Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Eleni Symeonaki | -- | 1998 | 2024-03-08 12:26:47 | | | |

| 2 | Fanny Huang | -1 word(s) | 1997 | 2024-03-11 06:06:17 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Symeonaki, E.; Maraveas, C.; Arvanitis, K.G. Digital Twins Concept Integration in Livestock Farming. Encyclopedia. Available online: https://encyclopedia.pub/entry/56060 (accessed on 08 February 2026).

Symeonaki E, Maraveas C, Arvanitis KG. Digital Twins Concept Integration in Livestock Farming. Encyclopedia. Available at: https://encyclopedia.pub/entry/56060. Accessed February 08, 2026.

Symeonaki, Eleni, Chrysanthos Maraveas, Konstantinos G. Arvanitis. "Digital Twins Concept Integration in Livestock Farming" Encyclopedia, https://encyclopedia.pub/entry/56060 (accessed February 08, 2026).

Symeonaki, E., Maraveas, C., & Arvanitis, K.G. (2024, March 08). Digital Twins Concept Integration in Livestock Farming. In Encyclopedia. https://encyclopedia.pub/entry/56060

Symeonaki, Eleni, et al. "Digital Twins Concept Integration in Livestock Farming." Encyclopedia. Web. 08 March, 2024.

Copy Citation

The potential application of the digital twins concept and its principles to all industries, including agriculture, has been the subject of considerable research interest. Since livestock farming is one of the mainstays of the agricultural industry, contributing to food security as well as employment and income generation, digital twins appear to be a promising technology to address issues related to the intensive nature of livestock production systems, which are typically characterized by high levels of input and output.

digital twins

livestock farming

1. Introduction

Food insecurity is a pervasive and pressing global issue that has far-reaching consequences for individuals, communities, and nations. Given that the world population in 2022 reached almost 8 billion and is expected to exceed 10 billion by the later part of the 21st century [1], the Food and Agriculture Organization (FAO) of the United Nations predicts that the production of food commodities needs to increase by at least 50% compared to 2012 [2]. On top of that, food insecurity is exacerbated by the intensification of occurrences of unusually severe weather events due to climate change and the economic crises, as well as ongoing armed conflicts like the Russo–Ukrainian war or other contingent circumstances, for instance, the COVID-19 pandemic [3]. Therefore, it seems imperative to ensure food security through higher agricultural productivity without compromising the long-term sustainability and resilience of agro-ecosystems [4]. In this sense, agricultural production systems face the challenge of meeting a rising food demand along with climate change-related conditions, the deterioration of natural resources due to their uncontrolled exploitation, the loss of biodiversity, and the increased food waste caused by the deficiencies in the agri-food supply chain while remaining profitable [5].

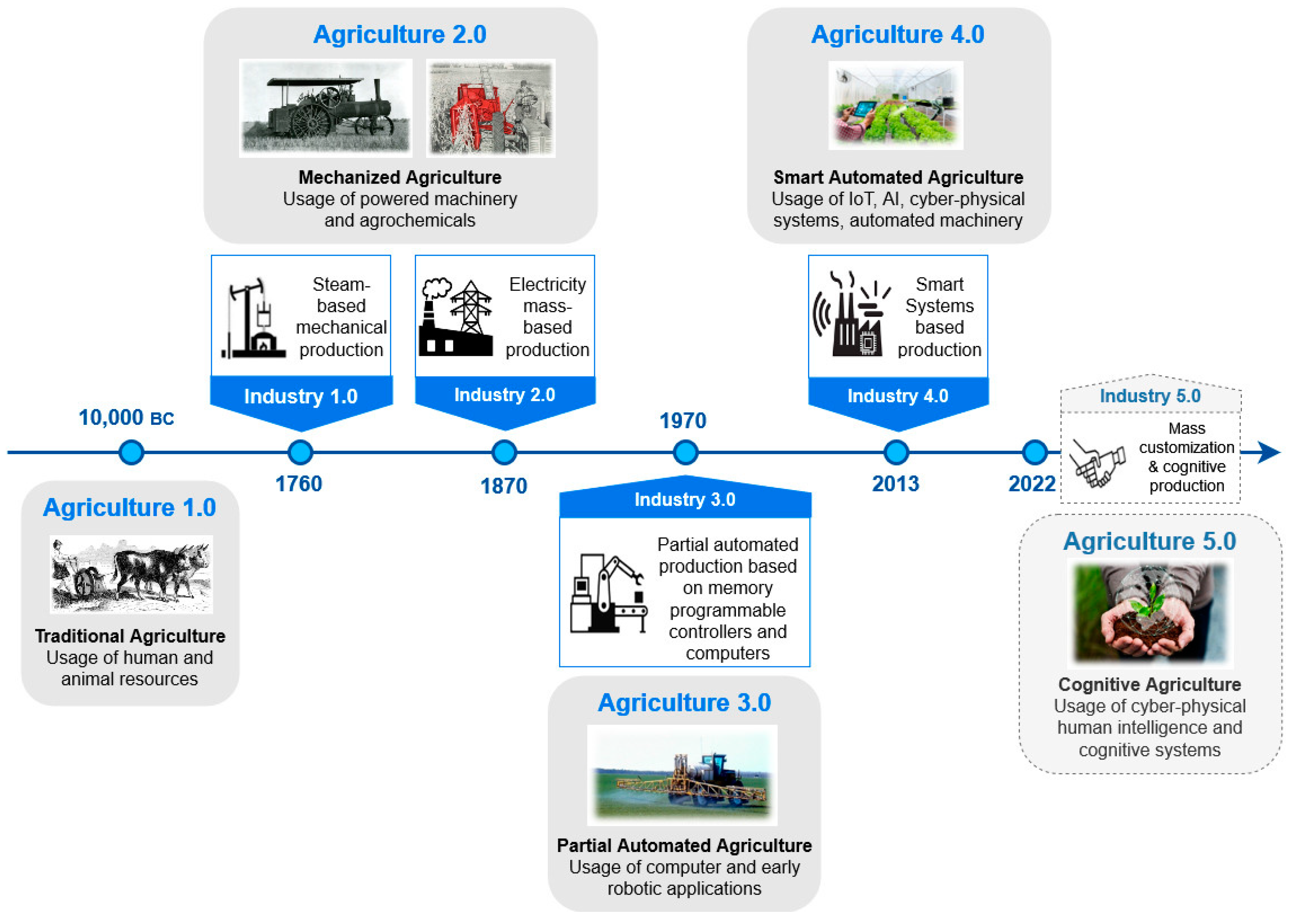

Considering the importance of the agricultural production system as a main pillar of the primary sector of industry, various scientific and technological approaches have been devised and implemented over time to increase the efficiency of their outputs [6]. Indeed, the agricultural sector has evolved throughout history, alongside the technological developments of all industrial revolutions, as illustrated in Figure 1, from the first agricultural revolution under the term “Agriculture 1.0” to the current agricultural revolution, attributed as “Agriculture 5.0” [5][7], which represents the emerging trend that the agricultural sector is going to adopt in the upcoming years. In particular, the concept of Agriculture 5.0 focuses on transforming agricultural production systems through the integration of the recent advancements in smart technologies [8] so as to enhance their efficiency while making them environmentally sustainable [9].

Figure 1. Timeline of industrial and agricultural revolutions.

Rapid progress in the application of leading-edge technologies, such as wireless sensor networks (WSNs) and real-time sensing [10], artificial intelligence (AI) [11] and machine learning (ML) [12], edge computing [13], big data analytics and the Internet of Things (IoT) [14] as part of Agriculture 4.0 [15], are enabling agricultural production systems to be fully data-driven in the context of Agriculture 5.0 [16] and, therefore, raise attention in the digital twins (DTs) concept and their feasible applications in the agricultural sector to achieve the objectives of sustainable development [17]. Actually, based on the integrated farm management (IFM) approach [18], an agricultural production system is potent at adapting to dynamic changes [19] as it is updated on a continuous basis and in real time based on data feedback from sensors and devices that collect the parameters related to the properties of its physical entities and environment, as well as the system itself [8][20]. In this respect, the DTs concept enables the virtual replication of physical entities with corresponding digital ones that are accurate and “live” [21], bridging them according to a cyber-physical architecture under which any change that occurs in the physical entities simultaneously and continuously modifies their virtual twins [22].

The potential of applying the DTs concept and the principles it represents to all industrial sectors, including the agricultural one, has lately gained great research interest, as reported in the recent literature [22][23][24][25][26][27], concerning the case of arable agriculture in particular. In this area, DTs represent virtual representations of extensive fields. These digital replicas enable farmers to accurately understand critical factors, such as soil health, moisture levels, and crop growth [28]. This approach goes beyond conventional practices, offering targeted interventions and resource optimization through the ability to rapidly adapt to evolving conditions and ensure resilience against uncertainties [29].

Likewise, considering that livestock farming is one of the leading sectors of the agricultural industry, adding to food safety [30], as well as creating work opportunities and income, DTs may emerge as a promising technology for addressing issues related to the intense nature of livestock production systems [30], which are typically characterized by high levels of input and output per farming unit [31]. To this end, by creating virtual counterparts of livestock and the environment, DTs can facilitate the real-time monitoring of individual animals, providing farmers with insights into feeding patterns, stress factors, and optimal breeding strategies, allowing for a proactive approach to health management as well as disease prevention, thereby ensuring not only productivity but also the welfare of the livestock [32].

Despite the prominent benefits that derive from the integration of the DTs technology into livestock production systems, the number of works in the literature that review recent advances in DTs technology (with a focus on their applications in livestock production systems) has been, to the best of researchers' knowledge, rather limited to date.

2. Digital Twins Concept Integration in Livestock Farming

2.1. The Digital Twins Concept

The digital twins (DTs) concept was initially conceptualized by Michael Grieves, referring to the management of the product life cycle in 2003 [33]—a virtual version of a physical product comprising information about the product in question [34]. In a more specific definition, a DT can be attributed as a virtual copy of a product, process, or service that incorporates all of the above features [35]. Miller et al. [36] further extended the definition of the DTs concept as the integration of multiple models within a model-based enterprise. According to this definition, a digital twin can be formed by establishing associations between different models as well as relationships between the data stored in various domains. Stark and Damerau [37] provided a more comprehensive definition of the DTs concept by describing it as “a digital representation of an active unique product (real device, object, machine, service, or intangible asset) or unique product-service system (a system consisting of a product and a related service) that comprises its selected characteristics, properties, conditions, and behaviours by means of models, information, and data within a single or even across multiple life cycle phases”. While the meaning of the DTs concept may seem straightforward, its definition is debated and constantly evolving, as is reported in the literature [38][39][40][41]. The various existing definitions are characterized by specific features deriving from multiple use cases employing the DTs concept. What may be expressed in the simplest terms, is that a DT consists a digital duplicate of an existing physical entity [23].

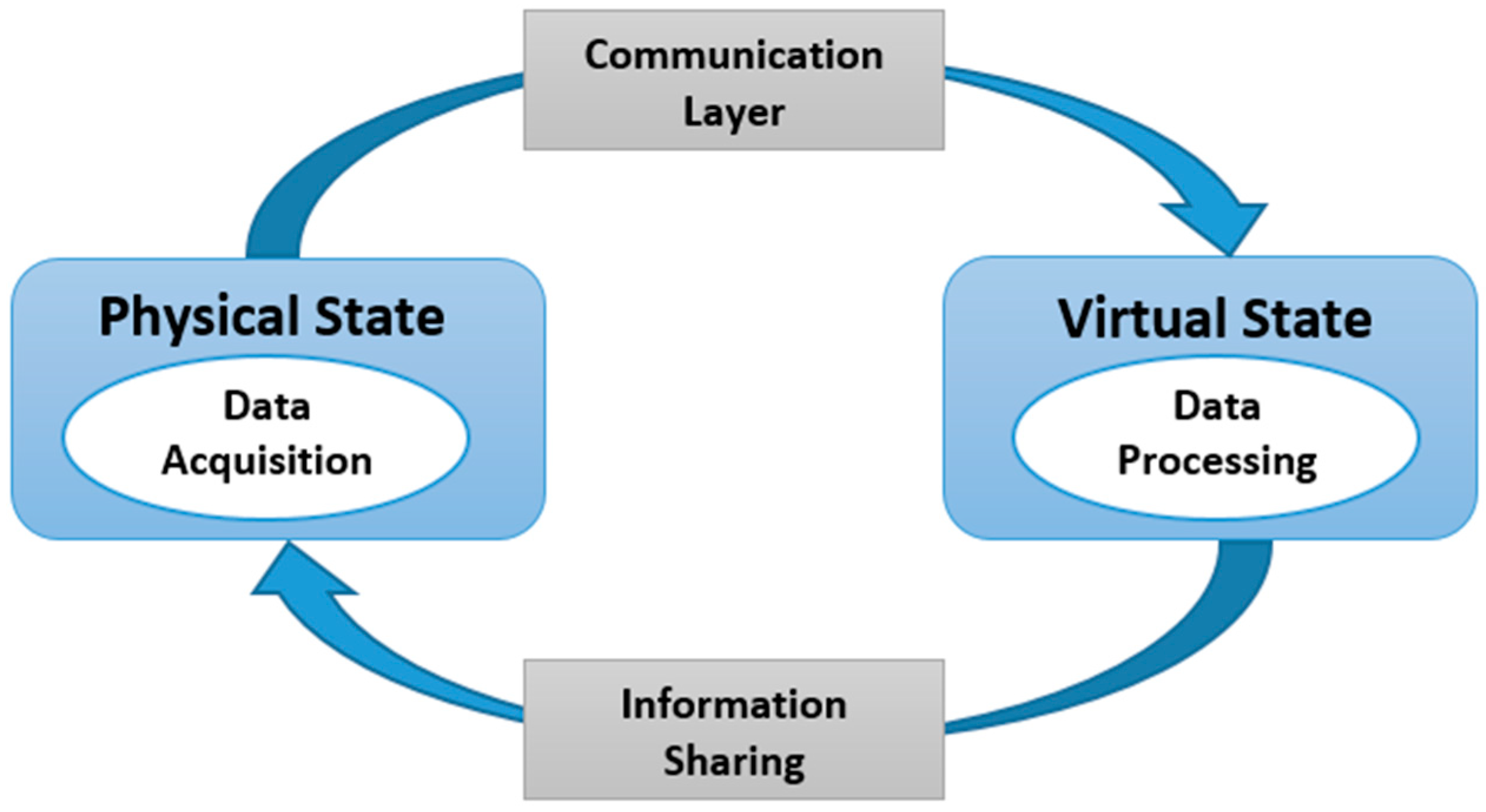

The lack of consistency in the definition of the DTs concept makes the identification of its main components rather challenging. As DTs was first introduced by Grieves [33], it applies to a system constituted of three principal subsystems: (a) the real space with the physical products, (b) the cyberspace with the virtual products, and (c) the interconnection of the virtual and real products via data and information. Based on this structure, the DTs flow is represented as a loop, called twinning, where data are directed from the physical to the virtual state, while information and processes are directed in reverse, as depicted in Figure 2 [26]. This concept has been recently extended by Tao et al. [42] to five components, involving data and services as a part of a DT system, while in [43], verification, validation, and accreditation were also identified as components of a DT system, stating that cyber and physical space are seamlessly integrated.

Figure 2. The basis of the digital twins concept.

Establishing a commonly accepted definition of the DTs concept constitutes a step forward in the advancement of this technology. By contextualizing future use cases of DTs in a unified notion and terminology, a broad set of the diverse DTs physical entities may be implemented in a way that remains consistent with the DTs paradigm so that its intended benefits can be fully achieved and shared across all sectors.

2.2. The Digital Twins Concept in Livestock Farming

Τhe livestock sector is undergoing rapid development on a worldwide level as a result of the growing demand for animal products, driven by the need for food safety [44] due to population increase and rapid urbanization, as well as stimulating prosperity in the industrialized world and most developing countries [45]. In addition to the potential benefits associated with the growing development of the livestock sector, a number of challenges seem to arise from operational, socio-economic, environmental, and sanitary issues [30].

That which is characteristic of livestock production systems (at present) is their intensive nature, which is associated with both greater volumes of inputs (i.e., farm size, manpower, financial resources, etc.) and outputs per production holding. In this perspective, the number of holdings is declining, while the number of animals reared in closed, environmentally controlled, automated facilities is rising [46]. Moreover, vertical integration is often embedded in the view that a single company can be in charge of the overall production system (e.g., from the feed mill to the processing plant), which is configured to achieve maximum output with all of its components running consistently at full load [47]. Therefore, whatever disorder may occur at any stage of the production chain will lead to a direct impact on both the upstream and downstream levels, with direct implications not just for animal welfare but for humans and the wider environment as well. This fact is aligned with the emergent notion of “One Welfare”, an approach which, as reported in [48], gives recognition to the immediate and implicit associations between animal welfare and the well-being of people and the broader environment.

In response, the entire digitization of livestock production systems is often suggested [17] in the context of Agriculture 4.0 and, consequently, Agriculture 5.0 [5][7]. According to this approach, computationally enabled technologies [8], incorporating smart sensors, WSNs, AI and ML, Edge computing, big data analytics, the IoT, and other cutting-edge technologies, with DTs among them, are considered to be of great importance.

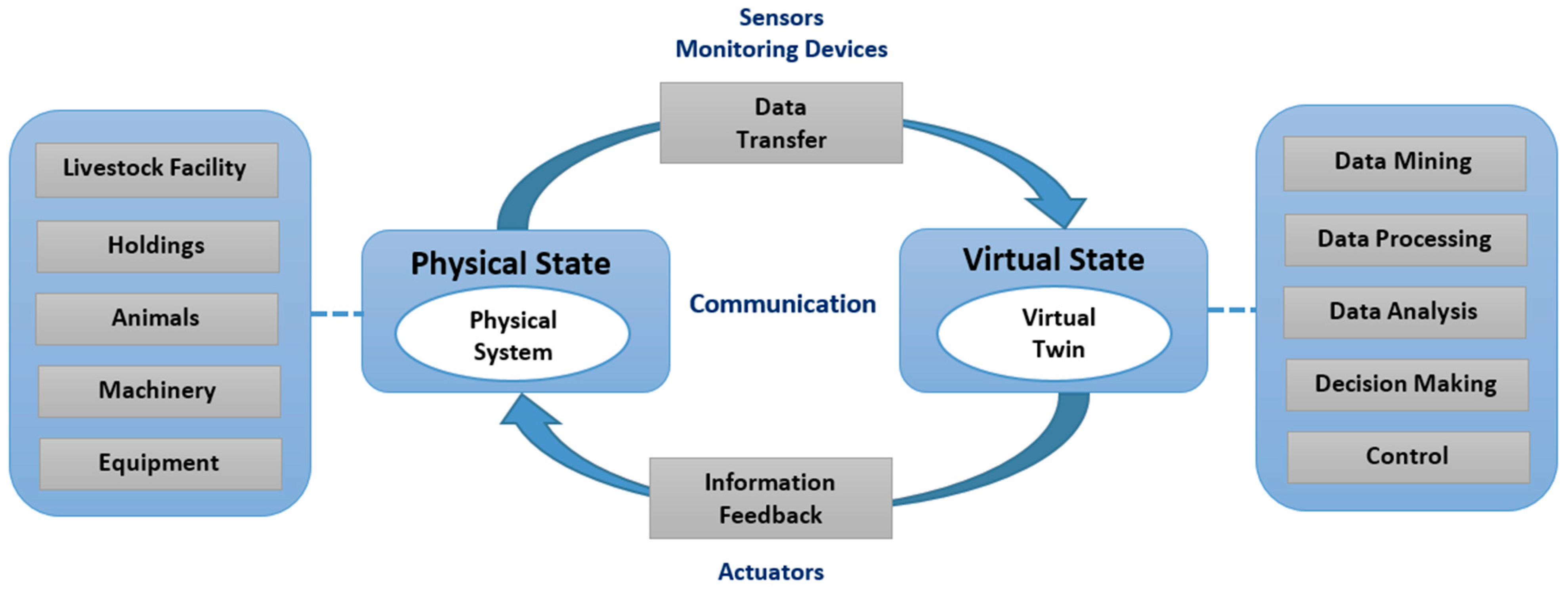

To this end, when integrating the DTs concept in livestock farming, the physical state accounts for a physical system that embodies the composite and dynamic environment of livestock facilities, with the boundaries of the DTs specified [49]. Herein, it has to be noted that the physical system is a fundamental component of a DT since the lack of it implies that the physical state merely represents a model [50]. To this end, the physical system involves the fundamental features of the incorporated physical objects and devices [51]; it can be comprised of an entire object with individual components found in a physical environment, a single component of the object [50], or an individual property of the object that is linked to other objects. In the case of livestock production systems, the physical system may indicatively consist of an entire facility, including animals, holdings, machinery, equipment, and feeding strategies, as well as a number of animals or just an animal body [52]. Finally, monitoring and sensing devices [53] are incorporated into the physical system so as to collect the data required. Accordingly, the virtual state accounts as a representation of the physical state model and data. By involving data mining, processing, and analytics by means of AI and ML techniques, the virtual state provides feedback for supporting decision-making and controlling the physical system so as to foresee any obscure matters and optimize its operation [54]. Finally, the twinning, which enables the interconnection between the physical and virtual state, accounts for the transmission of data from the physical system to its virtual twin, as well as for the reverse information feedback [55] to the livestock production system. The type of techniques incorporated for establishing such interconnection depends on the data volume, type, and source as well as the speed and rate that is required for achieving the minimum accepted delay both of the data transmission and information feedback [52][56]. Based on the aforementioned, Figure 2 has been elaborated upon, resulting in Figure 3, which depicts a schematic of the DTs concept in livestock farming.

Figure 3. The digital twins concept for livestock farming.

References

- World Population Trends. Available online: https://www.unfpa.org/world-population-trends#readmore-expand (accessed on 29 October 2023).

- The State of the World’s Land and Water Resources for Food and Agriculture 2021—Systems at Breaking Point; FAO: Rome, Italy, 2022.

- Global Report on Food Crises—2022|World Food Programme. Available online: https://www.wfp.org/publications/global-report-food-crises-2022 (accessed on 29 October 2023).

- Sundstrom, S.M.; Angeler, D.G.; Allen, C.R. Resilience Theory and Coerced Resilience in Agriculture. Agric. Syst. 2023, 206, 103612.

- Fraser, E.D.G.; Campbell, M. Agriculture 5.0: Reconciling Production with Planetary Health. One Earth 2019, 1, 278–280.

- Engås, K.G.; Raja, J.Z.; Neufang, I.F. Decoding Technological Frames: An Exploratory Study of Access to and Meaningful Engagement with Digital Technologies in Agriculture. Technol. Forecast. Soc. Chang. 2023, 190, 122405.

- Saiz-Rubio, V.; Rovira-Más, F. From Smart Farming towards Agriculture 5.0: A Review on Crop Data Management. Agronomy 2020, 10, 207.

- Alwis, S.D.; Hou, Z.; Zhang, Y.; Na, M.H.; Ofoghi, B.; Sajjanhar, A. A Survey on Smart Farming Data, Applications and Techniques. Comput. Ind. 2022, 138, 103624.

- Ragazou, K.; Garefalakis, A.; Zafeiriou, E.; Passas, I. Agriculture 5.0: A New Strategic Management Mode for a Cut Cost and an Energy Efficient Agriculture Sector. Energies 2022, 15, 3113.

- Loukatos, D.; Arvanitis, K.G. Multi-Modal Sensor Nodes in Experimental Scalable Agricultural IoT Application Scenarios. Lect. Notes Data Eng. Commun. Technol. 2021, 67, 101–128.

- Smith, M.J. Getting Value from Artificial Intelligence in Agriculture. Anim. Prod. Sci. 2018, 60, 46–54.

- Benos, L.; Tagarakis, A.C.; Dolias, G.; Berruto, R.; Kateris, D.; Bochtis, D. Machine Learning in Agriculture: A Comprehensive Updated Review. Sensors 2021, 21, 3758.

- Zhang, X.; Cao, Z.; Dong, W. Overview of Edge Computing in the Agricultural Internet of Things: Key Technologies, Applications, Challenges. IEEE Access 2020, 8, 141748–141761.

- Paraforos, D.S.; Griepentrog, H.W. Digital Farming and Field Robotics: Internet of Things, Cloud Computing, and Big Data. In Fundamentals of Agricultural and Field Robotics. Agriculture Automation and Control; Springer: Cham, Switzerland, 2021; pp. 365–385.

- da Silveira, F.; Lermen, F.H.; Amaral, F.G. An Overview of Agriculture 4.0 Development: Systematic Review of Descriptions, Technologies, Barriers, Advantages, and Disadvantages. Comput. Electron. Agric. 2021, 189, 106405.

- Kaklauskas, A. Agriculture 5.0: Smart Agriculture, AI, Iot, Society 5.0, Big Data Analytics, Blockchain, Digital Twins, Robotics, Drones and Immersive Reality. 2018. Available online: http://ir.lib.ruh.ac.lk/xmlui/handle/iruor/13735 (accessed on 1 November 2023).

- Tzachor, A.; Richards, C.E.; Jeen, S. Transforming Agrifood Production Systems and Supply Chains with Digital Twins. NPJ Sci. Food 2022, 6, 47.

- Rose, D.C.; Sutherland, W.J.; Barnes, A.P.; Borthwick, F.; Ffoulkes, C.; Hall, C.; Moorby, J.M.; Nicholas-Davies, P.; Twining, S.; Dicks, L.V. Integrated Farm Management for Sustainable Agriculture: Lessons for Knowledge Exchange and Policy. Land Use Policy 2019, 81, 834–842.

- Talavera, J.M.; Tobón, L.E.; Gómez, J.A.; Culman, M.A.; Aranda, J.M.; Parra, D.T.; Quiroz, L.A.; Hoyos, A.; Garreta, L.E. Review of IoT Applications in Agro-Industrial and Environmental Fields. Comput. Electron. Agric. 2017, 142, 283–297.

- Waleed, M.; Um, T.W.; Kamal, T.; Usman, S.M. Classification of Agriculture Farm Machinery Using Machine Learning and Internet of Things. Symmetry 2021, 13, 403.

- Niederer, S.A.; Sacks, M.S.; Girolami, M.; Willcox, K. Scaling Digital Twins from the Artisanal to the Industrial. Nat. Comput. Sci. 2021, 1, 313–320.

- Jiang, Y.; Yin, S.; Li, K.; Luo, H.; Kaynak, O. Industrial Applications of Digital Twins. Philos. Trans. R. Soc. A 2021, 379, 20200360.

- Sharma, A.; Kosasih, E.; Zhang, J.; Brintrup, A.; Calinescu, A. Digital Twins: State of the Art Theory and Practice, Challenges, and Open Research Questions. J. Ind. Inf. Integr. 2022, 30, 100383.

- Stark, R.; Fresemann, C.; Lindow, K. Development and Operation of Digital Twins for Technical Systems and Services. CIRP Ann. 2019, 68, 129–132.

- Ketzler, B.; Naserentin, V.; Latino, F.; Zangelidis, C.; Thuvander, L.; Logg, A. Digital Twins for Cities: A State of the Art Review. Built Environ. 2020, 46, 547–573.

- Agnusdei, G.P.; Elia, V.; Gnoni, M.G. Is Digital Twin Technology Supporting Safety Management? A Bibliometric and Systematic Review. Appl. Sci. 2021, 11, 2767.

- Pylianidis, C.; Osinga, S.; Athanasiadis, I.N. Introducing Digital Twins to Agriculture. Comput. Electron. Agric. 2021, 184, 105942.

- Nasirahmadi, A.; Hensel, O. Toward the Next Generation of Digitalization in Agriculture Based on Digital Twin Paradigm. Sensors 2022, 22, 498.

- Verdouw, C.; Tekinerdogan, B.; Beulens, A.; Wolfert, S. Digital Twins in Smart Farming. Agric. Syst. 2021, 189, 103046.

- Busch, G.; Gauly, M.; Spiller, A. Opinion Paper: What Needs to Be Changed for Successful Future Livestock Farming in Europe? Animal 2018, 12, 1999–2001.

- Symeonaki, E.; Arvanitis, K.G.; Piromalis, D.; Tseles, D.; Balafoutis, A.T. Ontology-Based IoT Middleware Approach for Smart Livestock Farming toward Agriculture 4.0: A Case Study for Controlling Thermal Environment in a Pig Facility. Agronomy 2022, 12, 750.

- García, R.; Aguilar, J.; Toro, M.; Pinto, A.; Rodríguez, P. A Systematic Literature Review on the Use of Machine Learning in Precision Livestock Farming. Comput. Electron. Agric. 2020, 179, 105826.

- Grieves, M.W. Product Lifecycle Management: The New Paradigm for Enterprises. Int. J. Prod. Dev. 2005, 2, 71–84.

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A Systematic Literature Review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52.

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Shaping the Digital Twin for Design and Production Engineering. CIRP Ann. 2017, 66, 141–144.

- Miller, A.M.D.; Alvarez, R.; Hartman, N. Towards an Extended Model-Based Definition for the Digital Twin. Comput. Aided Des. Appl. 2018, 15, 880–891.

- Stark, R.; Damerau, T. Digital Twin. CIRP Encycl. Prod. Eng. 2019, 1–8.

- Abramovici, M.; Göbel, J.C.; Dang, H.B. Semantic Data Management for the Development and Continuous Reconfiguration of Smart Products and Systems. CIRP Ann. 2016, 65, 185–188.

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A Survey on Digital Twin: Definitions, Characteristics, Applications, and Design Implications. IEEE Access 2019, 7, 167653–167671.

- Wilking, F.; Schleich, B.; Wartzack, S. Digital Twins—Definitions, Classes and Business Scenarios for Different Industry Sectors. Proc. Des. Soc. 2021, 1, 1293–1302.

- Botín-Sanabria, D.M.; Mihaita, S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.d.J. Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote Sens. 2022, 14, 1335.

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital Twin-Driven Product Design, Manufacturing and Service with Big Data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576.

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415.

- Qian, J.; Wu, Z.; Zhu, Y.; Liu, C. One Health: A Holistic Approach for Food Safety in Livestock. Sci. One Health 2022, 1, 100015.

- van der Linden, A.; de Olde, E.M.; Mostert, P.F.; de Boer, I.J.M. A Review of European Models to Assess the Sustainability Performance of Livestock Production Systems. Agric. Syst. 2020, 182, 102842.

- Saitone, T.L.; Sexton, R.J. Agri-Food Supply Chain: Evolution and Performance with Conflicting Consumer and Societal Demands. Eur. Rev. Agric. Econ. 2017, 44, 634–657.

- Robinson, S.; Petrick, M. Sustainable Development Goals and the Livestock Sector in Central Asia: A Course Outline; Universitätsbibliothek Gießen: Gießen, Germany, 2021.

- García Pinillos, R.; Appleby, M.C.; Manteca, X.; Scott-Park, F.; Smith, C.; Velarde, A. One Welfare—A Platform for Improving Human and Animal Welfare. Vet. Rec. 2016, 179, 412–413.

- Lu, J.; Zheng, X.; Schweiger, L.; Kiritsis, D. A Cognitive Approach to Manage the Complexity of Digital Twin Systems. In Smart Services Summit: Digital as an Enabler for Smart Service Business Development; Springer International Publishing: Cham, Switzelrand, 2021; pp. 105–115.

- Wright, L.; Davidson, S. How to Tell the Difference between a Model and a Digital Twin. Adv. Model. Simul. Eng. Sci. 2020, 7, 13.

- Juarez, M.G.; Botti, V.J.; Giret, A.S. Digital Twins: Review and Challenges. J. Comput. Inf. Sci. Eng. 2021, 21, 030802.

- Neethirajan, S.; Kemp, B. Digital Twins in Livestock Farming. Animals 2021, 11, 1008.

- Fera, M.; Greco, A.; Caterino, M.; Gerbino, S.; Caputo, F.; Macchiaroli, R.; D’amato, E. Towards Digital Twin Implementation for Assessing Production Line Performance and Balancing. Sensors 2019, 20, 97.

- Gámez Díaz, R.; Yu, Q.; Ding, Y.; Laamarti, F.; El Saddik, A. Digital Twin Coaching for Physical Activities: A Survey. Sensors 2020, 20, 5936.

- VanDerHorn, E.; Mahadevan, S. Digital Twin: Generalization, Characterization and Implementation. Decis. Support Syst. 2021, 145, 113524.

- Monteiro, J.; Barata, J.; Veloso, M.; Veloso, L.; Nunes, J. Towards Sustainable Digital Twins for Vertical Farming. In Proceedings of the 2018 Thirteenth International Conference on Digital Information Management (ICDIM), Berlin, Germany, 24–26 September 2018; pp. 234–239.

More

Information

Subjects:

Agricultural Engineering

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

946

Revisions:

2 times

(View History)

Update Date:

11 Mar 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No