| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Foteini Sakaveli | -- | 3228 | 2024-02-25 18:14:33 | | | |

| 2 | Catherine Yang | Meta information modification | 3228 | 2024-02-26 02:13:10 | | |

Video Upload Options

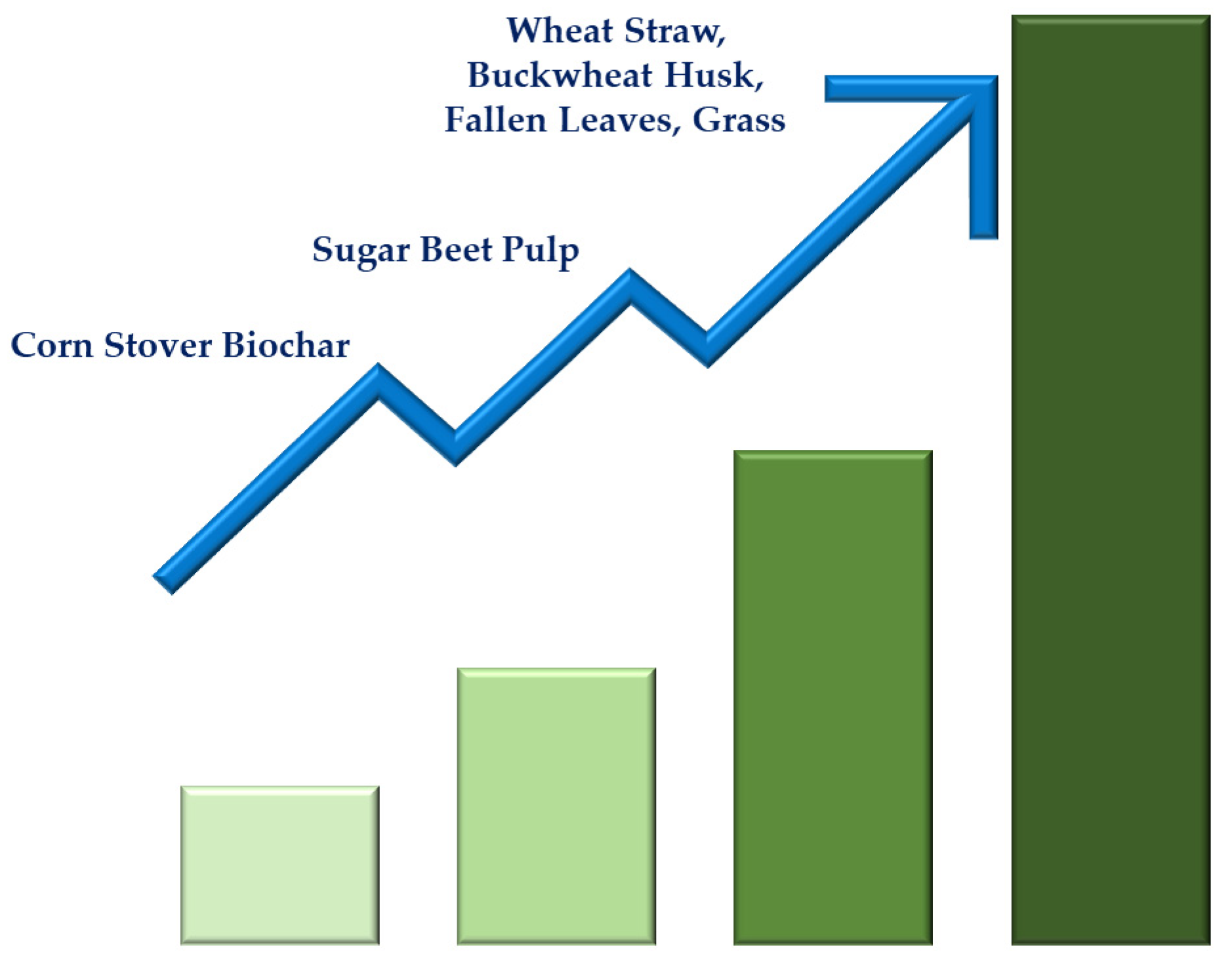

Primary sludge is a valuable substrate for anaerobic digestion as it contains a higher percentage of fatty acids and lipids compared to secondary sludge, although its carbon-to-nitrogen ratio is relatively low due to its inherent deficiency of carbon. This limiting factor of C/N ratio can be overwhelmed by the co-digestion of primary sludge with organic fractions such as agricultural byproducts and municipal solid wastes. The operating principle of this practice is based on the fact that organic fractions such as agricultural byproducts contain a high percentage of carbon and a low percentage of nitrogen, so the co-digestion of primary sludge with different organic fractions, such as animal manure, agricultural residues, organic fractions of municipal waste, or vegetable residues, may improve the balance of nutrients, provide buffering capacity, adjust the C/N ratio, reduce the concentration of ammonia, and hence its inhibitory effects, and overall promote the process of methanogenesis.

1. Introduction

2. Food Waste (FW), Fruit and Vegetable Waste (FVW), and the Organic Fraction of Municipal Solid Waste (OFMSW)

| Substrate 1 | Treatment 2 | Inoculum 3 | ISR * | Tested Conditions | Mode 4 | Scale 5 | T 6 | Efficiency 7 | Reference | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1. | CEPT | - | ADS | - | OLR 2, 1.5, 2.25, and 3 g VSS/L/d | SC | L | M | - | [15] |

| 2. | PS SS |

Advanced primary separation | ADS-LAB | - | SS: 0.5 and 1.5 g/L | - | L | - | - | [16] |

| 3. | PS | FNA (HNO2-N) |

ADS | 1.5–2 w/w VS for sludge, w/w TCOD for supernatant | 0.77, 1.54, 2.31, 3.08, and 3.85 mg HNO2-N/L | B | L | M | - | [17] |

| 4. | PS | Enzymatic treatment (P, LP) |

ADS-LAB | 1:1 g VSS/g VS | P/LP 3:1, 1:1, 1:3, 0:1 w/w | B | L | M | + | [18] |

| 5. | PS | NaOH | EBS | 4:1 | NaOH 0.1 mol/L to 5, 10, 15% recycled sludge | SC | L | M | + | [19] |

| 6. | PS | MCP | ADS | 0.3:1 v/v | 2, 4, 6, 8, and 10 min of MCP | B | L | M | +++ | [20] |

| 7. | PS | HTT | ADS | 0.3:1 w/w VS | 130, 150, 170, 190, and 210 °C for 30 min | B | L | M | + | [21] |

3. Agro-Industrial Wastes

| PS Substrate 1 | Co-Substrate 2 | Inoculum 3 | ISR * | OLR + initial | Tested Concentrations | Mode 4 | Scale 5 | T 6 | Efficiency 7 | Reference | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | PS | CSB | ADS | 2:1 w/w VS | - | 1.82, 2.55, 3.06 g/g TS− | B | L | TH | + | [42] |

| 1.82 g/g TS + 0.12 g/g TS/d | C | ||||||||||

| 2. | PS | WS BH |

CM | 2:1 w/w VS | 3.0, 6.0, 7.5, 8.0, 10.0, 12.0 g VS/L | PS/WS 1:2 w/w VS |

B | L | M | +++ | [23] |

| - | PS/WS BH C/N = 10.07, 13.06, 15.01, 20.03, 25.25 |

+++ | |||||||||

| 3. | PS | FL GR |

ADS + WAS | 2:1 w/w VS | - | PS FL GR C/N = 10, 13, 16, 20, 23 |

B | L | M | +++ | [24] |

| 0.5 g VS/L/d | PS FL GR C/N = 13 |

SC | |||||||||

| 4. | PS | SBP | ADS | 2:1 w/w VS | - | PS/SBP 7:3, 1:1, 3:7 w/w VS |

B | L | M | ++ | [26] |

| 5. | PS | SL CS |

CM RC |

2:1 w/w VS | - | PS SL CS C/N = 18, 21, 25, 30, 35 |

B | L | M | +++ | [25] |

| - | PS SL CS—CM, C/N = 18 PS SL CS—RC, C/N = 20.70 |

B | |||||||||

| 0.5 g VS/L/d | PS SL CS C/N = 18 |

SC | |||||||||

| 6. | PS | CM BS |

UASB | - | 0.71 g COD/L/d | PS/CM 3:1, 1:1 w/w | C | L | M | + | [40] |

| PS/BW 3:1, 1:1 w/w | +++ | ||||||||||

| PS/CM:BW 2:1:1 w/w | +++ | ||||||||||

| 7. | PS | WH CM |

ADS | - | PS/WH 4:1 w/w | SC | L | M | + | [41] | |

| PS/WH 1:1 w/w + Ca(OH) | |||||||||||

| PS/WH/CM (final) 1:0.8:0.2 w/w |

References

- Obulisamy, P.K.; Chakraborty, D.; Selvam, A.; Wong, J.W.C. Anaerobic Co-Digestion of Food Waste and Chemically Enhanced Primary-Treated Sludge under Mesophilic and Thermophilic Conditions. Environ. Technol. 2016, 37, 3200–3207.

- Chakraborty, D.; Karthikeyan, O.P.; Selvam, A.; Wong, J.W.C. Co-Digestion of Food Waste and Chemically Enhanced Primary Treated Sludge in a Continuous Stirred Tank Reactor. Biomass Bioenergy 2018, 111, 232–240.

- Kang, X.; Liu, Y. Chemically Enhanced Primary Sludge as an Anaerobic Co-Digestion Additive for Biogas Production from Food Waste. Processes 2019, 7, 709.

- Xie, S.; Wickham, R.; Nghiem, L.D. Synergistic Effect from Anaerobic Co-Digestion of Sewage Sludge and Organic Wastes. Int. Biodeterior. Biodegrad. 2017, 116, 191–197.

- Rakić, N.; Šušteršič, V.; Gordić, D.; Jovičić, N.; Bošković, G.; Bogdanović, I. Characteristics of Biogas Production and Synergistic Effect of Primary Sludge and Food Waste Co-Digestion. Bioenergy Res. 2023, 1–14.

- Gomez-Lahoz, C.; Fernández-Giménez, B.; Garcia-Herruzo, F.; Rodriguez-Maroto, J.M.; Vereda-Alonso, C. Biomethanization of Mixtures of Fruits and Vegetables Solid Wastes and Sludge from a Municipal Wastewater Treatment Plant. J. Environ. Sci. Health -Part A Toxic/Hazard. Subst. Environ. Eng. 2007, 42, 481–487.

- Elsayed, M.; Diab, A.; Soliman, M. Methane Production from Anaerobic Co-Digestion of Sludge with Fruit and Vegetable Wastes: Effect of Mixing Ratio and Inoculum Type. Biomass Convers. Biorefinery 2021, 11, 989–998.

- Gómez, X.; Cuetos, M.J.; Cara, J.; Morán, A.; García, A.I. Anaerobic Co-Digestion of Primary Sludge and the Fruit and Vegetable Fraction of the Municipal Solid Wastes. Conditions for Mixing and Evaluation of the Organic Loading Rate. Renew. Energy 2006, 31, 2017–2024.

- Habagil, M.; Keucken, A.; Horváth, I.S. Biogas Production from Food Residues—The Role of Trace Metals and Co-Digestion with Primary Sludge. Environments 2020, 7, 8–10.

- Ahmed, B.; Tyagi, V.K.; Priyanka; Khan, A.A.; Kazmi, A.A. Optimization of Process Parameters for Enhanced Biogas Yield from Anaerobic Co-Digestion of OFMSW and Bio-Solids. Biomass Convers. Biorefinery 2022, 12, 607–618.

- Iacovidou, E.; Ohandja, D.-G.; Voulvoulis, N. Food Waste Co-Digestion with Sewage Sludge—Realising Its Potential in the UK. J. Environ. Manag. 2012, 112, 267–274.

- Solé-Bundó, M.; Salvadó, H.; Passos, F.; Garfí, M.; Ferrer, I. Strategies to Optimize Microalgae Conversion to Biogas: Co-Digestion, Pretreatment and Hydraulic Retention Time. Molecules 2018, 23, 2096.

- Mehariya, S.; Patel, A.K.; Obulisamy, P.K.; Punniyakotti, E.; Wong, J.W.C. Co-Digestion of Food Waste and Sewage Sludge for Methane Production: Current Status and Perspective. Bioresour. Technol. 2018, 265, 519–531.

- Li, Y.; Ni, J.; Cheng, H.; Guo, G.; Zhang, T.; Zhu, A.; Qin, Y.; Li, Y.-Y. Enhanced Digestion of Sludge via Co-Digestion with Food Waste in a High-Solid Anaerobic Membrane Bioreactor: Performance Evaluation and Microbial Response. Sci. Total Environ. 2023, 899, 165701.

- Zhuang, H.; Amy Tan, G.Y.; Jing, H.; Lee, P.H.; Lee, D.J.; Leu, S.Y. Enhanced Primary Treatment for Net Energy Production from Sewage—The Genetic Clarification of Substrate-Acetate-Methane Pathway in Anaerobic Digestion. Chem. Eng. J. 2022, 431, 133416.

- Araneda, M.; Pavez, J.; Luza, B.; Jeison, D. Use of Activated Sludge Biomass as an Agent for Advanced Primary Separation. J. Environ. Manag. 2017, 192, 156–162.

- Zhang, T.; Wang, Q.; Ye, L.; Yuan, Z. Effect of Free Nitrous Acid Pre-Treatment on Primary Sludge Biodegradability and Its Implications. Chem. Eng. J. 2016, 290, 31–36.

- Tongco, J.V.; Kim, S.; Oh, B.R.; Heo, S.Y.; Lee, J.; Hwang, S. Enhancement of Hydrolysis and Biogas Production of Primary Sludge by Use of Mixtures of Protease and Lipase. Biotechnol. Bioprocess Eng. 2020, 25, 132–140.

- Li, H.; Zou, S.; Li, C.; Jin, Y. Alkaline Post-Treatment for Improved Sludge Anaerobic Digestion. Bioresour. Technol. 2013, 140, 187–191.

- Wang, X.; Xie, Y.; Qi, X.; Chen, T.; Zhang, Y.; Gao, C.; Zhang, A.; Ren, W. A New Mechanical Cutting Pretreatment Approach towards the Improvement of Primary Sludge Fermentation and Anaerobic Digestion. J. Environ. Chem. Eng. 2022, 10, 107163.

- Yuan, T.; Cheng, Y.; Zhang, Z.; Lei, Z.; Shimizu, K. Comparative Study on Hydrothermal Treatment as Pre- and Post-Treatment of Anaerobic Digestion of Primary Sludge: Focus on Energy Balance, Resources Transformation and Sludge Dewaterability. Appl. Energy 2019, 239, 171–180.

- Gerardi, M.H. The Microbiology of Anaerobic Digesters; Gerardi, M.H., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003; ISBN 0-471-20693-8.

- Elsayed, M.; Andres, Y.; Blel, W.; Gad, A.; Ahmed, A. Effect of VS Organic Loads and Buckwheat Husk on Methane Production by Anaerobic Co-Digestion of Primary Sludge and Wheat Straw. Energy Convers. Manag. 2016, 117, 538–547.

- Elsayed, M.; Blel, W.; Soliman, M.; Andres, Y.; Hassan, R. Semi-Continuous Co-Digestion of Sludge, Fallen Leaves, and Grass Performance. Energy 2021, 221, 119888.

- Elsayed, M.; Hassany, R.; Soliman, M. Anaerobic Co-Digestion of Sludge, Sugarcane Leaves, and Corchorus Stalks in Egypt. Biomass Convers. Biorefinery 2021, 13, 2177–2191.

- Elsayed, M.; Andres, Y.; Meky, N.; Hassan, R. Anaerobic Co-Digestion of Sugar Beet Pulp and Sludge: Influence of Periodic Intermittent Stirring and Mixing Ratio. Biomass Convers. Biorefinery 2023, 1–9.

- Rongpipi, S.; Ye, D.; Gomez, E.D.; Gomez, E.W. Progress and Opportunities in the Characterization of Cellulose—An Important Regulator of Cell Wall Growth and Mechanics. Front. Plant Sci. 2019, 9, 1894.

- Xia, T.; Huang, H.; Wu, G.; Sun, E.; Jin, X.; Tang, W. The Characteristic Changes of Rice Straw Fibers in Anaerobic Digestion and Its Effect on Rice Straw-Reinforced Composites. Ind. Crops Prod. 2018, 121, 73–79.

- Horn, S.J.; Vaaje-Kolstad, G.; Westereng, B.; Eijsink, V.G. Novel Enzymes for the Degradation of Cellulose. Biotechnol. Biofuels 2012, 5, 45.

- Xiao, B.; Sun, X.F.; Sun, R. Chemical, Structural, and Thermal Characterizations of Alkali-Soluble Lignins and Hemicelluloses, and Cellulose from Maize Stems, Rye Straw, and Rice Straw. Polym. Degrad. Stab. 2001, 74, 307–319.

- Dharmalingam, B.; Tantayotai, P.; Panakkal, E.J.; Cheenkachorn, K.; Kirdponpattara, S.; Gundupalli, M.P.; Cheng, Y.-S.; Sriariyanun, M. Organic Acid Pretreatments and Optimization Techniques for Mixed Vegetable Waste Biomass Conversion into Biofuel Production. BioEnergy Res. 2023, 16, 1667–1682.

- Nakamura, Y.; Ono, Y.; Saito, T.; Isogai, A. Characterization of Cellulose Microfibrils, Cellulose Molecules, and Hemicelluloses in Buckwheat and Rice Husks. Cellulose 2019, 26, 6529–6541.

- Huang, Y.; Li, F.; Meng, J.; Chen, W. Lignin Content of Agro-Forestry Biomass Negatively Affects the Resultant Biochar PH. BioResources 2019, 13, 5153–5163.

- Sarath, G.; Mitchell, R.B.; Sattler, S.E.; Funnell, D.; Pedersen, J.F.; Graybosch, R.A.; Vogel, K.P. Opportunities and Roadblocks in Utilizing Forages and Small Grains for Liquid Fuels. J. Ind. Microbiol. Biotechnol. 2008, 35, 343–354.

- Mann, D.G.J.; Labbé, N.; Sykes, R.W.; Gracom, K.; Kline, L.; Swamidoss, I.M.; Burris, J.N.; Davis, M.; Stewart, C.N. Rapid Assessment of Lignin Content and Structure in Switchgrass (Panicum virgatum L.) Grown under Different Environmental Conditions. Bioenergy Res. 2009, 2, 246–256.

- Ghimire, N.; Bakke, R.; Bergland, W.H. Liquefaction of Lignocellulosic Biomass for Methane Production: A Review. Bioresour. Technol. 2021, 332, 125068.

- Weiland, P. Biomass Digestion in Agriculture: A Successful Pathway for the Energy Production and Waste Treatment in Germany. Eng. Life Sci. 2006, 6, 302–309.

- Murto, M.; Björnsson, L.; Mattiasson, B. Impact of Food Industrial Waste on Anaerobic Co-Digestion of Sewage Sludge and Pig Manure. J. Environ. Manag. 2004, 70, 101–107.

- Ward, A.J.; Hobbs, P.J.; Holliman, P.J.; Jones, D.L. Optimisation of the Anaerobic Digestion of Agricultural Resources. Bioresour. Technol. 2008, 99, 7928–7940.

- Nansubuga, I.; Banadda, N.; Babu, M.; Devriez, J.; Verstraete, W.; Rabaey, K. Enhancement of Biogas Potential of Primary Sludge by Co-Digestion with Cow Manure and Brewery Sludge. Int. J. Agric. Biol. Eng. 2015, 8, 86–94.

- Shilton, A.; Powell, N.; Broughton, A.; Pratt, C.; Pratt, S.; Pepper, C. Enhanced Biogas Production Using Cow Manure to Stabilize Co-Digestion of Whey and Primary Sludge. Environ. Technol. 2013, 34, 2491–2496.

- Wei, W.; Guo, W.; Ngo, H.H.; Mannina, G.; Wang, D.; Chen, X.; Liu, Y.; Peng, L.; Ni, B.J. Enhanced High-Quality Biomethane Production from Anaerobic Digestion of Primary Sludge by Corn Stover Biochar. Bioresour. Technol. 2020, 306, 123159.