1. Light Pipes Combined with Artificial Lighting

Generally, solar altitude, cloud volume, and external illuminance are considered to be weather factors that affect the lighting performance of the light pipe. In a day, the luminous flux introduced by the light pipe increases with the increase of solar altitude and decreases with the increase of cloud cover

[1]. In addition, the light distribution on the working plane is more uniform when the solar altitude is low

[2]. The efficiency of the light pipe under overcast conditions is slightly higher than that under clear sky conditions

[3]. With the change of seasons, the luminous flux output by the light pipe in summer is better than that in winter, but there will be obvious light and dark changes on the working plane in summer

[4]. However, among solar altitude, cloud cover, and external illuminance, external illuminance has the greatest impact on internal illuminance. The influence of solar altitude and cloud cover on internal illuminance may be affected by changes in external illuminance

[5]. The research by Vasilakopoulou

[6] further pointed out that the average internal illuminance and the maximum internal illuminance have an exponential relationship with the external illuminance, respectively. In addition to the above factors that affect the daylighting performance of the light pipe, Kocifaj

[7] has shown that aerosols in the atmosphere are also one of the factors. Different types of aerosols will have different effects on illuminance patterns and efficiency.

Light pipes cannot meet the indoor illuminance requirements in some situations, and artificial lighting equipment is needed for auxiliary lighting. A study on light pipe systems stated that these devices, when paired with electric lighting controls, could achieve 20% energy savings

[8]. Thus, the combination of passive light pipes and artificial lighting equipment systems has come into being. In this integrated system, in most cases, luminaires are installed over individual workstations or defined visual task areas and equipped with, variously, integrated network controls, occupancy sensors, personal dimming, or daylight dimming. The two systems are not physically connected. This system can maximize the use of available daylight. However, the color rendering of the two light sources is significantly different, which may bring an uncomfortable visual experience. Unstable daylight makes the artificial lighting system open and close frequently or adds more complicated control systems, which may reduce the service life of the system or increase the cost. Görgülü and Ekren

[9] illuminated a windowless room via a light pipe and dimmable electronic ballasts. During the operation of the system, the required 350 lux illumination level on the work plane was measured and retained by the controller throughout the day.

2. Light Pipes Combined with the Ventilation System

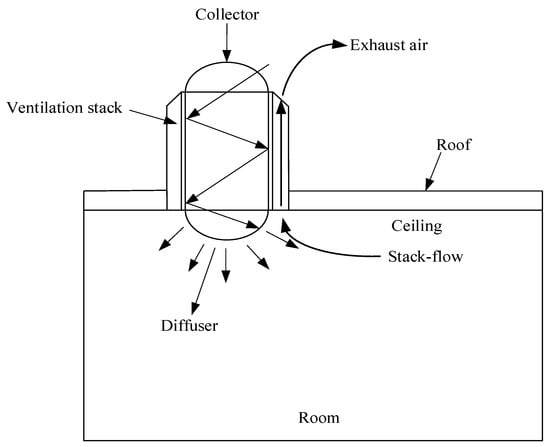

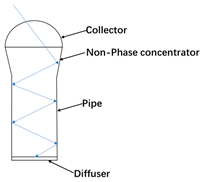

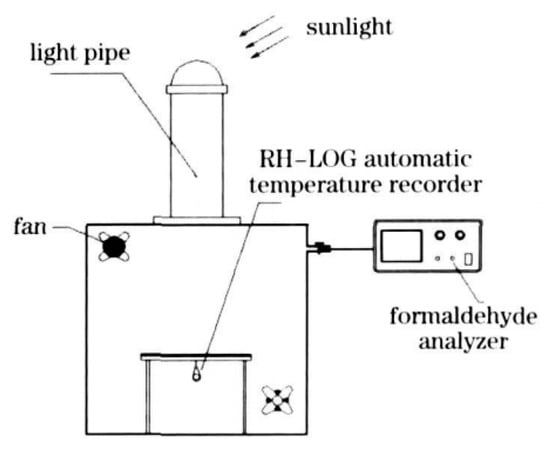

Integration of the passive stack ventilation system and light pipes would make both technologies more attractive. The basic idea is to guide daylight into the building and air out of the building using an integrated structure (see

Figure 1). The integration of these technologies proved to be feasible

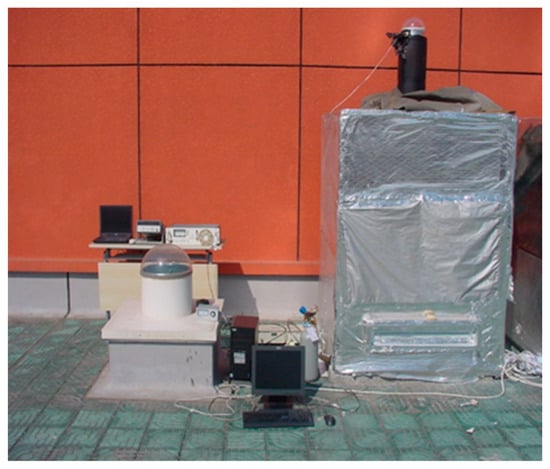

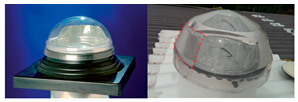

[10]. The light pipe-natural ventilation system experimental apparatus is shown in

Figure 2. To enhance the natural stack ventilation and prevent reverse flow, a winding terminal is installed on the top of the light-vent pipe

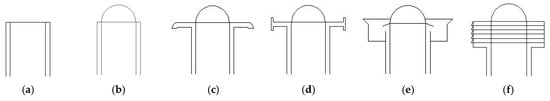

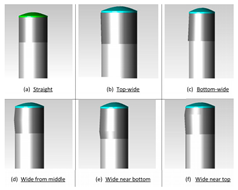

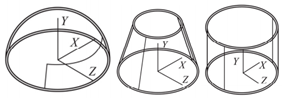

[11][12][13][14]. Common forms of wind terminals are shown in

Figure 3. To enhance the driving force of natural ventilation, Elmualim et al.

[15] used dichroic materials to construct light pipes, which increased the flow of natural ventilation by 14%. L. Shao and Riffat

[16] combined light-vent pipe with heat pipes and used the principle of thermosyphon, which can not only enhance ventilation but also be used for building heating. This system can be realized without relying on a mechanical driving force. Taengchum et al.

[17] designed a light pipe integrated with a solar-heated ventilation stack that can be used for night ventilation and designed a method that can be used to design a system to achieve the required ventilation rate, transmit a given luminous flux, and evaluate the cost-effectiveness of the configuration. This system needs to use a hot water pump as the circulating power.

Figure 1. Combined the light pipe and passive stack ventilation system.

Figure 2. Light pipe-natural ventilation system experimental apparatus.

Figure 3. Different ventilation terminals: (a) open channel, flat top; (b) open channel, hemispherical dome; (c) umbrella type; (d) H-pot type 1; (e) H-pot type 2; (f) shutter type.

3. Light Pipes Combined with ATO Nanofluids and Photocatalysis

The physical properties of the three components (light collector, hollow tube, and diffuser) of the light pipe affect the optical properties. The research on the three components is summarized in

Table 1. Mohelnikova et al.

[18] and Robertson et al.

[19] proved that the daylighting performance of the hemispherical dome is better than that of the flat glass cover. Collectors of the light pipes are installed outdoors. The surface of the collector is inevitably exposed to the sun and debris, which affects the lighting effect

[20] and reduces the service life of the collector. Applying a super-hydrophobic layer to the collector can realize self-cleaning, which plays an important role in improving the lighting performance

[21]. The major constraints to the development of superhydrophobic coatings are expensive superhydrophobic materials, nano-feature durability, coating stability, precipitation/condensation problems, impact problems, and emulsifier/oil wetting problems

[22][23].

The length, diameter, and inner wall material of the hollow tubes have an impact on the light reflectivity of light pipes. The ratio of the diameter to the length of the reflecting tube is defined as the aspect ratio of the light pipe. Only the length and diameter of light pipes are changed to obtain different specifications of light pipe. Different specifications of light pipes with the same aspect ratio have the same Transmission Tube Efficiency (TTE) under a CIE (International Commission on Illumination) standard overcast sky

[24]. Transmission Tube Efficiency (TTE) is defined as the ratio of the output light flux to the input light flux of the light pipe. The efficiency is a decreasing function of aspect ratio independent of whether overcast sky or clear sky conditions are taken into consideration

[25]. Wu et al.’s

[26] study showed that higher reflectance of the inner surface will lead to a higher efficiency of the straight pipe. For a light pipe with an elbow, under the same bending angle and light reflection ratio, the TTE of elbows with different pipe diameters is basically the same. The reflective material on the inner wall of the light pipe determines the color rendering properties of transmitted light

[27][28]. With an increase of the number of reflections and the change of the angle of incident ray, the color characteristics of the optical tube will change. Furthermore, Nilsson et al.

[28] used spectrophotometer measurement and ray-tracing simulation methods to quantitatively verify that highly reflective films with spectral variations of a few percent do not markedly affect the color of the transmitted light. Different geometrical shapes, thicknesses, and fabrication materials lead to different optical properties of the diffuser. The researchers found that light pipes with “snow type” diffusers had better performance compared with the “diamond type” ones

[29]. Swift et al.

[30] experimentally studied 1 mm thick diffuser (the diffusing material used is Plexiglas), finding that it performed better when the uniformity of illumination was improved and the loss of luminous flux was small. Robertson et al.

[19] compared three different diffuser types. From the perspective of luminous flux, flat Fresnel performed the best, followed by flat frosted, and curved frosted performed the worst. However, there is a modest disbenefit to the Fresnel when there is diffuse light only. Two-component glazing can solve this problem

[31]. The inner parts of circular glazing work like Lambertian diffusers while the edges of the glazing are built of clear glass. This diffuser can reduce light loss and enhance the use of direct light. Ikuz3and Sebitosi

[32] designed a light collimator made of frosted aluminum, which improved the illuminance of the working surface under sunny conditions compared with commercial diffusers. When rough re-used aluminum cooking foil is used as the interior lining of the collimator, uniform spatial light distribution can also be obtained. Kocifaj and Petržala

[33] proposed a new method of designing the diffuser. Under the premise of reducing light loss, the diffuser is designed according to the illuminance distribution required. It has been proven that such a slab can mimic the illuminance distribution required, while the particle sizes and refractive indices have been determined from optimization routines.

The incident angle of light affects the performance of the light pipe, and the number of reflections in the tube for light with different incident angles is different. The number of reflections of low-angle incident light is more than that of high-angle incident light. At the same time, the reflection coefficient of the reflective material on the inner wall of the tube will also affect the reflection of light. The larger the reflection coefficient, the smaller the light loss. Therefore, reducing the number of reflections of light in the tube is one of the ways to enhance the performance of light pipes. Optimization methods are described in

Table 2. Sharma et al.

[34] compared the performance of modified light pipes which have a slight difference in their designs in the upper 20 cm length of the pipe compared to a conventional light pipe. Wang et al.

[35] added a non-phase concentrator inside the light pipe to improve the lighting performance of the light pipe system. Kim and Kim

[36] developed a new type of light pipe. The south-facing optical device is placed in the dome. The inside of the tube is coated with thin prismatic material. The diffuser is made of acrylic. The efficiency of this new light pipe is 99%, and it is suitable for sunny and cloudy days. Robertson et al.

[19] experimentally showed that a deflector can provide up to a 22% increase in illuminance when there is significant direct light present and reduce the illuminances by approximately 5% under lower, diffuse light conditions. Malet-Damour et al.

[37] showed that the orientation of the deflector device placed in the dome needs to be adjusted according to sky conditions, otherwise the light transmittance will be affected. Similar experiments were also conducted. The researchers simulated the effects of different structures of domes and deflectors on the performance of the light pipe, and the results showed that the structure of the lighting hood, the size of the reflector, and sky conditions all affect the lighting performance

[38]. Edmonds et al.

[39] enhanced the performance under clear skies in winter by adding LCP (Laser-Cut Light-Deflecting Panels) to light pipe domes. However, this system fails to redirect light down the pipe for greater azimuth angles. Venturi et al.

[40] got a similar conclusion. Garcia Hansen et al.

[41] studied the influence of a pyramid LCP, which provides panel area exposed to the incident light, though it has a reduced area of light collection at any one time. The system can increase the performance of light pipes for low elevation angles.

Table 1. Papers devoted to studying the influence of the three main components of light pipes on daylighting.

| Authors |

Collector |

|

Tube |

|

|

|

Diffuser |

|

|

| Geometrical Shape |

Light Transmittance |

Length |

Diameter |

Inner Wall Material |

Bend |

Geometrical Shape |

Thicknesses |

Fabrication Material |

| Swift and Smith [27] |

|

|

√ |

√ |

√ |

|

|

|

|

| Swift et al. [30] |

|

|

√ |

√ |

|

|

|

√ |

|

| Mohelnikova et al. [18] |

√ |

√ |

√ |

√ |

√ |

|

|

|

|

| Wu et al. [29] |

|

|

|

|

|

|

√ |

|

|

| Kocifaj [31] |

|

|

|

|

|

|

|

|

√ |

| Robertson et al. [19] |

√ |

|

√ |

√ |

√ |

√ |

|

|

|

| Darula et al. [3] |

|

|

√ |

√ |

√ |

|

|

|

|

| Nilsson et al. [28] |

|

|

|

|

√ |

|

|

|

|

| Ikuzwe and Sebitosi [32] |

|

|

|

|

√ |

|

|

|

|

| Gao et al. [24] |

|

|

√ |

√ |

|

|

|

|

|

| Kocifaj and Petržala [33] |

|

|

|

|

|

|

|

|

√ |

| Wu et al. [26] |

|

|

√ |

√ |

√ |

√ |

|

|

|

It was found that the fluid mixed with metal or metal oxide nanoparticles, named nanofluids, would have unique optical and thermal properties

[42][43]. A new lighting-heating coupled TDDs (LH-TTDs) system was developed based on ATO nanofluids which can absorb thermal energy from solar IR radiation to heat domestic hot water, with almost no effects on the visible solar radiation, thus having both lighting and heating functions

[44]. The designed LH-TDD is composed of a receiving dome, lighting pipe, and ATO-nanofluid-contained diffuser. Results showed that the ATO nanofluids of 100 ppm can absorb 50% solar radiation coming along with more efficient visible lighting. In a case study in Beijing, the total energy-saving performance improved by 10%.

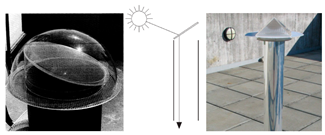

The researchers developed a system combining a light pipe with photocatalysis which could not only introduce sunlight into the room but also serve as an air purifier

[45][46]. A certain amount of photocatalyst sprayed on the outside of the diffuser of the light pipe can have a purifying effect on the air (see

Figure 4). However, this still has some technical problems, such as low efficiency and film curing of the catalyst. A new efficient catalyst will be pursued.

Figure 4. Experimental apparatus of the light pipe combined with photocatalysis.

4. Energy Consumption and Economic Efficiency of Light Pipes

The impact of light pipes on indoor energy consumption is mainly in three aspects: the influence of radiation and heat conduction of light pipes on indoor energy consumption, and the influence of light pipes on the energy consumption of artificial lighting. Compared to windows, the light pipe transfers less heat

[47]. In the case of excessive heat loss, the heating energy required in winter may be greater than the saved lighting energy consumption. Large-diameter light pipes cause higher heat loss than small-diameter light pipes

[48]. The research showed that under the same brightness conditions, the increased indoor heat of light pipes is less than that of artificial lighting equipment in Beijing

[29]. However, the increase in heat cannot be ignored in tropical regions

[49][50]. Pirasaci

[51] showed that the overall heat transfer coefficient of the light pipe can be decreased by using an acrylic separator plate in the light pipe. However, solar radiation was not considered. For the installation of light pipes on insulated roofs of low-energy buildings, thermal bridge effects may occur. Šikula et al.

[52] indicated that additional glasses units installed in light pipes have a positive effect on solving thermal bridging and condensation problems. However, this can also result in lower overall optical transmittance.

The light distribution of the working plane is composed of two parts. A large part of the light energy is directly irradiated to the working plane through the diffuser, and the rest of the light energy is refracted to the working plane through the ceiling, walls, furniture, floor, etc. The increase in the average reflection coefficient will lead to a significant increase in the average indoor illuminance, which will reduce the time spent on artificial lighting

[37].

The investment of the light pipe system includes initial investment and operation investment. The initial investment includes the cost of the light pipe system and the artificial lighting equipment. The initial investment of the light pipe system is much higher than that of the pure power system. To reduce the cost of the product, the polymer acrylonitrile butadiene styrene (ABS), coated with aluminum by physical vapor deposition (ionization), was evaluated for some tests

[53]. Although the market cost was reduced by about 50%, the reflectivity was affected. Operational investment is mainly electricity and maintenance costs. Mayhoub and Carter

[54] demonstrated that the light pipe system is generally not economical using conventionally accepted measures of both cost and benefit. They used whole life cycle costing (WLCC) to analyze the costs and benefits of using the two main classes of daylight guidance to light offices as an alternative to conventional electric lighting. A more favorable balance of cost and benefit is obtained. Feng et al.

[55] took an underground garage with a combined lighting scheme of a light pipe system and LED lighting system as the research object. This project designs and installs 20 sets of spherical light pipe systems and 15 sets of flat plate light pipe systems. The simulation results showed that the scheme met the standard illuminance requirements. This project can save 16,306.5 kWh of electricity throughout the year and save about 14,000 yuan in electricity bills.