Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | David Mendonça Dias | -- | 2669 | 2024-07-11 20:37:16 |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Dias, D.M.; Resende, P.R.; Afonso, A.M. Classification of Micro-Flame Behaviours. Encyclopedia. Available online: https://encyclopedia.pub/entry/56762 (accessed on 07 February 2026).

Dias DM, Resende PR, Afonso AM. Classification of Micro-Flame Behaviours. Encyclopedia. Available at: https://encyclopedia.pub/entry/56762. Accessed February 07, 2026.

Dias, David M., Pedro R. Resende, Alexandre M. Afonso. "Classification of Micro-Flame Behaviours" Encyclopedia, https://encyclopedia.pub/entry/56762 (accessed February 07, 2026).

Dias, D.M., Resende, P.R., & Afonso, A.M. (2024, July 11). Classification of Micro-Flame Behaviours. In Encyclopedia. https://encyclopedia.pub/entry/56762

Dias, David M., et al. "Classification of Micro-Flame Behaviours." Encyclopedia. Web. 11 July, 2024.

Copy Citation

The microflame is a complex phenomenon that can exhibit different behaviors, which are influenced by multiple factors, such as the input velocity of the fuel–oxidizer mixture, the heat flow rate supplied to the mixture, the thermal conduction coefficient of the burner walls (i.e., boundary conditions), and the burner geometry, among others.

micro-scale combustion

flame dynamics

micro-propulsion

flame types

1. Flashback and Blow-Off

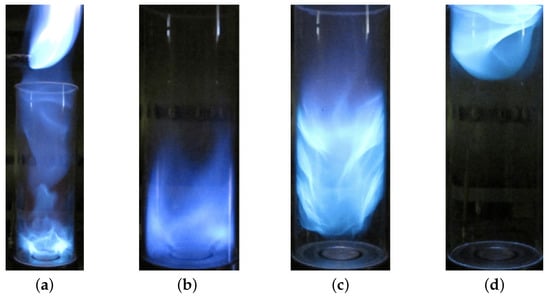

Premixed flames can experience situations where the reactant supply velocity exceeds or falls short of the flame speed, resulting in two possible scenarios for flame extinction [41,42], as observed in Figure 1:

-

Flashback: This occurs when the velocity of the reactants supplied to the burner chamber is lower than the flame speed. As a result, the flame propagates upstream towards the fuel injection system, burning the reactants in a zone increasingly upstream, possibly self-extinguishing (Combustion instability-induced flashback is connected to the phenomenon of the instantaneous axial flow velocity experiencing significant reductions, sometimes even reaching negative values, during large-amplitude oscillations [43]).

-

Blow-off: In this scenario, the reactants’ supply velocity is higher than the flame speed. The flame moves along the channel, burning the reactants in a zone increasingly downstream until it “blows off” (possibly self-extinguishing) when the fuel flow rate exceeds a certain limit.

Figure 1. Flashback and blow-off for flames with fixed swirl: (a) flashback; (b) before flashback; (c) stable flame; (d) after blow-off [42].

The research paper by Fruzza et al. [44] studies the flashback of different H2/CH4 mixtures and uses 2D unsteady simulations with detailed kinetics and considers the fundamental role of the combustor wall by considering the Conjugate Heat Transfer. Different flashback regimes were studied for different H2 contents which highlights the significant difference between the critical flashback velocity and laminar flame speed at high H2 contents. This work was recently extended by Fruzza et al. [45], in which the authors coupled the numerical simulations with stochastic sensitivity analysis based on Generalized Polynomial Chaos, which allowed for the construction of a set of comprehensive maps for flashback velocities and burner temperatures for the parametric space of H2 content, equivalence ratio, and slit width.

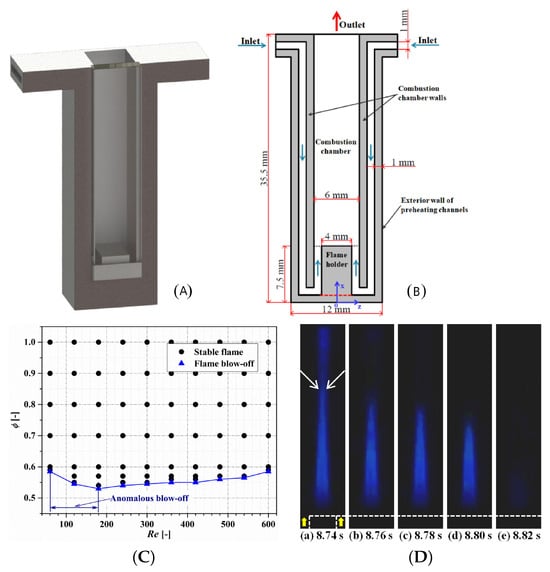

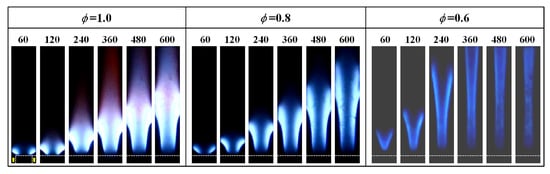

Recently, Cai et al. [46] performed an experimental study on the the the flame dynamics of CH4-air within a micro-combustor with a flame holder and preheating channels. In addition to stable flame results, different types of blow-off dynamics were also presented, including anomalous blow-off dynamics at lower Reynolds numbers and fuel ultra-lean conditions, as observed in the stability maps presented in Figure 2B. It is found that, in these anomalous blow-off dynamics, the middle of the flame in the vertical direction presents a constricted shape, and that a flame with local extinction and reignition occurs periodically (see Figure 2C).

Figure 2. Flame stability and blow-off dynamics for micro-combustion with a flame holder and preheating channels: (A) three-dimensional view of the burner; (B) cross-section drawn; (C) stability map; (D) blow-off dynamics [46].

2. Steady vs. Non-Steady Flames

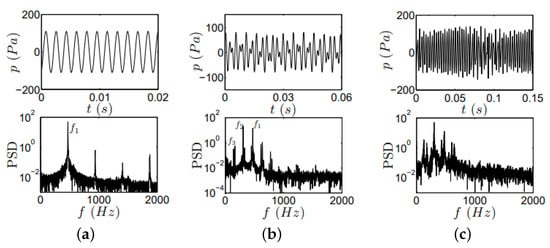

Combustion can be classified as steady or non-steady/unsteady, which can be latter divided into periodic, quasi-periodic, and chaotic. Non-steady flames show fluctuations in their behavior, such as changes in their burning rate or flame shape that happen over time, in contrast to steady flames, which keep a consistent burning pace [47].

As illustrated in Figure 3, non-steady flames can exhibit different types of dynamics, including periodic, quasi-periodic, and chaotic behavior [48]:

-

Periodic flames, which are characterized by fluctuations in their behavior that occur periodically over time, in a constant pattern, Figure 3a;

-

Quasi-periodic flames, in which the oscillations present irregular periodicity and recurrence are observed, Figure 3b;

-

Chaotic combustion, which can occur when steady combustion waves lose stability and transition to non-steady chaotic burning, exhibiting highly irregular and unpredictable behavior, Figure 3c.

The transition from steady to non-steady burning can be predicted using the nonlinear stability theory [47].

Figure 3. Time-spectrum (up) and power series (down) for different non-steady combustion modes in ducted premixed flames: (a) periodic; (b) quasi-periodic; (c) haotic [49].

3. Mild Combustion

Mild combustion, also called flameless combustion, is a combustion mode that is distinguished by a relatively small temperature rise and an incomplete but considerable fuel conversion. It is generally observed at low inflow velocities and exhibits an axisymmetric shape. This mode has been identified in numerous research studies, and is typically characterized by the lack of a distinct temperature peak, as documented in [50]. It is a potentially beneficial flame type for applications requiring a weak heat source in microsystems.

On the other hand, the combustion process is contingent upon two critical factors [51,52]: the reactants must be preheated above the temperature at which they will self-ignite, and enough inert combustion products must be incorporated into the reaction area to saturate the flame. Furthermore, it is noteworthy to mention High Temperature Air Combustion, a technique that often leads to mild combustion scenarios, characterized by the synergistic utilization of highly preheated air and exhaust gas recirculation (EGR) in furnaces, resulting in high thermal efficiency and low NOx emissions [53,54].

The phenomenon of interest was first observed in micro-scale systems in Maruta et al. [55]. The authors conducted a comprehensive investigation into the combustion characteristics of such systems employing experimental, numerical, and analytical techniques. Specifically, a narrow cylindrical quartz channel with a fixed temperature gradient was utilized, possessing an inner diameter of 2 [mm]. For sufficiently low velocities in the range of 2–3 [cm/s], it was observed that a sharp temperature gradient did not form between the chamber’s walls and the gas phase. The article by Pizza et al. [56] explored the combustion modes that occur in the three-dimensional combustion of premixed hydrogen and air in open cylindrical microtubes with the wall temperature controlled by gradually increasing it from the temperature of the incoming mixture �in to a final value of 960 [K] over the initial 1/20 length of the domain. This was achieved by applying a hyperbolic tangent function to smoothly ramp up the wall temperature. The researchers identified a particular type of mild combustion in both narrow and wider tubes with diameters of 1.0 [mm] and 1.5 [mm], respectively, when using the lowest air inlet velocities, which were 0.5 [cm·s−1]≤�in≤1.0 [cm·s−1]. The maximum temperature increase ranged from 1.5 [K] and 2.5 [K] (for �in of 0.5 [cm·s−1] to 1.0 [cm·s−1], respectively).

The findings were consistent with the antecedent investigations conducted by the authors in their prior 2D study [57], wherein the phenomenon of mild combustion was also observed for low inlet velocities. The authors examined the dynamics of premixed hydrogen/air flames in a microchannel that is confined between two parallel, infinitely wide plates, and maintained a constant length-to-height aspect ratio of �/ℎ = 10 [−].

4. Stable Flames

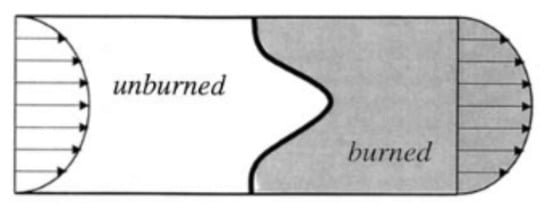

Upon initiation of combustion, the flame undergoes movement either upstream or downstream before stabilizing at a particular location on the burner, as reported numerically by several studies [58,59] and experimentally observed in Maruta et al. [55]. This constitutes the simplest form of micro-flame behavior and is illustrated schematically in Figure 4.

Figure 4. Schematic representation of a stable micro-flame [35].

Typically, flames of this type exhibit a reduction in flame temperature as inlet velocity increases, which can impact heat transfer to the wall [60]. Additionally, distinct velocity profiles can influence flame propagation and structure [61]. As seen in Norton et al. [62], an increase in inlet velocity necessitates a greater distance for incoming gases to preheat, leading to downstream stabilization of the flame. This stabilization results in higher wall temperatures at the flame location and lower heat losses, ultimately leading to increased reaction rates and elevated flame temperatures, exceeding the adiabatic flame temperature [60].

This phenomenon, which can exhibit symmetric and asymmetric characteristics (or both, depending on the axis, if in 3D settings), has been observed both numerically, as in the work of Lamione et al. [63], experimentally, and analytically in multiple studies such as Lewis and Von Elbe [34], Kurdyumov et al. [64,65], Dogwiller et al. [66], and Tsai [67]. The previously mentioned articles by Pizza et al. [56,57] and the experimental observations by Maruta et al. [50,55] also corroborate these findings since the phenomenon was also identified in these studies.

Cai et al. [46] obtained stable flame dynamics of CH4–air within a micro-combustor with a flame holder and preheating channels for non fuel ultra-lean conditions. The flame stability map is quite high, showing the importance of preheating the incoming unburned mixture. The results demonstrate that, in cases with a stable flame, the increasing Reynolds and equivalence ratios pushed the flame downstream, leading to a significant increase in the flame heigh, presenting a remarkable anchored effect of the flow recirculation, as observed Figure 5.

Figure 5. Stable flame dynamics of CH4–air within a micro-combustor with a flame holder for different Reynolds numbers and equivalence ratios [46].

5. FREI: Flames with Repetitive Extinction and Ignition

Flames with repetitive extinction and ignition (FREI) refer to a specific type of flame behavior characterized by the repeated extinguishing and reignition of the flame, and this phenomenon is observed in various systems, including micro flow reactors and lean premixed hydrogen–air combustion [1,68,69].

In the region characterized by the FREI phenomenon, a distinctive behavior of the flame is apparent: it ignites in a downstream region, propagates towards the unburned gases, and eventually extinguishes in an upstream region. Over the course of simulation, it becomes evident that the flame consistently occupies the same region, with the phenomenon recurring cyclically. Following ignition, the flame is transported through these vortices to an upstream position, ultimately leading to its cessation.

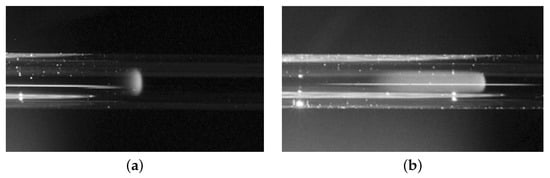

Maruta et al. [55] first captured experimentally FREI flames in a straight micro-channel. These flames exhibit cyclic behavior with luminescence starting at ignition, moving upstream to extinction, and then reigniting after a delay. This cyclic process, illustrated in Figure 6a contrasts with the stable flame behavior shown in Figure 6b. Furthermore, other experimental investigations established that the dynamics of FREI also manifest in curved mesoscale channels [70] and later in mesoscale cylindrical combustors featuring a backward-facing step [71].

Figure 6. Direct photographs of [55]: (a) stable flame; (b) FREI.

Numerous advancements in the computational field have been achieved by probing this phenomenon and utilizing lean hydrogen/air premixed flames, allowing for a better understanding of the FREI phenomena. Minaev et al. [72] provided a theoretical interpretation of FREI. They analyzed the non-stationary behavior of near-limit premixed flames in a microchannel with a temperature gradient. Their theoretical work resulted in a 1D nonlinear evolutionary equation for the flame front, explaining the flame stabilization, nonlinear oscillations, and repetitive extinction–ignition phenomena observed in the experiments. Later, Jackson et al. [73] numerically investigated FREI dynamics in a thermally active semi-infinite channel. They found stable solutions at specific flow rates, and instability leading to oscillations or extinction–reignition flames at higher flow rates, in alignment with experimental observations. The studies by Pizza et al., as mentioned earlier, observed FREI dynamics in planar micro combustors with prescribed wall temperatures at various channel heights [57] and also in 3D cylindrical microtubes [56]. Miyata et al. [74] performed direct numerical simulation to investigate FREI characteristics in a narrow circular channel, where they varied the wall temperature gradient and the inflow temperature in their study.

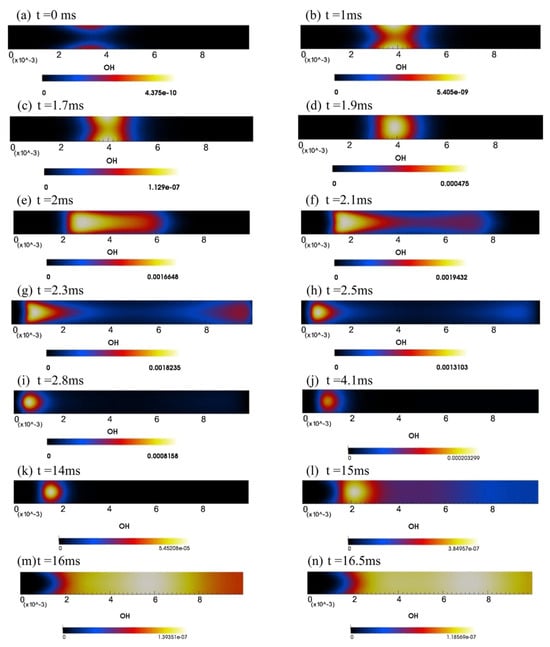

In a subsequent study, Alipoor and Mazaheri [68] scrutinized the FREI phenomenon through a singular simulation, affording a more intricate analysis of alternating extinction and ignition. In pursuit of this, contour maps of hydroxide radical (OH) concentrations were examined along the channel for various time instances, as shown in Figure 7. Furthermore, an investigation into heat release rate profiles, fluid and wall temperatures, the and molar concentrations of pertinent species central to the reaction was undertaken. Subsequently, flame bifurcation was evaluated from a hydrodynamic standpoint utilizing flow velocity vectors.

Figure 7. Repetitive extinction-ignition dynamics using hydroxide mass fraction (�OH) [68].

Subsequently, the same authors [75] delved into flames featuring equivalence ratios ranging from 0.5 up to the stoichiometric condition of �=1, in microchannels with widths spanning 0.4 to 1 mm. The accrued findings illustrated that augmentations to the equivalence ratio and burner width increased the amplitude of the FREI phenomenon while reducing its frequency. Furthermore, this examination illuminated that the phenomenon engenders fluid recirculation zones and flame bifurcation due to the presence of heavier species. These species exhibit an elevated heat absorption capacity, thereby inducing a temperature reduction.

Later, Alipoor and Mazaheri [76] conducted a comprehensive study concerning these flames within a heated microchannel possessing a hyperbolic temperature profile. Within this inquiry, three distinct flame behaviors were observed, including the FREI phenomenon. This phenomenon manifested under low velocities near the lower flammability limit. In pursuit of a deeper comprehension of the phenomenon’s causality, diverse simulations were performed, manipulating three key parameters: inlet velocity, equivalence ratio, and microchannel width. Elevating the velocity led to an escalated reaction intensity, consequently inducing rapid flame front extinction. Increasing the equivalence ratio from 0.5 to 0.6 resulted in an enhanced flame speed due to the augmented burning rate of the flame front, thus validating its accelerated extinction.

Beyond utilizing hydrogen as a fuel, the prospect of employing alternative fuels in microcombustion studies is viable. The FREI phenomenon was also observed in the research conducted by Biswas [77]. In this instance, a CH4/air mixture was employed, with ignition achieved through inserting a spark into the burner. The combustion of this mixture under stoichiometric conditions was examined within both a linear microchannel and a microchannel characterized by a contraction (convergent–divergent).

Additionally, other computational investigations have been conducted to enhance our comprehension of the FREI phenomenon across diverse fuel types. Nakamura et al. [78], Tsuboi et al. [79], and Miyata et al. [74] undertook analyses involving CH4 and air mixtures. Initially, they employed a one-dimensional model, subsequently validated against their experimental findings. Subsequently, they exclusively utilized direct numerical simulations to scrutinize the impact of boundary conditions—such as inlet temperature and wall temperature gradient—on the flame dynamics. The combustion characteristics of n-heptane–air were subject to experimental and numerical inquiry by Yamamoto et al. [80], wherein they also noted the manifestation of FREI dynamics.

6. PFB: Pulsatory Flame Burst

The phenomenon known as Pulsatory Flame Burst (PFB) is a specific flame behavior characterized by burst-like flame pulsation due to flow and combustion interactions. Currently, PFB only occurs in undulating geometries with premixed hydrogen and air, and the flame bursts involve the ignition, propagation, bifurcation (splitting), and extinction of the flame in a cyclic manner. Unlike FREI, where the flame extinguishes upstream, in PFB, a new flame emerges before the current one extinguishes. This prevents complete extinction, marking a significant difference.

PFB, though initially observed without distinction from FREI, was first identified in the course of micropropulsion studies conducted with wavy geometries [81,82], involving various inlet velocities and equivalence ratios, using a mixture of H2 and air. The geometry used is similar to our research, and it incorporated different wall conditions (hyperbolic and linear temperature profiles, as well as adiabatic conditions). Under the linear profile and adiabatic conditions, some simulations exhibited the phenomenon of PFB. This suggests that the microchannel geometry recirculates combustion energy, preventing flame extinction by flame lifting at higher speeds. Regarding propulsion capacity, it was found that increasing both the inlet velocity and equivalence ratio contribute to higher propulsion indicators. This underscores the significance of PFB, as pulsating flames exhibit substantial peaks in specific impulses.

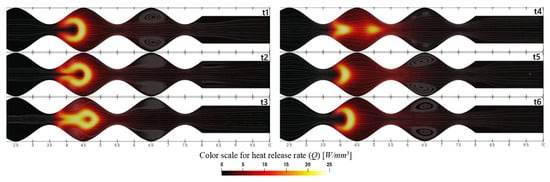

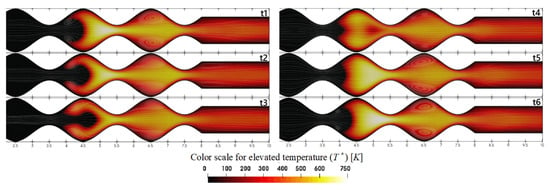

Only in a subsequent study by Resende et al. [83], was PFB accurately identified and named. This investigation delved into stable and pulsatory flame burst behaviors within an undulating geometry, utilizing premixed hydrogen and air (with an equivalence ratio of �=1.0) and applying a linear temperature profile along the wall. The findings revealed that, at a lower inlet velocity (4 [m/s]), the flame maintained stability, while at higher velocities, it exhibited pulsatory burst dynamics. The interplay between fluid dynamics and combustion response proved crucial, particularly due to vortices generated by the nonlinear burner geometry. With increased inlet velocity, the heat release rate transmitted through the vortices diminished, leading to ignition delay. This was evident through a reduced pulsatory burst frequency and a heightened peak heat release rate, albeit not substantial enough to amplify the maximum temperature amplitude. In Figure 8 and Figure 9 the results of a typical PFB flame are presented, as reported in [83].

Figure 8. Streamlines of the flow field and heat release rate distribution for the pulsatory flame burst dynamics with �in=6 [m/s], with 10 ms intervals [83].

Figure 9. Streamlines of the flow field and temperature distribution for the pulsatory flame burst dynamics with �in=6 [m/s], with 10 ms intervals [83].

Information

Subjects:

Energy & Fuels

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

521

Revision:

1 time

(View History)

Update Date:

11 Jul 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No