| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Ayyaz Mahmood | -- | 4242 | 2024-01-16 07:42:48 | | | |

| 2 | Rita Xu | -65 word(s) | 4177 | 2024-01-16 08:01:23 | | |

Video Upload Options

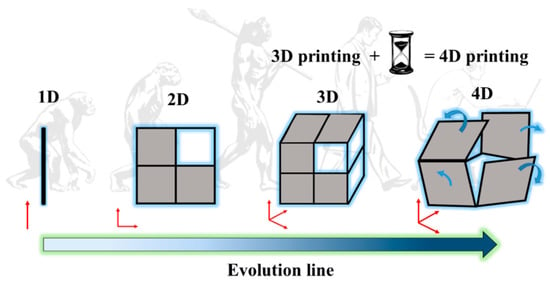

The scientific community is and has constantly been working to innovate and improve the available technologies in our use. In that effort, three-dimensional (3D) printing was developed that can construct 3D objects from a digital file. Three-dimensional printing, also known as additive manufacturing (AM), has seen tremendous growth over the last three decades, and in the last five years, its application has widened significantly. Three-dimensional printing technology has the potential to fill the gaps left by the limitations of the current manufacturing technologies, and it has further become exciting with the addition of a time dimension giving rise to the concept of four-dimensional (4D) printing, which essentially means that the structures created by 4D printing undergo a transformation over time under the influence of internal or external stimuli.

1. Introduction

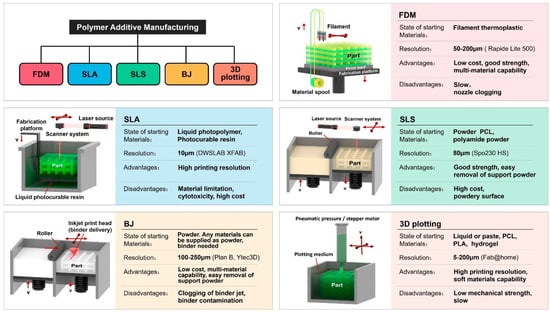

2. Three-Dimensional/Four-Dimensional Printing Process and Materials

2.1. General Process

-

Computer-aided Design (CAD): CAD software creates a three-dimensional model of the object. Using scientific data on the particular materials, the program may produce virtual simulations of how the thing would perform under various circumstances. The CAD model is next converted into Standard Tessellation Language (STL) conversion. STL is a file format that was designed for 3D systems in 1987 by their stereolithography apparatus (SLA) machines. STL files are supported by almost all 3D printers.

-

STL file manipulation and the transfer to machines: the STL file is then copied by the user to the computer that manages the 3D printer. There, the user may choose the printing’s size and direction. This is comparable to setting up a usual paper printer to print on both sides or in landscape rather than the portrait orientation.

-

The next step is to set up the machine. Each machine has specific guidelines for getting ready for a fresh print job. This entails restocking the printer’s polymers, binders, and other consumables.

-

Building process: at this point, you may sit back and relax, as the majority of the building process is handled automatically. Although it may be considerably thinner or thicker, each layer is typically 0.1 mm thick. This procedure might take hours or even days to complete, depending on the size of the item, the machine, and the materials utilized.

-

Post-processing: the printed object from many 3D printers will need some post-processing finishing. This can include washing the printed item to get rid of any residual powder or brushing off any water-soluble supports. Since certain materials require time to cure at this stage, the printed structure could be fragile, thus care may be needed to prevent it from breaking or disintegrating. Applications are the next steps, where printed structures/objects are installed and put to use.

| Fabrication Process | Methods | Materials | Applications | Surface Finish | Merits | Limitations |

|---|---|---|---|---|---|---|

| Extrusion | FDM/FFF | Thermoplastics filaments, e.g., PLA, ABS, Nylon |

Rapid prototyping Concept parts Advanced composite parts |

Standard | Low cost Versatile Simplicity High speed |

Weak mechanical properties Limited materials |

| DIW | Plastics, Ceramics, Composites, Living cells |

Packaging Scaffolds for bone regeneration |

Standard | Flexible | Requires post processing |

|

| Powder-bed fusion | SLS | Fine powders of polymers, alloys, composites, and ceramics |

Aerospace components Light-weight structures Electronics |

Standard | Fine resolution High quality Best mechanical properties |

Low resolution High cost High porosity |

| SLM | Fine powders of metals, alloys, and ceramics |

Aerospace components Light-weight structures Electronics |

Good | Good mechanical properties Wide range of materials |

Slow process | |

| Photopolymerization | SLA | Photopolymers UV curable resins |

Biomedical Prototyping |

Excellent | High precision Smooth surface finish Low cost |

Limited materials Weak mechanical properties Expensive |

| DLP | Elastomers, Photopolymers UV curable resins |

Biomedical Prototyping |

Good | High resolution High printing speeds |

Requires post processing |

2.2. Materials for 3D/4D Printing

| Materials | Main Applications | Benefits | Challenges |

|---|---|---|---|

| Metals and alloys | Aerospace and Automotive Military Biomedical |

Multifunctional optimization Mass-customization Reduced material waste Fewer assembly components Possibility to repair damaged or worn metal parts |

Limited selection of alloys Dimensional inaccuracy and poor surface finish Post-processing may be required (machining, heat treatment or chemical etching) |

| Polymers and composites | Aerospace and Automotive Sports Medical Architecture Toys Biomedical |

Fast prototyping Cost-effective Complex structures Mass-customisation |

Weak mechanical properties Limited selection of polymers and reinforcements Anisotropic mechanical properties (especially in fibre-reinforced composites) |

| Ceramics | Biomedical Aerospace and Automotive Chemical industries |

Controlling porosity of lattices Printing complex structures and scaffolds for human body organs Reduced fabrication time A better control on composition and microstructure |

Limited selection of 3D-printable ceramics Dimensional inaccuracy and poor surface finish Post-processing (e.g., sintering) may be required |

| Concrete | Infrastructure and construction | Mass-customization No need for formwork Less labour required especially useful in harsh environment and for space construction |

Layer-by-layer appearance Anisotropic mechanical properties Poor inter-layer adhesion Difficulties in upscaling to larger buildings Limited number of printing methods and tailored concrete mixture design |

2.2.1. Polymers

2.2.2. Metallic Materials

2.2.3. Ceramics

References

- DeSimone, J. What If 3D Printing Was 100× Faster? | TED Talk. Available online: https://www.ted.com/talks/joseph_desimone_what_if_3d_printing_was_100x_faster (accessed on 15 October 2022).

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. US Patent 4575330A, 1986.

- Yin, H.; Qu, M.; Zhang, H.; Lim, Y.C. 3D Printing and Buildings: A Technology Review and Future Outlook. Technol. Archit. Des. 2018, 2, 94–111.

- Wang, J.; Zhang, Y.; Aghda, N.H.; Pillai, A.R.; Thakkar, R.; Nokhodchi, A.; Maniruzzaman, M. Emerging 3D Printing Technologies for Drug Delivery Devices: Current Status and Future Perspective. Adv. Drug. Deliv. Rev. 2021, 174, 294–316.

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290.

- Yan, Q.; Dong, H.; Su, J.; Han, J.; Song, B.; Wei, Q.; Shi, Y. A Review of 3D Printing Technology for Medical Applications. Engineering 2018, 4, 729–742.

- Lee, J.Y.; An, J.; Chua, C.K. Fundamentals and Applications of 3D Printing for Novel Materials. Appl. Mater. Today 2017, 7, 120–133.

- Mallakpour, S.; Azadi, E.; Hussain, C.M. State-of-the-Art of 3D Printing Technology of Alginate-Based Hydrogels—An Emerging Technique for Industrial Applications. Adv. Colloid. Interface Sci. 2021, 293, 102436.

- Liu, G.; Zhang, X.; Chen, X.; He, Y.; Cheng, L.; Huo, M.; Yin, J.; Hao, F.; Chen, S.; Wang, P.; et al. Additive Manufacturing of Structural Materials. Mater. Sci. Eng. R Rep. 2021, 145, 100596.

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Sanz-Horta, R.; Rodriguez-Hernandez, J. Additive Manufacturing of Polymers: 3D and 4D Printing, Methodologies, Type of Polymeric Materials, and Applications. Macromol. Eng. 2022, 1–65.

- Tamay, D.G.; Dursun Usal, T.; Alagoz, A.S.; Yucel, D.; Hasirci, N.; Hasirci, V. 3D and 4D Printing of Polymers for Tissue Engineering Applications. Front. Bioeng. Biotechnol. 2019, 7, 164.

- Zhang, C.; Li, X.; Jiang, L.; Tang, D.; Xu, H.; Zhao, P.; Fu, J.; Zhou, Q.; Chen, Y. 3D Printing of Functional Magnetic Materials: From Design to Applications. Adv. Funct. Mater. 2021, 31, 2102777.

- Joshi, S.C.; Sheikh, A.A. 3D Printing in Aerospace and Its Long-Term Sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185.

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The Status, Challenges, and Future of Additive Manufacturing in Engineering. Comput.-Aided Des. 2015, 69, 65–89.

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Springer: New York, NY, USA, 2015.

- Melchels, F.P.W.; Domingos, M.A.N.; Klein, T.J.; Malda, J.; Bartolo, P.J.; Hutmacher, D.W. Additive Manufacturing of Tissues and Organs. Prog. Polym. Sci. 2012, 37, 1079–1104.

- Marchelli, G.; Prabhakar, R.; Storti, D.; Ganter, M. The Guide to Glass 3D Printing: Developments, Methods, Diagnostics and Results. Rapid Prototyp. J. 2011, 17, 187–194.

- Lu, B.H.; Lan, H.B.; Liu, H.Z. Additive Manufacturing Frontier: 3D Printing Electronics. Opto-Electron. Adv. 2018, 1, 17000401–17000410.

- Bose, S.; Vahabzadeh, S.; Bandyopadhyay, A. Bone Tissue Engineering Using 3D Printing. Mater. Today 2013, 16, 496–504.

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687.

- Zhang, F.; Wei, M.; Viswanathan, V.v.; Swart, B.; Shao, Y.; Wu, G.; Zhou, C. 3D Printing Technologies for Electrochemical Energy Storage. Nano Energy 2017, 40, 418–431.

- Layani, M.; Wang, X.; Magdassi, S. Novel Materials for 3D Printing by Photopolymerization. Adv. Mater. 2018, 30, e1706344.

- Bhattacharjee, N.; Urrios, A.; Kang, S.; Folch, A. The Upcoming 3D-Printing Revolution in Microfluidics. Lab Chip 2016, 16, 1720–1742.

- Sydney Gladman, A.; Matsumoto, E.A.; Nuzzo, R.G.; Mahadevan, L.; Lewis, J.A. Biomimetic 4D Printing. Nat Mater. 2016, 15, 413–418.

- Raviv, D.; Zhao, W.; McKnelly, C.; Papadopoulou, A.; Kadambi, A.; Shi, B.; Hirsch, S.; Dikovsky, D.; Zyracki, M.; Olguin, C.; et al. Active Printed Materials for Complex Self-Evolving Deformations. Sci. Rep. 2014, 4, 7422.

- Yang, H.; Leow, W.R.; Wang, T.; Wang, J.; Yu, J.; He, K.; Qi, D.; Wan, C.; Chen, X. 3D Printed Photoresponsive Devices Based on Shape Memory Composites. Adv. Mater. 2017, 29, 1701627.

- Kuksenok, O.; Balazs, A.C. Stimuli-Responsive Behavior of Composites Integrating Thermo-Responsive Gels with Photo-Responsive Fibers. Mater. Horiz. 2015, 3, 53–62.

- Ding, Z.; Yuan, C.; Peng, X.; Wang, T.; Qi, H.J.; Dunn, M.L. Direct 4D Printing via Active Composite Materials. Sci. Adv. 2017, 3, e1602890.

- Kotikian, A.; Truby, R.L.; Boley, J.W.; White, T.J.; Lewis, J.A. 3D Printing of Liquid Crystal Elastomeric Actuators with Spatially Programed Nematic Order. Adv. Mater. 2018, 30, 1706164.

- Nadgorny, M.; Xiao, Z.; Chen, C.; Connal, L.A. Three-Dimensional Printing of PH-Responsive and Functional Polymers on an Affordable Desktop Printer. ACS Appl. Mater. Interfaces 2016, 8, 28946–28954.

- Ge, Q.; Dunn, C.K.; Qi, H.J.; Dunn, M.L. Active Origami by 4D Printing. Smart Mater. Struct. 2014, 23, 094007.

- Tanaka, T.; Ishikawa, A.; Kawata, S. Two-Photon-Induced Reduction of Metal Ions for Fabricating Three-Dimensional Electrically Conductive Metallic Microstructure. Appl. Phys. Lett. 2006, 88, 081107.

- Breger, J.C.; Yoon, C.; Xiao, R.; Kwag, H.R.; Wang, M.O.; Fisher, J.P.; Nguyen, T.D.; Gracias, D.H. Self-Folding Thermo-Magnetically Responsive Soft Microgrippers. ACS Appl. Mater. Interfaces 2015, 7, 3398–3405.

- Lantean, S.; Roppolo, I.; Sangermano, M.; Hayoun, M.; Dammak, H.; Rizza, G. Programming the Microstructure of Magnetic Nanocomposites in DLP 3D Printing. Addit. Manuf. 2021, 47, 102343.

- Vaezi, M.; Chianrabutra, S.; Mellor, B.; Yang, S. Multiple Material Additive Manufacturing—Part 1: A Review: This Review Paper Covers a Decade of Research on Multiple Material Additive Manufacturing Technologies Which Can Produce Complex Geometry Parts with Different Materials. Virtual Phys. Prototyp. 2013, 8, 19–50.

- Khare, V.; Sonkaria, S.; Lee, G.Y.; Ahn, S.H.; Chu, W.S. From 3D to 4D Printing—Design, Material and Fabrication for Multi-Functional Multi-Materials. Int. J. Pre. Eng. Manu. GT 2017, 4, 291–299.

- Bandyopadhyay, A.; Heer, B. Additive Manufacturing of Multi-Material Structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16.

- Pei, E.; Loh, G.H. Technological Considerations for 4D Printing: An Overview. Prog. Addit. Manuf. 2018, 3, 95–107.

- Ryan, K.R.; Down, M.P.; Banks, C.E. Future of Additive Manufacturing: Overview of 4D and 3D Printed Smart and Advanced Materials and Their Applications. Chem. Eng. J. 2021, 403, 126162.

- Zastrow, M. 3D Printing Gets Bigger, Faster and Stronger. Nature 2020, 578, 20–23.

- Walker, D.A.; Hedrick, J.L.; Mirkin, C.A. Rapid, Large-Volume, Thermally Controlled 3D Printing Using a Mobile Liquid Interface. Science 2019, 366, 360–364.

- Kelly, B.E.; Bhattacharya, I.; Heidari, H.; Shusteff, M.; Spadaccini, C.M.; Taylor, H.K. Volumetric Additive Manufacturing via Tomographic Reconstruction. Science 2019, 363, 1075–1079.

- Saha, S.K.; Wang, D.; Nguyen, V.H.; Chang, Y.; Oakdale, J.S.; Chen, S.C. Scalable Submicrometer Additive Manufacturing. Science 2019, 366, 105–109.

- Grigoryan, B.; Paulsen, S.J.; Corbett, D.C.; Sazer, D.W.; Fortin, C.L.; Zaita, A.J.; Greenfield, P.T.; Calafat, N.J.; Gounley, J.P.; Ta, A.H.; et al. Multivascular Networks and Functional Intravascular Topologies within Biocompatible Hydrogels. Science 2019, 364, 458–464.

- Lee, A.; Hudson, A.R.; Shiwarski, D.J.; Tashman, J.W.; Hinton, T.J.; Yerneni, S.; Bliley, J.M.; Campbell, P.G.; Feinberg, A.W. 3D Bioprinting of Collagen to Rebuild Components of the Human Heart. Science 2019, 365, 482–487.

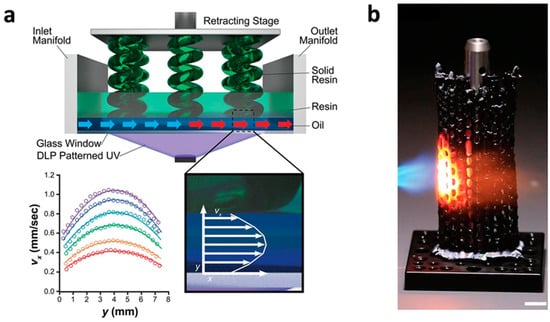

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Continuous Liquid Interface Production of 3D Objects. Science 2015, 347, 1349–1352.

- Zhang, D.; Qiu, D.; Gibson, M.A.; Zheng, Y.; Fraser, H.L.; StJohn, D.H.; Easton, M.A. Additive Manufacturing of Ultrafine-Grained High-Strength Titanium Alloys. Nature 2019, 576, 91–95.

- Kotz, F.; Arnold, K.; Bauer, W.; Schild, D.; Keller, N.; Sachsenheimer, K.; Nargang, T.M.; Richter, C.; Helmer, D.; Rapp, B.E. Three-Dimensional Printing of Transparent Fused Silica Glass. Nature 2017, 544, 337–339.

- Sun, W.; Starly, B.; Daly, A.C.; Burdick, J.A.; Groll, J.; Skeldon, G.; Shu, W.; Sakai, Y.; Shinohara, M.; Nishikawa, M.; et al. The Bioprinting Roadmap. Biofabrication 2020, 12, 022002.

- Skylar-Scott, M.A.; Mueller, J.; Visser, C.W.; Lewis, J.A. Voxelated Soft Matter via Multimaterial Multinozzle 3D Printing. Nature 2019, 575, 330–335.

- Bhushan, B.; Caspers, M. An Overview of Additive Manufacturing (3D Printing) for Microfabrication. Microsyst. Technol. 2017, 23, 1117–1124.

- Mao, M.; He, J.; Li, X.; Zhang, B.; Lei, Q.; Liu, Y.; Li, D. The Emerging Frontiers and Applications of High-Resolution 3D Printing. Micromachines 2017, 8, 113.

- Ru, C.; Luo, J.; Xie, S.; Sun, Y. A Review of Non-Contact Micro- and Nano-Printing Technologies. J. Micromech. Microeng. 2014, 24, 053001.

- Ambrosi, A.; Pumera, M. 3D-Printing Technologies for Electrochemical Applications. Chem. Soc. Rev. 2016, 45, 2740–2755.

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. B Eng. 2018, 143, 172–196.

- Momeni, F.; Mehdi, M.; Hassani, N.S.; Liu, X.; Ni, J. A Review of 4D Printing. Mater. Des. 2017, 122, 42–79.

- Wohlers, T. Wohlers Report 2018: 3d Printing and Additive Manufacturing State of the Industry, Wohlers Associates; Wohlers Associates: Washington, DC, USA; Fort Collins, CO, USA, 2018.

- Gundrati, N.B.; Chakraborty, P.; Zhou, C.; Chung, D.D.L. Effects of Printing Conditions on the Molecular Alignment of Three-Dimensionally Printed Polymer. Compos. B Eng. 2018, 134, 164–168.

- Gundrati, N.B.; Chakraborty, P.; Zhou, C.; Chung, D.D.L. First Observation of the Effect of the Layer Printing Sequence on the Molecular Structure of Three-Dimensionally Printed Polymer, as Shown by in-Plane Capacitance Measurement. Compos. B Eng. 2018, 140, 78–82.

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D Printing of Polymer Matrix Composites: A Review and Prospective. Compos. B Eng. 2017, 110, 442–458.

- Hammock, M.L.; Chortos, A.; Tee, B.C.K.; Tok, J.B.H.; Bao, Z. 25th Anniversary Article: The Evolution of Electronic Skin (E-Skin): A Brief History, Design Considerations, and Recent Progress. Adv. Mat. 2013, 25, 5997–6038.

- Chenoweth, K.; Cheung, S.; van Duin, A.C.T.; Goddard, W.A.; Kober, E.M. Simulations on the Thermal Decomposition of a Poly(Dimethylsiloxane) Polymer Using the ReaxFF Reactive Force Field. J. Am. Chem. Soc. 2005, 127, 7192–7202.

- Bîrca, A.; Gherasim, O.; Grumezescu, V.; Grumezescu, A.M. Introduction in Thermoplastic and Thermosetting Polymers. Mater. Biomed. Eng. Thermoplast. Polym. 2019, 1–28.

- Grumezescu, V.; Grumezescu, A. Materials for Biomedical Engineering: Thermoset and Thermoplastic Polymers; Elsevier: Amsterdam, The Netherlands, 2019; Volume 1.

- Lin, D.; Jin, S.; Zhang, F.; Wang, C.; Wang, Y.; Zhou, C.; Cheng, G.J. 3D Stereolithography Printing of Graphene Oxide Reinforced Complex Architectures. Nanotechnology 2015, 26, 434003.

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive Manufacturing of Metals. Acta Mater. 2016, 117, 371–392.

- Hu, Y.; Cong, W.; Wang, X.; Li, Y.; Ning, F.; Wang, H. Laser Deposition-Additive Manufacturing of TiB-Ti Composites with Novel Three-Dimensional Quasi-Continuous Network Microstructure: Effects on Strengthening and Toughening. Compos. B Eng. 2018, 133, 91–100.

- Sheydaeian, E.; Toyserkani, E. A New Approach for Fabrication of Titanium-Titanium Boride Periodic Composite via Additive Manufacturing and Pressure-Less Sintering. Compos. B Eng. 2018, 138, 140–148.

- Carlton, H.D.; Haboub, A.; Gallegos, G.F.; Parkinson, D.Y.; MacDowell, A.A. Damage Evolution and Failure Mechanisms in Additively Manufactured Stainless Steel. Mat. Sci. Eng. A 2016, 651, 406–414.

- Casalino, G.; Campanelli, S.L.; Contuzzi, N.; Ludovico, A.D. Experimental Investigation and Statistical Optimisation of the Selective Laser Melting Process of a Maraging Steel. Opt. Laser Technol. 2015, 65, 151–158.

- Murr, L.E.; Martinez, E.; Hernandez, J.; Collins, S.; Amato, K.N.; Gaytan, S.M.; Shindo, P.W. Microstructures and Properties of 17-4 PH Stainless Steel Fabricated by Selective Laser Melting. J. Mat. Res. Technol. 2012, 1, 167–177.

- Mazumder, J.; Choi, J.; Nagarathnam, K.; Koch, J.; Hetzner, D. The Direct Metal Deposition of H13 Tool Steel for 3-D Components. JOM 1997, 49, 55–60.

- Brice, C.; Shenoy, R.; Kral, M.; Buchannan, K. Precipitation Behavior of Aluminum Alloy 2139 Fabricated Using Additive Manufacturing. Mat. Sci. Eng. A 2015, 648, 9–14.

- Bartkowiak, K.; Ullrich, S.; Frick, T.; Schmidt, M. New Developments of Laser Processing Aluminium Alloys via Additive Manufacturing Technique. Phys. Procedia 2011, 12, 393–401.

- Liang, S.X.; Jia, Z.; Liu, Y.J.; Zhang, W.; Wang, W.; Lu, J.; Zhang, L.C. Compelling Rejuvenated Catalytic Performance in Metallic Glasses. Adv. Mater. 2018, 30, 1802764.

- Jia, Z.; Duan, X.; Qin, P.; Zhang, W.; Wang, W.; Yang, C.; Sun, H.; Wang, S.; Zhang, L.C. Disordered Atomic Packing Structure of Metallic Glass: Toward Ultrafast Hydroxyl Radicals Production Rate and Strong Electron Transfer Ability in Catalytic Performance. Adv. Funct. Mater. 2017, 27, 1702258.

- Jia, Z.; Wang, Q.; Sun, L.; Wang, Q.; Zhang, L.C.; Wu, G.; Luan, J.H.; Jiao, Z.B.; Wang, A.; Liang, S.X.; et al. Attractive In Situ Self-Reconstructed Hierarchical Gradient Structure of Metallic Glass for High Efficiency and Remarkable Stability in Catalytic Performance. Adv. Funct. Mater. 2019, 29, 1807857.

- Jia, Z.; Kang, J.; Zhang, W.C.; Wang, W.M.; Yang, C.; Sun, H.; Habibi, D.; Zhang, L.C. Surface Aging Behaviour of Fe-Based Amorphous Alloys as Catalysts during Heterogeneous Photo Fenton-like Process for Water Treatment. Appl. Catal. B 2017, 204, 537–547.

- Nakahara, S.; Périgo, E.A.; Pittini-Yamada, Y.; de Hazan, Y.; Graule, T. Electric Insulation of a FeSiBC Soft Magnetic Amorphous Powder by a Wet Chemical Method: Identification of the Oxide Layer and Its Thickness Control. Acta Mater. 2010, 58, 5695–5703.

- Liu, D.; Wu, C.; Yan, M.; Wang, J. Correlating the Microstructure, Growth Mechanism and Magnetic Properties of FeSiAl Soft Magnetic Composites Fabricated via HNO3 Oxidation. Acta Mater. 2018, 146, 294–303.

- Farmer, J.; Choi, J.S.; Saw, C.; Haslam, J.; Day, D.; Hailey, P.; Lian, T.; Rebak, R.; Perepezko, J.; Payer, J.; et al. Iron-Based Amorphous Metals: High-Performance Corrosion-Resistant Material Development. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009, 40, 1289–1305.

- Ouyang, D.; Li, N.; Xing, W.; Zhang, J.; Liu, L. 3D Printing of Crack-Free High Strength Zr-Based Bulk Metallic Glass Composite by Selective Laser Melting. Intermetallics 2017, 90, 128–134.

- Li, H.X.; Lu, Z.C.; Wang, S.L.; Wu, Y.; Lu, Z.P. Fe-Based Bulk Metallic Glasses: Glass Formation, Fabrication, Properties and Applications. Prog. Mater. Sci. 2019, 103, 235–318.

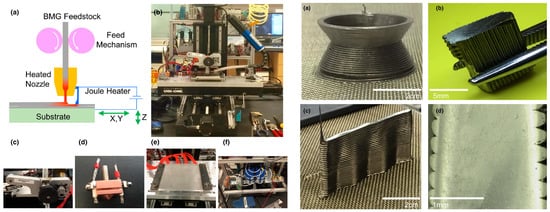

- Gibson, M.A.; Mykulowycz, N.M.; Shim, J.; Fontana, R.; Schmitt, P.; Roberts, A.; Ketkaew, J.; Shao, L.; Chen, W.; Bordeenithikasem, P.; et al. 3D printing metals like thermoplastics: Fused filament fabrication of metallic glasses. Mater. Today 2018, 21, 697–702.

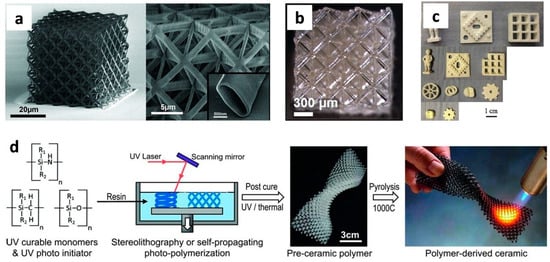

- Eckel, Z.C.; Zhou, C.; Martin, J.H.; Jacobsen, A.J.; Carter, W.B.; Schaedler, T.A. Additive Manufacturing of Polymer-Derived Ceramics. Science 2016, 351, 58–62.

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001.

- Shahzad, K.; Deckers, J.; Zhang, Z.; Kruth, J.P.; Vleugels, J. Additive Manufacturing of Zirconia Parts by Indirect Selective Laser Sintering. J. Eur. Ceram. Soc. 2014, 34, 81–89.

- Tang, H.H.; Yen, H.C. Slurry-Based Additive Manufacturing of Ceramic Parts by Selective Laser Burn-Out. J. Eur. Ceram. Soc. 2015, 35, 981–987.

- Chartier, T.; Duterte, C.; Delhote, N.; Baillargeat, D.; Verdeyme, S.; Delage, C.; Chaput, C. Fabrication of Millimeter Wave Components Via Ceramic Stereo- and Microstereolithography Processes. J. Am. Ceram. Soc. 2008, 91, 2469–2474.

- Zheng, X.; Lee, H.; Weisgraber, T.H.; Shusteff, M.; DeOtte, J.; Duoss, E.B.; Kuntz, J.D.; Biener, M.M.; Ge, Q.; Jackson, J.A.; et al. Ultralight, Ultrastiff Mechanical Metamaterials. Science 2014, 344, 1373–1377.

- Windsheimer, H.; Travitzky, N.; Hofenauer, A.; Greil, P. Laminated Object Manufacturing of Preceramic-Paper-Derived Si-SiC Composites. Adv. Mater. 2007, 19, 4515–4519.

- Fu, Q.; Saiz, E.; Tomsia, A.P. Bioinspired Strong and Highly Porous Glass Scaffolds. Adv. Funct. Mater. 2011, 21, 1058–1063.

- Özkol, E.; Wätjen, A.M.; Bermejo, R.; Deluca, M.; Ebert, J.; Danzer, R.; Telle, R. Mechanical Characterisation of Miniaturised Direct Inkjet Printed 3Y-TZP Specimens for Microelectronic Applications. J. Eur. Ceram. Soc. 2010, 30, 3145–3152.

- Jafari, M.A.; Han, W.; Mohammadi, F.; Safari, A.; Danforth, S.C.; Langrana, N. A Novel System for Fused Deposition of Advanced Multiple Ceramics. Rapid Prototyp. J. 2000, 6, 161–174.

- Liu, Y.; Chen, Z.; Li, J.; Gong, B.; Wang, L.; Lao, C.; Wang, P.; Liu, C.; Feng, Y.; Wang, X. 3D Printing of Ceramic Cellular Structures for Potential Nuclear Fusion Application. Addit. Manuf. 2020, 35, 101348.

- Meza, L.R.; Das, S.; Greer, J.R. Strong, Lightweight, and Recoverable Three-Dimensional Ceramic Nanolattices. Science 2014, 345, 1322–1326.

- Jang, D.; Meza, L.R.; Greer, F.; Greer, J.R. Fabrication and Deformation of Three-Dimensional Hollow Ceramic Nanostructures. Nat. Mater. 2013, 12, 893–898.

- Bauer, J.; Hengsbach, S.; Tesari, I.; Schwaiger, R.; Kraft, O. High-Strength Cellular Ceramic Composites with 3D Microarchitecture. Proc. Natl. Acad. Sci. USA 2014, 111, 2453–2458.

- Colombo, P.; Mera, G.; Riedel, R.; Sorarù, G.D. Polymer-Derived Ceramics: 40 Years of Research and Innovation in Advanced Ceramics. J. Am. Ceram. Soc. 2010, 93, 1805–1837.

- Ionescu, E.; Kleebe, H.J.; Riedel, R. Silicon-Containing Polymer-Derived Ceramic Nanocomposites (PDC-NCs): Preparative Approaches and Properties. Chem. Soc. Rev. 2012, 41, 5032–5052.

- Minas, C.; Carnelli, D.; Tervoort, E.; Studart, A.R. 3D Printing of Emulsions and Foams into Hierarchical Porous Ceramics. Adv. Mater. 2016, 28, 9993–9999.

- Yu, Y.; Liu, Y.; Fang, J.; An, L. Formation of Novel Microstructured SiCNO Films from Block Copolymer Micellar-Templating Approaches. J. Am. Ceram. Soc. 2015, 98, 2894–2901.

- Ionescu, E.; Linck, C.; Fasel, C.; Müller, M.; Kleebe, H.J.; Riedel, R. Polymer-Derived SiOC/ZrO2 Ceramic Nanocomposites with Excellent High-Temperature Stability. J. Am. Ceram. Soc. 2010, 93, 241–250.

- Li, J.; Lu, K.; Lin, T.; Shen, F. Preparation of Micro-/Mesoporous SiOC Bulk Ceramics. J. Am. Ceram. Soc. 2015, 98, 1753–1761.

- Zanchetta, E.; Cattaldo, M.; Franchin, G.; Schwentenwein, M.; Homa, J.; Brusatin, G.; Colombo, P. Stereolithography of SiOC Ceramic Microcomponents. Adv. Mater. 2016, 28, 370–376.

- Mera, G.; Navrotsky, A.; Sen, S.; Kleebe, H.J.; Riedel, R. Polymer-Derived SiCN and SiOC Ceramics-Structure and Energetics at the Nanoscale. J. Mater. Chem. A Mater. 2013, 1, 3826–3836.

- Kaspar, J.; Terzioglu, C.; Ionescu, E.; Graczyk-Zajac, M.; Hapis, S.; Kleebe, H.J.; Riedel, R. Stable SiOC/Sn Nanocomposite Anodes for Lithium-Ion Batteries with Outstanding Cycling Stability. Adv. Funct. Mater. 2014, 24, 4097–4104.

- Kashiwagi, T.; Du, F.; Douglas, J.F.; Winey, K.I.; Harris, R.H.; Shields, J.R. Nanoparticle Networks Reduce the Flammability of Polymer Nanocomposites. Nat. Mater. 2005, 4, 928–933.

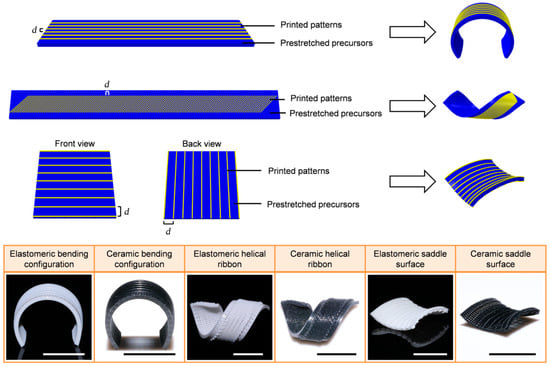

- Liu, G.; Zhao, Y.; Wu, G.; Lu, J. Origami and 4D Printing of Elastomer-Derived Ceramic Structures. Sci. Adv. 2018, 4, eaat0641.

- Studart, A.R. Additive Manufacturing of Biologically-Inspired Materials. Chem. Soc. Rev. 2016, 45, 359–376.