Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Chandrima Karthik | -- | 3499 | 2024-01-19 16:00:12 | | | |

| 2 | Wendy Huang | Meta information modification | 3499 | 2024-01-22 11:57:31 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Karthik, C.; Mavelil-Sam, R.; Thomas, S.; Thomas, V. Plasma Technology in Food Packaging. Encyclopedia. Available online: https://encyclopedia.pub/entry/54129 (accessed on 07 February 2026).

Karthik C, Mavelil-Sam R, Thomas S, Thomas V. Plasma Technology in Food Packaging. Encyclopedia. Available at: https://encyclopedia.pub/entry/54129. Accessed February 07, 2026.

Karthik, Chandrima, Rubie Mavelil-Sam, Sabu Thomas, Vinoy Thomas. "Plasma Technology in Food Packaging" Encyclopedia, https://encyclopedia.pub/entry/54129 (accessed February 07, 2026).

Karthik, C., Mavelil-Sam, R., Thomas, S., & Thomas, V. (2024, January 19). Plasma Technology in Food Packaging. In Encyclopedia. https://encyclopedia.pub/entry/54129

Karthik, Chandrima, et al. "Plasma Technology in Food Packaging." Encyclopedia. Web. 19 January, 2024.

Copy Citation

Biopolymers have intrinsic drawbacks compared to traditional plastics, such as hydrophilicity, poor thermo-mechanical behaviours, and barrier characteristics. Therefore, biopolymers or their film modifications offer a chance to create packaging materials with specified properties. Cold atmospheric plasma (CAP) or Low temperature plasma (LTP) has a wide range of applications and has been used in the food industry as a potent tool for non-thermal food processing. Though its original purpose was to boost polymer surface energy for better adherence and printability, it has since become an effective technique for surface decontamination of food items and food packaging materials.

plasma

CAP

food packaging

polymers

DBD

1. Introduction

Plasma, the fourth state of matter, consist of ions, electrons, and neutral molecules. In some plasmas, the density of charged particles is substantially lower than that of neutral species in because of their low level of ionization. As a result, electrons have kinetic energy that is substantially higher than that of bulk neutrals due to the interaction with the applied field, leading to non-equilibrium or cold atmospheric plasma. It is also known as non-thermal plasma because non-equilibrium plasma does not increase the temperature of the gas [1]. Plasma comes from a variety of sources, depending on the electrode and energy source used. Electron energy, density, and breakdown voltage are used to qualify and quantify plasma generators. Atmospheric pressure or low pressure both produce non-thermal plasmas. Vacuum maintenance for low-pressure plasma discharges necessitates expensive process chambers. The advantages of cold plasmas produced at atmospheric pressure outweigh the need for such arrangements [2]. Natural polymers like polysaccharides, proteins, and lipids are now frequently used in the production of biodegradable packaging materials for packaging due to rising consumer demand for products that are biodegradable, environmentally friendly, long-lasting, and safe [3][4]. The safety issues related to packaged foods are reduced by using various physical and chemical treatment techniques. As an illustration, the food business frequently uses preservatives like sorbic and benzoic acids. But certain chemical substances can also result in issues with environmental safety and have mutagenic and carcinogenic properties. But, used of cold atmospheric plasma can resolve these existing problems. By removing heat from the processing process, these novel non-thermal technologies improve sensory qualities and nutrition retention while preventing the growth of microorganisms. By changing the cell membrane or eliminating the genetic material of bacteria, non-thermal processing sterilizes food and the packaging.

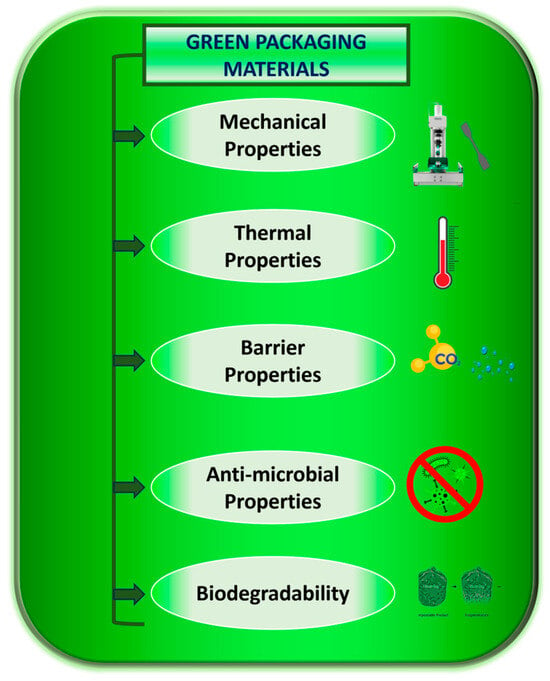

Polymers are widely used in a variety of industries, including biomedicine, manufacturing, and agriculture due to their strong chemical resistance, flexibility, and low density [5]. Some polymers have boundaries, which make them inappropriate for some applications. These downsides include poor adhesion, wettability, and low surface free energy, all of which are brought on by low surface polar groups [6]. The most sustainable method of processing is plasma. Since it only modifies the surface properties of the polymer without influencing the bulk properties, it is a low-temperature, low-cost, non-toxic, and efficient method of surface modification [7]. Figure 1 shows the various property requirements for polymeric packaging materials.

Figure 1. Pillar properties for a good green packaging material.

2. Effect of Plasma Treatment on Different Systems in the Field of Food and Pharmaceutical Packaging

Apt packaging is essential for maintaining and extending the shelf life of fresh produce, and the inclination to utilise non-thermal innovative technologies to extend the shelf life of fruits and vegetables has developed more recently than traditional techniques as a result of the need for environmental protection and energy conservation. Researchers in the packaging business believe it is crucial to use packaging materials to reduce the rate of respiration, the production of ethylene, the rate of deterioration, and the microbiological activity of fresh fruit and vegetables [8][9][10]. These technologies not only preserve the product’s aesthetic qualities but also result in less modifications to its qualitative attributes [11]. The information below is a thorough compilation of information drawn from recent research on the impact of plasma treatment on various systems in the food and pharmaceutical packaging industries (Table 1). It can be understood that the plasma treated samples, irrespective of the treatment conditions, always exhibited superior properties when compared to their pristine counterparts. The detailed understanding of the tabulated studies are also explained in latter sections.

Table 1. Detailed description from recent reports on the effect of plasma treatment on different systems in the field of food and pharmaceutical packaging.

| No. | Plasma Treatment Conditions | Matrix and Fillers; Composite Type | Applications | Effect of Plasma Treatment on Properties | References |

|---|---|---|---|---|---|

| 1. | Dielectric barrier discharge (DBD) cold plasma, for 5, 10 and 15 min. Maximum transmission power: 50 W; Voltage: 15 kV; Current: 10 mA; Frequency: 50 kHz; Power source: DC pulse type with pulse width modulation (PWM) |

Chitosan + cellulose nanoparticles; Films | Packaging of strawberry | For films: Improved mechanical properties (TS & EAB), water vapour permeability, oxygen transmission rate, moisture content and water contact angle. For substrates: Enhanced mechanical properties (firmness and Young’s modulus), chemical attributes (pH, soluble solid content and total ascorbic acid), physical characteristics (weight loss and colour features), microbial activities (bacteria, yeast and mould) |

[10] |

| 2. | Open-air DBD cold plasma. Peak voltage: 20 kV; Frequency: 20 kHz | Polylactic acid multilayer films | Active packaging of sunflower oil and “pesto” sauce; Biodegradable multilayer active packaging, to extend food products shelf-life and/or maintain high quality levels of oily foods during storage. | Immobilization of oxygen scavenger agent (ascorbic acid); Decreased oxidation kinetics; Better and more stable quality characteristics in terms of colorimetric, microbiological and textural parameters | [12] |

| 3. | DBD cold plasma, for 60 and 120 s. Gas source: Air; Argon gas type, oxygen gas pressure of 0.4 millibars equivalent to 0.3 Torr and power of 89 watts equivalent to radiometric waves |

Chitosan solution | Preservation of quality and safety (shelf life) of pistachios during storage | Significant reduction in the amount of aflatoxin, mold and yeast after 120 days; Physicochemical characteristics of pistachios did not change significantly; No adverse effect on the sensory characteristics of pistachios | [13] |

| 4. | Atmospheric air cold plasma treatment for 5, 10 and 15 min in the excitation mode. Input voltage: 6.2 kV; Power level: 60 kW; Pulse frequency: 10 kHz |

Wild almond protein isolate (WAPI) + Persian gum (PG); Films | Edible films in food packaging | Progressively improved mechanical properties (increased thickness, TS and EAB); No significant effect on WVP and solubility; Surface roughness directly proportional to plasma treatment time, but surface remained integrated; Best results obtained for films with 10 min treatment; Properties tend to deteriorate after 15 min treatment | [14] |

| 5. | Dielectric Barrier Discharge Atmospheric Cold Plasma (DBD–ACP); Fixed exposure time (3 min) with varying voltages of 10, 20, 30, 40, and 50 kV; Fixed voltage (30 kV) with varying exposure times (1, 2, 3, 4, 5 min) | Soy protein films | Edible packaging and food preservation | Increased water interactive properties and thermostability; Decreased surface roughness; Effects of different ACP treatment times too | [15] |

| 6. | Cold plasma based on helium. Glow discharge reactor at 13.56 MHz. Chamber vacuum: <8 Pa. Treatment with He: Self-bias voltage −100 V; Treatment time: 10 min. Treatment with HMDSO: Self-bias voltage −60 V; Treatment time: 20 min |

Hexamethyldisilox-ane (HMDSO) treated extruded corn starch films | Barrier films for food packaging and pharmaceutical products | More homogeneous coating and smaller granules; Increased hydrophobicity, but roughness created by helium plasma was not effective in increasing the water contact angle of the modified surface; No much effect on water vapour permeation; Significant reduction in absorbed water content, mostly due to the formation of a barrier to water absorption of around 80%; Physical barrier to water, while allowing permeation to water vapour | [16] |

| 7. | DBD cold plasma treatment. Voltage: 20 kV; Excitation frequencies: 50, 400 and 900 Hz; Treatment time: 5 min |

Starch, gelatin and bacterial cellulose films | Sustainable and biodegradable alternatives for plastic packaging | Improved hydrophobicity, surface morphology, tensile strength, and elasticity module; Reduced water solubility; Pronounced changes for starch films at low excitation frequency (50 Hz) of plasma, and for gelatin and bacterial cellulose films at high excitation frequency (900 Hz) |

[17] |

| 8. | Cold plasma treatment. Vacuum plasma reactor. Frequency: 13.56 MHz; Pressure: 0.0643 Torr; Power: 30 W; Treatment time: 60 s | LDPE + Myristica fragrans Essential Oil (MFEO); Films | Active food packaging material | Cold plasma treatment improved the properties of LDPE films by facilitating MFEO coating | [18] |

| 9. | Surface dielectric barrier discharge (SDBD) plasma from Plasma Assisted Sanitation System (PASS) for 5 and 10 min. Gas: Environmental air; Relative humidity: 20–40%; Voltage: 1–20 kV; Frequency: 1–20 kHz; Tunable duty cycle: 1–100%. Imposed voltage: 6 kV; Frequency: 5 kHz; Fixed duty cycle: 100% |

Polyethylene terephthalate (PET) trays (350 microns thick) and polypropylene (PP) film (69 microns thick) |

Newly developed plasma sanitation system for food packaging decontamination from SARS-CoV-2 RNA | Plasma treatment decontaminated virus, without significantly affecting the properties of packaging and food substrate; 5-min treatment reduced detected RNA for both surfaces, but to different extents. Indicated that interaction between reactive species and viral genetic material is affected by the matrix; 10-min treatment completely degraded RNA molecules from both surfaces | [19] |

| 10. | Plasma activated water (PAW) produced using surface barrier discharge (SBD) sourced high voltage cold plasma (CP). Sinusoidal signal frequency: 18 kHz; Atmospheric pressure; Plasma-inducing gas: Room air |

Sodium alginate films | Food packaging | Increased TS, tensile modulus, EAB, LVE region and storage modulus; No intersection between G′ & G″; Showed shear thinning properties or non-Newtonian behaviour; decreased WVTR | [20] |

| 11. | Cold plasma treatment. Treatment time: 30 s; Power: 350 W; Nitrogen flow rate: 100 standard cubic centimeters/min (sccm) | Momordica charantia polysaccharide (MCP) nanofibre + Phlorotannin (PT); Electrospun nanofibre membranes | Active food packaging | Increased release efficiency of PT, resulting in an increase in antibacterial and anti-oxidant activities, without the alteration of chemical structure | [21] |

| 12. | DBD cold plasma. Voltage changed group adjusted at a changed treatment of 0, 30, 40, 50, 60 and 70 V under the duration of 60 s. Time changed group subjected to a sustaining time of 0, 15, 30, 45, 60, 90 and 120 s under the voltage of 50 V; Current: 2 ± 0.2 A |

Casein edible films | Packaging material | Crystalloid migration and casein aggregation (via SEM) leading to reinforcement of structure stability; Slight change in crystal structure (via XRD); Stable state of molecular structure (via FTIR); Remarkable improvement in packing characters (including mechanical and barrier properties); Slight modifications of colour and transparency; Rearrangement in order of protein chains | [22] |

| 13. | Carbon tetrafluoride (CF4) reactive-ion etching (RIE) using 13.56 MHz radio-frequency plasma equipment. Flow rate: 3 sccm; Working pressure: 3.0 × 10−2 Torr; Treatment time: 4 min; Power: 100 W | Transparent, colourless and self-disinfecting polyethylene terephthalate (PET) film that mimics the surface structure of Progomphus obscurus (sand dragon) wing, physically killing the attached bacteria | Antibacterial overcoating with good optical properties for contactable surfaces in private and public interior spaces and packaging applications | Introduction of nanopillars; Improved optical properties (transparency and colourlessness); Notable enhancement in antibacterial activity against S. aureus and E. coli by activating or strengthening physical biocidal action | [23] |

| 14. | Cold plasma (CP) generated by dielectric barrier discharges (DBD) plasma reactor. Voltage: 60 V; Current: 1.5 A. Short-term treatment time: 60 s; Long-term treatment time: 120 s |

CP pre-treated zein films + Porous PLA layer coating by breath figure self-assembly | Biodegradable packaging | Better-ordered porous structure after coating with PLA; Induced compatibility between zein and PLA molecules, by changing the protein conformation and by enhancing the intermolecular hydrogen bonding interactions; Significant improvement in surface hydrophobicity, fracture resistance, water vapor barrier, and thermal stability; Improved UV barrier and excellent biodegradability; Potential to enhance adhesion and improve functionalities of porous coating on other biopolymer materials | [24] |

| 15. | DBD atmospheric air cold plasma (at ambient temperature and atmospheric pressure). Plasma discharge frequency: 50 Hz; Voltage: 31 kV; Treatment time: 1, 5, 10, 15 and 20 min | Polycaprolactone (PCL) or poly(lactic acid) (PLA) and cassava starch multilayers | Multilayer packaging materials | Increased hydrophilicity and surface roughness; Improved adhesion between layers, zeta potential, delamination resistance, etc. | [25] |

| 16. | Cold plasma treatment. Power: 400 W; Treatment time: 4 min; Nitrogen flow rate: 100 sccm | Silk fibroin nanofibers + Cold plasma treated thyme essential oil (TO) composite films, post-treated with cold plasma | Effective antimicrobial packaging to increase shelf life of foods |

Increased antibacterial activity by increasing TO release amount, due to surface modification, but without affecting chemical composition of the films; Decreased number of Salmonella Typhimurium in chicken and duck meat |

[26] |

| 17. | DBD-50 cold plasma reactor. Power: 100 W; Treatment time: 30, 60, 90, 120 and 150 s | Zein + Chitosan films | Food and pharmaceutical packaging materials | Improved wettability, TS, EAB, water vapour barrier and thermal stability; Secondary structure of zein molecules became ordered; Rougher surface morphology, increased surface free energy and enhanced hydrogen bond interactions between zein and chitosan after plasma treatment (optimum range: 60–90 s) | [27] |

As evidenced from the table above, different types of plasma treatments have been adopted by different researchers, and the treatment effects on the resultant composite and substrate properties seem to correlate or vary depending on the type of plasma treatment, type of raw materials, and intended end use applications. As shown in the table, majority of the studies were carried out using dielectric barrier discharge (DBD) cold plasma treatment, where researchers like Rashvand et al. [10], Goiana et al. [17], Wu et al. [22] and Chen et al. [24][27] reported improvements in tensile strength, elasticity and barrier properties like water vapour and oxygen transmission rates. Enhanced stability and shelf life of packaging films and substrates were observed by Glicerina et al. [12] and Akhavan-Mahdavi et al. [13], and modified surface properties of composite materials were reported by Goiana et al. [17] and Chen et al. [24], where they noted changes in surface morphology and hydrophobicity depending on the type of film and plasma treatment frequency, with improved wettability, roughness, and surface free energy after coating or plasma treatment. Additionally, changes in film structure were observed by Wu et al. [22] and Chen et al. [27], while observing rearrangement of protein chains, slight changes in crystal structure, and improved packing density within the film structure. Chen et al. [24] described better-ordered porous structure and enhanced compatibility between zein and coating materials, while Chen et al. [27] reported ordering of zein molecule secondary structure after plasma treatment. Cold plasma treatment, in general, were carried out by a few researchers including Yudhistira et al. [18], Cui et al. [21] and Lin et al. [26]. The major effects on composite properties reported by them include improved coating adhesion, controlled release of active agents and surface modification for enhanced antimicrobial activity. It is interesting to note that unlike the DBD cold plasma treatment, the enhancement of mechanical and barrier properties have not been significantly reported in general cold plasma treatment.

The key findings from two reported studies employing DBD atmospheric air cold plasma (DBD-ACP) include surface modifications, interfacial interactions, and stability and delamination resistance. Quite different from other reports, the use of DBD-ACP exhibited increased hydrophilicity, suggesting improved water absorption and wetting properties. Both Heidemann et al. [25] and Li et al. [15] observed enhanced adhesion and interaction, whether it be between film layers, or between the film and food materials, thereby leading to an improvement in barrier properties and film functionalities. Nevertheless, helium cold plasma treatment carried out by da Fonseca de Albuquerque et al. [16] did not significantly influence the water vapour permeation, but created an improved physical barrier to water. Moreover, even though this treatment technique increased the surface roughness, it was not significant enough in increasing the water contact angle of the modified surface. Surface dielectric barrier discharge (SDBD) plasma from Plasma Assisted Sanitation System (PASS) is another less common technique reported by Capelli et al. [19], predominantly used for food packaging decontamination from SARS-CoV-2 RNA. In this study, they observed that the plasma treatment decontaminated virus, without significantly affecting the properties of packaging and food substrate. Yet another plasma treatment method termed carbon tetrafluoride (CF4) reactive-ion etching (RIE) was reported by Kim et al. [23], where nanopillars are introduced to the film surface, with potential applications in developing antibacterial overcoating. Such films were observed to exhibit improved optical and antibacterial properties.

Overall, these reports indicate that various coating technologies can effectively enhance the functional characteristics of food packaging films, resulting in augmented product protection, prolonged shelf lives, and possibly improved sustainability. However, it’s important to note that explicit effects of each coating technology can depend on the type of film material, coating composition and treatment parameters.

The prospects of using plasma treated sodium alginate (SA) films for food packaging applications was studied by Sharmin and colleagues [20], where, unlike the traditional methods of plasma treatments, this research dealt with the use of plasma activated water (PAW). The main focus of the researchers remained on understanding the effect of citric acid (CA) and PAW on the mechanical, rheological and barrier properties of SA films (Also given in Table 1). The tensile strength and elongation at break values of the resultant films were seen to increase by 43 and 66% when PAW was used to prepare SA solutions, while a reduction in water vapour transmission rate (WVTR) up to 44% was obtained for 1% CA incorporated SA samples, all indicating the development of better films when compared to neat SA films.

Effect of different chitosan concentrations and plasma treatment durations on fresh pistachios was studied by Akhavan-Mahdavi and co-workers [13], and the radar chart depicted below provides an in-depth understanding on the sensory analysis results after 180 days of storage of pistachios after the treatments. In their study, the influence of varying amounts of chitosan (0.5 and 1.5% w/v) and cold plasma treatment duration (60 and 120 s) were observed and reported for 180 days of pistachio storage. The resultant effects on the pistachio shelf life were estimated by measuring various factors such as hardness, colour components, total mould and yeast, moisture and aflatoxin content, peroxide values, and sensory evaluations. From the reported results, it can be seen that the treatment with 1.5% chitosan and 120 s of cold plasma treatment produced highest conservation of pistachio hardness and colour indices. It has also been reported that among all the examined parameters, the plasma treated sample P120 C1.5 and the control sample exhibited the highest and lowest scores respectively.

While studying the decontamination of food packages from SARS-CoV-2 RNA with a cold plasma-assisted system, Capelli and team observed that plasma treatment decontaminated the virus, without significantly affecting the properties of either the packaging or the food substrate [19]. As reported for K5 and K10 samples, the viral RNA reduction driven merely by air exposure for both the packaging materials tested was very minimal. Both packing materials underwent a considerable but modest reduction in detectable RNA after 5 min of CAP treatment of around 10 and 16% for PP and PET, respectively. The RNA molecules, whose quantity was below the detection thresholds for each target sequence discovered by this PCR approach, were fully destroyed by CAP treatment for 10 min. Both PET and PP were used to study how O2, and CO2 changed in the headspaces of the packages as they were being stored. As predicted, the respiration of apple tissues resulted in CO2 building up and O2 being used up. Due to the greater thickness and reduced permeability of PET, the O2 loss was accelerated for apples in packaging. Also, O2 had been completely absorbed in just three days. However, for both packing materials, there was no discernible variation in CO2 and O2 concentration between treated (P5, P10) and control samples (C) [19]. The apple samples were also measured for titrable acidity (TA) and firmness values (N) during storage. TA showed an increase during storage in all apple samples packaged in PE, which was attributed to the generation of carbonic acid from CO2, which is present in higher concentration in PET packages than in PP ones. Although the exposure to CAP did not significantly affect the samples in either case, this difference was correlated with the type of components present.

The morphological changes induced by plasma treatment on PET surface has been reported by Kim et al. [23]. It was found that the CF4-RIE PET had a regular array structure made up of spherical capped nanopillars with 30 nm diameters, 237 nm heights, and 75 nm pitches (the space between two pillars), as opposed to the flat surface of neat PET. The Progomphus obscurus (sand dragon) wing, which exhibits a nanopillar array structure composed of high-aspect-ratio spherically capped nanopillars with an average diameter of 50 nm and an average height of 241 nm, served as the source of inspiration for the CF4-RIE’s nano surface structure. The optical improvement observed by the researchers were also attributed to these nanopillar array structure, where the rough surfaces tend to reduce transmittances by increasing the absorption capacity for incident light due to light scattering.

While studying the effect of cold plasma treatment on thyme essential oil (TO)/silk fibroin (SF) nanofibers against Salmonella Typhimurium in poultry meat, Lin and co-workers [26] conducted sensory evaluation tests were on chicken and duck meat. According to them, when compared to the control group, chicken and duck meat samples wrapped in plasma-TO/SF nanofibers membranes demonstrated an improvement in flavor and general appeal. The researchers also deduced that the sensory evaluation scores of poultry meat with plasma-TO/SF nanofibers were higher than the control group since the test group received a higher score after the plasma treatment, indicating that plasma-TO/SF nanofibers membrane could improve food quality without losing the good flavor.

As part of the U.S. National Science Foundation supported program on Future Technologies Enabled by Plasma Process (FTPP), at the University of Alabama at Birmingham (UAB), the developmental studies are focused on, a step further, to have smart sensor-integrated packaging against food pathogens or toxins via inkjet printing onto plasma treated films [2][28]. Moreover, the group recently published an invited mini review on mitigation strategies in engineered healthcare materials towards antimicrobial applications and another on non-thermal plasma processing for nanostructured biomaterial [29][30]. Plasma research programs for materials and biomatter for application in agriculture, medical materials [31][32][33][34][35][36][37][38][39][40], food packing, and other plasma-technologies for automobile and aerospace applications will establish Alabama State as a Southeastern regional hub for plasma science expertise and create thousands of high-paying technical careers in the state and region.

References

- Thomas, S.; Mozetic, M.; Cvelbar, U.; Špatenka, P.; Praveen, K.M. Non-Thermal Plasma Technology for Polymeric Materials; Elsevier Inc.: Amsterdam, The Netherlands, 2019; ISBN 978-0-12-813152-7.

- Karthik, C.; Rajalakshmi, S.; Thomas, S.; Thomas, V. Intelligent Polymeric Biomaterials Surface Driven by Plasma Processing. Curr. Opin. Biomed. Eng. 2023, 26, 100440.

- Das, D.; Panesar, P.S.; Saini, C.S.; Kennedy, J.F. Improvement in Properties of Edible Film through Non-Thermal Treatments and Nanocomposite Materials: A Review. Food Packag. Shelf Life 2022, 32, 100843.

- Joseph, B.; Ninan, N.; Visalakshan, R.M.; Denoual, C.; Bright, R.; Kalarikkal, N.; Grohens, Y.; Vasilev, K.; Thomas, S. Insights into the Biomechanical Properties of Plasma Treated 3D Printed PCL Scaffolds Decorated with Gold Nanoparticles. Compos. Sci. Technol. 2021, 202, 108544.

- Silva, E.G.S.; Cardoso, S.; Bettencourt, A.F.; Ribeiro, I.A.C. Latest Trends in Sustainable Polymeric Food Packaging Films. Foods 2023, 12, 168.

- Zhang, M.; Zhang, F.; Li, C.; An, H.; Wan, T.; Zhang, P. Application of Chitosan and Its Derivative Polymers in Clinical Medicine and Agriculture. Polymers 2022, 14, 958.

- Elashry, S.; ELsaeed, H.; El-Siragy, N.M. Microwave Plasma Discharge-Assisted Surface Modification of PVA Films: Coatings and Food Packaging. Eur. Phys. J. Plus 2022, 137, 1252.

- Ceylan, H.G.; Atasoy, A.F. New Bioactive Edible Packing Systems: Synbiotic Edible Films/Coatings as Carries of Probiotics and Prebiotics. Food Bioprocess Technol. 2023, 16, 1413–1428.

- Ranjha, M.M.A.N.; Shafique, B.; Aadil, R.M.; Manzoor, M.F.; Cheng, J.H. Modification in Cellulose Films through Ascent Cold Plasma Treatment and Polymerization for Food Products Packaging. Trends Food Sci. Technol. 2023, 134, 162–176.

- Rashvand, M.; Matera, A.; Altieri, G.; Genovese, F.; Nikzadfar, M.; Feyissa, A.H.; Renzo, G.C.; Carlo, G.; Renzo, D. Effect of Dielectric Barrier Discharge Cold Plasma on the Bio-Nanocomposite Film and Its Potential to Preserve the Quality of Strawberry under Modified Atmosphere Packaging. Res. Sq. 2023. preprint.

- Rashvand, M.; Abbaszadeh, R. Effect of Cold Plasma on the Firmness of Olive Fruit in Packaging and Atmospheric Space. J. Packag. Technol. Res. 2019, 3, 253–259.

- Glicerina, V.; Siroli, L.; Gottardi, D.; Ticchi, N.; Capelli, F.; Accorsi, R.; Gherardi, M.; Minelli, M.; Fiorini, M.; Andrisano, V.; et al. Influence of an Innovative, Biodegradable Active Packaging on the Quality of Sunflower Oil and “Pesto” Sauce during Storage. Appl. Food Res. 2023, 3, 100313.

- Akhavan-Mahdavi, S.; Mirzazadeh, M.; Alam, Z.; Solaimanimehr, S. The Effect of Chitosan Coating Combined with Cold Plasma on the Quality and Safety of Pistachio during Storage. Food Sci. Nutr. 2023, 11, 4296–4307.

- Tahsiri, Z.; Hedayati, S.; Niakousari, M. Improving the Functional Properties of Wild Almond Protein Isolate Films by Persian Gum and Cold Plasma Treatment. Int. J. Biol. Macromol. 2023, 229, 746–751.

- Li, Z.; Deng, S.; Chen, J. Surface Modification via Dielectric Barrier Discharge Atmospheric Cold Plasma (DBD–ACP): Improved Functional Properties of Soy Protein Film. Foods 2022, 11, 1196.

- da Fonseca de Albuquerque, M.D.; Bastos, D.C.; Ţălu, Ş.; Matos, R.S.; Pires, M.A.; Salerno, M.; da Fonseca Filho, H.D.; Simão, R.A. Vapor Barrier Properties of Cold Plasma Treated Corn Starch Films. Coatings 2022, 12, 1006.

- Goiana, M.L.; Mattos, A.L.A.; de Azeredo, H.M.C.; de Freitas Rosa, M.; Fernandes, F.A.N. Influence of Dielectric Barrier Discharge Cold Plasma Treatment on Starch, Gelatin, and Bacterial Cellulose Biodegradable Polymeric Films. Polymers 2022, 14, 5215.

- Yudhistira, B.; Sulaimana, A.S.; Punthi, F.; Chang, C.K.; Lung, C.T.; Santoso, S.P.; Gavahian, M.; Hsieh, C.W. Cold Plasma-Based Fabrication and Characterization of Active Films Containing Different Types of Myristica Fragrans Essential Oil Emulsion. Polymers 2022, 14, 1618.

- Capelli, F.; Tappi, S.; Gritti, T.; De Aguiar Saldanha Pinheiro, A.C.; Laurita, R.; Tylewicz, U.; Spataro, F.; Braschi, G.; Lanciotti, R.; Galindo, F.G.; et al. Decontamination of Food Packages from SARS-CoV-2 RNA with a Cold Plasma-Assisted System. Appl. Sci. 2021, 11, 4177.

- Sharmin, N.; Sone, I.; Walsh, J.L.; Sivertsvik, M.; Fernández, E.N. Effect of Citric Acid and Plasma Activated Water on the Functional Properties of Sodium Alginate for Potential Food Packaging Applications. Food Packag. Shelf Life 2021, 29, 100733.

- Cui, H.; Yang, X.; Abdel-Samie, M.A.; Lin, L. Cold Plasma Treated Phlorotannin/Momordica Charantia Polysaccharide Nanofiber for Active Food Packaging. Carbohydr. Polym. 2020, 239, 116214.

- Wu, X.; Liu, Q.; Luo, Y.; Murad, M.S.; Zhu, L.; Mu, G. Improved Packing Performance and Structure-Stability of Casein Edible Films by Dielectric Barrier Discharges (DBD) Cold Plasma. Food Packag. Shelf Life 2020, 24, 100471.

- Kim, J.H.; Mun, C.; Ma, J.; Park, S.G.; Lee, S.; Kim, C.S. Simple Fabrication of Transparent, Colorless, and Self-Disinfecting Polyethylene Terephthalate Film via Cold Plasma Treatment. Nanomaterials 2020, 10, 949.

- Chen, G.; Chen, Y.; Jin, N.; Li, J.; Dong, S.; Li, S.; Zhang, Z.; Chen, Y. Zein Films with Porous Polylactic Acid Coatings via Cold Plasma Pre-Treatment. Ind. Crops Prod. 2020, 150, 112382.

- Heidemann, H.M.; Dotto, M.E.R.; Laurindo, J.B.; Carciofi, B.A.M.; Costa, C. Cold Plasma Treatment to Improve the Adhesion of Cassava Starch Films onto PCL and PLA Surface. Colloids Surf. A Physicochem. Eng. Asp. 2019, 580, 123739.

- Lin, L.; Liao, X.; Cui, H. Cold Plasma Treated Thyme Essential Oil/Silk Fibroin Nanofibers against Salmonella Typhimurium in Poultry Meat. Food Packag. Shelf Life 2019, 21, 100337.

- Chen, G.; Dong, S.; Zhao, S.; Li, S.; Chen, Y. Improving Functional Properties of Zein Film via Compositing with Chitosan and Cold Plasma Treatment. Ind. Crops Prod. 2019, 129, 318–326.

- Pillai, R.R.; Adhikari, K.R.; Gardner, S.; Sunilkumar, S.; Sanas, S.; Mohammad, H.; Thomas, V. Inkjet-printed plasma-functionalized polymer-based capacitive sensor for PAHs. Mater. Today Commun. 2023, 35, 105659.

- Vijayan, V.M.; Walker, M.; Morris, J.J.; Thomas, V. Recent mitigation strategies in engineered healthcare materials towards antimicrobial applications. Curr. Opin. Biomed. Eng. 2022, 22, 100377.

- Tucker, B.S.; Aliakbarshirazi, S.; Vijayan, V.M.; Thukkaram, M.; De Geyter, N.; Thomas, V. Nonthermal plasma processing for nanostructured biomaterials and tissue engineering scaffolds: A mini review. Curr. Opin. Biomed. Eng. 2021, 17, 100259.

- Tucker, B.S.; Vijayan, V.M.; Vohra, Y.K.; Thomas, V. Novel magneto-plasma processing for enhanced modification of electrospun biomaterials. Mater. Lett. 2019, 250, 96–98.

- Vijayan, V.M.; Tucker, B.S.; Baker, P.A.; Vohra, Y.K.; Thomas, V. Non-equilibrium hybrid organic plasma processing for superhydrophobic PTFE surface towards potential bio-interface applications. Colloids Surf B Biointerfaces 2019, 183, 110463.

- Vijayan, V.M.; Tucker, B.S.; Hwang, P.T.J.; Bobba, P.S.; Jun, H.-W.; Catledge, S.A.; Vohra, Y.K.; Thomas, V. Non-equilibrium organosilane plasma polymerization for modulating the surface of PTFE towards potential blood contact applications. J. Mater. Chem. B 2020, 8, 2814–2825.

- Vijayan, V.M.; Tucker, B.S.; Dimble, P.S.; Vohra, Y.K.; Thomas, V. Dusty-Plasma-Assisted Synthesis of Silica Nanoparticles for in Situ Surface Modification of 3D-Printed Polymer Scaffolds. ACS Appl. Nano Mater. 2020, 3, 7392–7396.

- Vijayan, V.M.; Walker, M.; Pillai, R.R.; Moreno, G.H.; Vohra, Y.K.; Morris, J.J.; Thomas, V. Plasma Electroless Reduction: A Green Process for Designing Metallic Nanostructure Interfaces onto Polymeric Surfaces and 3D Scaffolds. ACS Appl. Mater. Interfaces 2022, 14, 25065–25079.

- Tucker, B.S.; Surolia, R.; Baker, P.A.; Vohra, Y.; Antony, V.; Thomas, V. Low-Temperature Air Plasma Modification of Electrospun Soft Materials and Bio-interfaces. In TMS 2019 148th Annual Meeting & Exhibition Supplemental Proceedings; Springer International Publishing: Cham, Switzerland, 2019; pp. 819–826.

- Bradford, J.P.; Tucker, B.; Hernandez-Moreno, G.; Charles, P.; Thomas, V. Low-temperature inductively coupled plasma as a method to promote biomineralization on 3D printed poly (lactic acid) scaffolds. J. Mater. Sci. 2021, 56, 14717–14728.

- Bradford, J.P.; Hernandez-Moreno, G.; Pillai, R.R.; Hernandez-Nichols, A.L.; Thomas, V. Low-Temperature Plasmas Improving Chemical and Cellular Properties of Poly (Ether Ether Ketone) Biomaterial for Biomineralization. Materials 2023, 17, 171.

- Karthik, C.; Sarngadharan, S.C.; Thomas, V. Low-Temperature Plasma Techniques in Biomedical Applications and Therapeutics: An Overview. Int. J. Mol. Sci. 2023, 25, 524.

- Deslima, C.; Vinoy, V.; Renjith, P.; Vijayan, V. Application of low-temperature plasma treatment for rapid and efficient polydopamine coating on 3D-printed polymer scaffolds. MRS Commun. 2023, 13, 1163–1170.

More

Information

Subjects:

Materials Science, Biomaterials

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

819

Revisions:

2 times

(View History)

Update Date:

23 Jan 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No