Mykhailyk, V.; Gondek, E.; Rybak, K.; Witrowa-Rajchert, D.; Parniakov, O. The effects of pulsed electric fields on the quality parameters of freeze-dried apples. J. Food Eng. 2019, 252, 36–43.

- Fauster, T.; Giancaterino, M.; Pittia, P.; Jaeger, H. Effect of pulsed electric field pretreatment on shrinkage, rehydration capacity and texture of freeze-dried plant materials. LWT 2020, 121, 108937.

- Liu, C.; Pirozzi, A.; Ferrari, G.; Vorobiev, E.; Grimi, N. Effects of pulsed electric fields on vacuum drying and quality characteristics of dried carrot. Food Bioprocess. Tech. 2019, 13, 45–52.

- Huang, H.-W.; Wu, S.-J.; Lu, J.-K.; Shyu, Y.-T.; Wang, C.-Y. Current status and future trends of high-pressure processing in food industry. Food Control. 2017, 72, 1–8.

- Rastogi, N.K.; Angersbach, A.; Knorr, D. Synergistic effect of high hydrostatic pressure pretreatment and osmotic stress on mass transfer during osmotic dehydration. J. Food Eng. 2000, 45, 25–31.

- Eshtiaghi, M.N.; Stute, R.; Knorr, D. High-pressure and freezing pretreatment effects on drying, rehydration, texture and color of green beans, carrots and potatoes. J. Food Sci. 1994, 59, 1168–1170.

- Janowicz, M.; Lenart, A. The impact of high pressure and drying processing on internal structure and quality of fruit. Eur. Food Res. Technol. 2018, 244, 1329–1340.

- Yucel, U.; Alpas, H.; Bayindirli, A. Evaluation of high pressure pretreatment for enhancing the drying rates of carrot, apple, and green bean. J. Food Eng. 2010, 98, 266–272.

- Kingsly, A.R.P.; Balasubramaniam, V.M.; Rastogi, N.K. Effect of high-pressure processing on texture and drying behavior of pineapple. J. Food Process. Eng. 2009, 32, 369–381.

- George, J.M.; Sowbhagya, H.B.; Rastogi, N.K. Effect of high pressure pretreatment on drying kinetics and oleoresin extraction from ginger. Dry. Technol. 2017, 36, 1107–1116.

- Núñez-Mancilla, Y.; Vega-Gálvez, A.; Pérez-Won, M.; Zura, L.; García-Segovia, P.; Di Scala, K. Effect of osmotic dehydration under high hydrostatic pressure on microstructure, functional properties and bioactive compounds of strawberry (Fragaria Vesca). Food Bioprocess. Tech. 2013, 7, 516–524.

- Kim, K.W.; Kim, Y.-T.; Kim, M.; Noh, B.-S.; Choi, W.-S. Effect of high hydrostatic pressure (HHP) treatment on flavor, physicochemical properties and biological functionalities of garlic. LWT Food Sci. Technol. 2014, 55, 347–354.

- Sampedro, F.; McAloon, A.; Yee, W.; Fan, X.; Geveke, D.J. Cost analysis and environmental impact of pulsed electric fields and high pressure processing in comparison with thermal pasteurization. Food Bioprocess. Tech. 2014, 7, 1928–1937.

- Pankaj, S.K.; Bueno-Ferrer, C.; Misra, N.N.; Milosavljević, V.; O’Donnell, C.P.; Bourke, P.; Keener, K.M.; Cullen, P.J. Applications of cold plasma technology in food packaging. Trends Food Sci. Tech. 2014, 35, 5–17.

- Niemira, B.A. Cold plasma decontamination of foods. Annu. Rev. Food Sci. Technol. 2012, 3, 125–142.

- Encinas, N.; Abenojar, J.; Martínez, M.A. Development of improved polypropylene adhesive bonding by abrasion and atmospheric plasma surface modifications. Int. J. Adhes. Adhes. 2012, 33, 1–6.

- Wiktor, A.; Hrycak, B.; Jasiński, M.; Rybak, K.; Kieliszek, M.; Kraśniewska, K.; Witrowa-Rajchert, D. Impact of atmospheric pressure microwave plasma treatment on quality of selected spices. Appl. Sci. 2020, 10, 6815.

- Bao, T.; Hao, X.; Shishir, M.R.I.; Karim, N.; Chen, W. Cold plasma: An emerging pretreatment technology for the drying of jujube slices. Food Chem. 2021, 337, 127783.

- Zhou, Y.-H.; Vidyarthi, S.K.; Zhong, C.-S.; Zheng, Z.-A.; An, Y.; Wang, J.; Wei, Q.; Xiao, H.-W. Cold plasma enhances drying and color, rehydration ratio and polyphenols of wolfberry via microstructure and ultrastructure alteration. LWT 2020, 134, 110173.

- Shishir, M.R.I.; Karim, N.; Bao, T.; Gowd, V.; Ding, T.; Sun, C.; Chen, W. Cold plasma pretreatment–A novel approach to improve the hot air drying characteristics, kinetic parameters, and nutritional attributes of shiitake mushroom. Dry. Technol. 2019, 38, 2134–2150.

- Li, S.; Chen, S.; Han, F.; Xv, Y.; Sun, H.; Ma, Z.; Chen, J.; Wu, W. Development and optimization of cold plasma pretreatment for drying on corn kernels. J. Food Sci. 2019, 84, 2181–2189.

- Zhang, X.-L.; Zhong, C.-S.; Mujumdar, A.S.; Yang, X.-H.; Deng, L.-Z.; Wang, J.; Xiao, H.-W. Cold plasma pretreatment enhances drying kinetics and quality attributes of chili pepper (Capsicum annuum L.). J. Food Eng. 2019, 241, 51–57.