Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Zhuoyue Zheng | -- | 1794 | 2024-03-11 08:18:40 | | | |

| 2 | Catherine Yang | Meta information modification | 1794 | 2024-03-11 08:33:47 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Zheng, Z.; Wang, C.; Wang, L.; Ji, Z.; Song, X.; Mak, P.; Liu, H.; Wang, Y. Denoising Techniques for High-Performance MEMS Microphones. Encyclopedia. Available online: https://encyclopedia.pub/entry/56087 (accessed on 07 February 2026).

Zheng Z, Wang C, Wang L, Ji Z, Song X, Mak P, et al. Denoising Techniques for High-Performance MEMS Microphones. Encyclopedia. Available at: https://encyclopedia.pub/entry/56087. Accessed February 07, 2026.

Zheng, Zhuoyue, Chen Wang, Linlin Wang, Zeyu Ji, Xiaoxiao Song, Pui-In Mak, Huafeng Liu, Yuan Wang. "Denoising Techniques for High-Performance MEMS Microphones" Encyclopedia, https://encyclopedia.pub/entry/56087 (accessed February 07, 2026).

Zheng, Z., Wang, C., Wang, L., Ji, Z., Song, X., Mak, P., Liu, H., & Wang, Y. (2024, March 11). Denoising Techniques for High-Performance MEMS Microphones. In Encyclopedia. https://encyclopedia.pub/entry/56087

Zheng, Zhuoyue, et al. "Denoising Techniques for High-Performance MEMS Microphones." Encyclopedia. Web. 11 March, 2024.

Copy Citation

The MEMS (Micro-Electro-Mechanical Systems) microphone is a representative device among the MEMS family, which has attracted substantial research interest, and those tailored for human voice have earned distinct success in commercialization. With the advancement of microphone technology and the market, microphones have become carriers for various intelligent applications, therefore demanding higher criteria in noise suppression. For instance, a hearing aid should suppress ambient noise while delivering relevant sounds to the user. Additionally, in specific environments, the noise performance of microphones is crucial for communication and intelligent voice-related needs such as voice activation and speech recognition.

MEMS microphone

environmental noise-cancelling

directional microphone

capacitive microphone

1. Introduction

The microphone, a device capable of sensing acoustic vibrations and transducing them into electrical signals, has experienced an exponential evolution since its emergence. Extending from its origins, it has expanded into various domains including commercial communication, medical applications, industrial usage, and both surveillance and military sectors.

The inception of the electret condenser microphone (ECM) marked a pivotal milestone, pioneered by Gerhard Sessler and James West in the early 1980s [1]. Subsequently, the advancement of MEMS (Micro-Electro-Mechanical Systems) technology coupled with strides in materials science drove a shift in this area, enabling the possibility of the miniaturization of macro-counterparts. This revolution not only reduced the size factor of the devices but also propelled substantial innovations in the operational mechanisms of microphones, offering newfound perspectives and increased design flexibility [2].

The merits of miniaturization are distinct, particularly in rendering a better noise performance, reduced power consumption, and multifunctional capabilities for electronic devices. As such, MEMS microphones are prevailing in consumer electronics like smartphones, tablets, wearables, computers, automobiles, and IoT devices, and are expected to see a consecutive growth in demand. According to a report from Maximize Market Research, MEMS Microphones Market is worth USD 1.82 billion in 2022 and is expected to hit USD 3.97 billion by 2029 at a CAGR of 11.8 percent [3].

Presently, the most economically competitive transduction mechanisms of MEMS microphones in use encompass capacitive, piezoresistive [4], and piezoelectric [5] types. Among these, capacitive microphones stand out for offering relatively higher signal strength, reaching up to hundreds of microvolts. However, they struggle with additional power consumption and exhibit a relatively high sensitivity to environmental factors such as dust and humidity, a complex manufacturing process, and could be more susceptible to electromagnetic interference. Despite these drawbacks, the simplicity of their structural design and compatibility with CMOS technology allows them to retain the leading position of capacitive MEMS microphones in the commercial market. In contrast, although piezoresistive microphones provide a wider dynamic range, they struggle with limitations regarding sensitivity and power consumption.

Utilizing piezoelectric-based materials to facilitate acoustic sensing presents the advantage of passive devices without additional input power, rendering them well-suited for portable applications. Furthermore, their robust design, making them less susceptible to environmental factors. requires simpler manufacturing process compared to capacitive MEMS microphones. However, achieving a comparable performance with capacitive microphones has posed a persistent challenge, in particular, concerning CMOS-compatible materials such as aluminum nitride (AlN) or zinc oxide (ZnO) [6]. In addition, the operational range of piezoelectric MEMS microphones is contingent upon the material used, indicating a promising potential in the future market. Collectively, microphone applications take into account a delicate balance between the demands of various usage scenarios, process intricacies, reliability, and environmental sustainability.

2. Utilizing the Resonant Responses of Membranes

Due to inherent resonant responses in membrane devices, strategically configuring mechanical structures and quality factors (Q-factors) theoretically enables passive noise filtering and desired signal amplification. Reger et al. [7] implement such practices by detailing piezoelectric MEMS microphones leveraging aluminum nitride (AlN). They fine-tuned the resonant frequency by suspending a diaphragm using etched tethers anchored to the boundary. Inevitably mentioning that a flat frequency response of microphones is of great importance for accurately reproducing speech characteristics. Although distorted speech may not suit most speech recognition-based applications, the zero-power-consumption feature of the piezoelectric principles suggests that passive filters might find appropriate usage in certain wake-up applications.

In addition to the inherent resonance of thin films for filtering, acoustic resonators have been explored [8]. Kusano [9], among others, took inspiration from the human cochlea, employing a 3D-printed spiral-shaped structure. The structure is in conjunction with a microphone to filter and select a specific frequency range while suppressing others through resonance and anti-resonance frequencies. However, the attenuation level can significantly reduce the quality factor of the resonance, potentially limiting its suitability to specific application scenarios. Moreover, the relatively large size of the assembled device is adverse for applications aimed at miniaturized microphones.

3. Utilizing BF-Compliant Directional Microphones

Among the noise reduction schemes for MEMS microphones, beamforming has proven a highly effective technique. Such a method suppresses noise by weighting audio signals from various directions, particularly enhancing specific sound directions while suppressing others. Presently, beamforming primarily relies on omnidirectional microphone arrays, in which each output undergoes digital signal processing (DSP) techniques to manipulate specific time delays and phase adjustments. This necessitates an additional DSP module in the interface or ASIC circuitry. Furthermore, integrating microphone arrays into compact packages poses significant challenges. To tackle those problems, implementing noise suppression on the basis of the mechanical or sensor system design with directional selectivity would further drive device miniaturization. For instance, bi-directional sound sensors are able to achieve acoustic beamforming in practice and the directional characteristics can be easily changed according to the weighted sum of the signals acquired from only a pair of sensors [10].

As previously mentioned, whether through piezoelectric or capacitive transductions, teetertotter-style microphones inherently possess directional selectivity and can generate bi-polar directional patterns. This is attributed to both sound pressure intensity and sound pressure-gradient information, and can be described as

in which the first part and the second part of the equation describe the omnidirectional load and gradient load separately. The Oromia Ochracea-inspired teetertotter-style microphone that was initially proposed by Mills et al. [11][12][13][14][15], Refs. [16][17][18][19], enabled the creation of an eight-shaped polar pattern. Subsequent research involved adjustments in the relative sizes of the two wings [20], varying diaphragm thickness to modulate sensitivity [21], and integrating a force feedback setup to manage thermal–mechanical noise and active Q control [22]. For more comprehensive insights into this subject, additional relevant literature can be found in the review paper compiled by Ishfaque [23].

in which the first part and the second part of the equation describe the omnidirectional load and gradient load separately. The Oromia Ochracea-inspired teetertotter-style microphone that was initially proposed by Mills et al. [11][12][13][14][15], Refs. [16][17][18][19], enabled the creation of an eight-shaped polar pattern. Subsequent research involved adjustments in the relative sizes of the two wings [20], varying diaphragm thickness to modulate sensitivity [21], and integrating a force feedback setup to manage thermal–mechanical noise and active Q control [22]. For more comprehensive insights into this subject, additional relevant literature can be found in the review paper compiled by Ishfaque [23].

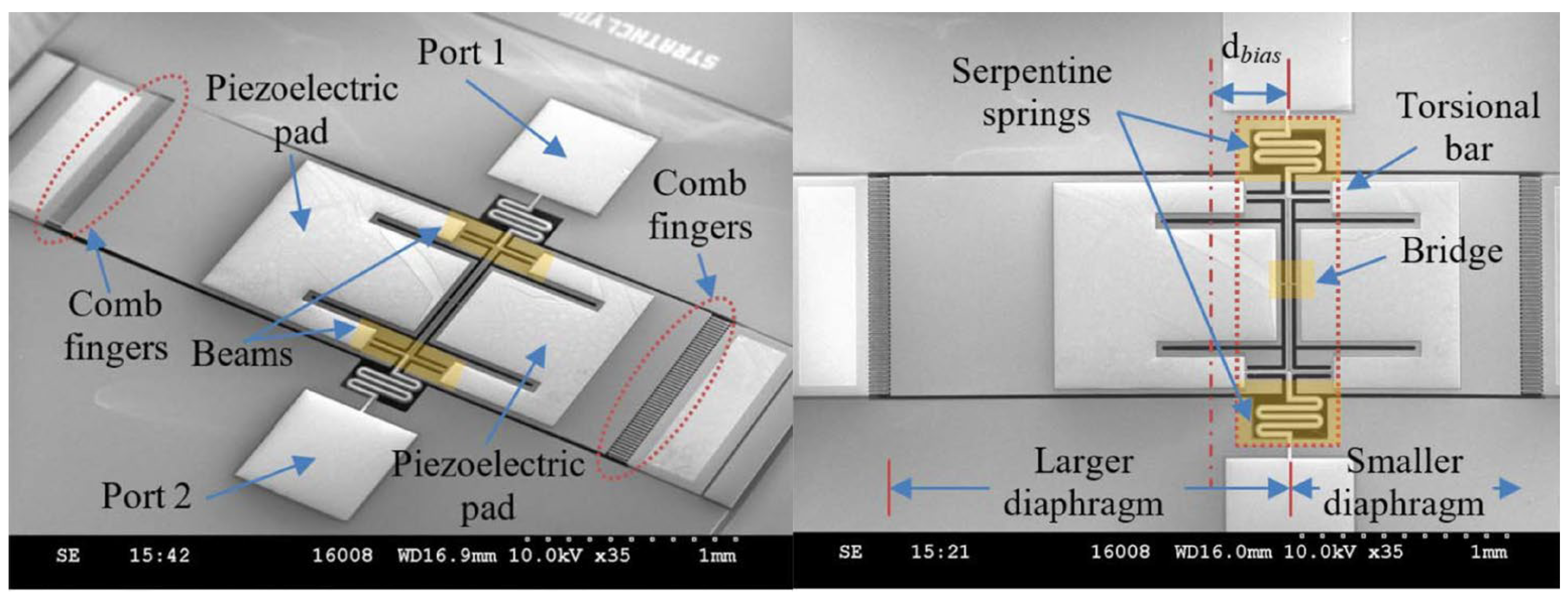

The teetertotter-style microphone primarily operates within two resonant frequencies (two vibration modes) and their adjacent bands, thus restricting the sensor’s working bandwidth (usually <1 kHz). Considering the fact that signals below 1 kHz are crucial for speech applications and environmental noise localization [24]. As illustrated in Figure 1, Zhang et al. [25] achieved low-frequency applications at 500 Hz and 2 kHz by adjusting the central axis position of the device to modify resonant frequencies, and they utilized piezoelectric detection and capacitive auxiliary detection. Ren et al. further optimized Zhang’s work by tuning the two modal frequencies to 395 Hz and 739 Hz therefore leveraging the high vibration sensitivity of the fiber-optic Fabry-Perot interferometer (FPI) at the diaphragm’s distal edge [26]. These advancements aim to implement cost-effective miniature directional microphones with exceptional low-frequency Sound Source Localization (SSL) capability.

Figure 1. SEM images of the asymmetric microphone (Reprinted with permission from Ref. [25]).

Whether operating with piezoelectric or capacitive transduction, the teetertotter-style microphone primarily faces challenges toward poor signal-to-noise ratio, narrow frequency bandwidth, and insufficiently flat responses [27]. Despite capacitive mechanism-based sensors having certain limitations in terms of device space compared to piezoelectric ones [28], they offer an alternative approach in terms of achieving a low-frequency sound pressure-referred noise floor and frequency selectivity.

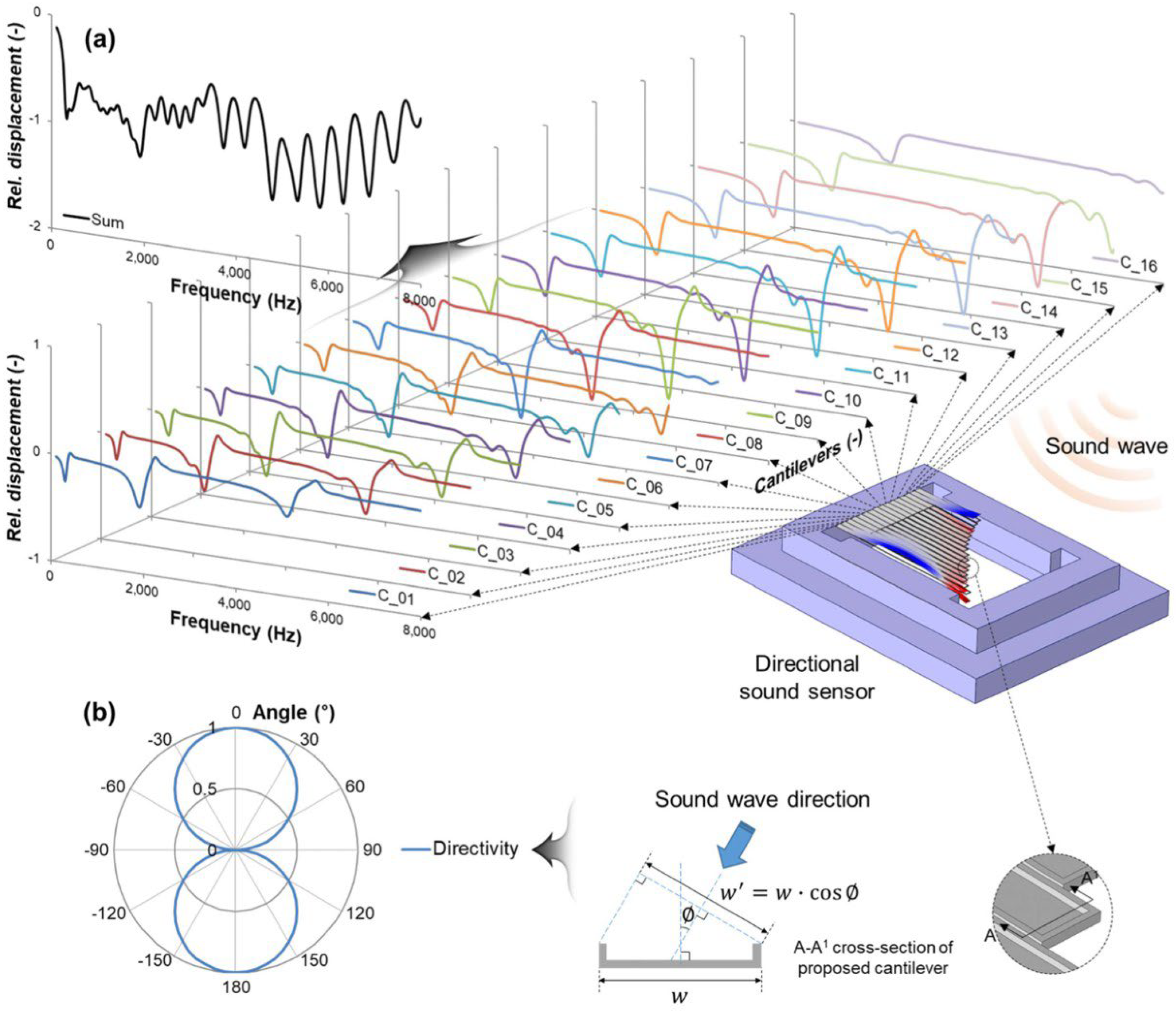

Inspired by the human cochlea, Kang et al. [29] proposed a bipolar (figure-of-8 pattern) directional sound sensor using 16 cantilevers operating under a resonant mode, as illustrated in Figure 2. Like the previous work of Baumgartel [30], these cantilevers have respective resonance frequencies and separately acquire signals to then combine them for sound sensing and cover a frequency range of 100 Hz to 8000 Hz, and overcome directional ambiguities introduced by bipolar directionality using a Canted Angle Design [10]. Another merit of cantilevers is the relatively low processing requirements since simple signal processing holds significant relevance for subsequent applications such as human voice localization and control design for wearable devices. However, in Kang’s work frequency-response ripples across for approximately 15 dB in the magnitude of sensitivity, occupying a significant proportion relative to the sensitivity data (−20 dB to −40 dB). Nonetheless, Kang’s work undoubtedly offers valuable insights for the subsequent design of directional microphones.

Figure 2. Design of proposed sensor. (a) Simulation model and results of cantilever displacements by a sound wave. (b) Bipolar directivity of proposed sensor (Reprinted with permission from Ref. [29]).

4. Other Applications in Noise Cancelation

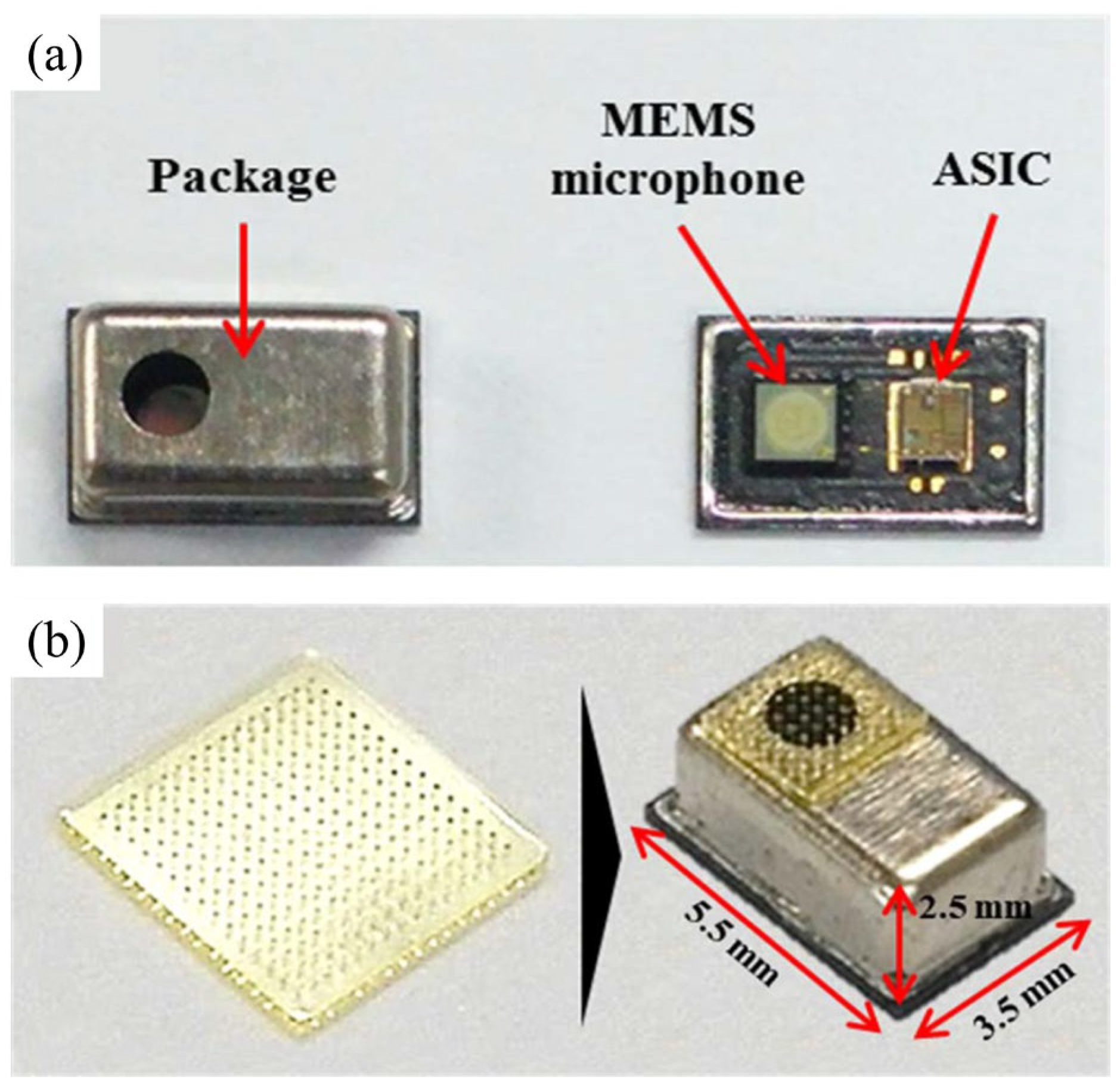

For more specific applications, such as in-vehicle noise reduction, directional signal selection can also be achieved at the packaging level. As illustrated in Figure 3a, Yoo et al. [31] presented a unidirectional microphone that enables the suppression of noise signals from undesired directions. As illustrated in Figure 3b, The directional characteristic of the microphone is realized by attaching a porous SU-8 filter to facilitate a delay in one of the two acoustic ports on the package. Experimental data indicated the proposed unidirectional MEMS microphone along with the devised packaging shows a front-back ratio of 27.1 dB, resulting in an effective suppression of fixed-directional noise. However, its drawback compared to device-based design lies in the challenge of controlling directional selection through circuits. Additionally, Packaging level filtering does not necessitate a high manufacturing requirement for the sensor but high demands on the manufacturing for controlling the hole ratio of the filter and the packaging assembly.

Figure 3. Directional MEMS microphone package: (a) Outside and inside images of package and (b) SU-8 filter attached on upper hole of package (Reprinted with permission from Ref. [32]).

Apart from suppressing specific directional noise, research also focuses on noise suppression in different frequency bands of omnidirectional microphones. Such designs primarily target applications akin to hearing aids. Although noises can be reduced using analog filters or digital signal processing [33] or a resonant microphone array (RMA), they cannot eliminate the original noises that directly get into the ear.

Hence, to address noise leakage, active noise cancellation (ANC) is carried out by picking up the noise in a specific frequency band [34]. Liu et al. [35] presented ANC based on MEMS RMA, and it demonstrated a better noise reduction level compared to flat band microphones. They used two sets of resonant microphone arrays composed of multiple piezoelectric cantilever microphones with different resonance frequencies covering two frequency ranges: one between 0.8 kHz to 5 kHz for vocal sensing and the other between 5 kHz to 9 kHz for ANC. The ANC was implemented with an analog inverter, digital phase compensator, digital adaptive filter, and deep learning technique, which outperformed the digital adaptive filter.

As the garnered results embodied, in all the tested cases, the word error rate improved with ANC, and the best performance was attained around the resonance frequencies of the resonant microphones. This suggests a way wherein specific frequencies’ active noise cancellation can be achieved through mechanical structural design.

References

- Hohm, D. An integrated silicon-electret-condenser microphone. In Proceedings of the 11th International Congress on Acoustics, Paris, France, 19–27 July 1983; Volume 6, pp. 29–32.

- Wang, L.; Wang, C.; Wang, Y.; Quan, A.; Keshavarz, M.; Madeira, B.P.; Zhang, H.; Wang, C.; Kraft, M. A review on coupled bulk acoustic wave mems resonators. Sensors 2022, 22, 3857.

- MEMS Microphones Market: Growth Potential of US$ 3.97 Billion. Maximize Market Research. Available online: https://www.maximizemarketresearch.com/market-report/mems-microphones-market/186923/ (accessed on 29 November 2023).

- Papila, M.; Haftka, R.T.; Nishida, T.; Sheplak, M. Piezoresistive Microphone Design Pareto Optimization: Tradeoff between Sensitivity and Noise Floor. J. Microelectromechan. Syst. 2006, 15, 1632–1643.

- Pinto, R.M.R.; Gund, V.; Dias, R.A.; Nagaraja, K.K.; Vinayakumar, K.B. CMOS-Integrated Aluminum Nitride MEMS: A Review. J. Microelectromechan. Syst. 2022, 31, 500–523.

- Fraga, M.A.; Furlan, H.; Pessoa, R.S.; Massi, M. Wide bandgap semiconductor thin films for piezoelectric and piezoresistive MEMS sensors applied at high temperatures: An overview. Microsyst. Technol. 2014, 20, 9–21.

- Reger, R.W.; Clews, P.J.; Bryan, G.M.; Keane, C.A.; Henry, M.D.; Griffin, B.A. Aluminum nitride piezoelectric microphones as zero-power passive acoustic filters. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 2207–2210.

- Cai, X.; Guo, Q.; Hu, G.; Yang, J. Ultrathin low-frequency sound absorbing panels based on coplanar spiral tubes or coplanar Helmholtz resonators. Appl. Phys. Lett. 2014, 105, 121901.

- Kusano, Y.; Segovia-Fernandez, J.; Sonmezoglu, S.; Amirtharajah, R.; Horsley, D.A. Frequency selective mems microphone based on a bioinspired spiral-shaped acoustic resonator. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 71–74.

- Wilmott, D.; Alves, F.; Karunasiri, G. Bio-Inspired Miniature Direction Finding Acoustic Sensor. Sci. Rep. 2016, 6, 29957.

- Ullmann, P.; Bretthauer, C.; Schneider, M.; Schmid, U. Stress analysis of circular membrane-type MEMS microphones with piezoelectric read-out. Sens. Actuators A Phys. 2023, 349, 114003.

- Lee, S.S.; Ried, R.P.; White, R.M. Piezoelectric cantilever microphone and microspeaker. J. Microelectromechan. Syst. 1996, 5, 238–242.

- Kuchiji, H.; Masumoto, N.; Baba, A. Piezoelectric MEMS wideband acoustic sensor coated by organic film. Jpn. J. Appl. Phys. 2023, 62, SG1021.

- Wang, T.; Lee, C. Zero-Bending Piezoelectric Micromachined Ultrasonic Transducer (pMUT) with Enhanced Transmitting Performance. J. Microelectromechan. Syst. 2015, 24, 2083–2091.

- Muralt, P.; Ledermann, N.; Baborowski, J.; Barzegar, A.; Gentil, S.; Belgacem, B.; Petitgrand, S.; Bosseboeuf, A.; Setter, N. Piezoelectric micromachined ultrasonic transducers based on PZT thin films. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 2276–2288.

- Miles, R.N.; Robert, D.; Hoy, R.R. Mechanically coupled ears for directional hearing in the parasitoid fly Ormia ochracea. J. Acoust. Soc. Am. 1995, 98, 3059–3070.

- Miles, R.N.; Su, Q.; Cui, W.; Shetye, M.; Degertekin, F.L.; Bicen, B.; Garcia, C.; Jones, S.; Hall, N. A low-noise differential microphone inspired by the ears of the parasitoid fly Ormia ochracea. J. Acoust. Soc. Am. 2009, 125, 2013–2026.

- Miles, R.N.; Gibbons, C.; Gao, J.; Yoo, K.; Su, Q.; Cui, W. A silicon nitride microphone diaphragm inspired by the ears of the parasitoid fly Ormia ochracea. J. Acoust. Soc. Am. 2001, 110, 2645.

- Tan, L.; Miles, R.N.; Weinstein, M.G.; Miller, R.A.; Su, Q.; Cui, W.; Gao, J. Response of a biologically inspired MEMS differential microphone diaphragm. In Unattended Ground Sensor Technologies and Applications IV; SPIE: Bellingham, WA, USA, 2002; pp. 91–98.

- Touse, M.; Sinibaldi, J.; Karunasiri, G. MEMS directional sound sensor with simultaneous detection of two frequency bands. In Proceedings of the 2010 Ninth IEEE Sensors Conference (SENSORS 2010), Waikoloa, HI, USA, 1–4 November 2010; pp. 2422–2425.

- Downey, R.H.; Karunasiri, G. Reduced residual stress curvature and branched comb fingers increase sensitivity of MEMS acoustic sensor. J. Microelectromechan. Syst. 2013, 23, 417–423.

- Bicen, B. Micromachined Diffraction Based Optical Microphones and Intensity Probes with Electrostatic Force Feedback. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2010.

- Ishfaque, A.; Kim, B. Fly Ormia Ochracea Inspired MEMS Directional Microphone: A Review. IEEE Sens. J. 2018, 18, 1778–1789.

- Ang, L.Y.L.; Koh, Y.K.; Lee, H.P. Plate-type acoustic metamaterials: Experimental evaluation of a modular large-scale design for low-frequency noise con-trol. Acoustics 2019, 1, 354–368.

- Zhang, Y.; Bauer, R.; Jackson, J.C.; Whitmer, W.M.; Windmill, J.F.C.; Uttamchandani, D. A Low-Frequency Dual-Band Operational Microphone Mimicking the Hearing Property of Ormia Ochracea. J. Microelectromechan. Syst. 2018, 27, 667–676.

- Ren, D.; Liu, X.; Zhang, M.; Gao, R.; Qi, Z.-M. Low-Frequency Bi-Directional Microphone Based on a Combination of Bionic MEMS Diaphragm and Fiber Acousto-Optic Transducer. IEEE Sens. J. 2021, 21, 14655–14665.

- Baumhauer, J.C., Jr.; Fengyuan, L.; Marcus, L.A.; Michel, A.D.; Reese, M. Gradient Micro-Electro-Mechanical Systems (MEMS) Microphone. U.S. Patent US10154330B2, 11 December 2018.

- Miles, R.N.; Cui, W.; Su, Q.T.; Homentcovschi, D. A MEMS Low-Noise Sound Pressure Gradient Microphone with Capacitive Sensing. J. Microelectromechan. Syst. 2015, 24, 241–248.

- Kang, S.; Hong, H.-K.; Rhee, C.-H.; Yoon, Y.; Kim, C.-H. Directional Sound Sensor with Consistent Directivity and Sensitivity in the Audible Range. J. Microelectromechan. Syst. 2021, 30, 471–479.

- Baumgartel, L.; Vafanejad, A.; Chen, S.-J.; Kim, E.S. Resonance-Enhanced Piezoelectric Microphone Array for Broadband or Prefiltered Acoustic Sensing. J. Microelectromechan. Syst. 2013, 22, 107–114.

- Yoo, I.; Kim, H.; Yang, S.; Kim, D.; Kwon, D.-S.; Lee, J.; Jeong, T. Development of Directional MEMS Microphone Single Module for High Directivity and SNR. IEEE Sens. J. 2022, 22, 6329–6335.

- Mao, W.-J.; Cheng, C.-L.; Lo, S.-C.; Chen, Y.-S.; Fang, W. Design and implementation of a CMOS-MEMS microphone without the back-plate. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 1037–1040.

- Chung, K. Challenges and Recent Developments in Hearing Aids: Part II. Feedback and Occlusion Effect Reduction Strategies, Laser Shell Manufacturing Processes, and Other Signal Processing Technologies. Trends Amplif. 2004, 8, 125–164.

- Shkel, A.A.; Baumgartel, L.; Kim, E.S. A resonant piezoelectric microphone array for detection of acoustic signatures in noisy environments. In Proceedings of the 2015 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015; pp. 917–920.

- Liu, H.; Liu, S.; Shkel, A.A.; Kim, E.S. Active Noise Cancellation with MEMS Resonant Microphone Array. J. Microelectromechan. Syst. 2020, 29, 839–845.

More

Information

Subjects:

Engineering, Electrical & Electronic

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.2K

Revisions:

2 times

(View History)

Update Date:

11 Mar 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No