As the aviation industry seeks sustainable propulsion solutions, innovative technologies have emerged, among which rim-driven fan (RDF) systems hold notable promise. Amid escalating concerns about greenhouse gas emissions, the aviation sector’s shift towards electric propulsion has gained impetus. RDF technology has emerged as a beacon of optimism, heralding the prospect of energy-efficient and eco-conscious air travel.

1. Introduction

In an era where the urgency to mitigate greenhouse gas emissions has reached a critical point, the aviation industry stands as a significant contributor to the global carbon footprint. Presently, aviation is responsible for approximately 2.4% of worldwide CO

2 emissions

[1], a statistic that could undergo alarming escalation if air traffic triples by 2050, potentially causing aviation-related emissions to constitute a staggering 20% of global warming pollutants

[2]. Addressing this dire scenario necessitates radical advancements in aircraft design and propulsion technology, driven by a commitment to drastically reduce the environmental impact of flight

[3][4][5][6][7].

The introduction of electrical propulsion represents a pivotal turning point in aeronautical engineering, heralding a new chapter of environmentally conscious innovation. Amid this backdrop, organizations like NASA and the Department of Energy have set ambitious benchmarks for motor power density in electric aircraft—a crucial step towards achieving commercially viable electric flight

[8][9]. As the aviation landscape evolves, the spotlight is increasingly trained on the concept of distributed propulsion systems, a design strategy that promises to usher in enhanced energy efficiency, diminished carbon emissions, reduced operational costs, and even reduced acoustic noise levels

[10][11].

This transformation towards electrification is not merely a theoretical endeavor. Rather, it is propelled by major industry players including NASA, Boeing, Airbus, Joby Aircraft, and Lilium, who are directing substantial investments towards the development of electric airplane technologies

[9][12][13][14]. A pivotal aspect of this evolution lies in the utilization of fans powered directly by electric motors, offering a simpler and more versatile alternative to traditional propulsion systems. Notably, the collaborative efforts of these industry giants have yielded promising outcomes in the field of fixed-wing distributed propeller and electric ducted fan aircraft designs.

A central tenet of this transition to electric aviation involves the pursuit of high-speed flight capabilities with electric motor technology—a challenge that is being squarely addressed by initiatives like NASA’s drive towards electric aircraft motors with exceptional power density and efficiency

[14]. Furthermore, the market’s growing anticipation of electric aviation’s market entry has fortified research and development endeavors, nurturing a fertile ground for the exploration of new possibilities and real-world applications. Electric airplanes, when compared to their traditional counterparts, often employ fans powered directly by electric motors. This system is significantly less intricate than turboprop engines, creating opportunities for more individualized propulsion system configurations that can be fine-tuned to enhance the capabilities of a particular aircraft. NASA, Joby Aircraft, and Lilium’s investment in fixed-wing distributed propeller and electric ducted fan aircraft designs has proven to be fruitful

[9]. The research and development of these designs have enabled us to explore new possibilities and increase the practical application of electric aviation technology

[15].

In order to achieve subsonic speeds for commercial flight, major civil aircraft manufacturers worldwide are adopting comparable methods that rely on hub-driven electric ducted fan technology

[13]. Nevertheless, it is widely acknowledged that employing large centralized electric ducted fan (EDF) propulsion and traditional aircraft wing and body configurations introduces inefficiencies in both electrical supply and aerodynamics, which could hinder the overall effectiveness of electric-powered aircraft

[16]. The benefits of electric propulsion, including blended wing body and distributed thrust systems, become more evident when contrasted with conventional design approaches

[17][18].

Ducted fan technology, which has been a staple since the 1960s, has now witnessed a transformative advancement in the form of rim-driven fan (RDF) technology. This innovation, which eschews the conventional motor designs in favor of a more compact and efficient approach, offers the potential to revolutionize the way aircraft propulsion is conceptualized and engineered. By embodying a unique rotor configuration that departs from traditional center hub designs, RDF technology not only enhances thrust and exhaust air velocity but also ushers in opportunities for more streamlined and effective designs.

As the aviation industry treads the path of electrification, the innovative prowess of rim-driven fan technology emerges as a beacon of hope, pointing towards a more sustainable and efficient future for air travel. The potential of rim-driven fan technology to revolutionize aircraft propulsion is a central theme in the subsequent sections.

2. Features and Benefits of the RDF Jet

The ducted fan concept, which uses a rotor to generate thrust enclosed in a cover, has been used since the 1960s and is widely used in manned aircraft. Electric ducted fan (EDF) is the same concept, but the rotor is driven by an electric motor. EDF offers advantages including high thrust-to-weight and thrust-to-diameter ratios, physical and environmental protection, and thrust vectoring. Design parameters, such as the end clearance and outlet opening to fan area ratio, affect performance parameters such as thrust, RPM, energy consumption, efficiency, and noise

[19]. Hence, compact electric ducted fan (EDF) modules enable the integration of propulsion configurations that distribute thrust, yet their usage remains confined to scenarios involving low-speed flight, like those observed in general aviation and small unmanned aerial systems. Owing to their design centered around a central hub, diminutive single-stage rotors necessitate exceedingly elevated rotational velocities to attain higher exhaust airspeeds, a limitation that poses significant challenges

[20][21][22].

However, rim-driven fan (RDF) technology has emerged as a possible solution. In contrast to conventional motor designs, this technique allows for smaller fan inlet diameters while still producing significant thrust and exhaust air velocity. The rim-driven fan (RDF), rim-driven thruster (RDT), or rim-driven propulsor/propeller (RDP) is an innovative electric propulsion unit. Unlike conventional propellers, which have a center hub through which the driving torque is transmitted, rim-driven thrusters only have a rotating outer ring

[23]. In contrast, the blades of a rim-driven thruster are not attached to a central hub but rather to an outer ring. The electric motor’s rotor, which is the ring, rotates inside the stator, which is also a ring, to provide the required torque. The stator of the electric motor is installed in the duct, and the rotor forms a ring around the propeller’s rim in this innovative design.

Nonetheless, recent technological advancements have reshaped this landscape. Progressions in computerized modeling and analysis methods, developments in materials science, the emergence of 3D prototyping, advancements in unmanned aircraft system (UAS) technology, and breakthroughs in power electronics and electric propulsion systems have jointly driven the progress and assessment of motorized RDFs for aerospace applications, including within the domain of unmanned aircraft. These developments have substantially reduced barriers that once hindered progress. While potential challenges and intricacies are outlined in the subsequent sections, the momentum gained through technological strides suggests that the incorporation of electric motors in aviation might offer a viable solution to the imperative of electrifying airplanes.

Rim-Driven Configuration

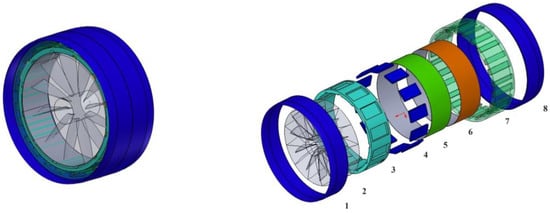

RDFs are primarily distinguished by their shaftless architecture as opposed to traditional motor-propeller designs. A ducted fan drum rotor with attached blades at the outer diameter makes up the actual arrangement. The rotor is housed inside a stator, and it is powered by electromagnetic fields that are modulated between the two components. The controller and power electronic drive circuits between the power source and integrated motor assembly provide optimal modulation. The rotor assembly is suspended and supported by magnetic fields inside the stator (Figure 1).

Figure 1. Configuration of a rim-driven thruster (RDT). 1. Front Cover, 2. Propellers, 3. Rotor, 4. Magnets, 5. Rotor Sealing, 6. Stator Sealing, 7. Stator, 8. Rear Cover.

Using torque applied to the drum rotor, which has blades mounted on the revolving shell, the levitated ducted fan, a self-contained electromagnetic propulsor, generates thrust. Using the large surface area and unique physical dimensions of the rotor’s outer circle is essential for developing the most efficient electromagnetic levitation and propulsion mechanism between the rotor and stator. Key to this concept is the novel application of electromagnetic propulsion and the non-contact support system.

The fan blades in a rim-driven propeller or turbofan are rotated by the rim, rather than an axis. Under the dynamic magnetic force between the inner rim and outer ring/shell magnets, the rim spins. High-intensity permanent magnet plates, which have no electrical connections, are implanted in the rotor’s inner rim. These stators, which are induced by an external power source, are effectively controlled by a high-power circuit. Hence, the stators within the rim of the RDF jet are supplied with significant electrical energy and are regulated through the utilization of a robust and powerful circuitry system. This is how RDF is able to distribute power from the rim to the blades without going via the central shaft. Therefore, more air can enter because there is no central shaft to restrict it.

Utilizing a rim-driven method rather than an axis-driven one makes it much easier to resist high torque. Direct power transfer is another distinction between rim-driven and axis-driven systems. With a typical fan, the original driving force is delivered in a two-step indirect way from the turbine to the shaft to the fan blade. Meanwhile, the rotor’s power is sent directly from the rim to the fan blade in an RDF. Its greater drivability enables a thicker blade to revolve faster and more easily to satisfy the resistive torque generated by the RDF jet engine’s high thrust output.

Unlike traditional jet engines that use gas turbines or diesel, the RDF uses an electric motor. Modern electric motor technology is used in the rim-driven motor, drastically increasing its power output per unit of weight. The RDF jet is able to utilize materials with a low specific density. Fiber-reinforced composite (FRC) plastic, ceramic matrix composite metal (CMC), new alloys, and many other composites can be used in the production of housings, wheels, and fans, respectively. Integrating these cutting-edge advances allows the RDF jet to be constructed while meeting stringent mass requirements.

RDF jets are compact cubic cylinders with easy installation and alignment. Hence, the implementation of distributed electric propulsion (DEP) can be straightforwardly achieved through the deployment of multiple RDF jets distributed across the entirety of the aircraft. Propulsion systems can harness the advantageous interactions between aerodynamics and propulsion, surpassing the capabilities of traditional setups due to their adaptable placement, scaling, and operational versatility

[24][25].

3. Innovation along with Development

In a German patent from 1940, Kort presented the basic design of an RDT

[26], with the rotor mounted on a ring around the propeller and the stator coils placed in the duct of the thruster.

With the development of modern electric motor technologies, the practical implementation of an efficient, compact RDT became possible in the following decades

[27][28][29][30][31][32][33][34]. In recent years, a growing number of research institutions have engaged in researching RDT technology. This technology has been thoroughly explored in relation to incompressible flows, its potential applications in the marine industry have been extensively studied, and some products have been implemented on operational ships

[26][35][36][37][38][39][40]. Efforts are being made to investigate the use of rim-driven thrusters, or RDFs, in compressible fluids, as it has not been explored in depth despite its potential. This technology is becoming increasingly relevant to the aerospace industry, leading to a growing interest in studying its applications in compressible flows.

The NASA conceptual design investigation centered on creating a levitated ducted fan (referred to as a rim-driven fan) with a diameter measuring 32 inches

[41]. The study specifically concentrated on the electromagnetic structure of an individual rotor within the rim-driven fan mechanism. The fan consists of 24 blades that extend from the rim towards an empty core rotor assembly. The propellers in question exhibit enhanced efficiency and mitigate the constraints that are commonly encountered in traditional aircraft propulsors, including but not limited to bearing wear, leaks, seals, and friction loss. The levitated ducted fan exhibits several advantages pertaining to its maintainability, reliability, and safety. A significant proportion of maintenance expenses in traditional engine systems can be attributed to malfunctions in the lubrication system and mechanical bearings. The implementation of magnetic suspension systems effectively mitigates apprehensions that are commonly associated with conventional bearings, including but not limited to active lubrication, wear, and restricted rotational velocity

[41].

A design for a compressible fluid capable of achieving a weight-to-thrust ratio of one-to-one was suggested by Bolam et al.

[42]. However, their prototype featured a centerline bearing that disrupted the core flow, appearing similar to a traditional hub fan design in terms of aerodynamics.

4. Type of Electric Motor

Induction motors (IM), switching reluctance motors (SRM), permanent-magnet direct-current motors (PMDCM), permanent-magnet alternating-current motors (PMACM), and high-temperature superconducting motors (HTSM) are only some of the electric motor types that may be employed with RDTs.

Brown et al. developed an IM-based RDT with a skewed-bar squirrel cage rotor connected to the blade tips

[43]. The researchers conducted tests to evaluate the propulsor’s performance in terms of speed, thrust, and noise level, and found that it achieved a high level of efficiency with reduced noise compared to traditional gasoline engines. The study highlights the importance of developing eco-friendly technologies as a means to minimize negative environmental impact, and the submersible electric motor propulsor is presented as a promising technology for small boats and watercraft. Additionally, an oil-filled metal container was laser-welded around the entire stator assembly. To streamline the rotor design, a conducting rotor can was implemented in place of the traditional “deep-bar” cage and a succession of air-gap cans were used to offer environmental shielding. Tuohy et al. developed this line-start rim-driven IM for application in RDTs

[31][44][45].

Because of the significant drag losses brought on by their radially thick ducts and rotors/stators, IM and SRM motors both suffer from low aerodynamic and hydrodynamic efficiency at high advance speeds. This is the case even though both types of motors have similar advance speeds. The poor performance of IM and SRM can be attributed to the wide air gap that is necessary in order to integrate corrosion protective layers on the surfaces of the rotor and stator.

PM motors can have a greater number of poles and are more tolerant of larger gaps, as stated by Sharkh et al.

[46][47]. The studies underscore the significance of PM motors due to their ability to have ultra-thin rotors and stators without compromising performance. They offer experimental and simulation-based evidence in support of the argument that PM motors have an efficiency that is intrinsic to their design, explain why a majority of researchers prefer incorporating this motor type into their RDT designs, and also emphasize the critical factors that affect the total efficiency of a PM motor. These factors include a large number of poles, a small radial thickness, a reasonably huge air gap, short axial length, and relatively thin magnets. The authors present the results of their experiments and simulations to demonstrate these factors’ importance and their impact on efficiency. Also they demonstrate the development and optimization of a slot-less PM brushless motor with helical edge-wound laminations and use various simulations and algorithms to obtain efficient and optimal motor designs

[48][49].

As the current density in the stator increases, heat is generated, which can affect the performance of the motor and potentially lead to failure. To mitigate these effects, various design strategies have been investigated, including the use of materials with high thermal conductivity, such as copper or aluminum, improved cooling techniques, and reducing the stator’s electric resistance. As mentioned earlier, Sharkh and Lai

[49] focus on optimizing the design of a slot-less permanent-magnet brushless motor with helical edge-wound laminations for rim-driven thrusters. They use a thermal finite element analysis to evaluate the temperature distribution inside the motor and investigate design parameters that can improve heat dissipation.

Powered by a permanent-magnet (PM) motor, Van Dine devised and manufactured a prototype RDT with 120 hp at 500 rpm

[50]. The propeller, housings, structural blading, motor canning, and fairings were all made of composite materials to reduce weight and cost and to prevent eddy current losses in the motor. The composite motor’s efficacy was 6% greater than that of a metallic motor (predicted 98.188% for composite, 92.285% for metallic). Moreover, the cost of this composite RDT was 35% less than that of a metal instrument.

5. Design

It is absolutely necessary to match the aerodynamic parameters of the propeller to the characteristics of the motor in order to obtain efficient RDFs. According to Sharkh et al.

[47], the pitch ratio of the propeller is the single most critical metric. The hydrodynamic efficiency can also be affected by the structural design of the propeller, the form and size of the duct, the thickness of the air gap, and a number of other parameters.

In a study by Jiang et al.

[51], numerical investigations to analyze the impact of blade count on the hydrodynamic performance with a fixed blade area ratio and pitch ratio are conducted. Their analysis focuses on comparing and contrasting the thrust coefficient, torque coefficient, and efficiency of RDTs with varying blade numbers. Furthermore, the study successfully identifies and meticulously analyzes the pressure distribution on the blade surface, as well as the velocity distribution surrounding the blade and within its wake. It is observed that the thrust coefficient and torque coefficient of the RDT exhibit an upward trend with the advance coefficient, while the efficiency of the RDT displays a downward trend with the increase in the number of blades, as per the findings.

In the analysis of the slot-less winding characteristics of motors, crucial factors driving the design include geometrical relationships and magnetic requirements

[52]. These factors encompass the width of each phase coil side, the skew angle, and the winding arrangement. Additionally, a preliminary design study of a winding model derived from a Faulhaber configuration has been subjected to scrutiny. It was determined that in order to ensure optimal efficiency, the skew angle must be maintained at a low level. However, it is also imperative that the angle be of sufficient magnitude to meet both the geometric and magnetic criteria.

Utilizing axial-flux motors for rim drives comes with certain limitations that require consideration. Unlike their radial-flux counterparts, axial-flux motors experience increased radius and tip speed when the stack length is augmented. This leads to larger machine radii, necessitating larger shells or housings around the propulsion system. This, in turn, contributes to heightened drag and system mass. Achieving optimal performance in axial-flux rim-driven fans requires a delicate balance among fan diameter, tip speed, and motor stack length. The manuscript presents a proof-of-concept iteration of an electric propulsion system design code

[53], employing low fidelity models of aircraft, fan, and motor to optimize the range of a specific aircraft.

6. Noise and Vibration

The development of quiet propulsion systems has become increasingly important in the field of unmanned aerial vehicle (UAV) operations, particularly in reconnaissance and surveying missions where low noise levels are imperative. The use of rim-driven thrusters has been shown to improve both the aerodynamic and acoustic capabilities of aerial vehicles compared to traditional propellers. However, external noise can still come from various sources, including aerodynamic and electromagnetic propeller noise and friction and impact noise caused by unbalanced force and thrust. The study offers insight into the potential for rim-driven fans to operate more quietly compared to conventional impellers, highlighting the importance of reducing both ring and blade commotion in future motor designs.

The research delves into how the cogging torque of a rim-electric driven propeller (REDP) is influenced by factors such as the slot number, pole number, tooth geometry, and pole arc coefficient. This investigation offers valuable insights to establish a theoretical basis for studying the motor’s impact on vibration and noise

[54]. The findings suggest that for a motor with frictional slots and concentrated windings, the cogging torque’s amplitude decreases as the lowest common multiple increases.

It is generally known that the typical propeller produces an audible acoustic signature due to blade tip vortices and other flow features

[55][56][57]. The tangential velocities are reduced and the tip vortices may be minimized if the blade tips are located closer to the center of the fan. The rim-driven thruster is an attractive choice for thrust production since it improves both the aerodynamic and acoustic capabilities of aerial vehicles. This is especially relevant in the field of tiny unmanned aerial vehicle (UAV) applications, which are finding widespread usage in reconnaissance and surveying operations that need a low noise footprint

[58][59][60].

The frequency spectra of acoustic signal for fanless motors and hubless fans have been plotted for comparison

[23]. The absence of air movement-associated broad-band frequencies was evident in the absence of a fan. The fan vibration frequencies drowned out the blade pass frequencies (BPF). The absence of a peak near the BPF may indicate that a rim-driven fan has the potential to operate more quietly compared to a conventional impeller.

Because conventional propulsion systems rely on drive shafts and reduction gear, shaft-less RDT propulsion devices offer a more comfortable riding experience. This is because these devices do not require the use of these components. However, external noise can come from a variety of sources, including aerodynamic propeller noise, electromagnetic propeller noise, vibration noise created by friction in the bearings, and impact noise caused by the propeller impacting the structure when subjected to unbalanced force and thrust force.

7. Control

RDFs are hindered in their ability to scale due to various design, construction, and operational limitations. When it comes to larger aircraft, multiple RDFs must be used for propulsion purposes. Recently, cooperative control among multiple RDFs has been gaining significant interest. In order to improve the efficiency, convenience, and safety of airplane navigation, it is important to understand the cooperative control mechanisms utilized among RDFs.

The installation of position sensors on RDTs can prove to be a challenging task. Consequently, the utilization of sensorless control technology is deemed to be a superior alternative, as supported in

[61][62][63]. Currently, the control technology in question exhibits a certain degree of sophistication and is capable of achieving control outcomes that are deemed satisfactory. Nevertheless, the precision of control for motors operating at low velocities remains an area that requires further enhancement. The pursuit of high-performance control for RDT drive motors entails the development of anti-chattering and sensorless control algorithms. The sensorless control algorithms for RDT motors encompass a range of techniques, such as direct calculation, back-EMF integration, model reference adaptive, and various observer methods

[63][64][65][66]. In the context of RDT motor sensorless control, the optimization and tuning of adjustable parameters play a pivotal role in determining the efficacy of the rotor speed and position estimation algorithm. It is important to note that changes in motor parameters or external conditions necessitate corresponding adjustments to the controller’s adjustable parameters.

8. Bearing

Operational and design limitations pose significant challenges. One such challenge is bearing-related noise, which significantly impacts engine operation. To address this issue, researchers have explored various approaches, including modifying RDT hubs and utilizing bearings with a proportional radius.

Hsieh et al. developed a hubless-type RDT with ball bearings embedded in the duct

[67]. Due to attrition in the bearings, the rotor was unable to achieve the specified speed at the rated voltage supply. Sharkh inserted bearings into the hub (on both extremities of the hub) to address this issue, resulting in a reduction in both the friction resistance moment and friction loss

[46].

In a study, a bearing with a small proportional radius is used to modify the fan’s centerline axis configuration

[23]. The bearing is mounted on the stator body and rotates at the same speed. At the point of contact, the tangential speed of the fan and the bearing must be equal. This indicates that the rotational speed of the bearing is proportional to the ratio of the fan’s radius to the bearing’s radius. Therefore, a fan with a lower rotational speed requires bearings to rotate more, and this significantly higher rotational speed is responsible for a high noise band between 2 and 8 kHz. A slip bearing support was also used in this study. Current trends in acoustic research indicate that engine operation must be made silent by addressing bearing-related noise.

9. FEA and CFD

Rim-driven thrusters (RDTs) have been studied extensively using various numerical methodologies, including finite element analysis (FEA) and computational fluid dynamics (CFD). A number of factors have been explored to optimize RDT performance, including length diameter ratio, diffusion ratio, contraction ratio, tip diameter ratio, and blade size and shape. Additionally, researchers have investigated the impact of different RDT configurations, including hubless and hub-type designs.

Finite element analysis (FEA) and computational fluid dynamics (CFD) methods have been used in previous studies to analyze the performance of rim-driven thrusters (RDTs)

[47][68].

A rotor parametric model comprising of blades and a rim has been formulated. The model incorporates a range of variables that have been subjected to multi-objective optimization using ModeFrontier (ESTECO). The optimization process involved measurement of selected parameters through CFD simulations conducted with the Star-CCM+ solver (SIEMENS)

[69].

The CFD simulation method was applied to design a rim-driven thruster and a comparison between the calculated and experimental results of NO. 19A + Ka4−70 ducted propeller was conducted

[70]. As a result, the numerical method was verified and the improved Ka-series propeller was introduced and implemented. Finally, the study analyzed the effects of the propeller’s hydrodynamic performance as regards the number of blades, rake angle, and pitch. The hydrodynamic performance of the propeller is similar to that of the traditional ducted propeller and the absence of a hub improves cavitation and reduces noise. The rake angle does not have much impact on performance, but it should be determined based on the vibration of the tail. The propeller’s thrust, torque, and efficiency increase with the pitch, while the number of blades increases torque and thrust but decreases efficiency and cavitation performance.

cavitation performance. A lesser number of blades helps avoid cavitation, but it increases vibration.

The aerodynamic characteristics of the RDF were studied by investigating the effects of four key parameters, including the rotor disk height, number of blades, central hole radius, and blade root mounting angle

[71]. The research found that rotational speed greatly affects thrust performance, with performance improving as speed increases. Placing the rotor away from the duct entrance results in better aerodynamic performance. A larger number of blades increases peak thrust and ducted thrust performance but reduces the power load.

10. Summary

In conclusion, rim-driven thrusters (RDTs) have been the subject of theoretical and practical studies that have led to significant developments and practical applications in both the marine and aerial sectors. When compared to standard shaft-driven thrusters, RDTs offer several benefits, including a compact design, improved motor efficiency, higher aerodynamic efficiency, reduced demand for secondary systems, and the possibility to produce an undetectable RDF jet. All this suggests that RDTs could offer a more sustainable and efficient alternative to conventional thrusters, especially in environments where high maneuverability, low acoustic noise, and low detectability are essential.