| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Urška Vrabič-Brodnjak | -- | 4757 | 2024-01-03 09:41:23 | | | |

| 2 | Jessie Wu | -1 word(s) | 4756 | 2024-01-04 06:12:52 | | |

Video Upload Options

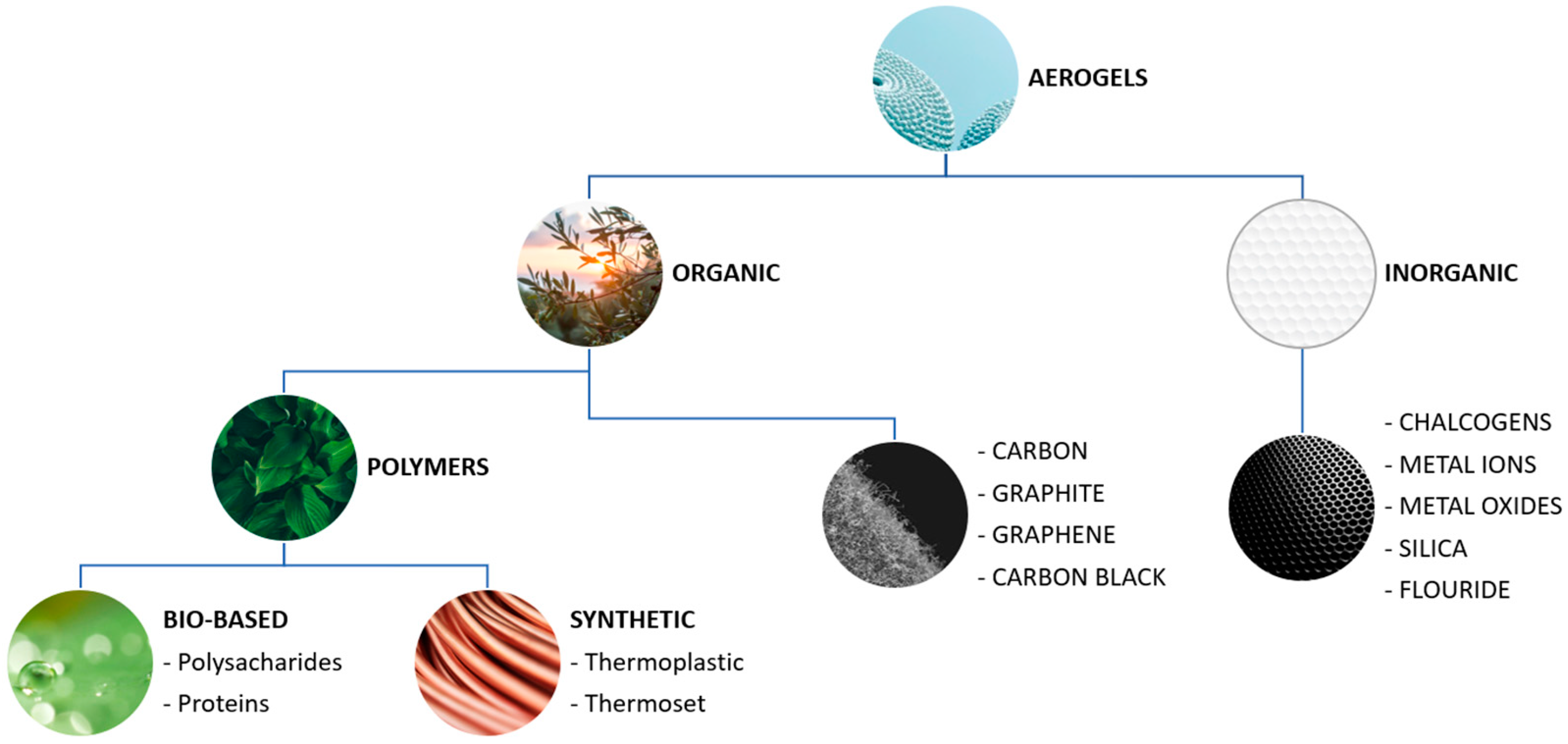

Bio-based aerogels are derived from various renewable sources such as sugar cane, vegetable oils, proteins, starches, chitosan, alginate, pectin, lignin, cellulose, and proteins, which have been shown to be useful in the production of aerogels. These aerogels have special properties that make them well suited for packaging applications and in bioengineering. Studies in this field have led to advances that shed light on their diverse applications, improved properties, and innovative synthesis methods. Researchers have investigated alternative feedstocks for bio-based aerogels to broaden their sources and enhance sustainability. Studies have explored the use of waste materials, agricultural by-products, and unconventional sources to synthesize aerogels, aligning with the principles of a circular and green economy.

1. Introduction

2. Polysaccharide-Based Aerogels

2.1. Cellulose-Based Aerogels

2.2. Chitosan-Based Aerogels

2.3. Alginate-Based Aerogels

2.4. Starch-Based Aerogels

2.5. Pectin-Based Aerogels

3. Protein-Based Aerogels

4. Lignin-Based Aerogels

| Type of Raw Materials for Aerogel Production |

Advantages | Disadvantages |

|---|---|---|

| Alginate-based aerogels |

|

|

| Cellulose-based aerogels |

|

|

| Chitosan-based aerogels |

|

|

| Lignin-based aerogels |

|

|

| Pectin-based aerogels |

|

|

| Protein-based aerogels |

|

|

| Starch-based aerogels |

|

|

References

- Liu, P.; Chen, X.; Li, Y.; Cheng, P.; Tang, Z.; Lv, J.; Aftab, W.; Wang, G. Aerogels Meet Phase Change Materials: Fundamentals, Advances, and Beyond. ACS Nano 2022, 16, 15586–15626.

- Shah, N.; Lin, D. Composite Aerogels for Biomedical and Environmental Applications. Curr. Pharm. Des. 2020, 26, 5807–5818.

- Selvasekaran, P.; Chidambaram, R. Food-grade aerogels obtained from polysaccharides, proteins, and seed mucilages: Role as a carrier matrix of functional food ingredients. Trends Food Sci. Technol. 2021, 112, 455–470.

- Montes, S.; Maleki, H. Aerogels and their applications. In Colloidal Metal Oxide Nanoparticles; Elsevier: Amsterdam, The Netherlands, 2020.

- Oves, M.; Rauf, M.; Warsi, M.; Husain, F.; Ansari, M.; Ismail, I. Aerogels as microbial disinfectant. In Advances in Aerogel Composites for Environmental Remediation; Elsevier: Amsterdam, The Netherlands, 2021; pp. 201–215.

- Le Thanh-Blicharz, J.; Lewandowicz, J.; Małyszek, Z.; Kowalczewski, P.; Walkowiak, K.; Masewicz, Ł.; Baranowska, H.M. Water Behavior of Aerogels Obtained from Chemically Modified Potato Starches during Hydration. Foods 2021, 10, 2724.

- El-Naggar, M. Synthesis, Drying Process and Medical Application of Polysaccharide-Based Aerogels. Int. J. Biol. Macromol. 2020, 145, 1115–1128.

- Zou, F.; Budtova, T. Tailoring the morphology and properties of starch aerogels and cryogels via starch source and process parameter. Carbohydr. Polym. 2020, 255, 117344.

- Adulpadungsak, K.; Lilitchan, S.; Aryusuk, K. The physical and chemical properties of policosanol-based organogel shortening for replacing saturated and trans-fat in cookies. NU Int. J. Sci. 2020, 17, 1–13.

- Narvaez, L.E.M.; Ferreira, L.M.d.M.C.; Sanches, S.; Gyles, D.A.; Silva-Júnior, J.O.C.; Costa, R.M.R. A Review of Potential Use of Amazonian Oils in the Synthesis of Organogels for Cosmetic Application. Molecules 2022, 27, 2733.

- Abdullah, T.; Colombani, T.; Alade, T.; Bencherif, S.A.; Memić, A. Injectable Lignin-co-Gelatin Cryogels with Antioxidant and Antibacterial Properties for Biomedical Applications. Biomacromolecules 2021, 22, 4110–4121.

- Savina, I.N.; Zoughaib, M.; Yergeshov, A.A. Design and Assessment of Biodegradable Macroporous Cryogels as Advanced Tissue Engineering and Drug Carrying Materials. Gels 2021, 7, 79.

- Fajardo, C.; Blánquez, A.; Domínguez, G.; Borrero-López, A.M.; Valencia, C.; Hernández, M.; Arias, M.E.; Rodríguez, J. Assessment of Sustainability of Bio Treated Lignocellulose-Based Oleogels. Polymers 2021, 13, 267.

- Papadaki, A.; Cipolatti, E.P.; Aguieiras, E.C.G.; Pinto, M.C.C.; Kopsahelis, N.; Freire, D.M.G.; Mandala, I.; Koutinas, A.A. Development of Microbial Oil Wax-Based Oleogel with Potential Application in Food Formulations. Food Bioprocess Technol. 2019, 12, 899–909.

- Maraveas, C. Production of Sustainable and Biodegradable Polymers from Agricultural Waste. Polymers 2020, 12, 1127.

- Gaisina, B.; Orazzhanova, L.; Sabitova, A.; Bayakhmetova, B.; Sharipkhan, Z. Synthesis and application of biocompatible cryogels. Bull. Shakarim Univ. Tech. Sci. 2023, 3, 6–15.

- He, Y.; Wang, C.; Wang, C.; Xiao, Y.; Lin, W. An Overview on Collagen and Gelatin-Based Cryogels: Fabrication, Classification, Properties and Biomedical Applications. Polymers 2021, 13, 2299.

- Wendels, S.; Porto, D.d.S.; Avérous, L. Synthesis of Biobased and Hybrid Polyurethane Xerogels from Bacterial Polyester for Potential Biomedical Applications. Polymers 2021, 13, 4256.

- Pramanik, R.; Ganivada, B.; Ram, F.; Shanmuganathan, K.; Arockiarajan, A. Influence of nanocellulose on mechanics and morphology of polyvinyl alcohol xerogels. J. Mech. Behav. Biomed. Mater. 2019, 90, 275–283.

- Yamasaki, S.; Sakuma, W.; Yasui, H.; Daicho, K.; Saito, T.; Fujisawa, S.; Isogai, A.; Kanamori, K. Nanocellulose Xerogels with High Porosities and Large Specific Surface Areas. Front. Chem. 2019, 7, 316.

- Awadallah-F, A.; Al-Muhtaseb, S.A. Influence of Chitosan Addition on Resorcinol–Formaldehyde Xerogel Structure. Appl. Sci. 2019, 9, 4582.

- Yahya, E.B.; Jummaat, F.; Amirul, A.A.; Adnan, A.S.; Olaiya, N.G.; Abdullah, C.K.; Rizal, S.; Mohamad Haafiz, M.K.; Abdul Khalil, H.P.S. A Review on Revolutionary Natural Biopolymer-Based Aerogels for Antibacterial Delivery. Antibiotics 2020, 9, 648.

- Zheng, L.; Zhang, S.; Ying, Z.; Liu, J.; Zhou, Y.; Chen, F. Engineering of Aerogel-Based Biomaterials for Biomedical Applications. Int. J. Nanomed. 2020, 15, 2363–2378.

- Nita, L.E.; Ghilan, A.; Rusu, A.G.; Neamtu, I.; Chiriac, A.P. New Trends in Bio-Based Aerogels. Pharmaceutics 2020, 12, 449.

- Nešić, A.; Cabrera-Barjas, G.; Dimitrijević-Branković, S.; Davidović, S.; Radovanović, N.; Delattre, C. Prospect of polysaccharide-based materials as advanced food packaging. Molecules 2019, 25, 135.

- Manzocco, L.; Mikkonen, K.S.; García-González, C.A. Aerogels as porous structures for food applications: Smart ingredients and novel packaging materials. Food Struct. 2021, 28, 100188.

- Wang, L.; Sánchez-Soto, M.; Abt, T.; Maspoch, M.L.; Santana, O.O. Microwave-crosslinked bio-based starch/clay aerogels. Polymer Int. 2016, 65, 899–904.

- Warrier, S.K.; Mathew, S.S.; Pothan, L.A.; Ajish, K.R. Biomedical Applications of Polysaccharide-Based Aerogels: A Review. Curr. Appl. Polym. Sci. 2022.

- Abdul Khalil, H.P.S.; Adnan, A.; Yahya, E.B.; Olaiya, N.; Safrida, S.; Hossain, M.S.; Balakrishnan, V.; Gopakumar, D.A.; Abdullah, C.; Oyekanmi, A.; et al. A Review on Plant Cellulose Nanofibre-Based Aerogels for Biomedical Applications. Polymers 2020, 12, 1759.

- Mandin, S.; Moreau, S.; Talantikite, M.; Novalès, B.; Maigret, J.-E.; Cathala, B.; Moreau, C. Cellulose Nanofibrils/Xyloglucan Bio-Based Aerogels with Shape Recovery. Gels 2021, 7, 5.

- Huang, Y.; Yang, H.; Yu, Y.; Li, H.; Li, H.; Bai, J.; Shi, F.; Liu, J. Bacterial cellulose biomass aerogels for oil-water separation and thermal insulation. J. Environ. Chem. Eng. 2023, 11, 110403.

- Andrew, L.J.; Gillman, E.R.; Walters, C.M.; Lizundia, E.; MacLachlan, M.J. Multi-Responsive Supercapacitors from Chiral Nematic Cellulose Nanocrystal-Based Activated Carbon Aerogels. Small 2023, 19, e2301947.

- Qiu, J.; Guo, X.; Lei, W.; Ding, R.; Zhang, Y.; Yang, H. Facile Preparation of Cellulose Aerogels with Controllable Pore Structure. Nanomaterials 2023, 13, 613.

- Tofanica, B.-M.; Belosinschi, D.; Volf, I. Gels, Aerogels and Hydrogels: A Challenge for the Cellulose-Based Product Industries. Gels 2022, 8, 497.

- Trache, D.; Thakur, V.K.; Boukherroub, R. Cellulose Nanocrystals/Graphene Hybrids—A Promising New Class of Materials for Advanced Applications. Nanomaterials 2020, 10, 1523.

- Jiang, X.; Li, Q.; Li, X.; Meng, Y.; Ling, Z.; Ji, Z.; Chen, F. Preparation and Characterization of Degradable Cellulose−Based Paper with Superhydrophobic, Antibacterial, and Barrier Properties for Food Packaging. Int. J. Mol. Sci. 2022, 23, 11158.

- Iskandar, M.A.; Yahya, E.B.; Abdul Khalil, H.P.S.; Rahman, A.A.; Ismail, M.A. Recent progress in modification strategies of nanocellulose-based aerogels for oil absorption application. Polymers 2022, 14, 849.

- Silva, T.C.F.; Habibi, Y.; Colodette, J.L.; Elder, T.; Lucia, L.A. A fundamental investigation of the microarchitecture and mechanical properties of tempo-oxidized nanofibrillated cellulose (NFC)-based aerogels. Cellulose 2012, 19, 1945–1956.

- Heath, L.; Thielemans, W. Cellulose nanowhisker aerogels. Green Chem. 2010, 12, 1448–1453.

- Rostamitabar, M.; Seide, G.; Jockenhoevel, S.; Ghazanfari, S. Effect of cellulose characteristics on the properties of the wet-spun aerogel fibers. Appl. Sci. 2021, 11, 1525.

- Revin, V.V.; Nazarova, N.B.; Tsareva, E.E.; Liyaskina, E.V.; Revin, V.D.; Pestov, N.A. Production of Bacterial Cellulose Aerogels with Improved Physico-Mechanical Properties and Antibacterial Effect. Front. Bioeng. Biotechnol. 2020, 8, 1392.

- Gavillon, R.; Budtova, T. Aerocellulose: New Highly Porous Cellulose Prepared from Cellulose−NaOH Aqueous Solutions. Biomacromolecules 2008, 9, 269–277.

- Gong, C.; Ni, J.-P.; Tian, C.; Su, Z.-H. Research in porous structure of cellulose aerogel made from cellulose nanofibrils. Int. J. Biol. Macromol. 2021, 172, 573–579.

- Alves, L.; Ramos, A.; Ferraz, E.; Ferreira, P.J.; Rasteiro, M.G.; Gamelas, J.A. Design of cellulose nanofibre-based composites with high barrier properties. Cellulose 2023, 30, 10157–10174.

- Korhonen, J.T.; Kettunen, M.; Ras, R.H.A.; Ikkala, O. Hydrophobic Nanocellulose Aerogels as Floating, Sustainable, Reusable, and Recyclable Oil Absorbents. ACS Appl. Mater. Interfaces 2011, 3, 1813–1816.

- Long, L.-Y.; Weng, Y.-X.; Wang, Y.-Z. Cellulose Aerogels: Synthesis, Applications, and Prospects. Polymers 2018, 10, 623.

- Buchtová, N.; Pradille, C.; Bouvard, J.L.; Budtova, T. Mechanical properties of cellulose aerogels and cryogels. Soft Matter 2019, 15, 7901–7908.

- Karadagli, I.; Schulz, B.; Schestakow, M.; Milow, B.; Gries, T.; Ratke, L. Production of porous cellulose aerogel fibers by an extrusion process. J. Supercrit. Fluids 2015, 106, 105–114.

- de Oliveira, J.P.; Bruni, G.P.; Fabra, M.J.; Zavareze, E.d.R.; López-Rubio, A.; Martínez-Sanz, M. Development of food packaging bioactive aerogels through the valorization of Gelidium sesquipedale seaweed. Food Hydrocoll. 2019, 89, 337–350.

- de Oliveira, J.P.; Bruni, G.P.; el Halal, S.L.M.; Bertoldi, F.C.; Dias, A.R.G.; Zavareze, E.d.R. Cellulose nanocrystals from rice and oat husks and their application in aerogels for food packaging. Int. J. Biol. Macromol. 2019, 124, 175–184.

- Jaafar, Z.; Quelennec, B.; Moreau, C.; Lourdin, D.; Maigret, J.; Pontoire, B.; D’orlando, A.; Coradin, T.; Duchemin, B.; Fernandes, F.; et al. Plant cell wall inspired xyloglucan/cellulose nanocrystals aerogels produced by freeze-casting. Carbohydr. Polym. 2020, 247, 116642.

- Chen, Y.; Zhang, L.; Yang, Y.; Pang, B.; Xu, W.; Duan, G.; Jiang, S.; Zhang, K. Recent Progress on Nanocellulose Aerogels: Preparation, Modification, Composite Fabrication, Applications. Adv. Mater. 2021, 33, 2005569.

- Geng, H. A facile approach to light weight, high porosity cellulose aerogels. Int. J. Biol. Macromol. 2018, 118, 921–931.

- Fu, J.; He, C.; Wang, S.; Chen, Y. A thermally stable and hydrophobic composite aerogel made from cellulose nanofibril aerogel impregnated with silica particles. J. Mater. Sci. 2018, 53, 7072–7082.

- Chang, X.; Chen, D.; Jiao, X. Chitosan-Based Aerogels with High Adsorption Performance. J. Phys. Chem. B 2008, 112, 7721–7725.

- Christy, E.; Rajeswari, A.; Gopi, S.; Pius, A. Chitin and chitosan-based aerogels. In Handbook of Chitin and Chitosan; Elsevier: Amsterdam, The Netherlands, 2020; pp. 285–334.

- Guerrero-Alburquerque, N.; Zhao, S.; Adilien, N.; Koebel, M.M.; Lattuada, M.; Malfait, W.J. Strong, Machinable, and Insulating Chitosan–Urea Aerogels: Toward Ambient Pressure Drying of Biopolymer Aerogel Monoliths. ACS Appl. Mater. Interfaces 2020, 12, 22037–22049.

- Zhang, S.; Xiao, Q.; Xiao, Y.; Li, Z.; Xiong, S.; Ding, F.; He, J. Chitosan Based Aerogels with Low Shrinkage by Chemical Cross-Linking and Supramolecular Interaction. Gels 2022, 8, 131.

- Wei, S.; Ching, Y.C.; Chuah, C.H. Synthesis of chitosan aerogels as promising carriers for drug delivery: A review. Carbohydr. Polym. 2020, 231, 115744.

- Zhang, S.; He, J.; Xiong, S.; Xiao, Q.; Xiao, Y.; Ding, F.; Ji, H.; Yang, Z.; Li, Z. Construction and Nanostructure of Chitosan/Nanocellulose Hybrid Aerogels. Biomacromolecules 2021, 22, 3216–3222.

- Liu, X.; Wang, M.; Risen, W. Polymer-Attached Functional Inorganic-Organic Hybrid Nano-composite Aerogels. In MRS Proceedings; Springer: Berlin/Heidelberg, Germany, 2002; p. 740.

- Pan, J.; Li, Y.; Chen, K.; Zhang, Y.; Zhang, H. Enhanced physical and antimicrobial properties of alginate/chitosan composite aerogels based on electrostatic interactions and noncovalent crosslinking. Carbohydr. Polym. 2021, 266, 118102.

- Takeshita, S.; Zhao, S.; Malfait, W.J.; Koebel, M.M. Chemistry of chitosan aerogels: Three-dimensional pore control for tailored applications. Angew. Chem. Int. Ed. 2021, 60, 9828–9851.

- Lin, D.; Zheng, Y.; Huang, Y.; Ni, L.; Zhao, J.; Huang, C.; Chen, X.; Chen, X.; Wu, Z.; Wu, D.; et al. Investigation of the structural, physical properties, antioxidant, and antimicrobial activity of chitosan- nano-silicon aerogel composite edible films incorporated with okara powder. Carbohydr. Polym. 2020, 250, 116842.

- Özen, E.; Yildirim, N.; Dalkiliç, B.; Ergun, M. Effects of microcrystalline cellulose on some performance properties of chitosan aerogels. Cienc. Tecnol. 2021, 23.

- Mallepally, R.R.; Bernard, I.; Marin, M.A.; Ward, K.R.; McHugh, M.A. Superabsorbent alginate aerogels. J. Supercrit. Fluids 2013, 79, 202–208.

- Lovskaya, D.; Menshutina, N. Alginate-Based Aerogel Particles as Drug Delivery Systems: Investigation of the Supercritical Adsorption and In Vitro Evaluations. Materials 2020, 13, 329.

- Gordienko, M.G.; Palchikova, V.V.; Kalenov, S.V.; Lebedev, E.A.; Belov, A.A.; Menshutina, N.V. The alginate–chitosan composite sponges with biogenic Ag nanoparticles produced by combining of cryostructuration, ionotropic gelation and ion replacement methods. Int. J. Polym. Mater. Polym. Biomater. 2022, 71, 34–44.

- Shang, K.; Liao, W.; Wang, J.; Wang, Y.-T.; Wang, Y.-Z.; Schiraldi, D.A. Nonflammable Alginate Nanocomposite Aerogels Prepared by a Simple Freeze-Drying and Post-Cross-Linking Method. ACS Appl. Mater. Interfaces 2016, 8, 643–650.

- Cheng, Y.; Lu, L.; Zhang, W.; Shi, J.; Cao, Y. Reinforced low density alginate-based aerogels: Preparation, hydrophobic modification and characterization. Carbohydr. Polym. 2012, 88, 1093–1099.

- Raman, S.; Gurikov, P.; Smirnova, I. Hybrid alginate based aerogels by carbon dioxide induced gelation: Novel technique for multiple applications. J. Supercrit. Fluids 2015, 106, 23–33.

- Chen, H.-B.; Wang, Y.-Z.; Schiraldi, D.A. Foam-like materials based on whey protein isolate. Eur. Polym. J. 2013, 49, 3387–3391.

- Alnaief, M.; Alzaitoun, M.; García-González, C.A.; Smirnova, I. Preparation of biodegradable nanoporous microspherical aerogel based on alginate. Carbohydr. Polym. 2011, 84, 1011–1018.

- Fu, Y.; Guo, Z. Natural polysaccharide-based aerogels and their applications in oil–water separations: A review. J. Mater. Chem. A 2022, 10, 8129–8158.

- Agulhon, P.; Robitzer, M.; David, L.; Quignard, F. Structural Regime Identification in Ionotropic Alginate Gels: Influence of the Cation Nature and Alginate Structure. Biomacromolecules 2012, 13, 215–220.

- Françon, H.; Wang, Z.; Marais, A.; Mystek, K.; Piper, A.; Granberg, H.; Malti, A.; Gatenholm, P.; Larsson, P.A.; Wågberg, L. Ambient-Dried, 3D-Printable and Electrically Conducting Cellulose Nanofiber Aerogels by Inclusion of Functional Polymers. Adv. Funct. Mater. 2020, 30, 1909383.

- Zhang, A.; Zou, Y.; Xi, Y.; Wang, P.; Zhang, Y.; Wu, L.; Zhang, H. Fabrication and characterization of bamboo shoot cellulose/sodium alginate composite aerogels for sustained release of curcumin. Int. J. Biol. Macromol. 2021, 192, 904–912.

- Wang, Z.; Zhu, W.; Huang, R.; Zhang, Y.; Jia, C.; Zhao, H.; Chen, W.; Xue, Y. Fabrication and characterization of cellulose nanofiber aerogels prepared via two different drying techniques. Polymers 2020, 12, 2583.

- Martins, M.; Barros, A.A.; Quraishi, S.; Gurikov, P.; Raman, S.P.; Smirnova, I.; Duarte, A.R.C.; Reis, R.L. Preparation of macroporous alginate-based aerogels for biomedical applications. J. Supercrit. Fluids 2015, 106, 152–159.

- Gonçalves, V.; Gurikov, P.; Poejo, J.; Matias, A.; Heinrich, S.; Duarte, C.; Smirnova, I. Alginate-based hybrid aerogel microparticles for mucosal drug delivery. Eur. J. Pharm. Biopharm. 2016, 107, 160–170.

- Greco, I.; Varon, C.; Iorio, C. Synthesis and Characterization of a new Alginate-Gelatine Aerogel for Tissue Engineering. In Proceedings of the 2022 44th Annual International Conference of the IEEE Engineering in Medicine & Biology Society (EMBC), Glasgow, UK, 11–15 July 2022; pp. 3915–3918.

- Mary, S.; Pothan, L. Chapter 4: Starch Based Aerogels: Processing and Morphology. In Biobased Aerogels: Polysaccharide and Protein-Based Materials; Royal Society of Chemistry: London, UK, 2018; pp. 42–53.

- Zhu, F. Starch based aerogels: Production, properties and applications. Trends Food Sci. Technol. 2019, 89, 1–10.

- Zheng, Q.; Tian, Y.; Ye, F.; Zhou, Y.; Zhao, G. Fabrication and application of starch-based aerogel: Technical strategies. Trends Food Sci. Technol. 2020, 99, 608–620.

- Zhai, Z.; Zheng, Y.; Du, T.; Tian, Z.; Ren, B.; Xu, Y.; Wang, S.; Zhang, L.; Liu, Z. Green and sustainable carbon aerogels from starch for supercapacitors and oil-water separation. Ceram. Int. 2021, 47, 22080–22087.

- Fonseca, L.M.; da Silva, F.T.; Bruni, G.P.; Borges, C.D.; Zavareze, E.d.R.; Dias, A.R.G. Aerogels based on corn starch as carriers for pinhão coat extract (Araucaria angustifolia) rich in phenolic compounds for active packaging. Int. J. Biol. Macromol. 2020, 169, 362–370.

- Zou, F.; Bouvard, J.L.; Pradille, C.; Budtova, T. Ice-templated additive-free porous starches with tuned morphology and properties. Eur. Polym. J. 2022, 176, 111403.

- Zhao, Y.; Zhang, H.; Ye, Y.; Shi, J.; Yan, M.; Liu, L.; Zhu, H.; Guo, J. Structure and performance preparation on alginate-based fibrous aerogel with double network. Int. J. Polym. Anal. Charact. 2021, 26, 218–227.

- Dogenski, M.; Navarro-Díaz, H.J.; de Oliveira, J.V.; Ferreira, S.R.S. Properties of starch-based aerogels incorporated with agar or microcrystalline cellulose. Food Hydrocoll. 2020, 108, 106033.

- Mary, S.K.; Koshy, R.R.; Arunima, R.; Thomas, S.; Pothen, L.A. A review of recent advances in starch-based materials: Bionanocomposites, pH sensitive films, aerogels and carbon dots. Carbohydr. Polym. Technol. Appl. 2022, 3, 100190.

- Wang, Y.; Wu, K.; Xiao, M.; Riffat, S.B.; Su, Y.; Jiang, F. Thermal conductivity, structure and mechanical properties of konjac glucomannan/starch-based aerogel strengthened by wheat straw. Carbohydr. Polym. 2018, 197, 284–291.

- Rudaz, C.; Courson, R.; Bonnet, L.; Calas-Etienne, S.; Sallée, H.; Budtova, T. Aeropectin: Fully Biomass-Based Mechanically Strong and Thermal Superinsulating Aerogel. Biomacromolecules 2014, 15, 2188–2195.

- Chen, H.-B.; Chiou, B.-S.; Wang, Y.-Z.; Schiraldi, D.A. Biodegradable Pectin/Clay Aerogels. ACS Appl. Mater. Interfaces 2013, 5, 1715–1721.

- Fraeye, I.; Duvetter, T.; Doungla, E.; Van Loey, A.; Hendrickx, M. Fine-tuning the properties of pectin–calcium gels by control of pectin fine structure, gel composition and environmental conditions. Trends Food Sci. Technol. 2010, 21, 219–228.

- Oakenfull, D.A.; Scott, A.L.; Chai, E.U. The mechanism of formation of mixed gels by high methoxyl pectins and alginates. Gums Stabilisers Food Ind. 1990, 5, 243–264.

- Chen, H.-B.; Li, X.-L.; Chen, M.-J.; He, Y.-R.; Zhao, H.-B. Self-cross-linked melamine-formaldehyde-pectin aerogel with excellent water resistance and flame retardancy. Carbohydr. Polym. 2018, 206, 609–615.

- Betz, M.; García-González, C.A.; Subrahmanyam, R.; Smirnova, I.; Kulozik, U. Preparation of novel whey protein-based aerogels as drug carriers for life science applications. J. Supercrit. Fluids 2012, 72, 111–119.

- Tkalec, G.; Knez, Z.; Novak, Z. Formation of polysaccharide aerogels in ethanol. RSC Adv. 2015, 5, 77362–77371.

- Ishwarya S, P.; Nisha, P. Advances and prospects in the food applications of pectin hydrogels. Crit. Rev. Food. Sci. Nutr. 2022, 62, 4393–4417.

- Arboleda, J.C.; Hughes, M.; Lucia, L.A.; Laine, J.; Ekman, K.; Rojas, O.J. Soy protein–nanocellulose composite aerogels. Cellulose 2013, 20, 2417–2426.

- Yuan, Y.; Solin, N. Protein-based luminescent aerogels with elastic properties. Green Chem. Lett. Rev. 2022, 15, 508–518.

- Andlinger, D.J.; Bornkeßel, A.C.; Jung, I.; Schroeter, B.; Smirnova, I.; Kulozik, U. Microstructures of potato protein hydrogels and aerogels produced by thermal crosslinking and supercritical drying. Food Hydrocoll. 2021, 112, 106305.

- Fitzpatrick, S.E.; Deb-Choudhury, S.; Ranford, S.; Staiger, M.P. Novel protein-based bio-aerogels derived from canola seed meal. J. Mater. Sci. 2020, 55, 4848–4863.

- Perez-Cantu, L.; Liebner, F.; Smirnova, I. Preparation of aerogels from wheat straw lignin by cross-linking with oligo(alkylene glycol)-α,ω-diglycidyl ethers. Microporous Mesoporous Mater. 2014, 195, 303–310.

- Xu, X.; Zhou, J.; Nagaraju, D.H.; Jiang, L.; Marinov, V.R.; Lubineau, G.; Alshareef, H.N.; Oh, M. Flexible, Highly Graphitized Carbon Aerogels Based on Bacterial Cellulose/Lignin: Catalyst-Free Synthesis and its Application in Energy Storage Devices. Adv. Funct. Mater. 2015, 25, 3193–3202.

- Jõul, P.; Ho, T.T.; Kallavus, U.; Konist, A.; Leiman, K.; Salm, O.-S.; Kulp, M.; Koel, M.; Lukk, T. Characterization of Organosolv Lignins and Their Application in the Preparation of Aerogels. Materials 2022, 15, 2861.

- Abdullah; Zou, Y.; Farooq, S.; Walayat, N.; Zhang, H.; Faieta, M.; Pittia, P.; Huang, Q. Bio-aerogels: Fabrication, properties and food applications. Crit. Rev. Food Sci. Nutr. 2022, 63, 6687–6709.