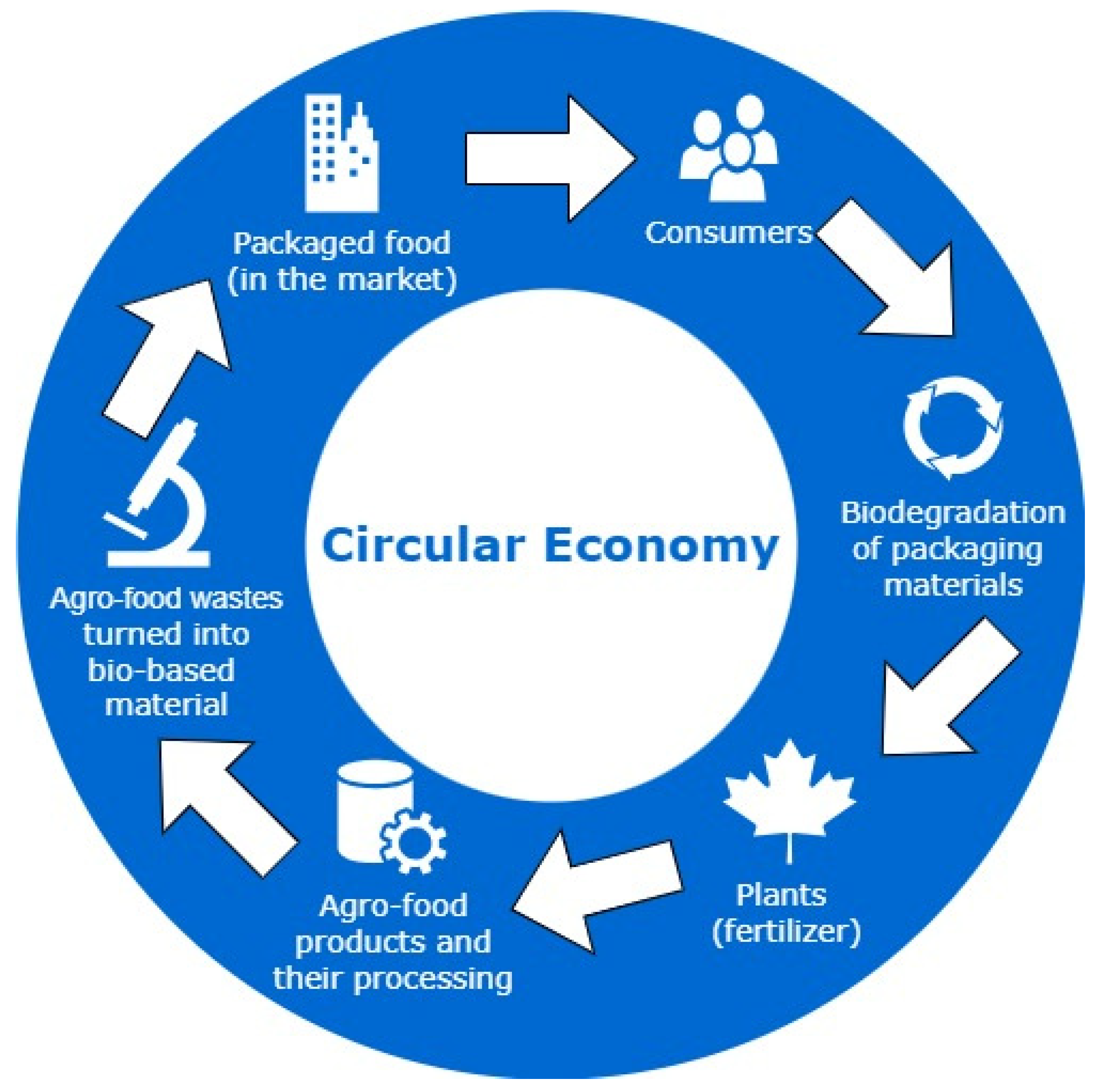

Around the world, large amounts of agro-industrial waste are generated, but only a small portion of it is valued. These residues contain a variety of nutritious substances, bioactive compounds, and materials with good film-forming abilities, among others of great relevance. The synthesis of bio-products using agro-industrial waste as a raw material aligns with the much-needed circular economy (

Figure 1), thus posing an urgent challenge for researchers and industries

[11]. Agro-industries, such as the cassava starch industry, produce large amounts of processing waste, which also means a waste of money, resources, labor, materials, water, and energy. These agro-industrial waste materials represent alternative sources of natural polymers and potential to be directly applied in biodegradable food packaging without any substantial procedures, which may lead to a significant reduction in time, cost, and effort

[12]. Annually, 20 million tons of corn husk, a by-product of corn production, is wasted. However, corn husk is a potential alternative for nanocellulose production, as its cellulose content varies from 30 to 50%, besides being a renewable and biodegradable raw material for packaging development

[13]. Banana peels have also been studied to create sustainable food packaging

[14]. Brewer’s spent grain is a significant by-product of beer production, generating about 20 kg per 100 L of beer produced. The European Union produces approximately 3.4 Mt of brewer’s spent grain each year, which mainly ends up as animal feedstock or in landfill. However, it constitutes a rich source of fibers (cellulose, arabinoxylan, and lignin), proteins, and phenolic compounds, leading this agro-waste to be a potential alternative to produce biomaterials for food packaging in the circular economy

[15].

2. Typical Agro-Food Waste Recovered for Development of/Obtaining Valuable Materials/Compounds Intended to Be Applied in Sustainable Food Packaging

Food waste generation spans all stages of the food supply chain, from postharvest, post-production, handling, and storage, to manufacturing and processing, wholesale, and retail and, ultimately, consumption stages. Europe, annually, contributes to food waste generation with about 90 million tons, 38% of which comes from food manufacturing sectors

[4]. Commodity-wise, roots, tubers, and oilseeds show the highest loss rate (25%), followed by fruits and vegetables (21%). Meat and animal products reach a loss of 12%, while cereals and pulses are only up to 8%

[21].

A range of significant by-products/wastes can be found in various industries. Fruits and vegetables show up as sources of polysaccharides, antioxidants, flavonoids, phenols, carotenoids, lipids, and phytochemicals. Through animal waste, meat, seafood, and derivatives, it is possible to obtain proteins, enzymes, chitin, collagen, and gelatin, as well as being relevant nitrogen sources. Dairy products are highly indicated as carbon and nitrogen sources, while waste oil offers fatty acid, methyl esters, and glycerol. Lastly, cereal and grain industries generate a fibrous waste rich in lignin and cellulose

[4].

Researchers worldwide have been dedicated to developing low-impact technologies capable of recovering such wastes and transforming them into valuable products

[1]. Agro-food wastes have been studied as primary or secondary feedstock for obtaining biopolymers, through extraction or fermentation (with or without pre-treatment), and natural bioactive compounds

[3]. Polysaccharides, such as starch and cellulose, are abundant in plant-based agricultural wastes, making them crucial precursors for the production of renewable natural materials. These materials are applied primarily in food packaging, tissue engineering, and bioplastic formation. Moreover, seafood debris is also a good source of natural polymers, such as chitin, which is a starting polysaccharide in chitosan biopolymer production

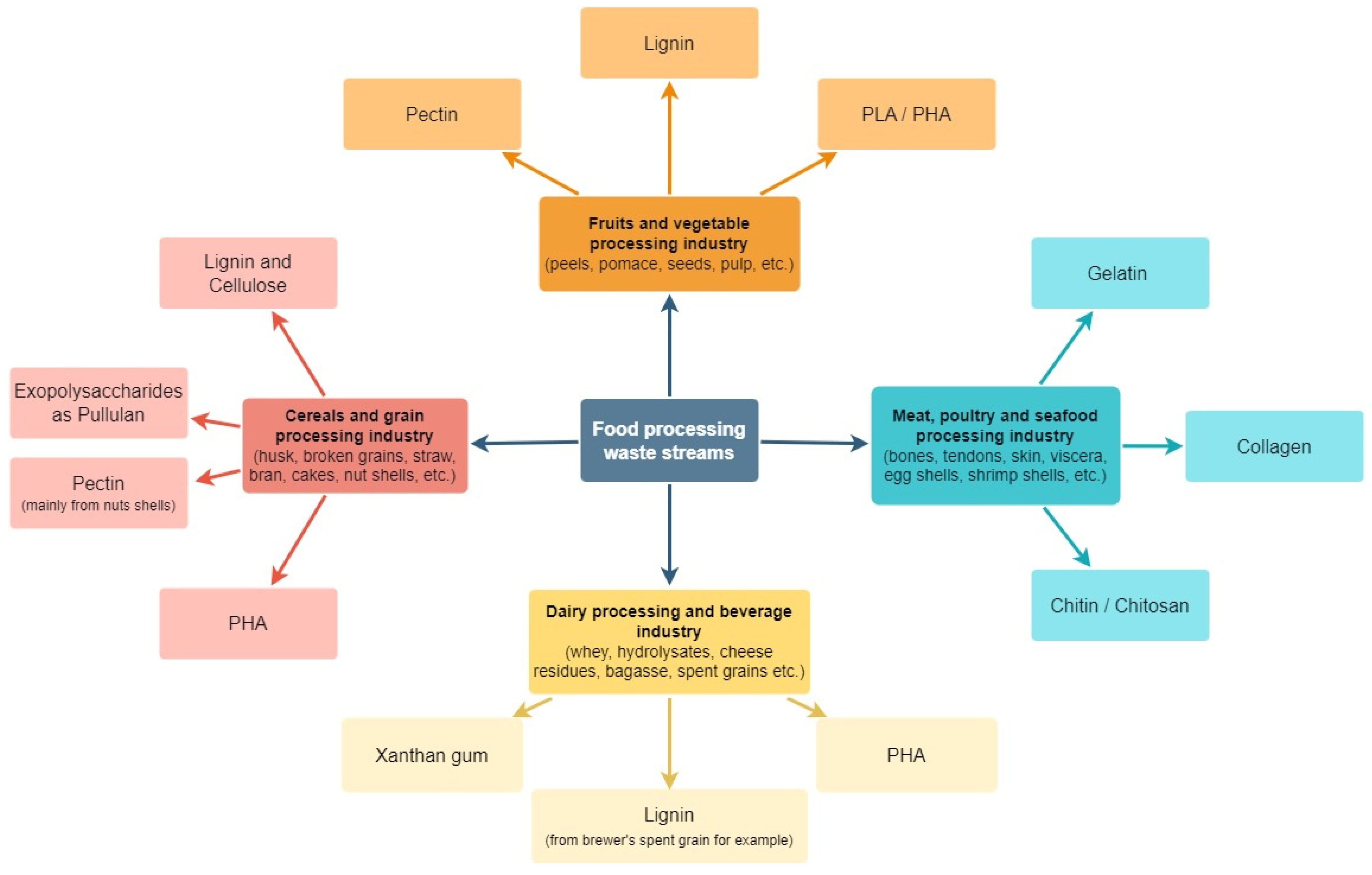

[1]. As depicted in

Figure 2, there is a broad range of biopolymers produced from different waste streams.

Figure 2. Biopolymers produced from different waste streams.

Agro-industrial food waste also contains a significant quantity of lipids, and this oily waste is a viable resource for the synthesis of biopolymers, acting as a carbon substrate. For instance, polyurethanes may be produced from lipids present in the food waste and then used in coating materials, foams, adhesives, etc. Dairy waste is an essential resource from which a variety of value-added products may be derived, such as whey and bioactive peptides. Protein-based biopolymers may also be produced from food waste generated during the processing of plant-based raw materials (sunflower, grains, soybean, cereal, and maize) and animal-based (collagen and gelatin). These protein-based biopolymers’ properties, such as biodegradability, biocompatibility, strong mechanical strength, thermal resistance, and water resistance, make them potentially attractive for films/coatings in food packaging

[1].

Therefore, agro-food wastes represent a potential research trend, and in recent years they have been applied as starting materials to produce bio-based plastics, as well as antioxidant and antimicrobial compounds, plasticizers, proteins, and other relevant substances, mainly focusing on sustainable packaging materials. Besides the environmental and sustainability aspect, agro-food waste is inexpensive and readily available

[20]. Moreover, food waste as a raw material for bio-based packaging must undergo a pre-treatment process to improve or modify its physicochemical and biological properties, alongside a successful recovery process to convert it into value-added substances

[4].

Despite their potential application in food packaging systems and importance for circular economy and environment, agro-food wastes and by-products present huge challenges that need further and detailed evaluation, such as the heterogeneity of each food waste and each food waste batch, hygiene and safety conditions, and cost-efficiency approaches. Furthermore, for industrial applications, the material must meet the protection and containment functions of food packaging, so normalization and scale-up of the production process for these waste materials still need to be deeply addressed

[22][23].

Therefore, the following sections will provide a detailed description of the main agro-food wastes and by-products, including cereal-, plant-, and animal-based ones, and how they have been recovered for packaging applications as films/coatings/composite materials, which covers bioactive compounds, polysaccharides, biopolymers, proteins, etc. Alongside this, the techniques, benefits, and challenges of waste valorization in terms of sustainable packaging, and how nanotechnology has emerged in this scenario, will also be discussed.

3. Agro-Food Waste Conversion Techniques Performed to Obtain Feasible Materials and Compounds Aiming at Sustainable Food Packaging Applications

Waste conversion processes aim for a partial or total liberation of target components, and increased accessibility of components such as proteins, lipids, and polysaccharides for subsequent applications. Examples include blending or cross-linking extracted biopolymers to obtain bio-based plastics for packaging, and extraction with subsequent encapsulation of bioactive compounds. Technologies used to convert food waste into feasible raw materials or to obtain relevant compounds from it include mechanical and thermal processes (e.g., ultrasound, microwaves, milling, and heating methods), chemical treatments (e.g., acid-alkali pre-treatments), biological conversion (e.g., fungal pre-treatment method), and enzymatic hydrolysis, which is the primary mechanism to breakdown polymers into their corresponding monomers and/or intermediates, converting polymeric structures into fermentable products

[4]. The latter, mainly related to polyhydroxyalkanoates (PHA) production, are the fundamentals of industrial biotechnology and, thus, beyond the scope of this research.

Physical methods are usually applied as the first step to change the particle size, reduce moisture content, or separate materials for subsequent stages. Chemical pre-treatments involving acids are often used for lignocellulosic waste to increase the accessibility of these low-cost materials. Pre-treatments involving alkalis are applied to hydrolyze ester bonds between vegetal polysaccharides and lignin for solubilizing lignin. Cellulose-based bioplastics can be obtained from food waste with high cellulose content, such as peanut husks and citrus peels via physical/chemical modification

[4]. Cesare Rovera et al.

[24] developed a protocol based on alkali and stirring methods for extraction of high-purity cellulose and cellulose nanocrystals from different lignocellulosic agro-food wastes, such as garlic stalk, corncob, and giant cane cut-up, and from this protocol it was also possible to extract lignin fractions. Furthermore, the conversion of macro-sized cellulose to cellulose nanocrystals was carried out by acid hydrolysis. A final yield of ∼40–50% cellulose nanocrystals was obtained for all three wastes, and the authors proposed further applications in the development of new materials for food packaging. For chitin-based biopolymers, they can be produced, via physical/chemical treatments, from crustacean-processing wastes (e.g., shrimp shells). Furthermore, the biological fungal pre-treatment aids in delignification, which leads to better productivity. Importantly, a combination of different pre-treatment processes aids in improving the performance or the final yield

[4].

A variety of vegetable/fruit wastes, such as peels, skin, fruit fractions, pomace, and fruit seeds, have been studied in recent years through valorization techniques. Among them, pectin is the main natural polymer recovered from fruit peels and its conventional extraction method includes high thermal and acidic (sulfuric, hydrochloric, and nitric acids) treatments, similar to other natural polymer extraction methods

[25]. Sani et al.

[26] extracted pectin from apple peels through an acidic treatment and applied it in the development of composite films based on potato starch/apple peel pectin/ZrO

2 nanoparticles/microencapsulated

Zataria multiflora essential oil to be used in quail meat packaging. The same method, with a few modifications, was used by Khalil et al.

[27] to extract pectin from citrus peel waste (grapefruit and lemon peel) and develop active edible films based entirely on citrus peel wastes. In addition to pectin, phenolic compounds were also extracted from the dried waste powders using different solvents, such as acetone, distilled water, ethanol, and methanol, and further encapsulated by applying maltodextrin.

Because of the environmental problems related to acidic/alkaline-extraction methods and significant energy input from high thermal treatment, novel and “green” technologies have been developed and optimized. Ultrasound-assisted extraction provides a lower energy requirement, reduced extraction duration, less solvent utilization, and enhanced yield compared to traditional techniques

[25]. Shivamathi et al.

[28] worked on the optimization of ultrasound-assisted extraction of pectin from custard apple peel. The extracted pectin was compared to commercially standard pectin of citrus, as well as showing improvements in gelling properties.

Non-conventional technologies also include pulse/moderate electric-field-mediated extraction that improves product quality and quantity using less energy and time. Microwave-assisted extraction, which constitutes a rapid, low-solvent, and improved yield/quality process, and enzyme-assisted extraction, which is an acid-free, low-temperature, and low-energy process, are also novel techniques for natural polymer extraction. However, the latter presents relevant challenges, such as the high cost of pure enzymes and the secondary metabolites (flavonoids and phenolic compounds) of fruit wastes may affect and limit enzyme activity. Combined strategies have also been considered to optimize these techniques and obtain bio-based materials feasible for up-scaled packaging

[25]. Food waste has also been applied through the nano-reinforcement technique, acting as nano-fillers to increase the strength, barrier properties, and feasibility of bio-based materials

[29].

Depending on the raw material, bio-polymeric materials can be produced through the direct application of agro-food waste (using minimum process steps), the extraction from that waste, a combination of techniques, or synthetized by microorganisms using the biomass as a nutrient source, which are the fundamentals of industrial biotechnology. Regarding the development of sustainable food packaging systems based on valorization of agro-food wastes, the main techniques applied are the recovery and extraction of value-added compounds and their incorporation into sustainable packaging systems, as well as the production of biomaterials. A variety of pre-treatments and extraction processes have been applied to separate valuable compounds, such as antioxidants and nutraceuticals, from food waste matrices, as well as additional isolation and purification steps to ensure purity and remove residues. Considering the production of biomaterials, different routes can be taken

[30].

The direct use of agro-food by-products to obtain bio-based materials and biopolymers has been highlighted because of advantages such as the use of whole waste and the decreasing of process steps, waste, and the cost of production, compared to pure biopolymers extracted from agro-food sources

[31]. Therefore, some of the waste generated along the agro-food industrial chain can be applied directly as a bio-based material to produce bioplastics without any specific pre-treatments or high-tech processing techniques. Xie et al.

[31] produced active films using whole potato peel waste, combined with additive agents (bacterial cellulose and curcumin). The potato peel waste powder was prepared through simple steps (cleaning, drying, and grinding) and it worked as the base material for direct production of films. Their films showed improved mechanical properties and a relevant reduction in oxygen and water vapor permeability.

Another example is the co-product from the potato starch industry, known as potato protein concentrate, which can be molded by a compression process to obtain a bio-based plastic. This technique is often used to manufacture thermoset and thermoplastic polymeric composites. Another common technique used in conventional plastics’ processing is injection molding, which could also be applied to some agro-food wastes, such as the by-products (press cake and meal) generated from the rapeseed oil industry

[30]. Furthermore, naturally presenting polysaccharides, such as starch, cellulose, and pectin, can be extracted from the biomass for packaging applications. However, because of challenging limitations, alternatives such as blending, nanoparticle additives, cross-linking, and different modifications have been applied to these biopolymers to produce feasible materials. For example, banana peel extract has been applied as a cross-linking agent in composite coatings. The incorporation of banana peel extract resulted in a greater strengthening of the binding between phenolic compounds present in the extract and chitosan molecules. This was possible through a strong interaction between the phenolics in banana peel extract and the -NH

2 group of chitosan molecules. Overall, the incorporation of 4% of extract was capable of making the structure of the films denser and more uniform

[32].

Overall, common pre-treatment techniques for agro-food waste valorization cover mechanical, thermal, biological, and chemical treatments, extraction of target compounds, as well as encapsulation of bioactive compounds, and they aim to reduce the waste size, extract target, and smaller compounds, improve their bioavailability, and eliminate inert or undesired materials. Combined processes help to achieve the intended properties of the final bio-based packaging materials or to more efficiently obtain the relevant target compounds from waste

[30].

4. Potential Uses of Typical Agro-Food Waste/Residues for the Development of Sustainable Bio-Based Packaging

The conversion of agro-food waste into value-added products is gaining attention from scientific and industrial fields due to the urgent demand for renewable, cheap, and sustainable materials

[33]. For example, seafood-processing waste (such as shrimp and crab shells) is a valuable source of chitosan, a crucial biopolymer for many industrial applications, including the production of films and coatings. Plant-derived polymers, such as cellulose, are another potential resource from agro-industrial waste to produce bioplastics for packaging applications

[11].

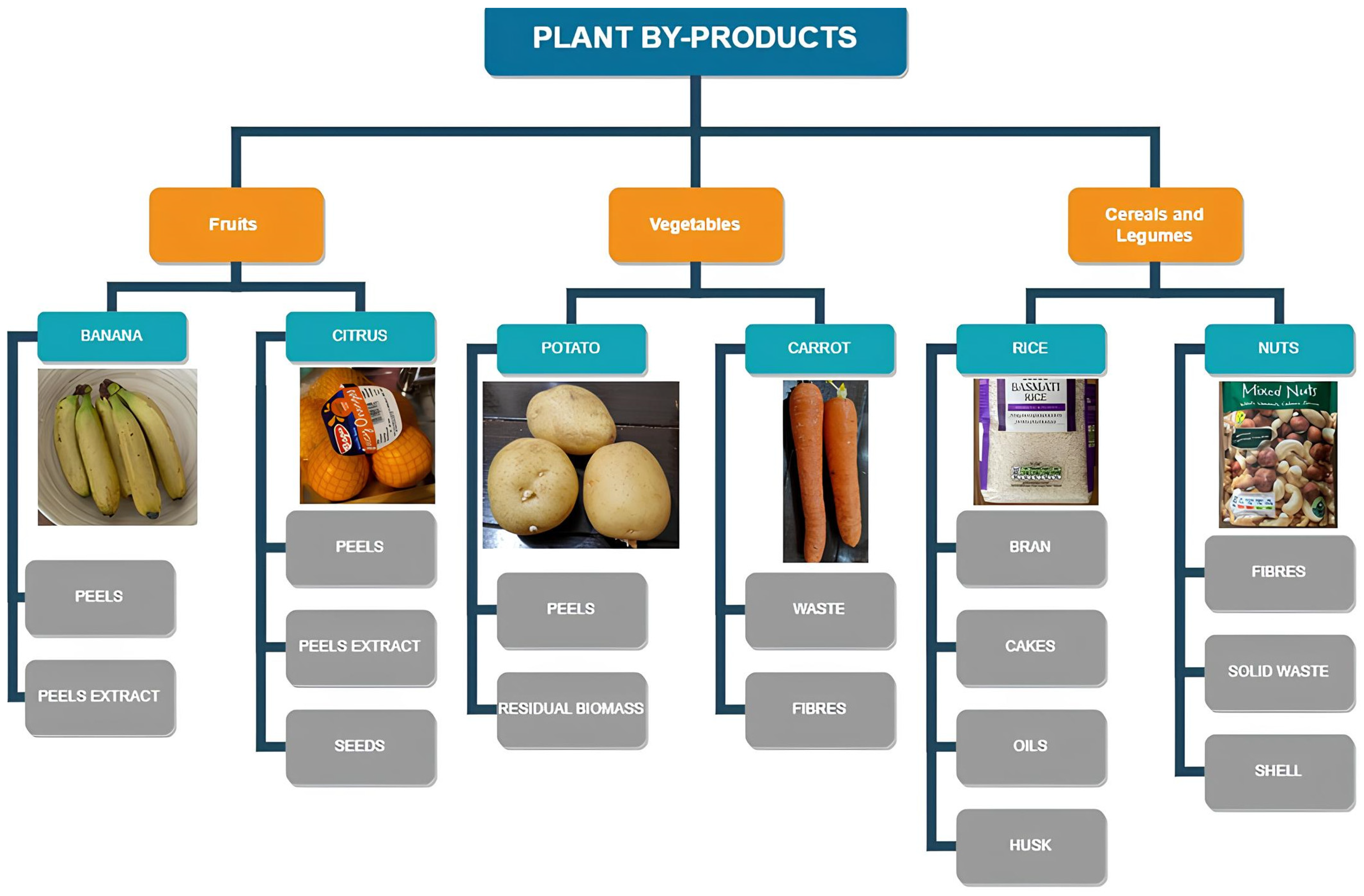

Sustainable food packaging materials have been extensively studied, particularly in recent years, due to the increasing need to explore alternative routes for their development. Agro-food processing by-products have proven to be a viable resource for this. Plant-based by-products account for a significant portion of food waste generation, and they can be derived from various parts of plant systems, such as the husk, pomace, peel, skin, seed, and hull

[34].

Figure 3 shows some important components of these plant wastes that have been exploited to develop biodegradable/sustainable coatings and films.

Figure 3. Components of plant-based by-products with potential application in sustainable packaging.

In the fruit and vegetable agro-industrial sectors, the generated waste represents about 42% and includes peels, seeds, skins, stems, leaves, roots, pomace, and leftovers from processing industries, which are also potential sources of a wide variety of bioactives

[1][21][27]. For instance, about 40% of the total weight of a fresh banana is made up of the peel. Among tropical fruits, mango is the second-highest produce after banana, and the major by-products from mango-processing industries are mango peel and seed, which represent 35–60% of the total weight of mango fruit and can be considered a potential resource of antioxidant agents for biodegradable and edible packaging. In addition, the mango seed makes up 45–85% of the kernel, which is an inexpensive and renewable source of starch

[34]. Pomegranate-processing industries generate a considerable amount of waste, such as peels, which make up about 50% of the total pomegranate weight. This undervalued waste is a potential source of bioactive compounds such as phenolic acids, flavonoids, lignans, stilbenes, and hydrolysable tannins, which have showed feasibility for being incorporated in packaging materials providing active properties

[35].

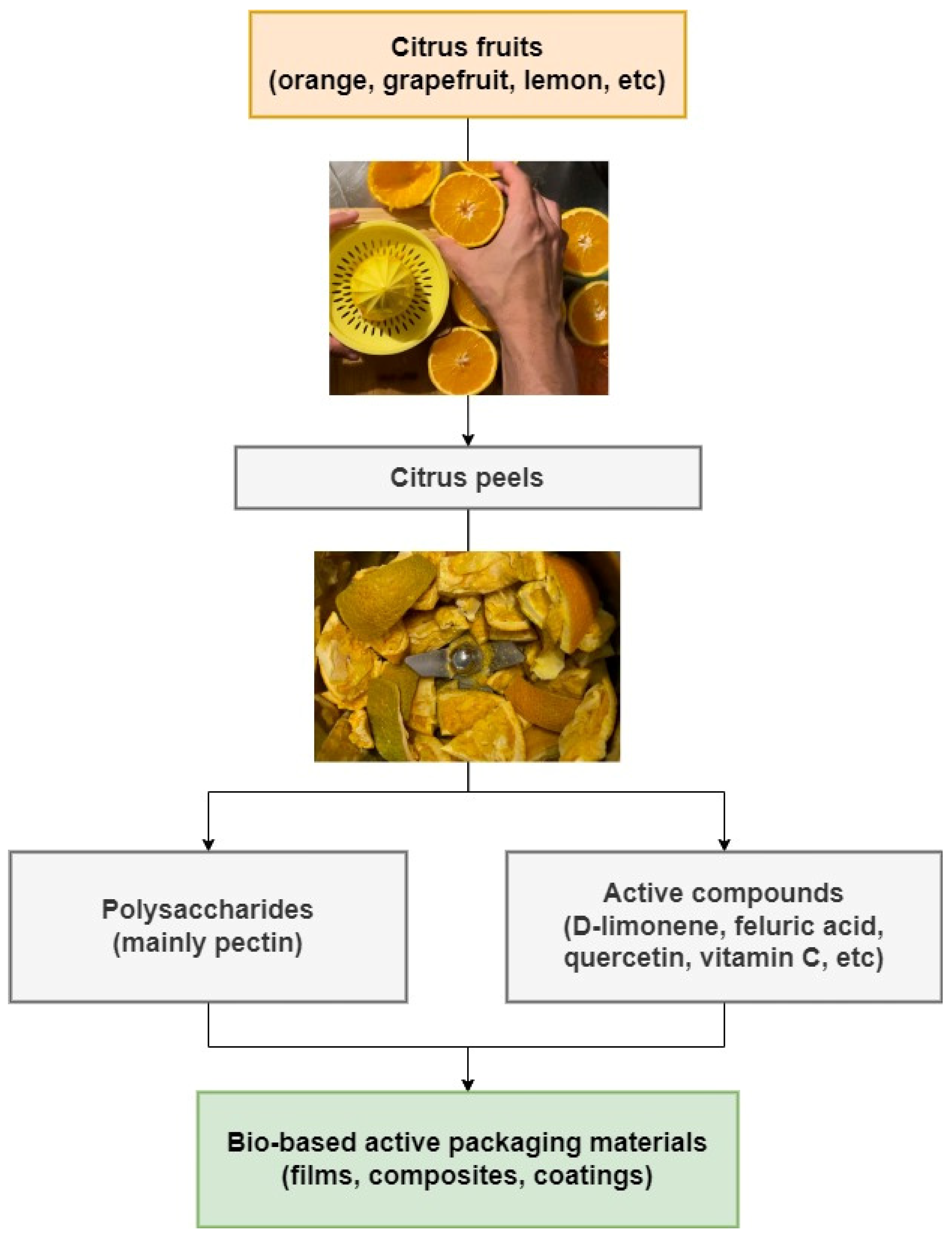

Citrus fruits, one of the most popular crops globally, provide peel wastes, which are excellent sources of vitamins, polyphenols, and D-limonene. As shown in

Figure 4, citrus peels have been valorized in many ways intended for packaging applications

[21][27]. In addition to the antioxidant characteristics of the active compounds, they also display important health-promoting attributes, such as anti-inflammatory, cardio-protective, anti-carcinogenic, and lipid reduction effects. However, their exposure to light, heat, moisture, and acids can lead to oxidation and degradation, causing undesirable organoleptic changes. This instability can also make their application difficult in food packaging systems. To overcome this challenge and preserve the sensitive active compounds, encapsulating technologies have been applied, in addition to promoting stabilization and improving their bioavailability. Moreover, polysaccharides, such as pectin, can also be obtained from citrus fruit waste. Polymeric matrices based on citrus peel pectin play an important role in the production of active contact materials, such as edible films, composites, and coatings, adding value and promoting a sustainable approach for bio-based packaging materials

[27].

Figure 4. Scheme for valorization of citrus peels intended for packaging applications.

Given the relevance of these bioactive compounds obtained from different agro-food waste sources, nano-delivery systems have been designed for the encapsulation and protection of target active compounds and their release control, especially for applications in food packaging materials. In addition, nano-encapsulated systems have helped to improve the bioavailability of health-promoting active compounds. These nano-systems can include nanoparticles, nano-emulsions, nanocarriers, and nano-composites

[35].

Based on the concept of a circular economy, increasing efforts have been made to achieve the goal of a zero-waste economy and to find sustainable processing methods to produce renewable polymeric materials instead of conventional ones, as well as obtain natural active compounds, such as essential oils and phenolic components, to be applied in functional sustainable packaging

[19].

5. Toxicological, Safety, and Migration Aspects Related to Development of Novel Sustainable Packaging Based on Agro-Food Waste Valorization Approaches

There has been a significant increase in interest in recycling, reusing, and recovering food by-products and waste due to the circular economy approach and environmental concerns related to waste mismanagement. Achieving these goals involves the valorization of waste/by-products across a wide range of applications and fields. However, reintegrating these materials into the food chain requires thorough and careful evaluation of processes to ensure their suitability, feasibility, and above all, consumer safety and health. Presently, EU food safety regulations mandate that modified or new materials based on valorized residues comply with established requirements as non-hazardous products for human consumption, which also applies to those aimed at animal feed. While many studies focus on extracting nutrients and bioactive compounds from food by-products and waste, few of them deeply evaluate safety aspects, which limits their application at the industrial level. Assurance of quality and safety, including toxicological and migration aspects, is a crucial step for this type of research

[36].

Food contact packaging materials address risks related to safety and health aspects, and these should be carefully examined and thoroughly monitored to prevent toxic, carcinogenic, and harmful compounds in food. Migration is influenced by a variety of factors, such as the type of contact, duration, temperature, nature of packaging material, nature of migrant substances, and concentration of these migrants in the packaging. Therefore, the application of antioxidants, pigments, and bio-based polymers should consider this concern, and deeply evaluate all migration routes and factors related to the novel packaging materials

[37].

Most safety assessments performed by researchers in the food industry cover physicochemical and quality studies, such as solubility, mechanical and barrier properties, color, and texture, microbiological tests concerning foodborne pathogens, such as

Salmonella,

Listeria, and

E. coli, and evaluations of contaminants, including pesticides, metals, toxins, and the migration of hazardous organic/inorganic compounds. In addition, cytotoxicity and mutagenic activity must be taken into consideration

[36].

Another concern in this field is the potential toxicity when compounds are nanosized. Some researchers question whether certain safe compounds could become toxic at the nanoscale, leading to doubts about whether these nanomaterials should be specifically regulated. The lack of sufficient scientific data gives rise to relevant concerns about the toxicity, behavior, and bioaccumulation of these new materials/compounds. Therefore, further research should be conducted to deeply assess the risk and exposure associated with the application of nanoscale materials. This will not only support their efficacy but also ensure their safety

[35]. Despite the significant progress of nanomaterials in the last few years, their toxicity, accumulation, and safety aspects remain uncertain. Nanoparticle food applications are increasing at a rate faster than they should be, without the necessary knowledge and proper regulations and standardization. In addition to public engagement and participation, safe and useful food products, including food packaging systems, will only be achieved through a better understanding of the characteristics surrounding these nanomaterials (mainly nature, size, and composition), exposure levels to them, and individual sensitivity. Cellular toxicity can be reached according to the composition and shape of each nanomaterial, through a variety of mechanisms

[38]. Therefore, a deep investigation of components’ migration from food contact packaging into food products must be carried out upon the development of novel food packaging materials to ensure food safety and integrity, as well as consumer health and environmental assurance

[39].