Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Dilshad Shaikhah | -- | 3845 | 2024-01-15 09:32:54 | | | |

| 2 | Camila Xu | Meta information modification | 3845 | 2024-01-16 02:19:05 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Shaikhah, D.; Loise, V.; Angelico, R.; Porto, M.; Calandra, P.; Abe, A.A.; Testa, F.; Bartucca, C.; Oliviero Rossi, C.; Caputo, P. Enhanced Oil Recovery Techniques. Encyclopedia. Available online: https://encyclopedia.pub/entry/53822 (accessed on 07 March 2026).

Shaikhah D, Loise V, Angelico R, Porto M, Calandra P, Abe AA, et al. Enhanced Oil Recovery Techniques. Encyclopedia. Available at: https://encyclopedia.pub/entry/53822. Accessed March 07, 2026.

Shaikhah, Dilshad, Valeria Loise, Ruggero Angelico, Michele Porto, Pietro Calandra, Abraham A. Abe, Flaviano Testa, Concetta Bartucca, Cesare Oliviero Rossi, Paolino Caputo. "Enhanced Oil Recovery Techniques" Encyclopedia, https://encyclopedia.pub/entry/53822 (accessed March 07, 2026).

Shaikhah, D., Loise, V., Angelico, R., Porto, M., Calandra, P., Abe, A.A., Testa, F., Bartucca, C., Oliviero Rossi, C., & Caputo, P. (2024, January 15). Enhanced Oil Recovery Techniques. In Encyclopedia. https://encyclopedia.pub/entry/53822

Shaikhah, Dilshad, et al. "Enhanced Oil Recovery Techniques." Encyclopedia. Web. 15 January, 2024.

Copy Citation

Enhanced oil recovery (EOR) processes are technologies used in the oil and gas industry to maximize the extraction of residual oil from reservoirs after primary and secondary recovery methods have been carried out. EOR processes involve various methods, including thermal, chemical, gas and microbial methods.

enhanced oil recovery

biosurfactants

microbes

interfacial tension

1. Introduction

Petroleum, also known as crude oil, is a vital raw material in the chemical industry, playing a significant role in global economic development for the past century [1]. It is a primary energy source for transportation, power generation, and a range of industrial and household applications. The estimated daily oil consumption is about 90 million bbl of oil [2], and it is projected to continue until 2030 with an annual increase of 1.7% in the number of oil barrels produced annually [3][4][5]. With the continuous worldwide increase in energy demand, it is crucial to develop new alternatives, such as wind, solar, nuclear energy, and biomass-converted products, to reduce reliance on fossil fuels [6][7][8][9]. However, although the energy transition favors the use of renewable sources, oil and natural gas will remain the main source of energy for the next decades.

Although several technologies for alternative energy sources are under development, it will take a few decades until global reliance on petroleum and fossil fuels becomes a thing of the past. A lot of research is ongoing in this regard and, according to [10], energy sources capable of completely replacing petroleum are being projected to be in place by the year 2050 at the latest. In order to optimize the availability and use of crude oil and petroleum products, it is essential to improve oil recovery processes by using more environmentally friendly techniques to extract oil from subsurface reservoirs [11][12]. As the reservoirs run out during primary recovery, oil recovery becomes increasingly difficult, even for partially emptied shales or other tight deposits. The oil recovery process involves three stages: primary, secondary, and tertiary recovery. The primary and secondary recovery processes use conventional technologies, including natural energy, water/gas injection, and gas injection, to extract crude oil from the reservoirs [13][14][15][16][17][18]. Several studies show that the primary process only recovers 10–20% of the total oil in the reservoirs.

After the depletion of natural energy, the secondary recovery involves water/gas injection into the reservoir through the injection wells to increase oil displacement toward the producing wellhead. Consequently, the final recovery of crude oil rarely exceeds 50% of the oil originally present. Nonetheless, after the primary and secondary recovery processes, more than two-thirds of the original crude oil remains trapped due to factors such as high viscosity, reduced mobility, and the retention of oil in the pores of rocks [19][20].

To increase the final oil recovery from the reservoirs, tertiary recovery processes, known as enhanced oil recovery (EOR), are applied. Hence, a higher percentage of crude oil recovery can be achieved by lowering the crude oil’s viscosity, improving its flow properties, and modifying the rock wettability, interfacial tension (IFT), and capillary forces.

Among EOR processes, chemical recovery typically utilizes conventional surfactants such as polyoxyethylene alkyl ethers (AE), sodium dodecyl sulfate (SDS), alkyl sulfates (AS), alkyl benzene sulfonates (ABS), alkylpolyoxyethylene sulfates (AES), and polyoxyethylene alkylphenyl ethers (APE) [21]. Despite their effectiveness, these petroleum-based molecules are often non-biodegradable and pose a threat to the environment [22][23]. To address this issue, research efforts have shifted toward identifying biodegradable and bio-based alternatives for surfactants in the oil recovery process. The oil recovery process is crucial to meeting the world’s energy demand and while alternative energy sources are under development, petroleum remains a vital energy source. Therefore, enhancing oil recovery processes, particularly through the use of environmentally friendly technologies based on biosurfactants, is critical for ensuring a sustainable energy future.

2. EOR Techniques

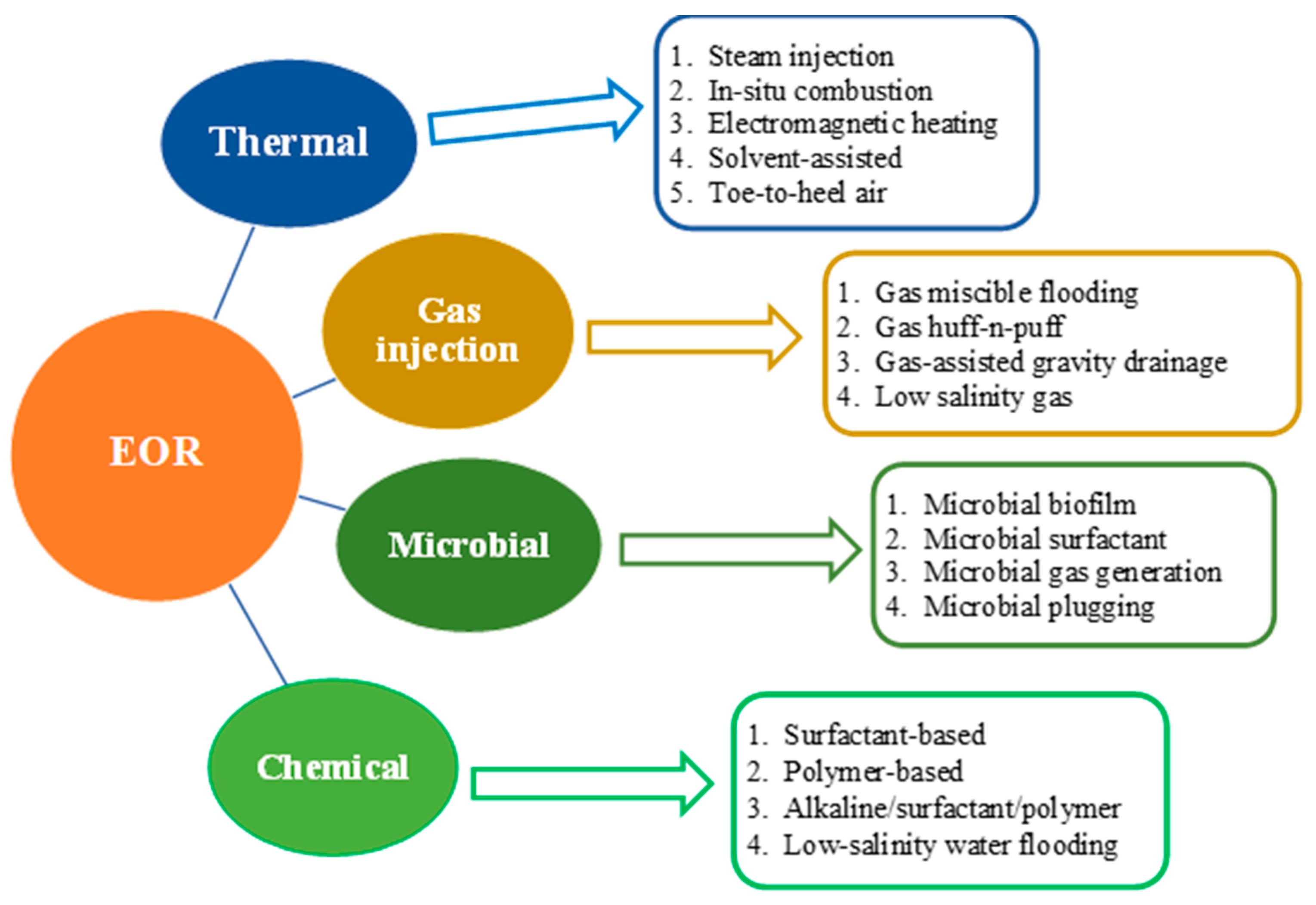

EOR processes involve various methods, including thermal, chemical, gas and microbial methods, which are listed in Figure 1. In the following subsections, solely the chemical and microbial techniques are revisited critically.

Figure 1. Main methods of enhanced oil recovery.

2.1. Chemical EOR

Chemical EOR is a technique that involves the injection of chemicals into the reservoir to increase the amount of oil that can be extracted. The chemicals can change the physical and chemical properties of the reservoir rock and fluids, reducing the oil viscosity and improving oil mobility. The different types of techniques employed in chemical EOR are described below.

2.1.1. Surfactant-Based EOR

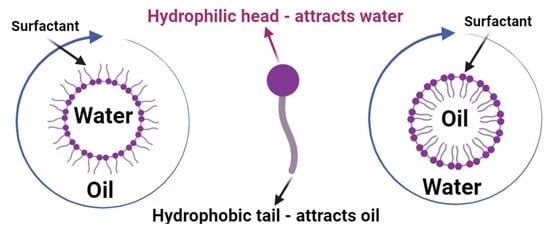

Surfactants are the most commonly used chemicals in surfactant-based EOR. Owing to the presence of both a hydrophilic polar head and one or two hydrophobic tails (Figure 2), these chemicals can be used to lower the interfacial tension between oil and water, improve the wettability of the reservoir rock, and mobilize the residual oil. However, the effectiveness of surfactants in EOR is limited by factors such as surfactant adsorption, salinity, and temperature. To address these limitations, researchers have developed novel surfactants and surfactant formulations that are more effective in EOR applications [18].

Figure 2. General representation of a surfactant molecule with hydrophilic head and hydrophobic tail and their rearrangement in water and oil.

Indeed, due to the environmentally toxic nature of a significant number of synthetic surfactants, research has drifted towards the development of surfactants of low environmental impact which are derived from bio-based sources. Most of these biosurfactants are more eco-friendly than conventional surfactants and also cost-effective in some cases. The cost-effectiveness of biosurfactants depends on the starting material or substrate needed for their production. In most cases, the substrate or starting material is found freely in nature or exists in the form of waste or biomass derived from different processes. However, in some cases, biosurfactant production could require expensive raw material or substrates/feedstock, specialized equipment, and/or high levels of expertise and technical know-how. In previous years, biosurfactant production was not so economically effective, as the cost per kilogram of large quantities of low-value biosurfactants, mostly derived from vegetable oils and highly processed biomass, ranged between 1.5 and 2.5 euros, which is about 20% more than the cost of conventional surfactants [24]. In recent years, however, the cost of biosurfactant production is being alleviated with the advent of several strategies for feasible commercial biosurfactant production such as the use of industrial and agro-based waste and other low-cost renewable substrates [25], genetic recombination and mutation of the starter culture/substrate [26], and the in situ microbial production of biosurfactants in oil reservoirs where they can enhance oil recovery, making the process economically viable [27]. Scientific attempts to produce bio-based surfactants have produced promising results and some biosurfactants capable of replacing conventional chemical surfactants now exist for use in EOR. Several studies conducted by different investigators, such as Li et al. [28], Haghighi & Firozjaii [29], Wu et al. [30], Haq [31], have demonstrated that biosurfactants have been quite effective in EOR applications. Biosurfactants can be obtained from a variety of natural, bio-based, renewable sources. These include microorganisms, animals and parts of plants such as seeds, roots, leaves, natural oils extracted from plants [32][33][34], and waste vegetable oils. Vegetable oils contain triglyceride fatty acid residue, which, when reacted with an alcohol (either methanol or ethanol), produces fatty acid methyl or ethyl esters depending on which alcohol is used [35].

Biosurfactants can also be derived from amino acids which can be obtained from plant and animal sources. The ability of these amino acids to be modified according to the required application makes them very valuable for the production of surfactants [36].

Just like their synthetic counterparts, bio-based surfactants can be classified into anionic, cationic, non-ionic, and zwitterionic surfactants. Two other classes of bio-based surfactants exist: bio-based Gemini surfactants and bio-based polymeric surfactants derived from bio-oils.

-

Bio-based anionic surfactants. These are surfactants with a negatively charged head and they are the most widely used group of surfactants; hence, they are produced in large quantities in industries. Amino acids and fatty acids obtained from natural oils are viable sources of anionic surfactants. Methyl and ethyl ester sulfonates are derived from these amino and fatty acids via trans-esterification and sulfonation reactions [37]. The sulfonate group (SO−3SO3−) present in the chemical structure of these surfactants is responsible for their anionic nature and thermal stability [38]. Another class of anionic amphiphiles can be obtained by linking one or two hydrophobic chains to the DNA nucleotides, giving them the ability to generate supramolecular colloidal structures [39][40][41][42].

-

Bio-based cationic surfactants. These are surfactants with a positively charged headgroup, and although they are not commonly used in EOR due to their high adsorption in sandstone reservoirs, they are very useful in carbonate reservoirs. Although many plant extracts are considered to be non-ionic, some plant extracts, such as mulberry leaves, olive leaves, and henna leaves, are examples of cationic surfactants [43].

-

Bio-based non-ionic surfactants. These are surfactants that have no charge on their head. They do not ionize in water, and their solubility is influenced by hydrogen bonds and van der Waal interactions. Most non-ionic surfactants have a high biodegradability and are very cost-effective. Saponins, which are triterpenic or steroidal glycosides, are the most common type of non-ionic surfactant, and they can be obtained from natural plant extracts. They are highly emulsifiable, having excellent solubility and foaming properties, which gives them a wide range of applicability in industrial processes [43][44][45]. Alkyl polyglucoside is a common non-ionic surfactant from a natural and renewable source. Ziziphus Spina-christy and soap nut saponin are excellent sources of natural non-ionic surfactants, which have been evaluated for their potential in EOR applications [46][47].

-

Bio-based zwitterionic surfactants. These surfactants contain both positively and negatively charged residues in their head polar groups having zero net charge. They are very versatile, and natural zwitterionic surfactants have excellent properties that are ideal for EOR applications. For example, a zwitterionic surfactant derived from castor oil, N-phenyl-fattyamido-propyl-N, N-dimethyl-carboxyl betaine (CPDB) has been shown to have excellent thermal properties, dispersion efficiency, optimal wetting and foaming performance and also strong electrolyte tolerance [48]. Despite the versatility and compatibility of zwitterionic surfactants, they are one of the least applied for EOR operations. This is mostly associated with the high costs involved in their production. More work has to be performed to develop cheaper base materials for the synthesis of zwitterionic surfactants and apply this class of surfactants in EOR contexts.

-

Polymeric bio-based surfactants. They can be synthesized either by polymerizing a surface-active monomer or by the copolymerization of hydrophobic and hydrophilic monomers. Although polymeric surfactants, in most cases, perform poorly regarding surface tension modification—making it difficult to obtain ultra-low IFT values—they could improve oil recovery by combining the high viscosity property of a polymer with the interfacial surface properties of the surfactant present within its structure. This unique combination of properties makes polymeric surfactants ideal for use as thickening agents, IFT-reducing agents, and emulsifying agents for EOR applications [49][50]. A classic example of a polymeric biosurfactant is emulsan, which is produced by Acinetobacter calcoaceticus [51].

-

Bio-based Gemini surfactants. Just like zwitterionic surfactants, bio-based Gemini surfactants are another underused group of bio-based surfactants. They have excellent properties that make them optimal for EOR purposes but ironically, not many research studies investigating their EOR potential are found in the scientific literature. They are very unique in their nature as they are made up of two or more hydrophilic groups, which constitute the head, one hydrophobic group, which makes up the tail, and a spacer linking these two constituents (head and tail). The hydrophilic head could be either anionic, cationic, zwitterionic, or non-ionic [52][53][54]. This means that Gemini surfactants are a sort of hybrid of all the aforementioned classes of bio-based surfactants. This class of surfactants has excellent wetting, solubility, and foaming properties coupled with an ultra-low critical micelle concentration (CMC) and Krafft point [54]. Gemini surfactants can be obtained from amino acids, oils, and sugar [55].

2.1.2. Polymer-Based EOR

Polymers are used in polymer-based EOR to increase the viscosity of the injected water, which helps displace the oil in the reservoir. The effectiveness of polymer flooding is influenced by factors such as polymer concentration, injection rate, and reservoir heterogeneity. To improve the performance of polymer flooding, researchers have explored the use of nanoparticles, smart polymers, and other novel materials [56].

2.1.3. Alkaline/Surfactant/Polymer (ASP) Flooding

ASP flooding is a combination of surfactant, polymer, and alkali flooding techniques. The surfactants are used to reduce the interfacial tension between oil and water, the polymer is used to increase the viscosity of the injected water, and the alkali is used to reduce the acidity of the reservoir rock and improve the wettability. ASP flooding has shown promise in reducing oil viscosity and improving oil recovery, but its effectiveness is influenced by factors such as the choice of chemicals, reservoir characteristics, and operational parameters [57].

2.1.4. Low-Salinity Water Flooding

Low-salinity water flooding involves the use of water with reduced salinity to displace the oil in the reservoir. The low-salinity water can change the wettability of the reservoir rock and reduce the residual oil saturation. However, the effectiveness of low-salinity water flooding is influenced by factors such as the reservoir temperature, salinity, and mineralogy [58].

2.1.5. Critical Features of Chemical EOR

While chemical EOR has shown some promise and has been successfully implemented in certain cases, there are several critical aspects that still need to be considered:

-

Economic feasibility. Chemical EOR methods often demand substantial initial investments for the acquisition and injection of chemicals, as well as infrastructure modifications. Evaluation of economic viability becomes paramount, taking into account oil prices, field characteristics, and project lifespan.

-

Environmental impact. The substantial use of chemicals in the process can lead to adverse environmental consequences. Toxicity and improper handling risks must be addressed, along with considerations of energy consumption and associated greenhouse gas emissions.

-

Geologic and reservoir constraints. Geological and reservoir characteristics, such as permeability, heterogeneity, and natural fractures, profoundly influence the effectiveness of chemical EOR. In-depth reservoir property understanding and rigorous laboratory testing are prerequisites for large-scale implementation.

-

Chemical optimization. Challenges often arise from chemical compatibility and precise composition optimization. Incompatibilities can lead to precipitation or emulsion formation, reducing efficacy. Optimizing the chemical composition and concentration is pivotal for maximum recovery with minimal side effects.

-

Uncertainty and risk. Inherent uncertainties, including reservoir heterogeneity, fluid behavior, and chemical reactions, pose risks to the success of chemical EOR. Rigorous risk assessment and contingency planning are crucial to mitigate potential setbacks.

In essence, while chemical EOR shows promise, its success hinges on comprehensive evaluation encompassing economic, environmental, geological, and chemical aspects, along with vigilant risk mitigation.

2.2. Microbial EOR

Microbial EOR (MEOR) is a technique that involves the injection of microorganisms into the reservoir to enhance oil recovery. The microorganisms can alter the physical and chemical properties of the reservoir, reducing the oil viscosity and improving oil mobility. The first ever field test using MEOR was performed in Arkansas, United States in 1954 when Clostridium acetobutylicum was injected alongside molasses into an oil field and the results showed the production of various metabolites such as gases, acids and biosurfactants [59]. Strappa et al. [60] also reported a 20% increase in crude oil recovery yield when they injected facultative anaerobic bacteria along with their nutrients into an oil field. A similar study was carried out by Davidson and Russell [61] by the injection of a specially adapted strain of Clostridium, which brought about a reduction in oil viscosity due to the production of carbon dioxide, and this improved oil mobility and sweep efficiency. In China, an incremental production of 219,000 tons of crude oil was reported when microbial huff and puff was carried out on 1640 oil wells [62]. Table 1 groups the products of microbial activity according to the microorganisms that produce them and the type of oil reservoirs they are suitable for, while Table 2 classifies the microorganisms according to their products and the effects they bring about in the oil reservoirs. The techniques used in microbial EOR are described as follows [63].

2.2.1. Microbial Biofilm Injection

In microbial biofilm injection, a microbial biofilm is injected into the reservoir to improve oil recovery. The biofilm can alter the permeability of the reservoir rock and improve oil mobility. However, the effectiveness of microbial biofilm injection is influenced by factors such as the reservoir temperature, salinity, and nutrient availability [64].

2.2.2. Microbial Surfactant Injection

In microbial surfactant injection, microorganisms are used to produce surfactants that can reduce the interfacial tension between the oil and water phases in the reservoir. The reduced interfacial tension can improve oil mobility and enhance oil recovery. Several studies [65][66][67] have been carried out and their results demonstrate the applicability of microbial surfactant injection techniques in field trials. Although microbial surfactant injection and MEOR, in general, have achieved a reasonable amount of success, a study carried out in an offshore field trial in Norway showed negative results when nitrate-reducing bacteria with compatible nutrient support were used for EOR purposes [68]. However, the effectiveness of microbial surfactant injection is influenced by factors such as microbial strain, surfactant production rate, and reservoir conditions [69].

2.2.3. Microbial Gas Generation

In microbial gas generation, microorganisms are used to produce gases such as methane and carbon dioxide that can enhance oil recovery. The gases can reduce the oil viscosity and improve oil mobility. Gao [62] reported the successful application of the microbial huff and puff technique in several field trials in the Shengli and Daqing oil fields in China over the years. However, the effectiveness of microbial gas generation is influenced by factors such as the microbial strain, gas production rate, and reservoir environment [70].

2.2.4. Microbial Plugging

In microbial plugging, microorganisms are used to block high-permeability channels in the reservoir and divert the flow of water and gas to low-permeability regions. The technique can improve oil recovery by increasing the oil saturation in the low-permeability regions. This method was employed to great effect in a field trial in Brazil in 2010 where microbial EOR was carried out in five wells in an onshore field to plug high permeable zones in the reservoir by producing biomass and biopolymer [71]. However, the effectiveness of microbial plugging is influenced by factors such as the microbial strain, injection rate, and reservoir heterogeneity [72].

Table 1. Classification of microbial bio-products for EOR, their producing organisms, and the various types of oil reservoirs/formations in which they are applied. Adapted from [70].

| Microbial Product Class | Microorganisms and Their Sample Products | Type of Oil Reservoir/Formation | |

|---|---|---|---|

| Biosurfactants | Surfactin | Rhodococcus sp. | Sandstone or carbonate reservoirs with moderate temperature (<50 °C) and relatively light oil (API > 25) |

| Rhamnolipid | Acinetobacter | ||

| Emulsan | Bacillus sp. | ||

| Lichenysin | Bacillus sp. | ||

| Alasan | Pseudomonas | ||

| Viscosin | Arthrobacter | ||

| Biopolymers | Xanthan gum | Xanthomonas sp. | Stratified reservoirs with permeable zones |

| Pullulan | Aureobasidium sp. | ||

| Levan | Bacillus sp. | ||

| Curdlan | Alcaligeness sp. | ||

| Dextran | Leuconostoc sp. | ||

| Scleroglucan | Sclerotium sp. | ||

| Gases | CO2 | Fermentative bacteria | Heavy-oil-bearing formations (API < 15) |

| CH4 | Methanogens | ||

| H2 | Clostridium | ||

| N2 | Enterobacter | ||

| Acids | Propionic acid | Fermentative bacteria | Carbonate or carbonaceous reservoirs |

| Butyric acid | Clostridium | ||

| Alcohol/Solvents | Alcohols and Ketones (co-surfactants) | Fermentative bacteria | Heavy-oil-bearing formations (API < 15) and strongly oil-wet, waterflooded reservoirs |

| Acetone | Clostridium | ||

| Butanol | Zymomonas | ||

| Propan-2-diol | Kliebsella | ||

The effects conferred by the different groups of microbial bio-products are listed in Table 2.

Table 2. Microbial EOR classification based on the types of microorganisms, their products, and their effects in the oil reservoirs. Adapted from [70][73][74][75].

| Microorganism Genus | Products | Effect |

|---|---|---|

| Pseudomonas | Surfactants and polymers | Production of biopolymers and biosurfactants, which reduce permeability and enhance capillary number. |

| Clostridium | Gases, acids, alcohols, and surfactants | Production of acid and gases, which reduce oil viscosity. |

| Bacillus | Acids and surfactants | Production of gases, alcohol, and biosurfactants, which modify permeability, which improves sweep efficiency in waterflooding processes. |

| Desulfovibrio | Gases and acids | Oil biodegradability and viscosity reduction along with methane production. |

| Corynebacterium | Surfactants | Production of low-viscosity molecules and permeability modification by promoting oil biodegradability. |

| Others | Polymers, gases, surfactants, acids, and alcohol | Oxidation and biodegradability of hydrocarbons, permeability modification, and methane production, which lead to oil viscosity reduction. |

2.2.5. Critical Features of Microbial EOR

While MEOR shows potential as an environmentally friendly and cost-effective method, there are several essential parts that require attention:

-

Efficacy and reliability. MEOR’s effectiveness varies based on microbial strains, reservoir conditions, and oil type. Microorganism growth is sensitive to factors like temperature, pH, and nutrient availability. Strain selection and reliability necessitate thorough evaluation via field testing and case studies;

-

Reservoir compatibility. MEOR may not suit all reservoir types due to factors like permeability, heterogeneity, and oil properties. A rigorous assessment of microorganism-reservoir compatibility is essential to determine MEOR applicability;

-

Long-term effects and sustainability. The enduring impacts of introducing microorganisms into the reservoir require further understanding. Microbial activities can influence permeability, fluid behavior, and geochemical reactions, necessitating an evaluation of risks and effects on reservoir integrity and oil recovery sustainability;

-

Regulatory compliance. MEOR involves the introduction of living organisms into the reservoir, which may raise regulatory concerns. It is important to comply with relevant environmental regulations and obtain necessary permits for the use of microorganisms in oil reservoirs. Additionally, potential risks associated with the release of genetically modified organisms (GMOs) should be carefully assessed and addressed in accordance with applicable regulations and guidelines;

-

Implementation challenges. Specialized equipment, ideal growth conditions, and the management of risks such as biofouling and corrosion present implementation challenges. Proper engineering design, operational protocols, and monitoring strategies are essential for successful MEOR implementation;

-

Knowledge gaps and research requirements. Despite advancements, significant knowledge gaps persist. Further research is vital to improve microbial strain selection, enhance reservoir suitability assessment, and understand MEOR mechanisms, long-term sustainability, and optimization.

Overall, MEOR presents a potentially environmentally friendly and cost-effective EOR method. However, validation through research, testing, and regulatory compliance, along with thorough evaluation and continuous monitoring, is imperative for its successful and sustainable implementation.

2.3. A Brief Comparison: Chemical–Microbial and Traditional EOR Techniques Employed

Chemical–microbial EOR techniques are a subset of EOR methods that utilize both chemicals and microbes to enhance oil recovery. These techniques are highly effective due to their ability to reduce interfacial tension, increase sweep efficiency, and alter wettability, which are key factors in improving oil recovery [76][77][78]. However, the implementation of these techniques often involves higher costs. This is primarily due to the price of the chemicals and microbes used, as well as the need for sophisticated injection equipment [79][80].

On the other hand, thermal and gas injection methods are other types of EOR techniques that can be more cost-effective, although their suitability can vary depending on reservoir conditions [81][82][83]. Thermal recovery methods typically involve the use of heat, often in the form of steam generated by burning natural gas, to reduce oil viscosity and improve its flow. Solar-generated steam in EOR is another method that uses concentrating solar power technology to produce steam. Gas injection methods, which serve as a main EOR method in fractured-vuggy carbonate reservoirs, involve injecting gases like carbon dioxide or nitrogen into the reservoir to increase pressure and displace oil [84]. In terms of environmental impact, chemical-microbial EOR methods can pose challenges due to potential groundwater contamination. However, these risks can be mitigated with proper management and the use of environmentally friendly chemicals and microbes [79][80]. Thermal EOR methods also face environmental challenges, such as cyclic fluctuations in steam injection rate associated with sunlight hours and seasonal variations, which challenge this technology from becoming a standalone solution [81]. Gas injection methods have been shown to provide major contributions during EOR, including crude-oil viscosity reduction, thermal expansion, and crude oil vaporization [84].

While chemical-microbial EOR techniques offer high efficiency in oil recovery, they also involve considerations such as cost and environmental impact. Therefore, it is crucial to choose the most suitable EOR technique based on reservoir conditions and economic feasibility.

References

- Niu, J.; Liu, Q.; Lv, J.; Peng, B. Review on microbial enhanced oil recovery: Mechanisms, modeling and field trials. J. Pet. Sci. Eng. 2020, 192, 107350.

- Xi, W.; Ping, Y.; Alikhani, M.A. A Review on Biosurfactant Applications in the Petroleum Industry. Int. J. Chem. Eng. 2021, 2021, 5477185.

- De Almeida, D.G.; Soares Da Silva, R.d.C.F.; Luna, J.M.; Rufino, R.D.; Santos, V.A.; Banat, I.M.; Sarubbo, L.A. Biosurfactants: Promising Molecules for Petroleum Biotechnology Advances. Front. Microbiol. 2016, 7, 1718.

- Silva, R.D.C.F.S.; Almeida, D.G.; Rufino, R.D.; Luna, J.M.; Santos, V.A.; Sarubbo, L.A. Applications of Biosurfactants in the Petroleum Industry and the Remediation of Oil Spills. Int. J. Mol. Sci. 2014, 15, 12523–12542.

- Elraies, K.A.; Tan, I.M. The Application of a New Polymeric Surfactant for Chemical EOR. In Introduction to Enhanced Oil Recovery (EOR) Processes and Bioremediation of Oil-Contaminated Sites; Romero-Zerón, L., Ed.; IntechOpen: Rijeka, Croatia, 2012.

- Kåberger, T. Progress of renewable electricity replacing fossil fuels. Glob. Energy Interconnect. 2018, 1, 48–52.

- Demirbas, M.; Balat, M. Recent advances on the production and utilization trends of bio-fuels: A global perspective. Energy Convers. Manag. 2006, 47, 2371–2381.

- Naik, S.N.; Goud, V.V.; Rout, P.K.; Dalai, A.K. Production of first and second generation biofuels: A comprehensive review. Renew. Sustain. Energy Rev. 2010, 14, 578–597.

- Chisti, Y. Biodiesel from microalgae. Biotechnol. Adv. 2007, 25, 294–306.

- IEA World Energy Outlook 2022. Available online: https://www.iea.org/reports/world-energy-outlook-2022 (accessed on 18 December 2023).

- Pillapi, P.; Mariyate, J.; Lall, U. Application of Sustainable Natural Surfactants for Enhanced Residual Oil Recovery in Petroleum Industry. EasyChair 2022, 9259.

- Alsabagh, A.M.; Aboulrous, A.A.; Abdelhamid, M.M.; Mahmoud, T.; Haddad, A.S.; Rafati, R. Improvement of Heavy Oil Recovery by Nonionic Surfactant/Alcohol Flooding in Light of the Alkane Carbon Number and Interfacial Tension Properties. ACS Omega 2021, 6, 18668–18683.

- He, C.; Fan, Z.; Xu, A.; Zhao, L. Foamy oil properties and horizontal well inflow performance relationship under solution gas drive. Geosystem Eng. 2019, 22, 151–160.

- Tayari, F.; Blumsack, S.; Johns, R.T.; Tham, S.; Ghosh, S. Techno-economic assessment of reservoir heterogeneity and permeability variation on economic value of enhanced oil recovery by gas and foam flooding. J. Pet. Sci. Eng. 2018, 166, 913–923.

- Aljuboori, F.A.; Lee, J.H.; Elraies, K.A.; Stephen, K.D. Gravity Drainage Mechanism in Naturally Fractured Carbonate Reservoirs; Review and Application. Energies 2019, 12, 3699.

- Gudiña, E.J.; Pereira, J.F.B.; Costa, R.; Coutinho, J.A.P.; Teixeira, J.A.; Rodrigues, L.R. Biosurfactant-producing and oil-degrading Bacillus subtilis strains enhance oil recovery in laboratory sand-pack columns. J. Hazard. Mater. 2013, 261, 106–113.

- Gyan, P.S.; Xie, C.; Brantson, E.T.; Atuahene, S. Computer modeling and simulation for undersaturated primary drive recovery mechanism. Adv. Mech. Eng. 2019, 11, 1687814019841948.

- Massarweh, O.; Abushaikha, A.S. The use of surfactants in enhanced oil recovery: A review of recent advances. Energy Reports 2020, 6, 3150–3178.

- Haq, B.; Liu, J.; Liu, K.; Al Shehri, D. The role of biodegradable surfactant in microbial enhanced oil recovery. J. Pet. Sci. Eng. 2020, 189, 106688.

- Sen, R. Biotechnology in petroleum recovery: The microbial EOR. Prog. Energy Combust. Sci. 2008, 34, 714–724.

- Thomas, S. Enhanced Oil Recovery—An Overview. Oil Gas Sci. Technol. Rev. 2007, 63, 9–19.

- Anastas, P.; Eghbali, N. Green Chemistry: Principles and Practice. Chem. Soc. Rev. 2010, 39, 301–312.

- Pinazo, A.; Pons, R.; Pérez, L.; Infante, M.R. Amino Acids as Raw Material for Biocompatible Surfactants. Ind. Eng. Chem. Res. 2011, 50, 4805–4817.

- Gusmão, C.; Rufino, R.; Sarubbo, L. Laboratory production and characterization of a new biosurfactant from Candida glabrata UCP1002 cultivated in vegetable fat waste applied to the removal of hydrophobic contaminant. World J. Microbiol. Biotechnol. 2010, 26, 1683–1692.

- Mukherjee, S.; Das, P.; Sen, R. Towards commercial production of microbial surfactants. Trends Biotechnol. 2006, 24, 509–515.

- Shaligram, N.S.; Singhal, R.S. Surfactin—A Review on Biosynthesis, Fermentation, Purification and Applications. Food Technol. Biotechnol. 2010, 48, 119–134.

- Youssef, N.; Simpson, D.; Duncan, K.; Mcinerney, M.; Folmsbee, M.; Fincher, T.; Knapp, R. In Situ Biosurfactant Production by Bacillus Strains Injected into a Limestone Petroleum Reservoir. Appl. Environ. Microbiol. 2006, 73, 1239–1247.

- Li, G.; Chen, L.; Ruan, Y.; Guo, Q.; Liao, X.; Zhang, B. Alkyl polyglycoside: A green and efficient surfactant for enhancing heavy oil recovery at high-temperature and high-salinity condition. J. Pet. Explor. Prod. Technol. 2019, 9, 2671–2680.

- Mosalman Haghighi, O.; Mohsenatabar Firozjaii, A. An experimental investigation into enhancing oil recovery using combination of new green surfactant with smart water in oil-wet carbonate reservoir. J. Pet. Explor. Prod. Technol. 2020, 10, 893–901.

- Wu, B.; Xiu, J.; Yu, L.; Huang, L.; Yi, L.; Ma, Y. Biosurfactant production by Bacillus subtilis SL and its potential for enhanced oil recovery in low permeability reservoirs. Sci. Rep. 2022, 12, 7785.

- Haq, B. Green Enhanced Oil Recovery for Carbonate Reservoirs. Polymers 2021, 13, 3269.

- Putra, W.; Hakiki, F. Microbial enhanced oil recovery: Interfacial tension and biosurfactant-bacteria growth. J. Pet. Explor. Prod. Technol. 2019, 9, 2353–2374.

- De, S.; Malik, S.; Ghosh, A.; Saha, R.; Saha, B. A review on natural surfactants. RSC Adv. 2015, 5, 65757–65767.

- Bragoni, V.; Rit, R.K.; Kirchmann, R.; Trita, A.S.; Gooßen, L.J. Synthesis of bio-based surfactants from cashew nutshell liquid in water. Green Chem. 2018, 20, 3210–3213.

- Yusoff, M.F.M.; Xu, X.; Guo, Z. Comparison of Fatty Acid Methyl and Ethyl Esters as Biodiesel Base Stock: A Review on Processing and Production Requirements. J. Am. Oil Chem. Soc. 2014, 91, 525–531.

- Perinelli, D.R.; Casettari, L.; Cespi, M.; Fini, F.; Man, D.K.W.; Giorgioni, G.; Canala, S.; Lam, J.K.W.; Bonacucina, G.; Palmieri, G.F. Chemical–physical properties and cytotoxicity of N-decanoyl amino acid-based surfactants: Effect of polar heads. Colloids Surfaces A Physicochem. Eng. Asp. 2016, 492, 38–46.

- Hutchinson, J.C.; Lee, J.; Eigley, T.M.; Krueger, R.A. Method of Making Methyl Ester Surfactants. U.S. Patent 10/534,244, 29 June 2006.

- Hirasaki, G.J.; Miller, C.A.; Puerto, M. Recent Advances in Surfactant EOR. SPE J. 2011, 16, 889–907.

- Angelico, R.; Ceglie, A.; Cuomo, F.; Cardellicchio, C.; Mascolo, G.; Colafemmina, G. Catanionic Systems from Conversion of Nucleotides into Nucleo-Lipids. Langmuir 2008, 24, 2348–2355.

- Cuomo, F.; Lopez, F.; Angelico, R.; Colafemmina, G.; Ceglie, A. Nucleotides and nucleolipids derivatives interaction effects during multi-lamellar vesicles formation. Colloids Surfaces B Biointerfaces 2008, 64, 184–193.

- Angelico, R.; Ambrosone, L.; Ceglie, A.; Losito, I.; De Zio, G.; Palmisano, F. Complementary amphiphilic ribonucleotides confined into nanostructured environments. Phys. Chem. Chem. Phys. 2010, 12, 7977–7987.

- Angelico, R.; Losito, I.; Cuomo, F.; Ceglie, A.; Palmisano, F. Alkylation of complementary ribonucleotides in nanoreactors. Phys. Chem. Chem. Phys. 2013, 15, 586–595.

- Rahmati, M.; Mashayekhi, M.; Songolzadeh, R.; Daryasafar, A. Effect of Natural Leaf-derived Surfactants on Wettability Alteration and Interfacial Tension Reduction in Water-oil System: EOR Application. J. Japan Pet. Inst. 2015, 58, 245–251.

- Yusuf, M.; Wathon, M.H.; Thanasaksukthawee, V.; Saul, A.; Tangparitkul, S. Adsorption of Saponin Natural Surfactant on Carbonate Rock and Comparison to Synthetic Surfactants: An Enhanced Oil Recovery Prospective. Energy Fuels 2021, 35, 11193–11202.

- Norouzpour, M.; Nabipour, M.; Azdarpour, A.; Akhondzadeh, H.; Santos, R.M.; Keshavarz, A. Experimental investigation of the effect of a quinoa-derived saponin-based green natural surfactant on enhanced oil recovery. Fuel 2022, 318, 123652.

- Pordel Shahri, M.; Shadizadeh, S.R.; Jamialahmadi, M. Applicability Test of New Surfactant Produced from Zizyphus Spina-Christi Leaves for Enhanced Oil Recovery in Carbonate Reservoirs. J. Japan Pet. Inst. 2012, 55, 27–32.

- Fazio, A.; La Torre, C.; Caroleo, M.C.; Caputo, P.; Plastina, P.; Cione, E. Isolation and Purification of Glucans from an Italian Cultivar of Ziziphus jujuba Mill. and In Vitro Effect on Skin Repair. Molecules 2020, 25, 968.

- Zhang, Q.-Q.; Cai, B.-X.; Xu, W.-J.; Gang, H.-Z.; Liu, J.-F.; Yang, S.-Z.; Mu, B.-Z. Novel zwitterionic surfactant derived from castor oil and its performance evaluation for oil recovery. Colloids Surfaces A Physicochem. Eng. Asp. 2015, 483, 87–95.

- Tadros, T.; Vandamme, A.; Levecke, B.; Booten, K.; Stevens, C.V. Stabilization of emulsions using polymeric surfactants based on inulin. Adv. Colloid Interface Sci. 2004, 108–109, 207–226.

- Cao, Y.; Li, H. Interfacial activity of a novel family of polymeric surfactants. Eur. Polym. J. 2002, 38, 1457–1463.

- Gurkok, S.; Ozdal, M. Microbial Biosurfactants: Properties, Types, and Production. J. Biol. 2021, 2, 2–7.

- Faustino, C.M.C.; Serafim, C.S.; Ferreira, I.N.; Branco, M.A.; Calado, A.R.T.; Garcia-Rio, L. Mixed Micelle Formation between an Amino Acid-Based Anionic Gemini Surfactant and Bile Salts. Ind. Eng. Chem. Res. 2014, 53, 10112–10118.

- Castro, M.J.L.; Kovensky, J.; Fernández Cirelli, A. New Family of Nonionic Gemini Surfactants. Determination and Analysis of Interfacial Properties. Langmuir 2002, 18, 2477–2482.

- Kamal, M.S.; Hussein, I.A.; Sultan, A.S. Review on Surfactant Flooding: Phase Behavior, Retention, IFT, and Field Applications. Energy Fuels 2017, 31, 7701–7720.

- Wang, J.; Wang, D.; Shang, S. Research progress in Gemini surfactants from natural products. Chem. Ind. Eng. Progree 2021, 31, 2761–2765.

- Afolabi, F.; Mahmood, S.M.; Yekeen, N.; Akbari, S.; Sharifigaliuk, H. Polymeric surfactants for enhanced oil recovery: A review of recent progress. J. Pet. Sci. Eng. 2022, 208, 109358.

- Yang, P.; Li, Z.; Xia, B.; Yuan, Y.-J.; Huang, Q.; Liu, W.-L.; Cheng, C. Comprehensive Review of Alkaline–Surfactant–Polymer (ASP)-Enhanced Oil Recovery (EOR); Springer: Singapore, 2019; pp. 858–872. ISBN 978-981-10-7559-9.

- Sheng, J.J. Critical review of low-salinity waterflooding. J. Pet. Sci. Eng. 2014, 120, 216–224.

- Lazar, I.; Petrisor, I.G.; Yen, T.F. Microbial Enhanced Oil Recovery (MEOR). Pet. Sci. Technol. 2007, 25, 1353–1366.

- Strappa, L.A.; De Lucia, J.P.; Maure, M.A.; Llopiz, M.L.L. A Novel and Successful MEOR Pilot Project in a Strong Water-Drive Reservoir Vizcacheras Field, Argentina. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 17–21 April 2004; Volume All Days, p. SPE-89456-MS.

- Davidson, S.; Russell, H.A. A MEOR pilot test in the Loco field. In Proceedings of the Symposium on the Application of Microorganisms to Petroleum Technology, Midland, TX, USA, 10–11 March 1988.

- Gao, C. Experiences of microbial enhanced oil recovery in Chinese oil fields. J. Pet. Sci. Eng. 2018, 166, 55–62.

- Maudgalya, S.; Knapp, R.; Mcinerney, M. Microbial Enhanced-Oil-Recovery Technologies: A Review of the Past, Present, and Future. In Proceedings of the SPE Oklahoma City Oil and Gas Symposium/Production and Operations Symposium, Oklahoma City, OK, USA, 31 March–3 April 2007.

- Cao, J. Impact of Biofilm Formation in Microbial Enhanced Oil Recovery Performance; University of Calgary: Calgary, AB, Canada, 2018.

- Zahari, I.; Omar, M.; Khor, F.; Elias, E.; Mohamad, O. Simulation Analysis of Microbial Well Treatment of Bokor Field, Malaysia. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia, 18–20 October 2004.

- Sabut, B.; Salim, M.; Hamid, A.; Khor, F. Further Evaluation of Microbial Treatment Technology for Improved Oil Production in Bokor Field, Sarawak. In Proceedings of the SPE International Improved Oil Recovery Conference in Asia Pacific, Kuala Lumpur, Malaysia, 20–21 October 2003.

- Patel, J.; Borgohain, S.; Kumar, M.; Rangarajan, V.; Somasundaran, P.; Sen, R. Recent developments in microbial enhanced oil recovery. Renew. Sustain. Energy Rev. 2015, 52, 1539–1558.

- Rassenfoss, S. From Bacteria to Barrels: Microbiology Having an Impact on Oil Fields. J. Pet. Technol. 2011, 63, 32–38.

- Bordoloi, N.K.; Konwar, B.K. Microbial surfactant-enhanced mineral oil recovery under laboratory conditions. Colloids Surf. B. Biointerfaces 2008, 63, 73–82.

- Safdel, M.; Anbaz, M.; Daryasafar, A.; Jamialahmadi, M. Microbial enhanced oil recovery, a critical review on worldwide implemented field trials in different countries. Renew. Sustain. Energy Rev. 2017, 74, 159–172.

- Reksidler, R.; Torres Volpon, A.G.; Barbosa, L.C.; Brasileiro, C.G.; Nicolau, H.C.; de Calasans, J.A. A Microbial Enhanced Oil Recovery Field Pilot in a Brazilian Onshore Oilfield. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010; Volume All Days, p. SPE-129930-MS.

- Raiders, R.A.; Knapp, R.M.; McInerney, M.J. Microbial selective plugging and enhanced oil recovery. J. Ind. Microbiol. 1989, 4, 215–229.

- Bubela, B. Chapter 4 Geobiology and Microbiologically Enhanced Oil Recovery. In Microbial Enhanced Oil Recovery; Donaldson, E.C., Chilingarian, G.V., Yen, T.F., Eds.; Developments in Petroleum Science; Elsevier: Amsterdam, The Netherlands, 1989; Volume 22, pp. 75–97.

- Marsh, T.L.; Zhang, X.; Knapp, R.M.; McInerney, M.J.; Sharma, P.K.; Jackson, B.E. Mechanisms of Microbial Oil Recovery by Clostridium Acetobutylicum and Bacillus Strain JF-2; BDM Oklahoma, Inc.: Bartlesville, OK, USA, 1995.

- Kianipey, S.A.; Donaldson, E.C. Mechanisms of Oil Displacement by Microorganisms; Society of Petroleum Engineers: Richardson, TX, USA, 1986.

- Liu, K.; Wei, X. Oil Recovery: Experiences and Economics of Microbially Enhanced Oil Recovery (MEOR) BT—Consequences of Microbial Interactions with Hydrocarbons, Oils, and Lipids: Production of Fuels and Chemicals; Lee, S.Y., Ed.; Springer International Publishing: Cham, Switzerland, 2017; ISBN 978-3-319-31421-1.

- Volk, H.; Liu, K. 3° Oil Recovery: Experiences and Economics of Microbially Enhanced Oil Recovery (MEOR) BT—Handbook of Hydrocarbon and Lipid Microbiology; Timmis, K.N., Ed.; Springer: Berlin, Heidelberg, 2010; pp. 2739–2751. ISBN 978-3-540-77587-4.

- Yernazarova, A.; Kayirmanova, G.; Zhubanova, A.B. Microbial Enhanced Oil Recovery; Romero-Zeron, L., Ed.; IntechOpen: Rijeka, Croatia, 2016; p. Ch. 5. ISBN 978-953-51-2701-7.

- Shafiai, S.; Gohari, A. Conventional and electrical EOR review: The development trend of ultrasonic application in EOR. J. Pet. Explor. Prod. Technol. 2020, 10, 2923–2945.

- Mokheimer, E.M.A.; Hamdy, M.; Abubakar, Z.; Shakeel, M.R.; Habib, M.A.; Mahmoud, M. A Comprehensive Review of Thermal Enhanced Oil Recovery: Techniques Evaluation. J. Energy Resour. Technol. 2018, 141, 030801.

- Song, Z.-J.; Li, M.; Zhao, C.; Yang, Y.-L.; Hou, J.-R. Gas injection for enhanced oil recovery in two-dimensional geology-based physical model of Tahe fractured-vuggy carbonate reservoirs: Karst fault system. Pet. Sci. 2020, 17, 419–433.

- Iino, A.; Onishi, T.; Datta-Gupta, A. Optimizing CO2- and Field-Gas-Injection EOR in Unconventional Reservoirs Using the Fast-Marching Method. SPE Reserv. Eval. Eng. 2020, 23, 261–281.

- Azin, R.; Izadpanahi, A.; Shahkarami, A. Introduction to Gas Injection BT—Fundamentals and Practical Aspects of Gas Injection; Azin, R., Izadpanahi, A., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 1–22. ISBN 978-3-030-77200-0.

- Edouard, M.N.; Dong, P.; Okere, C.J.; Nkok, L.Y.; Adoum, A.Y.; muchiri, N.D.; Xiaodong, G.; Jacques, F.N.; Prosper, S.K. Optimization of triple-alternating-gas (TAG) injection technique for enhanced oil recovery in tight oil reservoirs. J. Pet. Explor. Prod. Technol. 2022, 12, 215–225.

More

Information

Subjects:

Engineering, Petroleum

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.5K

Revisions:

2 times

(View History)

Update Date:

16 Jan 2024

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No