Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Qiang Zhang | -- | 2341 | 2024-03-09 03:13:14 | | | |

| 2 | Peter Tang | + 1 word(s) | 2342 | 2024-03-11 03:06:11 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Zhang, Q.; Liu, J.; Chen, X. Crucial Technologies of Digital Thread Implementation. Encyclopedia. Available online: https://encyclopedia.pub/entry/56066 (accessed on 08 February 2026).

Zhang Q, Liu J, Chen X. Crucial Technologies of Digital Thread Implementation. Encyclopedia. Available at: https://encyclopedia.pub/entry/56066. Accessed February 08, 2026.

Zhang, Qiang, Jihong Liu, Xu Chen. "Crucial Technologies of Digital Thread Implementation" Encyclopedia, https://encyclopedia.pub/entry/56066 (accessed February 08, 2026).

Zhang, Q., Liu, J., & Chen, X. (2024, March 09). Crucial Technologies of Digital Thread Implementation. In Encyclopedia. https://encyclopedia.pub/entry/56066

Zhang, Qiang, et al. "Crucial Technologies of Digital Thread Implementation." Encyclopedia. Web. 09 March, 2024.

Copy Citation

The digital thread is identified as an integrated information flow using recognized authoritative data sources (e.g., requirements, system architecture, technical data packages (TDP), 3D CAD models) connecting all stages of the product lifecycle. The objective of the digital thread is to establish an integrated framework that consolidates all stages of the product lifecycle and systems, facilitating efficient and effective lifecycle measurements and supporting a data-driven approach.

digital thread

authoritative sources of truth

data linkage

model integration

1. Introduction

In the entire lifecycle of a complex product system, the digital thread facilitates decision making for managers at various levels by providing actionable information derived from disparate data sources. It expedites the interaction between production management data, information, and knowledge, enabling dynamic real-time assessments of a product’s capabilities in stages such as capability planning and analysis, preliminary design, detailed design, manufacturing, testing, and maintenance. Through the analysis of the earlier definition of the digital thread, the researchers identify three crucial technologies for its implementation: authoritative sources of truth (ASTs), data linkage, and model integration [1]. The selection of these specific technologies was made due to their fundamental roles in ensuring data accuracy, consistency, and integration throughout the product lifecycle. Unlike some alternative technologies, such as data visualization tools or project management software, ASTs, data linkage, and model integration directly address the challenges of data fragmentation, siloed systems, and disparate models commonly encountered in traditional product development processes.

2. Authoritative Sources of Truth

An authoritative source of truth (AST) is a model and database capable of storing standardized modeling and standardized data from all versions throughout the entire lifecycle of a system. It supports the extraction of data and models during the design process, ensuring consistency, traceability, verification, confirmation, visual representation, and automated reporting. This enables a continuous digital representation of the system and full lifecycle traceability, enhancing collaborative efficiency, reducing development time, and improving product quality.

ASTs are not only a core element in the implementation of the digital thread but also a crucial component of the “Digital Engineering Strategy”. According to the “Digital Engineering Strategy”, ASTs are considered the central reference point for models and data throughout the entire lifecycle [2].

In ASTs, “A” signifies uniqueness, holding dominion throughout the system engineering implementation. The data and models within the AST possess commanding influence, exerting impact on other parts of the system, with the rest of the system subservient to the AST. “T” implies precision; thus, the data and models within the AST must be accurate, effective, and unambiguous to ensure both their authority and the correctness of the system engineering implementation. “S” indicates the origin, with the data and models within the authoritative source of truth serving as the wellspring for the design, computation, and analysis processes in the system engineering implementation. These data and models originate from the AST and, in turn, reconverge into the AST during the design and analytical phases.

From this perspective, the digital thread appears more like a meta-model, capable of linking to models in specific disciplines that possess a certain “authoritativeness” [3]. The concept of the AST aims to grant access to the most authoritative data at the element level known in the system design at any given moment [4]. Research in the realm of Industry 4.0 suggests that semantic web technologies may be a key driver for the digital thread [5]. However, a significant portion of current research still employs Model-Based Definition (MBD) as the authoritative source of truth for all product information, replacing traditional 2D drawings [6]. By integrating and hierarchically organizing design information within the MBD model, digital threads are created, providing a common data source for various supportive analyses. Digital threads in MBD can enhance communication, productivity, and the validation of designs. They enable the sharing of data and information across different disciplines within the scope of support, such as reliability, maintainability, testability, safety, and logistics [7].

3. Data Linkage

The interoperability of data, systems, and perspectives poses an increasingly severe challenge for industries. The industry necessitates cross-enterprise collaboration, interconnected systems, and correlated data. There are primarily three approaches to achieving interoperability. The first involves standard-based data translation, such as from STEP AP242 to AP238 [8]. The second relies on standards like OSLC and FMI to facilitate interoperability between tools [9]. The third method employs ontologies and knowledge graphs (KGs) for semantic-based data integration [10].

3.1. Standard-Based Data Transformation

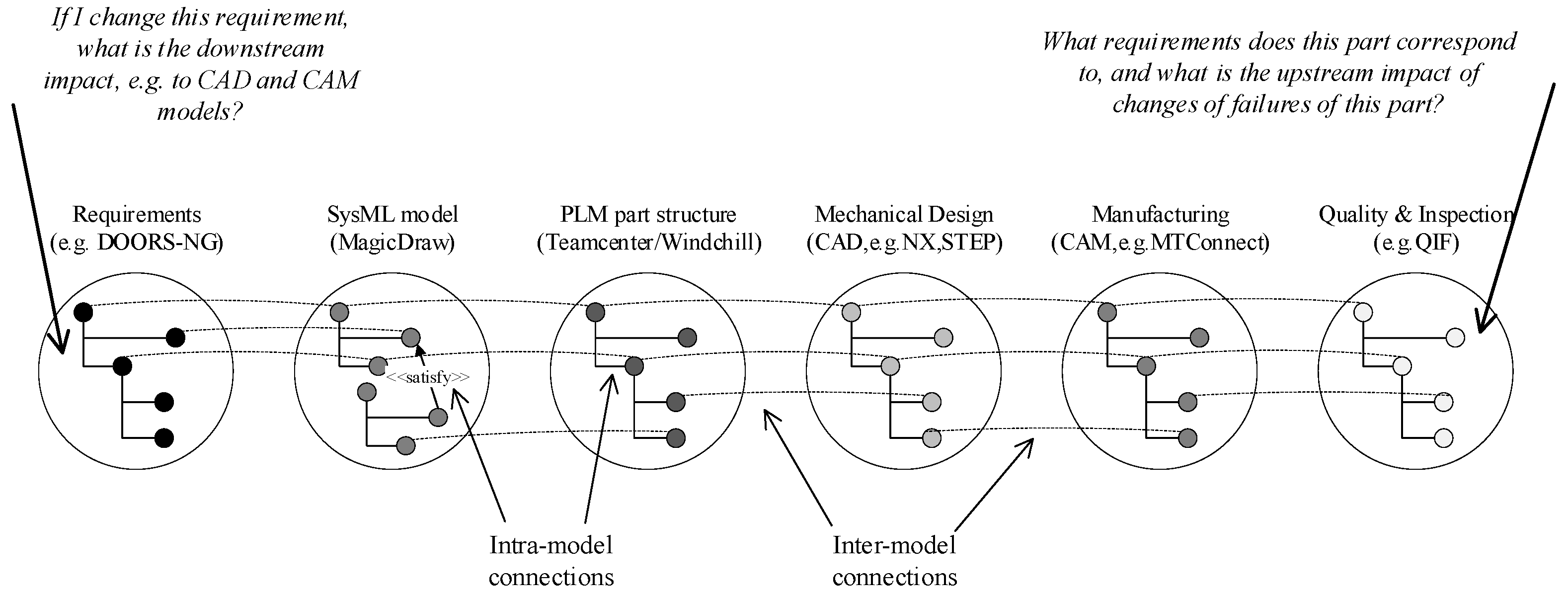

Lu et al. [11] emphasized the significance of standards in the automation of manufacturing processes within the context of the manufacturing digital thread. As illustrated in Figure 1, the product design initiates from the DOORS requirements model, establishing links with the SysML system model and the PLM model [12]. Subsequently, it connects to the design model in the STEP AP242 format (as-designed model), which is then transformed into the STEP-NC or G-code (as-planned model), encompassing all planning rules and encoding procedures required for the execution of the manufacturing process. All data describing actual construction events in the manufacturing environment are monitored within MTConnect (as-executed model) [13][14][15]. However, the existing technology falls short of establishing a truly integrated manufacturing thread. There is a pressing need for the development of algorithms and technologies to contextualize and interlink data from multiple standards effectively.

Helu et al. [16] introduced a reference architecture aimed at facilitating the integration of manufacturing and other product lifecycle data within the digital thread. They have also proposed an approach to linking planning and execution data in a standards-based digital thread [8]. Cho et al. [17], aiming to enhance the detection planning strategy for carving surfaces in an improved on-machine measurement system, integrated CAD/CAM data into the CAI process. Another endeavor to integrate CAD, CAM, and CAI involves extracting feature information from STEP files for improved reference data in quality control [18]. Liu et al. [19] encapsulated all information generated during the inspection process into an MBD model. Bonnard et al. [20] introduced a novel STEP-NC data model supporting direct additive manufacturing and hybrid manufacturing from STEP-NC files. It allows the integration of multiple optimization and simulation modules, thereby expanding the possibilities for advanced and intelligent additive manufacturing.

3.2. Interface-Based Tool Interoperability

Empirical evidence demonstrates that widespread adoption of interoperability standards for linking various tools can significantly reduce the effort required to connect diverse elements within an extensive IT infrastructure [21]. Therefore, there is a need to construct the digital thread based on industry standards and facilitate connectivity among tools employed in this environment. Standards such as OSLC and FMI have been utilized for both lifecycle and non-lifecycle interoperability, fostering interdisciplinary and correlated interactions [9].

The Open Services for Lifecycle Collaboration (OSLC) offers a universal service definition for information communication, along with a set of general technical protocols and loosely coupled automation techniques (e.g., service discovery, querying, delegated user interfaces, change logs) to support lifecycle collaboration in daily work methods [22]. The OSLC specifications provide a loosely coupled foundation for tool integration within specific domains. The Functional Mock-up Interface (FMI) establishes an open standard for integrating different tools, models, and simulation environments, enabling seamless collaboration among various software and hardware components. This fosters the construction and optimization of digital thread systems [23].

Lu et al. [24] introduced a service-oriented toolchain framework that utilizes the GOPPRR meta-meta-modeling approach to construct domain-specific models in the aviation engine domain. Leveraging the OSLC specifications, they established a model-driven digital thread (DT) platform from a process perspective, enabling collaborative simulation between Functional Model Units (FMUs) and Simulink models. Wu et al. [25] proposed a method for constructing cognitive threads based on the OSLC specification and knowledge graphs. This approach supports decision making and management in Systems of Systems (SoSs).

3.3. Semantic Definition-Based Data Integration

The digital thread comprises a variety of lifecycle models and interconnected data through topological relationships. Numerous studies have endeavored to transform existing information models and data, including those based on Extensible Markup Language (XML) and EXPRESS, into ontologies and knowledge graphs. This is because ontology models offer additional formal analysis capabilities and facilitate the reuse of domain knowledge [26]. In recent years, knowledge graphs have emerged as a pivotal technology for linking models and data, with broad applications in constructing and managing the digital thread [27].

Sudarsan et al. [28] advocate using ontologies to expand the proposed product lifecycle management model. Matsokis et al. [29] transform the Semantic Object Model (SOM)-based Unified Modeling Language (UML) into ontologies, showcasing its applicability through a case study in the automotive industry. Orellana [30] outlines the development of a system engineering (SE) reference ontology grounded in ISO/IEC/IEEE 15288 [31]. Unlike other ontologies that target specific systems, this reference ontology centers around system engineering processes, providing context and purpose for establishing and connecting vocabularies across various digital assets.

Panetto et al. [32] developed OntoPDM, aimed at defining product ontologies allowing interoperability using STEP and the International Electrotechnical Commission (IEC) 62264 standards. Barbau et al. [33][34] created OntoSTEP, a tool that facilitates the transformation of STEP schemas and instances into ontologies and knowledge graphs in a simple and automated manner. Sarigecili et al. [35] established EXPRESS data models for tolerance analysis, subsequently using OntoSTEP to convert them into ontologies, facilitating the inference of new knowledge from existing knowledge graphs in a more comprehensible manner. Kwon et al. [10] discussed semantic definition-based data integration using ontologies and knowledge graphs. Ontologies and knowledge graphs offer a structured approach to integrating various data formats and achieving interoperability in data representation. Hedberg et al. [13] introduced an approach utilizing graphical representations to form digital threads, linking and tracking data throughout the entire product lifecycle.

Leveraging semantic-based methods in digital threads has the potential to address challenges related to managing manufacturing data. These approaches provide scalable and contextualized data views, enabling efficient decision making and knowledge generation. The implementation of data integration through ontologies and knowledge graphs remains an ongoing endeavor with ample opportunities. However, the current emphasis is primarily on the early stages of the product lifecycle, posing a hurdle when attempting to establish digital threads.

4. Model Integration

The ability to integrate data models from various sources is essential for comprehending, analyzing, and managing product performance [36]. Consequently, numerous frameworks for the digital thread have been proposed, and corresponding platforms have been developed to achieve model integration [37][38][39][40][41][42][43][44][45][46].

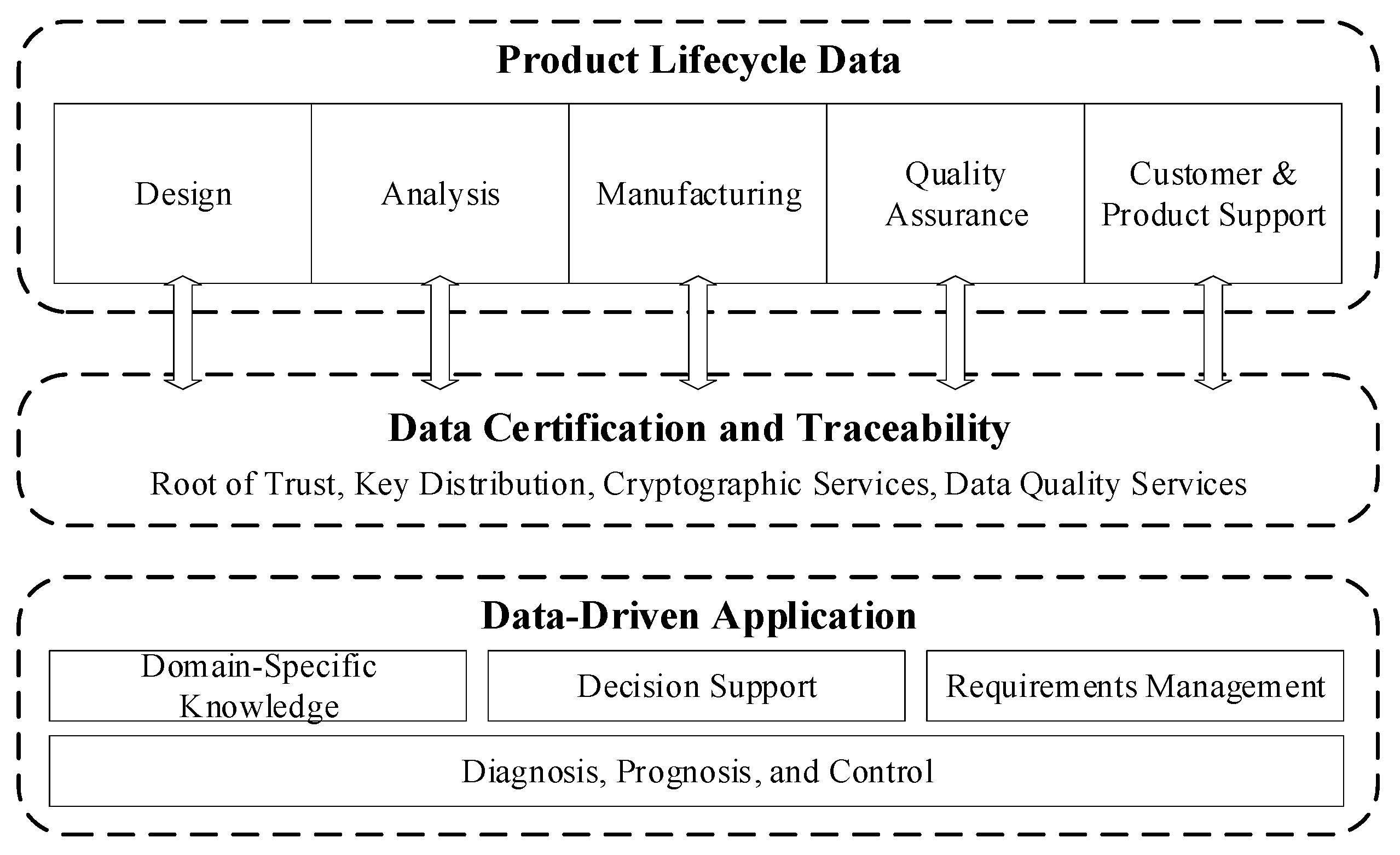

Hedberg et al. [37] introduced the concept of the Lifecycle Information Framework and Technology (LIFT) to support the effective implementation of the digital thread. LIFT represents a conceptual framework that integrates lifecycle information management with emerging and existing technologies, forming the foundational basis for the research agenda on dynamic information modeling. This framework is designed to facilitate digital data management and reuse in manufacturing. It comprises three layers—(1) product lifecycle data, (2) data authentication and traceability, and (3) data-driven applications—as illustrated in Figure 2. The LIFT concept is committed to linking data across information silos, establishing trust through traceability, and propelling applications with data.

Figure 2. The LIFT architecture [37].

Kovalyov et al. [39] proposed a mathematical framework leveraging category theory to facilitate interoperability across diverse engineering modeling languages and tools for Model-Based Engineering (MBE). This work introduces an approach to address assembly issues that arise during the construction of product models for specific configurations. Airbus Group Innovations (AGI) [40], in pursuit of PLM interoperability, developed the Federated Interoperability Framework (FIF). The FIF integrates open standards from manufacturing, Information Systems (ISs), and Information and Communication Technology (ICT). It sequentially addresses concurrent engineering and collaborative product design in virtual enterprises. However, Tchoffa et al. [41] identified limitations in using semantic graphs to address PLM semantics within the FIF framework. To overcome this challenge, they extended the prior work with a novel approach based on UML2/SysML for composite modeling.

Bajaj et al. [47] introduced a conceptual software environment, the System Lifecycle Handler (SLH), developed for digital thread planning. This environment utilizes the Syndeia platform and demonstrates its functionalities via a web dashboard and standard REST/HTTP API. Nguyen et al. [43] outlined the components of the proposed Flexible, Robust, and Agile Digital Engineering (FADE) platform, including a reference architecture model, a connection matrix, digital use case modeling, a modularized database, and data portability. The FADE platform leverages the digital thread to connect system elements, define interface specifications, and achieve seamless data exchange between digital databases and digital system architecture models. Helu et al. [46] developed an integrated product lifecycle testbed that incorporates design, manufacturing, and inspection technologies. This testbed facilitates shared access and exchange of data and information between CAx and manufacturing labs through networked physical infrastructure.

In addition to academic research, various software companies have developed model integration software to support the implementation of the digital thread. Examples include ModelCenter, TeamCenter, ThingWorx, 3DExperience, Aras Innovator®, and Autodesk Fusion Lifecycle. These tools are utilized to manage centralized data storage and integrate simulation models for optimizing product and system design [48].

The digital thread provides significant quantitative and qualitative added values and contributions across various stages of system development, including system design, generating system concepts, system manufacturing, system testing and evaluation, and system support. The digital thread, through the application of real-time data and simulation technology, effectively reduces design risks and costs during the system design phase while promoting collaboration and information sharing among teams, thereby accelerating the design process and enhancing design quality. During the generation of system concepts, the digital thread rapidly evaluates various design schemes, expediting concept validation and prototype development processes. It also provides a unified platform for teams, facilitating the exploration and discussion of potential solutions and driving innovation. In the system manufacturing phase, the digital thread optimizes production processes and resource utilization through real-time monitoring and data analysis, resulting in increased production efficiency and quality assurance. Additionally, it offers a unified information environment for manufacturing teams to better understand and execute design intent, reducing misunderstandings and errors in the manufacturing process. During the system testing and evaluation phase, the digital thread provides comprehensive data support, enabling a more thorough and traceable testing process. It also fosters communication and collaboration between testing teams and other departments, expediting issue resolution and the implementation of improvements. Finally, in the system support phase, the digital thread achieves real-time monitoring and predictive maintenance, reducing system failure rates and maintenance costs. It provides an integrated information platform for support teams to respond to and resolve user needs and issues more quickly, thereby enhancing customer satisfaction and service quality.

References

- Chown, B. Applying a Single Source of Truth Approach to the Information Needed for Functional Safety. In Proceedings of the 2018 IEEE/AIAA 37th Digital Avionics Systems Conference (DASC), London, UK, 23–27 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–5.

- Department of Defense. Digital Engineering Strategy. Available online: https://www.Acq.Osd.Mil/Se/Docs/2018-DES.Pdf (accessed on 22 November 2018).

- West, T.D.; Blackburn, M. Is Digital Thread/Digital Twin Affordable? A Systemic Assessment of the Cost of DoD’s Latest Manhattan Project. Procedia Comput. Sci. 2017, 114, 47–56.

- Bone, M.A.; Blackburn, M.R.; Rhodes, D.H.; Cohen, D.N.; Guerrero, J.A. Transforming Systems Engineering through Digital Engineering. J. Def. Model. Simul. 2019, 16, 339–355.

- Biffl, S.; Sabou, M. (Eds.) Semantic Web Technologies for Intelligent Engineering Applications; Springer International Publishing: Cham, Switzerland, 2016.

- Goher, K.; Shehab, E.; Al-Ashaab, A. Model-Based Definition and Enterprise: State-of-the-Art and Future Trends. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 2288–2299.

- Beshears, R.; Bouma, A. Engaging Supportability Analysis through Model-Based Design. In Proceedings of the 2020 Annual Reliability and Maintainability Symposium (RAMS), Palm Springs, CA, USA, 27–30 January 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–5.

- Helu, M.; Joseph, A.; Hedberg, T. A Standards-Based Approach for Linking as-Planned to as-Fabricated Product Data. CIRP Ann. 2018, 67, 487–490.

- Bachelor, G.; Brusa, E.; Ferretto, D.; Mitschke, A. Model-Based Design of Complex Aeronautical Systems Through Digital Twin and Thread Concepts. IEEE Syst. J. 2020, 14, 1568–1579.

- Kwon, S.; Monnier, L.V.; Barbau, R.; Bernstein, W.Z. Enriching Standards-Based Digital Thread by Fusing as-Designed and as-Inspected Data Using Knowledge Graphs. Adv. Eng. Inform. 2020, 46, 101102.

- Lu, Y.; Xu, X.; Wang, L. Smart Manufacturing Process and System Automation—A Critical Review of the Standards and Envisioned Scenarios. J. Manuf. Syst. 2020, 56, 312–325.

- Canedo, A. Industrial IoT Lifecycle via Digital Twins. In Proceedings of the Proceedings of the Eleventh IEEE/ACM/IFIP International Conference on Hardware/Software Codesign and System Synthesis, Pittsburgh, PA, USA, 7–14 October 2016; ACM: New York, NY, USA, 2016; p. 1.

- Hedberg, T.D.; Bajaj, M.; Camelio, J.A. Using Graphs to Link Data Across the Product Lifecycle for Enabling Smart Manufacturing Digital Threads. J. Comput. Inf. Sci. Eng. 2020, 20, 011011.

- Bajaj, M.; Backhaus, J.; Walden, T.; Waikar, M.; Zwemer, D.; Schreiber, C.; Issa, G.; Intercax; Martin, L. Graph-Based Digital Blueprint for Model Based Engineering of Complex Systems. Incose Int. Symp 2017, 27, 151–169.

- Bajaj, M.; Zwemer, D.; Yntema, R.; Phung, A.; Kumar, A.; Dwivedi, A.; Waikar, M. MBSE++—Foundations for Extended Model-Based Systems Engineering Across System Lifecycle. Incose Int. Symp 2016, 26, 2429–2445.

- Helu, M.; Hedberg, T.; Barnard Feeney, A. Reference Architecture to Integrate Heterogeneous Manufacturing Systems for the Digital Thread. CIRP J. Manuf. Sci. Technol. 2017, 19, 191–195.

- Cho, M.-W.; Seo, T.-I. Inspection Planning Strategy for the On-Machine Measurement Process Based on CAD/CAM/CAI Integration. Int. J. Adv. Manuf. Technol. 2002, 19, 607–617.

- Sivakumar, S.; Dhanalakshmi, V. An Approach towards the Integration of CAD/CAM/CAI through STEP File Using Feature Extraction for Cylindrical Parts. Int. J. Comput. Integr. Manuf. 2013, 26, 561–570.

- Liu, R.; Duan, G.; Liu, J. A Framework for Model-Based Integrated Inspection. Int. J. Adv. Manuf. Technol. 2019, 103, 3643–3665.

- Bonnard, R.; Hascoët, J.-Y.; Mognol, P.; Stroud, I. STEP-NC Digital Thread for Additive Manufacturing: Data Model, Implementation and Validation. Int. J. Comput. Integr. Manuf. 2018, 31, 1141–1160.

- Chown, B.; Blyler, J. Increasing the Productivity of an MBSE Development Team throughout the System Design Lifecycle. In Proceedings of the 2018 Annual IEEE International Systems Conference (SysCon), Vancouver, BC, Canada, 23–26 April 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–3.

- OASIS OSLC. Available online: http://Open-Services.Net (accessed on 28 January 2024).

- Blockwitz, T.; Otter, M.; Akesson, J.; Arnold, M.; Clauss, C.; Elmqvist, H.; Friedrich, M.; Junghanns, A.; Mauss, J.; Neumerkel, D.; et al. Functional Mockup Interface 2.0: The Standard for Tool Independent Exchange of Simulation Models. In Proceedings of the 9th International Modelica Conference, Munich, Germany, 3–5 September 2012; pp. 173–184.

- Lu, J.; Wang, J.; Chen, D.; Wang, J.; Torngren, M. A Service-Oriented Tool-Chain for Model-Based Systems Engineering of Aero-Engines. IEEE Access 2018, 6, 50443–50458.

- Wu, S.; Lu, J.; Hu, Z.; Yang, P.; Wang, G.; Kiritsis, D. Cognitive Thread Supports System of Systems for Complex System Development. In Proceedings of the 2021 16th International Conference of System of Systems Engineering (SoSE), Västerås, Sweden, 14 June 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 82–87.

- Lu, W.; Qin, Y.; Liu, X.; Huang, M.; Zhou, L.; Jiang, X. Enriching the Semantics of Variational Geometric Constraint Data with Ontology. Comput.-Aided Des. 2015, 63, 72–85.

- Banerjee, A.; Dalal, R.; Mittal, S.; Joshi, K.P. Generating Digital Twin Models Using Knowledge Graphs for Industrial Production Lines. In Proceedings of the Proceedings of the 2017 ACM on Web Science Conference, Troy, NY, USA, 25 June 2017; ACM: New York, NY, USA, 2017; pp. 425–430.

- Sudarsan, R.; Fenves, S.J.; Sriram, R.D.; Wang, F. A Product Information Modeling Framework for Product Lifecycle Management. Comput.-Aided Des. 2005, 37, 1399–1411.

- Matsokis, A.; Kiritsis, D. An Ontology-Based Approach for Product Lifecycle Management. Comput. Ind. 2010, 61, 787–797.

- Orellana, D.; Mandrick, W. The Ontology of Systems Engineering: Towards a Computational Digital Engineering Semantic Framework. Procedia Comput. Sci. 2019, 153, 268–276.

- ISO/IEC/IEEE 15288:2023; Systems and Software Engineering—System Life Cycle Processes. IEEE SA Standards Association: Piscateville, NJ, USA, 2023.

- Panetto, H.; Dassisti, M.; Tursi, A. ONTO-PDM: Product-Driven ONTOlogy for Product Data Management Interoperability within Manufacturing Process Environment. Adv. Eng. Inform. 2012, 26, 334–348.

- Krima, S.; Barbau, R.; Fiorentini, X.; Sudarsan, R.; Sriram, R.D. OntoSTEP: OWL-DL Ontology for STEP; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2009; p. NIST IR 7561.

- Barbau, R.; Krima, S.; Rachuri, S.; Narayanan, A.; Fiorentini, X.; Foufou, S.; Sriram, R.D. OntoSTEP: Enriching Product Model Data Using Ontologies. Comput.-Aided Des. 2012, 44, 575–590.

- Sarigecili, M.I.; Roy, U.; Rachuri, S. Interpreting the Semantics of GD&T Specifications of a Product for Tolerance Analysis. Comput.-Aided Des. 2014, 47, 72–84.

- Kim, D.B. An Approach for Composing Predictive Models from Disparate Knowledge Sources in Smart Manufacturing Environments. J. Intell. Manuf. 2019, 30, 1999–2012.

- Hedberg, T.; Feeney, A.B.; Helu, M.; Camelio, J.A. Toward a Lifecycle Information Framework and Technology in Manufacturing. J. Comput. Inf. Sci. Eng. 2017, 17, 021010.

- Guo, T.; Khoo, D.; Coultis, M.; Pazos-Revilla, M.; Siraj, A. Poster Abstract: IoT Platform for Engineering Education and Research (IoT PEER)--Applications in Secure and Smart Manufacturing. In Proceedings of the 2018 IEEE/ACM Third International Conference on Internet-of-Things Design and Implementation (IoTDI), Orlando, FL, USA, 17–20 April 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 277–278.

- Kovalyov, S.P. Leveraging Category Theory in Model Based Enterprise. Adv. Syst. Sci. Appl. 2020, 20, 50–65.

- Figay, N.; Ghodous, P. Extended Hypermodel for Interoperability within the Virtual Enterprise. In Proceedings of the 2009 Fifth International Conference on Signal Image Technology and Internet Based Systems, Marakesh, Morocco, 29 November–4 December 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 393–400.

- Tchoffa, D.; Figay, N.; Ghodous, P.; Exposito, E.; Apedome, K.S.; El Mhamedi, A. Dynamic Manufacturing Network—From Flat Semantic Graphs to Composite Models. Int. J. Prod. Res. 2019, 57, 6569–6578.

- Gopalakrishnan, S.; Hartman, N.W.; Sangid, M.D. Model-Based Feature Information Network (MFIN): A Digital Twin Framework to Integrate Location-Specific Material Behavior Within Component Design, Manufacturing, and Performance Analysis. Integr. Mater. Manuf. Innov. 2020, 9, 394–409.

- Nguyen, T.M.; Guillen, A.T.; Freeze, T.; Chang, A.; Zahidi, F.; Singh, J.; Lee, J.; Nguyen, H.H.; Avedissian, V.; Dang, A.X. Innovative Flexible, Robust and Agile Digital Engineering Platform Development for Supporting Future Space Systems Acquisition; SPIE: Bellingham, WA, USA, 2020; Volume 11422, pp. 180–184.

- Gharbi, A.; Sarojini, D.; Kallou, E.; Harper, D.J.; Petitgenet, V.; Rancourt, D.; Briceno, S.I.; Mavris, D.N. A Single Digital Thread Approach to Aircraft Detailed Design; Aerospace Research Central: Reston, VA, USA, 2017; p. 0693.

- Wang, P.; Luo, M. A Digital Twin-Based Big Data Virtual and Real Fusion Learning Reference Framework Supported by Industrial Internet towards Smart Manufacturing. J. Manuf. Syst. 2021, 58, 16–32.

- Helu, M.; Hedberg, T. Enabling Smart Manufacturing Research and Development Using a Product Lifecycle Test Bed. Procedia Manuf. 2015, 1, 86–97.

- Bajaj, M.; Hedberg, T., Jr. System Lifecycle Handler—Spinning a Digital Thread for Manufacturing; Wiley Online Library: Hoboken, NJ, USA, 2018; Volume 28, pp. 1636–1650.

- Bone, M.; Blackburn, M.; Kruse, B.; Dzielski, J.; Hagedorn, T.; Grosse, I. Toward an Interoperability and Integration Framework to Enable Digital Thread. Systems 2018, 6, 46.

More

Information

Subjects:

Engineering, Manufacturing; Engineering, Industrial; Computer Science, Information Systems

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.4K

Revisions:

2 times

(View History)

Update Date:

11 Mar 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No