| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Helmut Schift | -- | 1114 | 2025-11-25 10:00:57 | | | |

| 2 | Abigail Zou | Meta information modification | 1114 | 2025-11-25 10:01:45 | | |

Video Upload Options

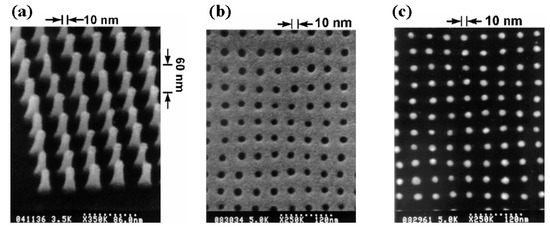

Nanoimprint lithography (NIL) is a high-resolution parallel patterning method based on molding. It has proven resolution down to the nanometer range and can be scaled up for large areas and high throughput. Its main characteristic is that the surface pattern of a mold is imprinted on a material that is displaced locally by using the difference in hardness of the mold and the moldable material, thus replicating its surface topography. This can be achieved by shaping a thermoplastic film by heating and cooling (T-NIL) or a photosensitive resin followed by a curing process for hardening (UV-NIL). In lithography, the local thickness contrast of the thin molded film can be used as a masking layer to transfer the pattern onto the underlying substrate. Therefore, NIL will be an alternative in fields in which electron-beam lithography and photolithography do not provide sufficient resolution at reasonable throughput. Direct imprint enables applications where a modified functional surface is needed without pattern transfer. NIL is currently used for high-volume manufacturing in different applications, like patterned sapphire substrates, wire grid polarizers, photonic devices, lightguides for AR/VR devices, metalenses, and biosensors for DNA analysis, and is being tested for semiconductor integrated circuit chips.

-

It imprints extremely thin polymer films, which result in residual layers of a few nm thickness and can be removed by anisotropic reactive ion etching [1].

References

- Heyderman, L.J.; Schift, H.; David, C.; Gobrecht, J.; Schweizer, T. Flow behaviour of thin polymer films used for hot embossing lithography. Microelectron. Eng. 2000, 54, 229–245.

- Schift, H. Nanoimprint lithography: An old story in modern times? A review. J. Vac. Sci. Technol. B 2008, 26, 458–480.

- Schift, H.; Kristensen, A. Nanoimprint lithography—Patterning resists using molding. In Handbook of Nanotechnology, 3rd ed.; Bhushan, B., Ed.; Springer: Berlin/Heidelberg, Germany, 2010; Chapter Part A/9; pp. 271–312. Available online: https://link.springer.com/chapter/10.1007/978-3-642-02525-9_9 (accessed on 7 July 2025).

- Schift, H.; Kristensen, A. Nanoimprint lithography—Patterning resists using molding. In Handbook of Nanotechnology, 4th ed.; Bhushan, B., Ed.; Springer: Berlin/Heidelberg, Germany, 2017; Chapter Part A/5; pp. 113–142.

- Resnick, D.; Schift, H. Nanoimprint lithography. In Microlithography—Science and Technology, 3rd ed.; Suzuki, K., Smith, B.W., Eds.; CRC Press: Boca Raton, FL, USA, 2020; Chapter 12; pp. 595–678.

- International Conference on Nanoimprint and Nanoprint (NNT). Available online: http://www.nntconf.org (accessed on 7 July 2025).

- Fujimori, S. Fine pattern fabrication by the molded mask method (nanoimprint lithography) in the 1970s. Jpn. J. Appl. Phys. 2009, 48, 06FH01.

- Chou, S.Y.; Kraus, P.R.; Renstrom, P.J. Imprint of sub-25 nm vias and trenches in polymers. Appl. Phys. Lett. 1995, 67, 3114–3116.

- Chou, S.Y.; Kraus, P.R.; Zhang, W.; Guo, L.; Zhuang, L. Sub-10 nm imprint lithography and applications. J. Vac. Sci. Technol. B 1997, 15, 2897–2903.

- Haisma, J.; Verheijen, M.; van den Heuvel, K.; van den Berg, J. Mold-assisted lithography: A process for reliable pattern replication. J. Vac. Sci. Technol. B 1996, 14, 4124–4128.

- Huang, G.T. 10 Emerging Technologies That Will Change the World. In MIT Technology Review; Technology Review Inc.: Cambridge, MA, USA, 2003; Available online: https://www.technologyreview.com/10-breakthrough-technologies/2003/ (accessed on 7 July 2025).

- Hua, F.; Sun, Y.; Gaur, A.; Meitl, M.A.; Bilhaut, L.; Rotkina, L.; Wang, J.; Geil, P.; Shim, M.; Rogers, J.A.; et al. Polymer imprint lithography with molecular-scale resolution. Nano Lett. 2004, 4, 2467–2471.

- Tan, G.; Nozawa, Y.; Funabasama, T.; Koyama, K.; Mita, M.; Kaneko, S.; Komura, M.; Matsuda, A.; Yoshimoto, M. Atomic-scale thermal behavior of nanoimprinted 0.3 nm high step patterns on PMMA polymer sheets. Polym. J. 2016, 48, 225–227.

- Chou, S.Y.; Keimel, C.; Gu, J. Ultrafast and direct imprint of nanostructures in silicon. Nature 2002, 417, 835–837.

- Tormen, M.; Sovernigo, E.; Pozzato, A.; Pianigiani, M.; Tormen, M. Sub-100 μs nanoimprint lithography at wafer scale. Microelectron. Eng. 2015, 141, 21–26.

- Schift, H. Nanoimprint lithography: 2D or not 2D? A review. Appl. Phys. A 2015, 121, 415–435.

- Becker, E.W.; Ehrfeld, W.; Hagmann, P.; Maner, A.; Münchmeyer, D. Fabrication of microstructures with high aspect ratios and great structural heights by synchrotron radiation lithography, galvanoforming and plastic molding (LIGA process). Microelectron. Eng. 1986, 4, 35–56.

- Gale, M.T. Replication techniques for diffractive optical elements. Microelectron. Eng. 1997, 34, 321–339.

- Schift, H.; David, C.; Gabriel, M.; Gobrecht, J.; Heyderman, L.J.; Kaiser, W.; Köppel, S.; Scandella, L. Nanoreplication in polymers using hot embossing and injection molding. Microelectron. Eng. 2000, 53, 171–174.

- Heckele, M.; Schomburg, W.K. Review on micro molding of thermoplastic polymers. J. Micromech. Microeng. 2004, 14, R1–R14.