Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Laura Moretti | -- | 2357 | 2024-03-12 15:54:24 | | | |

| 2 | Sirius Huang | Meta information modification | 2357 | 2024-03-13 03:03:16 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Moretti, L.; Palozza, L.; D’andrea, A. Causes of Asphalt Pavement Blistering. Encyclopedia. Available online: https://encyclopedia.pub/entry/56169 (accessed on 07 February 2026).

Moretti L, Palozza L, D’andrea A. Causes of Asphalt Pavement Blistering. Encyclopedia. Available at: https://encyclopedia.pub/entry/56169. Accessed February 07, 2026.

Moretti, Laura, Leonardo Palozza, Antonio D’andrea. "Causes of Asphalt Pavement Blistering" Encyclopedia, https://encyclopedia.pub/entry/56169 (accessed February 07, 2026).

Moretti, L., Palozza, L., & D’andrea, A. (2024, March 12). Causes of Asphalt Pavement Blistering. In Encyclopedia. https://encyclopedia.pub/entry/56169

Moretti, Laura, et al. "Causes of Asphalt Pavement Blistering." Encyclopedia. Web. 12 March, 2024.

Copy Citation

No theoretical model effectively explains the blistering process, which provokes functional distress in asphalt pavements worldwide. Over the years, it has been possible to observe blistering on many asphalt pavements, collect information related to the specific contexts of its occurrence, and formulate hypotheses on the potential causes.

blistering

buckling

air voids

permeability

solar radiation

bulges

1. Introduction

The design and construction of road and airport pavements aim to meet structural and functional requirements [1] that ensure regular and safe service. Functional properties of a horizontal surface to be ridden require smoothness and adherence to allow for safe and comfortable vehicle mobility [2]. Several distresses (e.g., cracks, potholes, rutting, and raveling) have been recognized and investigated in the literature to counteract their appearance and manage their effects [3]. However, blistering negatively affects surface flatness and integrity [4], but it is still not fully understood [5]. It is frequent in hot climates and often appears upon exposure to rain, fog, or other water sources [6]. It is an irreversible (or partially reversible) process that consists of nonlinear blister growth dynamics that can start at the interface between two layers or within the upper layer and can have different consequences [7]. Indeed, blisters can reach a stable state, break, or lead to delamination, depending on the mechanical and adhesion properties of the materials [8][9]. The uplifts have a circular shape with extremely variable dimensions: their diameter can reach 1 m, and their maximum elevation is usually a few centimeters over the ideal and initial flat surface [10]. It often affects asphalt mixtures on asphalt roof shingles [11], pipelines [12], pipes for drinking water supply [13], Portland cement concrete bridge decks [14][15], steel deck bridge pavements [16], dams [7], pumped-storage power stations [7], runways [17], sidewalks [18], carriageways [5], waterproofing membranes [19], and asphalt-covered concrete structures [20] in south- and west-facing areas. According to the literature, the main physical mechanisms that drive blistering are temperature fluctuation [21], bottom-up pressure [22], loss of adhesion [23], peeling fracture [20], thermal expansion, and buckling [24]. Moreover, the blister failure mode has a direct relationship with the air void content, air and water permeability [25], stripping [23], the tensile/bond strength of the asphalt mixture [26][27], and the surface roughness [28]. The properties of the lower layer play a pivotal role: asphalt over granular or permeable layers does not suffer from blisters [29]. Moreover, a rough lower surface (e.g., milled binder) ensures a higher bonding performance between the tack coat and the upper layer [30]. Additionally, subsurface void detection with ground penetrating radar allowed for the identification of cavities filled with water [31].

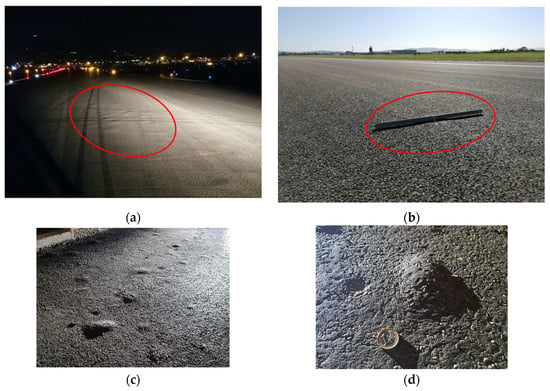

The complex mechanisms damage the surface of pavement, requiring maintenance and rehabilitation work. Indeed, neglecting the problem causes further distress with the onset of cracks, the infiltration of water, and removal of the bulge surface [32]. Cracks, potholes, raveling, surface wearing, and stripping affect pavement use when a low tolerance for out-of-flatness has to be applied (e.g., for airport runways where blistering can cause foreign object debris) [33]. Figure 1a,b shows night and day images of two runway pavements where blisters are in the red circles. Figure 1c,d shows the effects on sidewalks whose surface has numerous bulges; both images present a 1 euro coin (23.2 mm diameter).

Figure 1. Blisters. (a) On runway pavement; (b) on runway pavement; (c) on sidewalks; (d) on sidewalks.

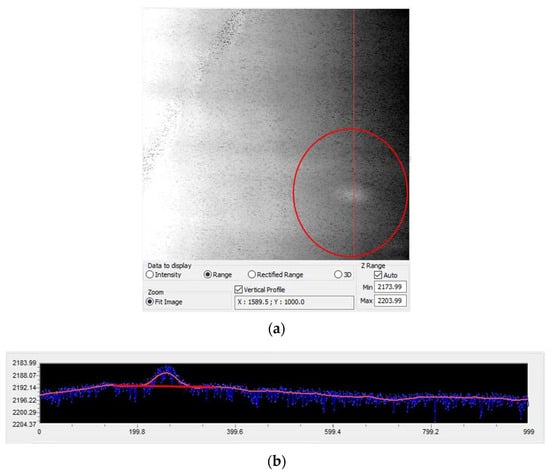

Moradi et al. [34] proposed a machine vision system to detect and grade the blistering defects of coatings according to [35]. Although there is a lack of standardized assessment methods to classify the severity and impact of pavement blisters, bulges higher than 3 mm prevent aircraft movements [36], and vertical differences in elevation higher than 1.25 cm are hazards for sidewalks and crosswalks [37]. Figure 2b shows the surface laser profile of the red alignment in Figure 2a and highlights the blister profile. The red circle in Figure 2a highlights the position of a blister.

Figure 2. Blister. (a) Surface image; (b) surface laser profile.

2. What Are the Potential Causes of Blistering?

Over the years, it has been possible to observe blistering on many asphalt pavements, collect information related to the specific contexts of its occurrence, and formulate hypotheses on the potential causes. Blisters (or bulges) occur during daytime hours and have regular circular shapes whose diameters range from a few centimeters to more than 1 m. Sasaki et al. [38] identified two blistering processes: primary blistering is observed just after the completion of the pavement and is usually caused by water trapped within the layers during laying [39]; secondary blistering occurs in hot periods following the end of the work and has been attributed to chemical, physical, and organic reactions within the asphalt surface, buckling effects, or moisture intrusion into upper layers. Whatever period they appear in, the necessary conditions for uplift occurring are high surface temperatures and an imperfect bond between the upper and lower layers (e.g., wearing and binder courses, or overlay and existing wearing layer) [40] or low tensile strength of the asphalt mixture [41].

2.1. Chemical Reactions within the Asphalt Surface

In 1984, blistering appeared on Runway 14–32 of the Marine Corps Air Station in Beaufort, South Carolina. In summer, secondary blisters involving a thin asphalt overlay two years after its construction occurred during the cold period. The bubbles were observed in limited areas of the pavement, and chemical reactions between the pavement materials and/or the biological activity of organisms present have been investigated as the causes of blistering [42]. A complex bacterial composition was found in blisters on asphalt concrete linings in the Czech Republic [43]. Both chemical reactions and biological activities can lead to the production of gases that are responsible for the observed distress. Hironaka and Holland [42] came to rule out such a possibility. Firstly, they noticed the fast occurrence of high surface temperatures of the surface due to solar radiation. Daytime blister behavior occurs at the upper layer of asphalt pavement because the maximum daily temperature range occurs within the topmost 5 cm of the surface. This condition suggests a close and reasonable correlation with the climatic conditions to which the pavement was exposed. The bubbles raised when the temperature increased, receded when the temperature decreased, and deflated when punctured. Therefore, the blisters contained pressured gases and were not caused by buckling effects. Due to the deep (more than 3 m) groundwater table and the sandy subgrade, steam from the groundwater or soil could not cause gas pressure beneath the wearing layer. Four gas samples from the blisters were analyzed to investigate their composition. However, the chemical approach was incorrect:

-

According to [42], it is unlikely that chemical activity was responsible for the gas production since the materials used in the production process were chemically stable. The inversion of a chemical reaction requires a certain amount of energy and a catalyst, which were unavailable within the pavement considering the daily cyclicity. Finally, the amount of gas generated by reactions over time would have decreased due to the progressive consumption of available resources until exhaustion. Therefore, the daytime increase in gas pressure and the sudden appearance of blistering would not have been possible after many cycles;

-

The chemical analyses of the gases contained under the surface uplifts revealed a high concentration of carbon dioxide and a low methane content, which is the main product of anaerobic activities. Such conditions suggest the presence of aerobic biological activities, which need a continuous oxygen supply. Blister gases do not differ from those in the normal air, and no other found gases could be responsible for the bubbles. However, the low void content of the asphalt and the lack of interaction of the latter with the outside make aerobic activities unlikely [43].

A finite element analysis was implemented to estimate the pressure necessary to develop bubbles under a thin asphalt layer [42] and compare the numerical results with those from the thermodynamic equations of gases [44]. ADINA 1.0 software was used to develop a three-dimensional model of a blister with no bonding of the asphalt layer except at the blister perimeter. The calculated pressures were higher than those from the thermodynamic analysis due to the boundary conditions and the thermal–mechanical properties of the modeled materials. The field measurements, laboratory tests, and numerical results confirmed that the blistering was caused by the thermal expansion of air- and water vapor-trapped gases in the asphalt voids [42]. Voids and cracks in the asphalt allow gases to move into the pavement until the pavement matrix expands due to the diurnal temperature changes, trapping air and moisture. Blisters arise where the bonding between the asphalt layers or the tensile strength is deficient, and the gas pressure overcomes the adhesion forces.

2.2. Unsuitable Aggregates

Potentially harmful materials in aggregates caused blisters in two pumped-storage power stations built in Poland and Germany in the 1970s [45][46][47]. In Germany, after 3 and 20 years of operation, a multi-layer facing of asphalt laid and rolled to seal the upper reservoir had bulges. The long interval time between the construction and the appearance of the blisters reveals that the cause was a ratchet process driven by progressive decay due to evolutionary materials whose properties evolved during their service life. In particular, petrographic investigations and electron microscopy proved the presence of weak cracked basalt and marl within the asphalt mixtures exposed to severe cyclic weather conditions. In semi-arid or arid climates, improper aggregates can modify the skeleton of the upper layer during its service life. Materials with more than 0.2% soluble salts [48] allow for the growth of salt crystals within the road pavement that cause blisters due to water fluctuations and steam [49]. In Botswana, detrimental salts (NaHCO3) caused the loss of adhesion between the aggregates and bitumen [5] of road and airport pavements. In Algeria, salt whiskers of halite (NaCl) caused blisters up to 10–15 cm high on the runway of Adrar [50]. Other studies have investigated salt contamination due to sodium chloride as the cause of pavement blistering [51][52].

2.3. Inside Overpressure

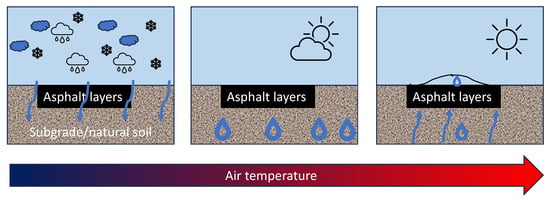

The currently most accredited hypothesis explains blistering with the following theory: during scorching summer days, exposure to solar radiation leads to high surface temperature values [53]. High air temperatures contribute to such conditions because the cooling capacity of the air is reduced. This heating process also affects any gas and/or water within the wearing layer or at the interface with the lower layers [54]. Changes in the water–heat regime in the base and lower layers of the pavement and the subgrade cause blistering as a deep process [55]. Soil moisture retention properties for unbound materials modify the water content during the seasonal drying and wetting cycles [56]. Increases in moisture inside the granular layers due to rainy and humid periods change the volume and strength of the granular soils [57] and contributes to blister development inside the upper dense layers [47] (Figure 3).

Figure 3. Blister deep process.

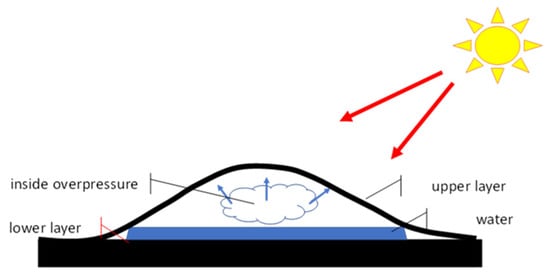

Volumetric expansion and evaporation can be countered by the wearing course avoiding interaction with the atmosphere and by the tack coat preventing downward expansion. Thus, gas and water vapor trapped under the surface break the interface bonding between layers [58]. The pressure causes bulges when it overcomes the opposing forces [55] (Figure 4).

Figure 4. Blister mechanism.

A surface bulge depends on a pressure increase that lifts the wearing layer to a stable condition. According to these hypotheses, exposure to solar radiation and inside overpressure are the driving variables behind blistering [55]. When solar radiation reaches the pavement surface, some is absorbed, some is reflected, and the remaining is transmitted [59]. The asphalt reflection coefficient depends on several factors (e.g., the age of the material, type of aggregates, and surface color). Since traffic erosion leads to lightening of the pavement color and increases the albedo (e.g., from the initial values of 0.04–0.06 to 0.09–0.18), the increased reflective capacity slows down the heating and decreases the pavement peak temperature on a summer day [60]. Therefore, higher temperatures reached by a recently laid layer lead to a higher probability that secondary blistering will occur in the first hot season of a pavement laid in cold months.

2.4. Thermal Buckling

In 2008, Croll [18] studied the blisters on the asphalt sidewalks on Gower Street that required several maintenance works and led to hazardous potholes for pedestrians. In [38], the surveyed surfaces involved a secondary blister process. According to Croll [18] and Castaing et al. [61], thermodynamic models cannot determine the process or predict gas pressure under the upper layer. Therefore, they did not consider the hypothesis that the pressure increase in the trapped gases determines the appearance of bubbles as sufficiently explanatory. Indeed, according to the theory of plates in flexure [62], the underlying pressure would deform the surface into the highest wavelengths. Given the deformation shape, the pressure is inversely proportional to the fourth power of the characteristic wavelength. Pavement blisters overcome this condition. The upward expansion is inversely proportional to the second power of the plane radius, and the pressure is inversely proportional to the fourth power of the plane radius: the energy required for a volume change is inversely proportional to the sixth power of the plane radius. Finally, the gas law [38] requires that expansion reduces the pressure beneath the bulge, while the growth of incremental blistering needs increases in both the pressure and deformation. In the examined sidewalks, some blisters were drilled without the evidence of pressured gases and uplifted after drilling, and others were not drilled. Thus, Croll [18] investigated an alternative thermal source as a cause of blistering. Cyclic thermal stresses induce expansion and contraction constrained at the surface, as confirmed by concentric ridges and furrows around the bubbles. Thus, asphalt slabs can be compared to heavy elastic sheets affected by a temperature increase. However, asphalt does not behave linearly or elastically because it depends on the time and temperature [63], but Croll [18] believes that the structural model of an elastic plate constrained and subjected to in-plane compression supports the hypothesis of asphalt blistering and pingos within permafrost [64]. Indeed, daily temperature ranges cause the expansion and contraction of asphalt, giving rise to traction and compression cycles that generate instability and the appearance of bubbles when geometric imperfections of the lower pavement layer cause upward curvature of the upper layer [65]. Deformation steps of the asphalt surface cause a ratchet process and lead to incremental plastic deformation. Indeed, part of the elevation generated at hot temperatures is not recovered in the subsequent cooling phase, and over time, this leads to the gradual growth of a generic bubble. The asphalt body cannot recover uplifts despite the restoration of the initial conditions due to the variation in stiffness caused by the changing temperature.

References

- Yoder, E.J.; Witczak, M.W. Principles of Pavement Design; John Wiley & Sons: New York, NY, USA, 1975.

- Hu, J.; Gao, X.; Wang, R.; Sun, S. Research on Comfort and Safety Threshold of Pavement Roughness. Transp. Res. Rec. 2017, 2641, 149–155.

- Chopra, T.; Parida, M.; Kwatra, N.; Chopra, P. Development of Pavement Distress Deterioration Prediction Models for Urban Road Network Using Genetic Programming. Adv. Civ. Eng. 2018, 2018, 1253108.

- Peng, Z.L.; Zhang, X.Y.; Liu, L.B.; Xu, G.T.; Wang, G.; Zhao, M.H. Effect of high-speed ultrasonic vibration cutting on the microstructure, surface integrity, and wear behavior of titanium alloy. J. Mater. Res. Technol. 2023, 24, 3870–3888.

- Busang, S.; Maina, J. Laboratory simulation and mechanical performance of asphalt materials under the action of saline. Construct. Build. Mater. 2021, 313, 125387.

- Effendy, S.; Zhou, T.; Eichman, H.; Petr, M.; Bazant, M.Z. Blistering failure of elastic coatings with applications to corrosion resistance. Soft Matter 2021, 17, 9480–9498.

- Wang, Z.; Hao, J.; Sun, Z.; Ma, B.; Xia, S.; Li, X. Blistering Mechanism Analysis of Hydraulic Asphalt Concrete Facing. Appl. Sci. 2019, 9, 2903.

- Fini, E.H.; Al-Qadi, I.L.; Masson, J.-F. Interfacial fracture energy: An indicator of the adhesion of bituminous materials. J. Assoc. Asph. Paving Technol. 2010, 77, 827–850.

- Abo-Qudais, S.; Al-Shweily, H. Effect of aggregate properties on asphalt mixtures stripping and creep behaviour. Construct. Build. Mater. 2007, 21, 1886–1898.

- Chmielewska, B.; Garbacz, A.; Adamczewski, G.; Rymsza, B. Thermal actions on the materials during deck and pavement construction. Arch. Civ. Eng. 2018, 64, 101–118.

- Petty, S.E. Attic and crawlspace ventilation. In Forensic Engineering: Damage Assessments for Residential and Commercial Structures; CRC Press: Boca Raton, FL, USA, 2017; pp. 437–459.

- Linchtenstein, J. Effectiveness of pipeline coatings for corrosion control. Mater. Perform. 2003, 42, 74–75.

- Lindman, E.K. Internal Surface Coatings for Steel and Cast Iron Pipes for Drinking-Water Supply; Swedish Corrosion Inst: Stockholm, Sweden, 1977.

- Chmielewska, B.; Adamczewski, G. Mechanisms of defects formation of waterproofing membranes on concrete bridge decks. Paper presented at the IABSE Symposium, Wroclaw 2020: Synergy of Culture and Civil Engineering—History and Challenges, Wrocław, Poland, 7–9 October 2020; pp. 1016–1023.

- Liu, H.; Li, Y.; Zhang, Q.; Hao, P. Deformation characteristic and mechanism of blisters in cement concrete bridge deck pavement. Construct. Build. Mater. 2018, 172, 358–369.

- Zhang, H.; Hao, P.; Zhang, H. Initiation and propagation mechanism of blisters on the epoxy asphalt concrete paving course of steel deck bridge pavement. J. Beijing Univ. Technol. 2016, 42, 737–741.

- Moriyoshi, A.; Shibata, E.; Natsuhara, M.; Sakai, K.; Kondo, T.; Kasahara, A. Deterioration of modern concrete structures and asphalt pavements by respiratory action and trace quantities of organic matter. PLoS ONE 2021, 16, e0249761.

- Croll, J.G.A. A new hypothesis for the development of blisters in asphalt pavements. Int. J. Pavement Eng. 2008, 9, 59–67.

- Zhao-dong, X.; De-kun, C. Research into aperture parameters of point bonded roof waterproofing membranes. Matériaux Et Constr. 1984, 17, 379–384.

- Hailesilassie, B.W. Mechanisms of Blister Formation on Concrete Bridge Decks with Waterprooving Asphalt Pavement Systems; Division of Highway and Railway Engineering, Department of Transport Science, School of Architecture and the Built Environment, Royal Institute of Technology: Stockholm, Sweden, 2013.

- Hailesilassie, B.W.; Partl, M.N. Mechanisms of asphalt blistering on concrete bridges. J. ASTM Int. 2012, 9, 1–16.

- Hailesilassie, B.W.; Hean, S.; Partl, M.N. Testing of blister propagation and peeling of orthotropic bituminous waterproofing membranes. Mater. Struct./Mater. Constr. 2015, 48, 1095–1108.

- Bagampadde, U.; Isacsson, U.; Kiggundu, B.M. Classical and contemporary aspects of stripping in bituminous mixes. Road Mater. Pavement Des. 2004, 5, 7–43.

- Croll, J.G.A. A simplified model of upheaval thermal buckling of subsea pipelines. Thin-Walled Struct. 1997, 29, 59–87.

- Nitta, N.; Kasahara, A.; Sugawara, T. Effects of degree of compaction on the mechanical properties of bituminous mixtures. J. Jpn. Pet. Inst. 1980, 23, 118–126.

- Al-Qadi, I.L.; Fini, E.H.; Masson, J.F.; McGhee, K.M. Effect of bituminous material rheology on adhesion. Transp. Res. Rec. 2008, 2044, 96–104.

- Abedali, A.H.; Tariq, N.; Meqtoof, F.H. Measured bond strength of asphaltic material using developed blister method. Construct. Build. Mater. 2017, 143, 189–197.

- Oba, K.; Partl, M.N. Adhesion of bituminous waterproofing membranes for bridge applications. ASTM Spec. Tech. Publ. 1998, 1334, 251–267.

- Bicheron, G.; Lopez, P.; Quentin, F.; Fournier, X.; Pawlak, F. Asphalt, bubbles, blisters and swellings. . Bull. De Liaison Des Lab. Des Ponts Chaussees 1994, 191, 27–30.

- Tang, Z.; Huang, F.; Peng, H. Effect of 3D roughness characteristics on bonding behaviors between concrete substrate and asphalt overlay. Constr. Build. Mater. 2021, 270, 121386.

- Li, X.; Hao, J.; Wang, Z. Experimental study on ground penetrating radar in quality inspection of asphalt concrete impervious facing of pumped storage power station. IOP Conf. Ser. Mater. Sci. Eng. 2018, 423, 012020.

- Rollings, R.S.; Wong, G.S. Investigation of a concrete blistering failure. In Proceedings of the Materials: Performance and Prevention of Deficiencies and Failures, Materials Engineering Congress, Atlanta, GA, USA, 10–12 August 1992; pp. 16–30.

- Li, X.; Keegan, K.; Yazdani, A. Index of foreign object damage in airfield pavement management. Transp. Res. Rec. 2010, 2153, 81–87.

- Moradi, N.; Gorji Kandi, S.; Yahyaei, H. A new approach for detecting and grading blistering defect of coatings using a machine vision system. Measurement 2022, 203, 111954.

- ISO 4628; Paints and Varnishes–Evaluation of Degradation of Coatings–Designation of Quantity and Size of Defects, and of Intensity of Uniform Changes in Appearance. International Organization for Standardization (acronym ISO): Geneva, Switzerland, 2016.

- ICAO. International Civil Aviation Organisation—Annex 14 Chapter 9: Emergency and Other Services; International Civil Aviation Organisation: Montreal, QC, Canada, 2013.

- Ayres, T.J.; Kelkar, R. Sidewalk potential trip points: A method for characterizing walkways. Int. J. Ind. Ergon. 2006, 36, 1031–1035.

- Sasaki, I.; Moriyoshi, A.; Hachiya, Y. Water/Gas Permeability of Bituminous Mixtures and Involvement in Blistering Phenomenon. J. Jpn. Pet. Inst. 2006, 49, 57–64.

- Chernotowich, K.; Brzozowski, K.J.; Sanicky, P.J. Effects of application technique and temperature on characteristics of modified bitumen membrane assemblies. ASTM Spec. Tech. Publ. 2004, 1451, 86–95.

- Scharmacher, F.; Müller, A.; Brunner, M. Asphalt Surfacing on Timber Bridges. In Proceedings of the World Conference on Timber Engineering, Renaissance of Timber Construction, WCTE 2014, Quebec City, QC, Canada, 10–14 August 2014.

- Si, W.; Li, N.; Ma, B.; Tian, Y.-X.; Zhou, X.-Y. Temperature response to tensile characteristics of the hot asphalt mixtures. Ksce J. Civ. Eng. 2016, 20, 1336–1346.

- Hironaka, M.C.; Holland, T.J. Blistering of Asphalt Pavement Overlay on Runway 14–32 at MCAS.; NCEL Technical Note N-1744; NCEL: Beaufort, SC, USA, 1986.

- Špano, M.; Říha, J.; Španová, A.; Šedo, O.; Rittich, B. Bacterial Diversity in the Asphalt Concrete Lining of the Upper Water Reservoir of a Pumped-Storage Scheme. Water 2020, 12, 3045.

- Vallance, C. An Introduction to the Gas Phase; Morgan Claypool Publishers: San Rafael, CA, USA, 2017.

- Szling, Z.; Szymański, A. The origin of and prevention from damage to impervious facings. In Proceedings of the ICOLD 17th Congress, Vienna, Austria, 14–17 October 1991; pp. 95–102.

- Frohnauer, R. Special application of asphaltic concrete for dam water barrier construction. In Proceedings of the Waterpower Conference 1999, Las Vegas, NV, USA, 6–9 July 1999; pp. 1–10.

- Sobolewski, T. PGE Energia Odnawialna SA.; Monografia Elektrowni Szczytowo-Pompowej Porabka Žar Wydanie II: Biala, Polska, 2010.

- Blight, G.E. Migration of Subgrade Salts Damages Thin Pavements. Transp. Eng. J. 1976, 102, 779–791.

- Government of Western Australia. Surface “Blistering” and Soil “Fluffing”; Government of Western Australia: Perth, WA, Australia, 2004.

- Horta, J.C.O.S. Salt heaving in the Sahara. Geotechnique 1985, 35, 329–337.

- Januszke, R.M.; Booth, E.H.S. Soluble salt damage to sprayed seals on the Stuart Highway. Conf. Aust. Road Res. Board 1984, 12, 18–31.

- West, J. Relationship between coating thickness and salt contamination on blistering of coatings. UK Corrosion 1985, 7949, 39–54.

- Moretti, L.; Cantisani, G.; Carpiceci, M.; D’Andrea, A.; Del Serrone, G.; Di Mascio, P.; Peluso, P.; Loprencipe, G. Investigation of Parking Lot Pavements to Counteract Urban Heat Islands. Sustainability 2022, 14, 7273.

- Macnaughton, A.A. A Theory for Blistering and Alligatoring in Asphalt Bitumen Built-up Roofs. In Durability of Building Materials and Components; ASTM STP 691; ASTM International: West Conshohocken, PA, USA, 1980.

- Stene, S.B. Investigation of Causes to Blistering of Asphalt Pavements. Master’s Thesis, NTNU–Norwegian University of Science and Technology, Trondheim, Norway, 2020.

- Gupta, S.; Singh, A.; Ranaivoson, A. Moisture Retention Characteristics of Base and Sub-Base Materials; Technical Report Documentation MN/RC–2005-06; Minnesota Department of Transportation: St Paul, MN, USA, 2004; Available online: https://cts-d8resmod-prd.oit.umn.edu/pdf/mndot-2005-06.pdf (accessed on 3 March 2024).

- Marks, B.D., III; Haliburton, A. Subgrade moisture variations studied with nuclear depth gages. Highw. Res. Rec. 1969, 76, 1–24.

- Fini, E.H.; Al-Qadi, I.A. Development of a Pressurized Blister Test for Interface Characterization of Aggregate Highly Polymerized Bituminous Materials. J. Mater. Civ. Eng. 2011, 23, 656–663.

- Bryce, J.; Chattopadhyay, A.; Esmaeilpour, M.; Ihnat, Z.E. Detailing an Improved Heat Transfer Model for Pavements. Transp. Res. Rec. 2021, 2675, 153–165.

- Roesler, J.; Sen, S. Aging albedo model for asphalt pavement surfaces. J. Clean. Prod. 2016, 117, 169–175.

- Castaing, P.; Lemoine, L.; Gourdenne, A. Mechanical modelling of blisters in coated laminated i–theoretical aspects. Compos. Struct. 1995, 30, 217–222.

- Timoshenko, S.P.; Woinowsky-Krieger, S. Theory of Plates and Shells, 2nd ed.; McGraw-Hill: New York, NY, USA, 1959.

- Huang, Y. Pavement Analysis and Design, 2nd ed.; Pearson/Prentice Hall: Upper Saddle River, NJ, USA, 2004.

- Croll, J.G.A. An Alternative Model for “Pingo” Formation in Permafrost Regions. In Proceedings of the 21st International Congress of Theoretical and Applied Mechanics, ICTAM-04, Warsaw, Poland, 15–21 August 2004.

- Croll, J.G.A. Thermal buckling of pavement slabs. ICE Proc. Transp. 2005, 158, 115–126.

More

Information

Subjects:

Engineering, Civil

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.7K

Revisions:

2 times

(View History)

Update Date:

13 Mar 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No