| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Abdelaziz Lafi Khlaifat | -- | 3399 | 2024-02-24 19:25:20 | | | |

| 2 | Lindsay Dong | Meta information modification | 3399 | 2024-02-26 01:31:21 | | |

Video Upload Options

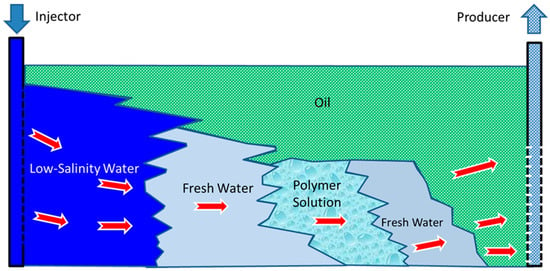

Polymer flooding is an enhanced oil recovery (EOR) method used to increase oil recovery from oil reservoirs beyond primary and secondary recovery. Although it is one of the most well-established methods of EOR, there are still continuous new developments and evaluations for this method. This is mainly attributed to the diverse polymers used, expansion of this method in terms of application, and the increase in knowledge pertaining to the topic due to the increase in laboratory testing and field applications.

1. Introduction

2. Polymer Flooding Principles and Mechanisms

3. Types of Polymers

-

Temperature: The ability of the polymer to withstand high temperatures depends on an innate property of the polymer itself. This is a strong function of the main compounds that form the monomer; the type and orientation of the bonds present within the monomer structure; and, finally, the bond strength between the individual monomer units that form the long-chain polymer. The measure of the ability of the polymer to resist degradation under a specific temperature is referred to as thermal stability. Depending on the type of polymer, the temperature range for thermal stability can be extremely high according to previous research, ranging from 31 °C to 212 °C [43]. It is also important to note that for a specific polymer, multiple thermal stability ranges can be mentioned. The variation in the thermal stability values is the result of two main parameters. The first is the molecular weight of the polymer; this can vary significantly for the same polymer depending on the initiator used to link the monomers; the purity of the monomers; and the monomer density, which is reflected directly in the molecular weight, since the definition of molecular weight is the number of grams of the chemical per mole. The variation in thermal stability could also be due to variation in testing conditions [44]. Some researchers have focused on using freshwater and neutral pH when measuring thermal stability, whereas others have used tap water, which has a variety of salinity and pH values depending on the country and location. It is therefore highly advised to measure the thermal stability of each polymer individually before testing, since it may vary relative to the calculated value [45].

-

Pressure: Pressure is usually divided into two main types: injection pressure and the pressure differential during propagation into the formation. The ability of the polymer to withstand high pressure without failing is important to evaluate to avoid premature or excessive polymer degradation. It can be measured using pressure differential laboratory experiments involving core flooding [42][43][44][45].

-

pH: Different polymers can tolerate a wide range of pH values depending on the monomer used to develop the polymer. Although a wide range of polymers can function well under high pH values or basic conditions, a limited number of polymers can resist degradation under low pH values or acidic conditions. These polymers can be applied under highly acidic conditions such as in the presence of high concentrations of hydrogen sulfide or carbon dioxide or when the crude oil has a high total acid number. It is important to note that these types of polymers are usually much more costly than other conventional polymers [46][47][48].

-

Salinity: When referring to salinity, there are two main categories of interest: monovalent cations and divalent cations. Monovalent cations include any salt that is formed of an element with one valence electron, such as sodium, while divalent cations are salts that are formed of an element with two valence electrons, such as calcium. Salts have an overall negative impact on polymers, with monovalent cations being less damaging compared to divalent cations. A detailed description of the impact of salt in field applications of polymer flooding is presented in [30].

-

Rock Type: The type of rock involves both its lithology and its properties. The lithology of rock has an impact on the polymer if it can react with the polymer itself, causing polymer structural change and, eventually, degradation. The rock property that has the most significant impact on the polymer is wettability. If the polymer has a tendency to adhere to the rock surface, a large volume of the injected polymer is lost in the formation, failing to perform its function. This results in a significant increase in the polymer flooding cost [40][41][42][43].

-

Polymer Molecular Weight: The specific molecular weight of the polymer depends on the selected type of polymer and the method of polymerization. The molecular weight of the polymer impacts the concentration of polymer added to the water prior to injection, the injectivity of the polymer, and the ability of the polymer to propagate in different pore sizes in the formation. It is therefore extremely important to measure the molecular weight of the polymer prior to injection. It is also important to note that the molecular weight of the polymer can change over time due to polymer degradation [40][41][42][43][44][45][46][47][48].

-

Polymer Cost: The overall cost of a polymer flooding operation relies on multiple components, including the cost of the polymer itself. Depending on the polymer used, the cost can be extremely low, while for more specialized polymers, the cost of the polymer can be extremely high. The selection of the polymer itself is dependent on reservoir rock and fluid properties, reservoir thermodynamics, and operational considerations [47].

3.1. Organic Polymers

3.2. Inorganic Polymers

4. Polymer Flooding

Lab Scale

Many studies have investigated the use of polymers for different applications in laboratory-based experiments. These experiments investigated either the ability of a specific or a newly synthesized polymer to improve oil recovery or the impact of a specific parameter on polymer performance and degradation [32][33][34][35][36][37][38][39][40][41][42][43][44][45][46][47][48][49]. The majority of polymer flooding experiments conducted on polymer flooding EOR can be classified as core flooding experiments, polymer flooding in fractures, polymer application in microfluidics, or reservoir simulation of polymer flooding.

Core flooding is a broad term that refers to the injection of fluid into a confined core plug. The plug can be cylindrical or rectangular depending on the core holder. The dimensions of the plug can vary significantly depending on the core holder capacity and the type of experiment being conducted. Core flooding can include continuous cores or cores with fractures. Fractures involve two distinct modes: either continuous or partial fracture. Continuous fractures involve a fracture that covers the entire length of the core plug. A partial fracture is a fracture that propagates partially across the core [32][33][34].

Microfluidics studies the flow of the polymer through microchannels or porous media. The key difference between microfluidics and core flooding is the size of the observation, where microfluidics focuses on micro- and, sometimes, nanosized observations. Microfluidics is a key area of research with respect to the evaluation of the interactions occurring between polymers and rock, reservoir fluids, or both at the microscopic scale. Analysis of microchannels is usually conducted using imaging techniques such as magnifying microscopy, scanning electron microscopy, or transmission electron microscopy. There are several methods by which microfluidic channels can be created to model polymer flooding behavior in micropores. For all the methods summarized below, precision is key to producing a representative microfluidic rock sample for analysis [52][53][54][55][56][57][58][59][60][61].

Reservoir simulation of polymer flooding projects involves studying the ability of the polymer to increase oil recovery at the entire field scale rather than the small core scale. The polymer should be defined in the reservoir simulation process based on its properties and characteristics. This can be achieved by creating a new phase with unique properties, the most important of which is viscosity. It is important to note that many reservoir simulators do not take into consideration polymer degradation based on the change in conditions, assuming an ideal polymer [32][33][34][35][36][37][38][39].

Field Scale

Polymer dehydration is the process of the loss of water or fluid from the hydropolymer lattice. Loss of water can be due to several factors. An increase in temperature can result in significant and rapid polymer dehydration. The thermal stability of different polymers varies; therefore, dehydration should be tested to determine polymer compatibility with the reservoir. High pressure differentials can also result in polymer dehydration. This may be due to large depths, which require high injection pressure, or small pore sizes, which require high pressure for the polymer to propagate through the pores. Salinity is another significant factor that can impact polymer dehydration. When the formation water salinity is high compared to the hydropolymer water salinity, osmotic pressure causes the salt in the formation water to penetrate the polymer lattice. This results in polymer shrinkage and, therefore, loss of fluid. This can also result in polymer syneresis, which can damage the polymer structure and result in irreversible degradation [15][16][17][18][19][20][21][22][23][24].

Polymer degradation involves permanent damage to the polymer chains. Degradation can occur due to many factors depending on the polymer type and properties. Polymer degradation involves the weakening or destruction of the polymer chains, resulting in the polymer losing its high viscosity, which is attributed to the long chains and the high molecular weight of the polymer prior to degradation. Degradation is a strong function of the polymer limitations and can occur due to excessive temperature, pressure differentials, pH, salinity (including both monovalent and divalent cations), gasses such as carbon dioxide or hydrogen sulfide, pore size distribution in the formation, or shearing of the polymer during injection [57][58][59][60][61].

Polymer syneresis is the process of the loss of fluid from the polymer, which results in an increase in polymer rigidity and a significant reduction in polymer mobility. Syneresis differs from dehydration in that syneresis is usually associated with polymer structural degradation. This results in difficulty for the polymer structure in reabsorbing the lost fluid; therefore, the polymer degrades beyond return. In contrast, if the polymer dehydrates, it can be rehydrated by the addition of fluid, usually water. Polymer syneresis is impacted by the same factors that impact polymer degradation and dehydration.

During its injection, the polymer is subjected to extremely high shear rates. This shearing can damage the polymer chain and result in excessive polymer degradation. Some types of polymers can resist shearing more than others depending on their molecular structure. Vinyl acetate polymer can withstand some degree of shearing, for example, compared to weaker polymers such as acetic acid-based polymers. Although shearing cannot be entirely avoided, it can be reduced by proper design of the polymer injection on the surface. If the polymer is homogenously dissolved in the water, shearing tends to be significantly reduced. Decreasing the injection time and the injection pressure also tends to reduce polymer shearing [2][3][4][5][6][7][8][62][63].

5. Conclusions

-

Polymer-enhanced oil recovery is one of the most applied EOR methods in terms of both laboratory studies and field applications. The main factors impacting polymer injection are tied to polymer selection, reservoir rock and fluid properties, polymer concentration, and injection methodology.

-

Polymer degradation is represented in multiple steps depending on the severity of impact. This can include the less severe dehydration and partial hydrolysis and the more severe shearing and syneresis.

-

When coupled with other chemical EOR methods, polymers can be used in two main manners: either as a mechanism to support oil recovery by increasing sweep efficiency or as a sacrificial polymer to avoid the loss of the more costly surfactant to the formation.

-

Some polymers can pose severe environmental concerns, especially if they react with underground fluids or break down into hazardous chemicals.

References

- Thomas, S. Enhanced Oil Recovery—An Overview. Oil Gas Sci. Technol. Rev. D’ifp Energ. Nouv. 2008, 63, 9–19.

- Nwidee, L.N.; Theophilus, S.; Barifcani, A.; Sarmadivaleh, M.; Iglauer, S. EOR Processes, Opportunities and Technological Advancements. In Chemical Enhanced Oil Recovery (cEOR)—A Practical Overview; InTechOpen: London, UK, 2016; pp. 2–52.

- Al-Jaber, H.A.; Arsad, A.; Tahir, M.; Nuhma, M.J.; Bandyopadhyay, S.; Abdulmunem, A.R.; Abdul Rahman, A.F.; Harun, Z.b.; Agi, A. Enhancing Oil Recovery by Polymeric Flooding with Purple Yam and Cassava Nanoparticles. Molecules 2023, 28, 4614.

- Sun, Y.; Zhang, W.; Li, J.; Han, R.; Lu, C. Mechanism and Performance Analysis of Nanoparticle-Polymer Fluid for Enhanced Oil Recovery: A Review. Molecules 2023, 28, 4331.

- Ali, J.A.; Kolo, K.; Manshad, A.K.; Stephen, K.D. Potential application of low-salinity polymeric-nanofluid in carbonate oil reservoirs: IFT reduction, wettability alteration, rheology and emulsification characteristics. J. Mol. Liq. 2019, 284, 735–747.

- Bahraminejad, H.; Manshad, A.K.; Riazi, M.; Ali, J.A.; Sajadi, S.; Keshavarz, A. CuO/TiO2/PAM as a Novel Introduced Hybrid Agent for Water-Oil Interfacial Tension and Wettability Optimization in Chemical Enhanced Oil Recovery. Energy Fuels 2019, 33, 10547–10560.

- Izadi, N.; Koochi, M.M.; Amrollahi, A.; Pourkhalil, M. Investigation of functionalized polyelectrolyte polymer-coated Fe3O4 nanoparticles stabilized in high salinity brine at high temperatures as an EOR agent. J. Pet. Sci. Eng. 2019, 178, 1079–1091.

- Asif, M.; Muneer, T. Energy supply, its demand and security issues for developed and emerging economies. Renew. Sustain. Energy Rev. 2007, 11, 1388–1413.

- Detling, K.D. Process of Recovering Oil from Oil Sand. U.S. Patent 2,341,500, 8 February 1944.

- Pye, D.J. Improved secondary oil recovery by control of water mobility. J. Pet. Technol. 1964, 16, 911–916.

- Sandiford, B.B. Laboratory and field studies of water floods using polymer solutions to increase oil recovery. J. Pet. Technol. 1964, 16, 917–922.

- Maerker, J.M. Shear degradation of partially hydrolyzed Polyacrylamide solutions. Soc. Pet. Eng. J. 1975, 15, 311–322.

- Cyr, T.J.; Cruz, V.; Spanos, T.J.T. An analysis of the viability of polymer flooding as an enhanced oil recovery technology. Transp. Porous Media 1988, 3, 591–618.

- Hodaie, H.; Bagci, A.S. Polymer-Augmented Water flooding in a Reservoir with a Bottom-water Zone. In Middle East Oil Show 25633-MS; Society of Petroleum Engineers (SPE): Awali, Bahrain, 1993.

- Barteids, G.A.; Bruining, J.; Molenaar, J. The modeling of velocity enhancement in polymer flooding. Transp. Porous Media 1997, 26, 75–88.

- Haugse, V.; Karisen, K.H.; Lie, K.A.; Natvig, J.R. Numerical solution of the polymer system by front tracking. Transp. Porous Media 2001, 44, 63–83.

- Wang, W.; Liu, Y.; Gu, Y. Application of a Novel Polymer System in Chemical Enhanced Oil Recovery (EOR). Colloid Polym. Sci. 2003, 281, 1046–1054.

- Lu, H. Improving Oil Recovery with Polymer Flooding in a Heavy-Oil River Channel Sandstone Reservoir. Ph.D. Thesis, Freiberg University of Mining and Technology, Freiberg, Germany, 2004.

- Shedid, A. Influences of fracture orientation on oil recovery by water and polymer flooding process: An experimental approach. J. Pet. Sci. Eng. 2006, 50, 285–292.

- Wang, D.; Seright, R.S.; Shao, Z.; Wang, J. Key aspects of project design for polymer flooding. SPE Reserv. Eval. Eng. 2008, 11, 1117–1124.

- Bai, Y.; Li, J.; Zhou, J.; Li, Q. Sensitivity analysis of the dimensionless parameters in scaling a polymer flooding reservoir. Transp. Porous 2008, 73, 21–37.

- Lee, K.S. Simulation of polymer flood processes in heterogeneous layered systems with crossflow and adsorption. J. Jpn. Pet. Inst. 2009, 52, 190–197.

- Zhang, Y.; Huang, S.; Luo, P. Coupling immiscible C02 technology and polymer injection to maximize EOR performance for heavy oils. J. Can. Pet. Technol. 2010, 49, 25–33.

- Ramazani, A.; Tamsilian, Y. Manufacturing of Nano-Scale Coated Polyacrylamide Particles in Order to Control and Improve of the Solubility during Polymer Flooding Process. Iran Patent 68076, 2010.

- Ramazani, A.; Nourani, M.; Emadi, M.A. Investigation of rheological behaviour and hydrodynamic diameter of high molecular weight, partially hydrolyzed Polyacrylamide in high salinity and temperature conditions. Iran. Polym. J. 2010, 19, 105–113.

- Emami, H.; Kharrat, R.; Wang, X. Study of microscopic and macroscopic displacement behaviors of polymer solution in water-wet and oil-wet media. Transp. Porous Media 2011, 89, 97–120.

- Dupuis, G.; Nieuwerf, J. A Cost-Effective EOR Technique To Reduce Carbon Intensity with Polymer Flooding and Modular Skids. 2020. Available online: https://jpt.spe.org/cost-effective-eor-technique-reduce-carbon-intensity-polymer-flooding-and-modular-skids (accessed on 25 October 2023).

- Sheng, J.J. A comprehensive review of alkaline–surfactant–polymer (ASP) flooding Asia-Pacific. J. Chem. Eng. 2014, 9, 471–489.

- Craig, F.F. The Reservoir Engineering Aspect of Water Flooding; SPE Monograph Series; No 3; SPE Richardson: Richardson, TX, USA, 1971.

- Buckley, S.E.; Leverett, M.C. Mechanism of fluid displacement in sands. Trans. AIME 1942, 146, 107–116.

- Khlaifat, A.L.; Dakhlallah, D.; Sufyan, F. A Critical Review of Alkaline Flooding: Mechanism, Hybrid Flooding Methods, LaboratoryWork, Pilot Projects, and Field Applications. Energies 2022, 15, 3820.

- Rashid, B.; Stapley, J.; Clifford, P.; Chappell, D.; Kiani, M.; Andrews, W.J.; Hart, E.C. Successful Field Trial of a Novel, Reservoir-Triggered Polymer: Results, Interpretation and Simulation. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14 April 2018.

- Nadirov, M.; Moldabekov, B.; Benther, A.; Kurimov, D.; Subramanian, S.; Zhumagulov, K.; Aitkazin, M.; Nemanic, M.; Suleimenov, O.; Gubashov, R.; et al. Application of Drag Reducing Agent DRA in Tengiz Field Gathering System to Reduce Frictional Pressure Drop in the Pipelines and Increase Production: Best Practices and Challenges. In Proceedings of the SPE Caspian Technical Conference and Exhibition, Baku, Azerbaijan, 21 November 2023.

- Li, Z.; Espinoza, D.N.; Balhoff, M.T. Simulation of Polymer Injection in Granular Media: Implications of Fluid-Driven Fractures, Water Quality, and Undissolved Polymers on Polymer Injectivity. SPE J. 2023, 28, 289–300.

- Anand, A.; Al Sulaimani, H.; Riyami, O.; AlKindi, A. Success and Challenges in Ongoing Field Scale Polymer Flood in Sultanate of Oman—A Holistic Reservoir Simulation Case Study for Polymer Flood Performance Analysis & Prediction. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 26 March 2018.

- Lu, M.; Singh, H.; Li, J.; Huang, Q.; Ma, C.; Shan, G.; Du, Q.; Cai, M.; Wang, H.; Liu, X.; et al. Water Shutoff and Conformance Improvement for Lamadian Oilfield in Daqing Using a Novel Polymer System: Experimental Study, Simulation, and Pilot Tests. In Proceedings of the ADIPEC, Abu Dhabi, United Arab Emirates, 2 October 2023.

- Hwang, J.; Sharma, M.; Chiotoroiu, M.M.; Clemens, T. Viscoelastic Polymer Injectivity: A Novel Semi-Analytical Simulation Approach and Impact of Induced Fractures and Horizontal Wells. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 23 September 2019.

- Leon, J.M.; Masalmeh, S.K.; AlSumaiti, A.M.; Baslaib, M. Assessment of World First Two Polymer Injectivity Tests Performed in Two Giant High Temperature/High Salinity Carbonate Reservoirs Using Single Well Simulation Models and PFO’s Analysis. In Proceedings of the ADIPEC, Abu Dhabi, United Arab Emirates, 31 October 2022.

- Gandomkar, A.; Guises, R.; Pedreira, J. Assessment of Shape Memory Polymer Sand Control Performance and Integrity under Field Conditions via Geomechanical Simulation. In Proceedings of the ADIPEC, Abu Dhabi, United Arab Emirates, 31 October 2022.

- Keith, C. Evaluation of the Oil Recovery and Economic Benefit of the First-Ever Polymer Flood Field Pilot to Enhance the Recovery of Heavy Oils on Alaska’s North Slope using Machine-Assisted Reservoir Simulation. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26 October 2022.

- Dennar, L.; Amro, M.; Kummer, N.A.; Arochukwu, E.; Suleiman, A.; Ekpeyong, O. Exploring the Suitability of Polymer Injection in the Niger Delta Sands Using 3-D Simulation and Experimental Analysis—A Case Study-Paper ID 28. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 2 August 2021.

- Gumpenberger, T.; Deckers, M.; Kornberger, M.; Clemens, T. Experiments and Simulation of the Near-Wellbore Dynamics and Displacement Efficiencies of Polymer Injection, Matzen Field, Austria. In Proceedings of the Abu Dhabi International Petroleum Conference and Exhibition, Abu Dhabi, United Arab Emirates, 11 November 2012.

- Sabirov, D.G.; Demenev, R.A.; Isakov, K.D.; Ilyasov, I.R.; Orlov, A.G.; Glushchenko, N.A. Reservoir Simulation of Polymer Flooding: Challenges and Current Results. In Proceedings of the SPE Russian Petroleum Technology Conference, Virtual, 26 October 2020.

- Jenei, B.; Manasipov, R.; Langanke, N.; Samara, H. SCAL-On-Chip: Measurement and Interpretation of Multiphase Fluid Flow Characteristics in Porous Media. A Microfluidic Approach. In Proceedings of the SPE Reservoir Characterisation and Simulation Conference and Exhibition, Abu Dhabi, United Arab Emirates, 24 January 2023.

- Schumi, B.; Clemens, T.; Wegner, J.; Ganzer, L.; Kaiser, A.; Hincapie, R.E.; Leitenmueller, V. Alkali/Cosolvent/Polymer Flooding of High-TAN Oil: Using Phase Experiments, Micromodels, and Corefloods for Injection-Agent Selection. SPE Res. Eval. Eng. 2020, 23, 463–478.

- Wu, D.; Liu, Y.; Lu, X.; Hou, J.; Zhou, K.; Wei, B.; Du, Q.; An, Z.; Zheng, H. Study on Blockage and Fluid Diversion Behaviors of Polymer Microspheres. In Proceedings of the SPE EuropEC—Europe Energy Conference Featured at the 83rd EAGE Annual Conference & Exhibition, Madrid, Spain, 6 June 2022.

- Raffa, D.; Abedini, A. Learnings from the Planning and Execution of a Heavy Oil Polymer Flood Pilot in North Saskatchewan, Canada. In Proceedings of the SPE Canadian Energy Technology Conference and Exhibition, Calgary, AB, Canada, 10 March 2023.

- Brovina, A.; Reina, R.E.H.; Clemens, T.; Hoffmann, E.; Wegner, J.; Steindl, J. Polymer Selection for Sandstone Reservoirs Using Heterogeneous Micromodels, Field Flow Fractionation and Corefloods. In Proceedings of the SPE Improved Oil Recovery Conference, Virtual, 18 April 2022.

- Khlaifat, A.L. Displacement Efficiency in Tight Sandstone Based on Fractional Flow Curve Using Relative Permeability Data. J. Geotechnol. Energy 2021, 38, 5–10.

- Kumar, M.; Hoang, V.T.; Satik, C.; Rojas, D.H. High-Mobility-Ratio waterflood performance prediction: Challenges and new insights. SPE Reserv. Eval. Eng. 2008, 11, 186–196.

- Fakher, S.; Khlaifat, A.L. Experimental Investigation of Polymer Injection in High Permeability Conduits for Material Sustainability and Behavior in Oil Reservoirs. Polymers 2023, 15, 2950.

- Muhammed, N.S.; Haq, M.B.; Al-Shehri, D.; Rahaman, M.M.; Keshavarz, A.; Hossain, S.M.Z. Comparative Study of Green and Synthetic Polymers for Enhanced Oil Recovery. Polymers 2020, 12, 2429.

- Willhite, G.P.; Green, D.W. Enhanced Oil Recovery, 2nd ed.; SPE Textbook Series; SPE: Richardson, TX, USA, 2018; Volume 6, p. 896. ISBN 978-1-61399-494-8.

- Oyatobo, A.; Muoghalu, A.; Ikeokwu, C. An Experimental Research on Enhanced Oil Recovery Using Local Polymers. In Proceedings of the Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 2–4 August 2021.

- Gao, H.W. Mobility Control in Oil Recovery by Chemical Flooding, State-of-the Art Review, Topical Report NIPER-146 (DE87001210); National Institute for Petroleum and Energy Research-U.S. Department of Energy: Bartlesville, OK, USA, 1987.

- Toms, R.V.; Balashov, M.S.; Gervald, A.Y.; Prokopov, N.I.; Plutalova, A.V.; Chernikova, E.V. Influence of Monomer Sequence on the Cyclization Behavior of Poly(acrylonitrile-co-acrylamide). Appl. Sci. 2023, 13, 3734.

- Duits, M.H.; Le-Anh, D.; Ayirala, S.C.; Alotaibi, M.B.; Gardeniers, H.; Yousef, A.A.; Mugele, F. Microfluidics for Carbonate Rock Improved Oil Recovery: Some Lessons from Fabrication, Operation, and Image Analysis. SPE J. 2023, 26, 3148–3164.

- Dupas, A.; Hénaut, I.; Rousseau, D.; Poulain, P.; Tabary, R.; Argillier, J.F.; Aubry, T. Impact of Polymer Mechanical Degradation on Shear and Extensional Viscosities: Towards Better Injectivity Forecasts in Polymer Flooding Operations. In Proceedings of the SPE International Symposium on Oilfield Chemistry, The Woodlands, TX, USA, 8 April 2013.

- Sheng, J. Status of surfactant EOR technology. Pet. J. 2015, 1, 97–105.

- Azad, M.S.; Trivedi, J.J. Synergistic behavior of anionic surfactant and hydrolyzed polyacrylamide under extensional field: Effect of hydrophobicity. Langmuir 2021, 37, 13645–13653.

- Afolabi, F.; Mahmood, S.M.; Yekeen, N.; Akbari, S.; Sharifigaliuk, H. Polymeric surfactants for enhanced oil recovery: A review of recent progress. J. Pet. Sci. Eng. 2022, 208, 109358.

- Esmaeilnezhad, E.; Van, S.L.; Chon, B.H.; Choi, H.J.; Schaffie, M.; Gholizadeh, M.; Ranjbar, M. An experimental study on enhanced oil recovery utilizing nanoparticle ferrofluid through the application of a magnetic field. J. Ind. Eng. Chem. 2018, 58, 319–327.

- Negin, C.; Saeedi, A.; Xie, Q. Most common surfactants employed in chemical enhanced oil recovery. Petroleum 2017, 3, 197–211.