| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Inês Flores-Colen | -- | 1995 | 2023-12-04 09:35:59 | | | |

| 2 | Catherine Yang | Meta information modification | 1995 | 2023-12-05 01:38:36 | | |

Video Upload Options

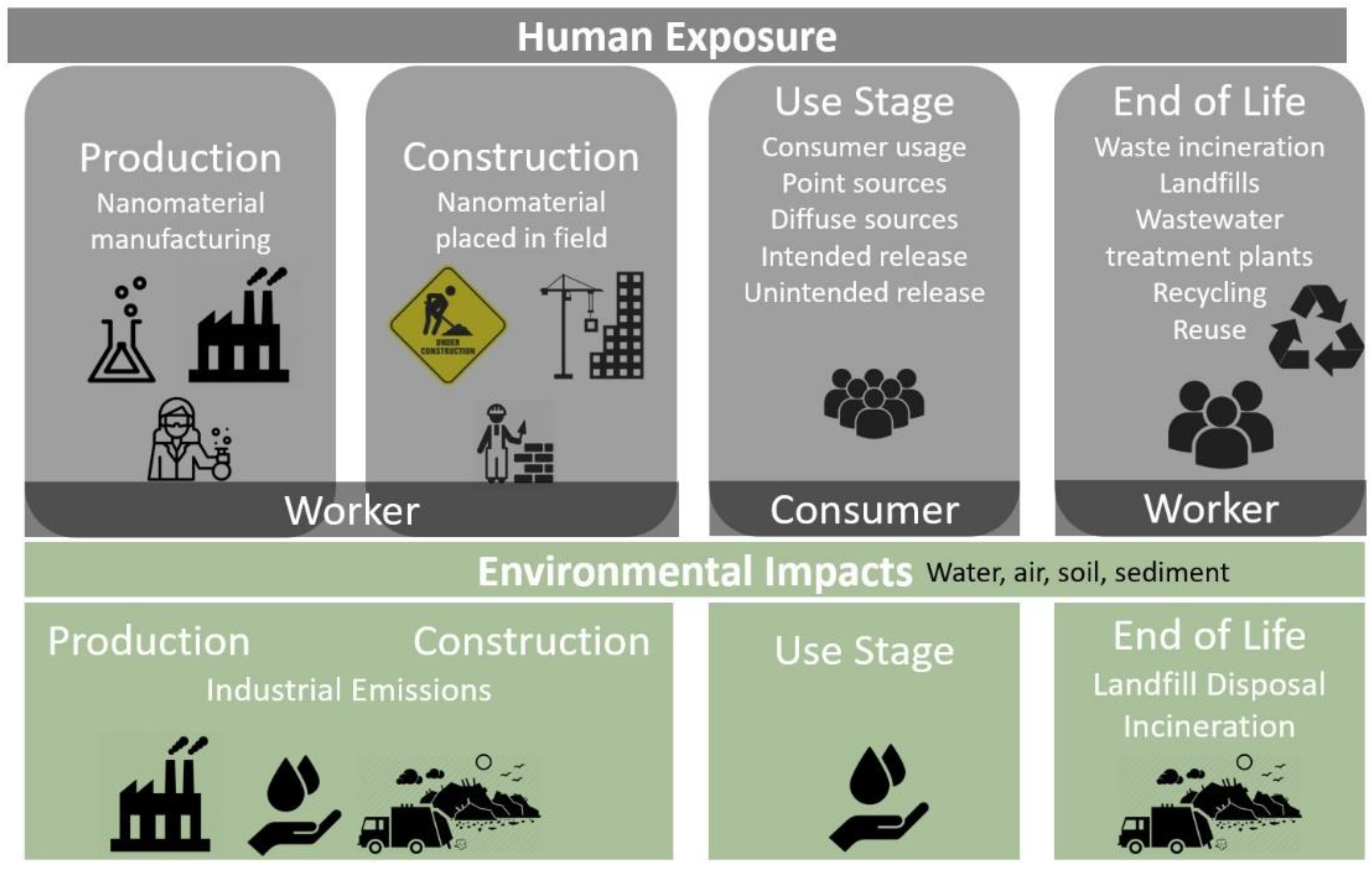

Advanced nanomaterials (NMs) have been widely used in several sectors, from medicine to electronics, aerospace, biotechnology, textiles, agriculture, and, most importantly, in the construction sector. Over the past two decades, the application of nanostructured materials in construction, such as concrete, paint, coatings, glass, renders, plasters, thermal insulation, steel, and even sensors, has become increasingly prevalent. However, previous studies and reports have raised concerns about the ecotoxicity and long-term impact of nanomaterials on human health and the environment. National and international legislation and regulations are struggling to keep up with the rapid development of nanomaterials, taking into account their unique characteristics and essential requirements for application and commercialization. This ressearch, based on existing standards for conventional materials and bibliometric networks of papers focused on nanomaterials, conducts a critical review and proposes relevant indicators for the application of nanomaterials in the construction sector. These indicators should be mandatory and are divided into environmental, human health, and economic perspectives, providing a risk assessment framework for applying nanomaterial-based constructive solutions oriented to environmental, social, and economic sustainability.

1. Overview

| Nanomaterial | Synthesis or Production Method | Applications | Functionality/Improvement | References |

|---|---|---|---|---|

| Nanosilica | Sol-gel | Mortars, concrete | Abrasion resistance; Acceleration on cement hydration; Concrete-to-steel bonding; Improved freeze–thaw resistance; Mechanical improvement; Pozzolanic activity; Paste–aggregate bonding; Permeability reduction | [12][13][14][15][16][17][18][19][20][21] |

| Coatings | Corrosion inhibition efficiency | [22] | ||

| Roads, footpaths | Mechanical improvement | [23][24] | ||

| Iron oxide | Mechanical milling; electro explosion; laser ablation; sol-gel; atomic condensation; template-assisted | Mortars, concrete | Electrical conductivity; Enhanced ductility; Mechanical improvement; Piezoresistive property; Permeability reduction; Self-sensing | [25][26][27][28] |

| Nanosilver | Electro-explosion | Paints, coatings | Biocidal activity | [29][30][31][32] |

| Titanium dioxide | Sol-gel; chemical vapor deposition; template-assisted | Mortars, concrete | Abrasion resistance; Acceleration on cement hydration; Increased durability; Mechanical improvement; Self-cleaning | [27][33][34] |

| Glass | Anti-fogging; Fouling resistance; Self-cleaning | [35] | ||

| Paints, coatings | Antimicrobial; Anti-pollution; Air-purifying surfaces; Coolant; Hydrophobic; UV resistance | [36][37] | ||

| Calcium hydroxide and alkoxides | Colloidal; microemulsion; micelle-assisted; solvothermal reaction; sol-gel | Wall paintings | Biocidal activity; De-acidification; Protection of cultural heritage | [38][39][40][41][42][43][44] |

| Limestone | ||||

| Lime-based mortars | ||||

| Renders and plaster | [45][46] | |||

| Cellulose-based materials (canvas/wood) | [47] | |||

| Magnesium or barium hydroxides | Colloidal; sol solutions | Wall paintings, Lime-based mortars |

Biocidal activity; Protection of cultural heritage | [48][49] |

| Nanoclay | Mechanical milling | Mortars, concrete | Mechanical improvement | [50] |

| Carbon nanotubes | Mechanical milling; laser ablation; chemical vapor deposition; template-assisted | Mortars, concrete | Crack prevention; Concrete-to-steel bonding; Decreased porosity; Mechanical improvement; Self-sensing | [17][19][51] |

| Sensors | Health monitoring in construction | [2] | ||

| Solar cells | Electrical conductivity | [52] | ||

| Graphene oxide | Mechanical milling; chemical vapor deposition | Mortars, concrete | Mechanical improvement | [53][54][55][56] |

| Paints, coatings | Biocidal activity; Corrosion inhibition efficiency | [57][58] | ||

| Phase change materials | Sol-gel | Building components, thermal insulation materials, wallboards | Thermal resistance | [59][60][61] |

| Silica aerogel |

Sol-gel | Mortars, concrete, renders | Decreased thermal conductivity | [62][63][64] |

| Blanket | Acoustic insulation; Thermal resistance | [65][66][67] | ||

| Glazing, window | Dispersion of the incident light | [61][68][69][70] | ||

| Nano copper | Colloidal methods | Steel mesh | Corrosion inhibition efficiency; Formability; Weldability | [71] |

| Aluminum oxide | Sol-gel | Asphalt concrete | Increased serviceability | [72] |

| Concrete | Acceleration on cement hydration; Mechanical improvement | [12][21][27] |

2. Impact on Human Health and on the Environment

3. Conclusions

This work intended to address the current concerns, evaluate the sustainability (environmental, social, economic) and viability, and thus contribute to the implementation of regulations on NMs, which are often commercialized and categorized similarly to regular construction materials. Based on an extensive literature review for nanomaterials and European standards for regular building materials, environmental, human health, and economic indicators were proposed as mandatory for nanomaterials to be applied in the construction sector.

A particular focus on toxicity (ecotoxicity and human toxicity), soil impacts (land-use-related impacts / soil quality), and emissions into the air (particulate matter emissions) was identified. The use of these indicators should be considered for nanomaterials such as copper, aluminum oxide, titanium nanoparticles, or carbon nanotubes which have significant levels of toxicity and are widely used in the construction sector.

Regarding the economic indicators, it was concluded that the evaluation of the cost impact throughout the various stages of the whole life cycle is essential, focusing not only on the initial cost but also on optimizing the less economically viable stages. These indicators would be particularly relevant for nanomaterials which are generally incorporated in large quantities (e.g., silica-aerogel in thermal insulation composites) and may cause economic problems during recycling processes. Furthermore, the lack of data on durability and end-of-life processes hinders the applicability on a larger scale of nanomaterials such as carbon nanotubes, iron oxide, and graphene oxide.

These proposed indicators could be a good basis for their integration into a risk assessment framework of nanomaterials to be applied in construction.

Limitations of the proposed indicators can be identified in terms of their applicability to certain nanomaterials, functionalized and designed according to specific applications, presenting different physicochemical properties and thus environmental risks. Although the evaluation of the physicochemical properties of nanomaterials that may affect human health, and aquatic and terrestrial ecotoxicology, has been widely debated, the categorization of a small number of nanomaterial groups was identified, which often resulted in specific tests being waived, creating consistent data gaps.

References

- Hund-Rinke, K.; Nicke, C.; Kühnel, D. Considerations about the Relationship of Nanomaterial’s Physical-Chemical Properties and Aquatic Toxicity for the Purpose of Grouping. TEXTE 102/2017; Umweltbundesamt: Dessau-Roßlau, Germany, 2017.

- Hanus, M.J.; Harris, A.T. Nanotechnology Innovations for the Construction Industry. Prog. Mater. Sci. 2013, 58, 1056–1102.

- Firoozi, A.A.; Naji, M.; Dithinde, M.; Firoozi, A.A. A Review: Influence of Potential Nanomaterials for Civil Engineering Projects. Iran. J. Sci. Technol. 2021, 45, 2057–2068.

- Saleem, H.; Zaidi, S.J.; Alnuaimi, N.A. Recent Advancements in the Nanomaterial Application in Concrete and Its Ecological Impact. Materials 2021, 14, 6387.

- European Chemicals Agency (ECHA). Study of the EU Market for Nanomaterials, Including Substances, Uses, Volumes and Key Operators; European Chemicals Agency (ECHA): Helsinki, Finland, 2022.

- Saeli, M.; Tobaldi, D.M.; Rozman, N.; Škapin, A.S.; Labrincha, J.A.; Pullar, R.C. Photocatalytic Nano-Composite Architectural Lime Mortar for Degradation of Urban Pollutants under Solar and Visible (Interior) Light. Constr. Build. Mater. 2017, 152, 206–213.

- Shakrani, S.A.; Ayob, A.; Rahim, M.A.A. A Review of Nanoclay Applications in the Pervious Concrete Pavement. AIP Conf. Proc. 2017, 1885, 020049.

- Borsoi, G. Nanostructured Lime-Based Materials for the Conservation of Calcareous Substrates. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2017.

- Utsev, T.; Tiza, T.M.; Mogbo, O.; Kumar Singh, S.; Chakravarti, A.; Shaik, N.; Pal Singh, S. Application of Nanomaterials in Civil Engineering. Mater. Today Proc. 2022, 62, 5140–5146.

- Hou, P.-X.; Liu, C.; Cheng, H.-M. Field Emission from Carbon Nanotubes. In Nanomaterials Handbook, 2nd ed.; Gogotsi, Y., Ed.; Series: Advanced Materials and Technologies Series; CRC Press: Boca Raton, FL, USA; Taylor & Francis: New York, NY, USA, 2017; ISBN 9781315371795.

- Giovannelli, A.; Di Maio, D.; Scarpa, F. Industrial-Graded Epoxy Nanocomposites with Mechanically Dispersed Multi-Walled Carbon Nanotubes: Static and Damping Properties. Materials 2017, 10, 1222.

- Ismael, R.; Silva, J.V.; Carmo, R.N.F.; Soldado, E.; Lourenço, C.; Costa, H.; Júlio, E. Influence of Nano-SiO2 and Nano-Al2O3 Additions on Steel-to-Concrete Bonding. Constr. Build. Mater. 2016, 125, 1080–1092.

- Palla, R.; Karade, S.R.; Mishra, G.; Sharma, U.; Singh, L.P. High Strength Sustainable Concrete Using Silica Nanoparticles. Constr. Build. Mater. 2017, 138, 285–295.

- Huang, J.; Wang, Z.; Li, D.; Li, G. Effect of Nano-SiO2/PVA Fiber on Sulfate Resistance of Cement Mortar Containing High-Volume Fly Ash. Nanomaterials 2022, 12, 323.

- Li, G. Properties of High-Volume Fly Ash Concrete Incorporating Nano-SiO2. Cem. Concr. Res. 2004, 34, 1043–1049.

- Saleh, H.M.; El-Saied, F.A.; Salaheldin, T.A.; Hezo, A.A. Macro- and Nanomaterials for Improvement of Mechanical and Physical Properties of Cement Kiln Dust-Based Composite Materials. J. Clean. Prod. 2018, 204, 532–541.

- Varisha; Zaheer, M.M.; Hasan, S.D. Mechanical and Durability Performance of Carbon Nanotubes (CNTs) and Nanosilica (NS) Admixed Cement Mortar. Mater. Today Proc. 2021, 42, 1422–1431.

- Gonzalez, M.; Tighe, S.L.; Hui, K.; Rahman, S.; de Oliveira Lima, A. Evaluation of Freeze/Thaw and Scaling Response of Nanoconcrete for Portland Cement Concrete (PCC) Pavements. Constr. Build. Mater. 2016, 120, 465–472.

- Narasimman, K.; Jassam, T.M.; Velayutham, T.S.; Yaseer, M.M.M.; Ruzaimah, R. The Synergic Influence of Carbon Nanotube and Nanosilica on the Compressive Strength of Lightweight Concrete. J. Build. Eng. 2020, 32, 101719.

- Atmaca, N.; Abbas, M.L.; Atmaca, A. Effects of Nano-Silica on the Gas Permeability, Durability and Mechanical Properties of High-Strength Lightweight Concrete. Constr. Build. Mater. 2017, 147, 17–26.

- Silva, J.V.; Ismael, R.; Carmo, R.N.F.; Lourenço, C.; Soldado, E.; Costa, H.; Júlio, E. Influence of Nano-SiO2 and Nano-Al2O3 Additions on the Shear Strength and the Bending Moment Capacity of RC Beams. Constr. Build. Mater. 2016, 123, 35–46.

- Xu, Y.; Gao, D.; Dong, Q.; Li, M.; Liu, A.; Wang, X.; Wang, S.; Liu, Q. Anticorrosive Behavior of Epoxy Coating Modified with Hydrophobic Nano-Silica on Phosphatized Carbon Steel. Prog. Org. Coat. 2021, 151, 106051.

- Ghasemi, M.; Morteza Marandi, S.; Tahmooresi, M.; Jalalkamali, R.; Author, C.; Kamali, R.J.; Taherzade, R. Modification of Stone Matrix Asphalt with Nano-SiO2. J. Basic Appl. Sci. Res. 2012, 2, 1338–1344.

- Amin, G.M.; Esmail, A. Application of Nano Silica to Improve Self-Healing of Asphalt Mixes. J. Cent. South Univ. 2017, 24, 1019–1026.

- Khoshakhlagh, A.; Nazari, A.; Khalaj, G. Effects of Fe2O3 Nanoparticles on Water Permeability and Strength Assessments of High Strength Self-Compacting Concrete. J. Mater. Sci. Technol. 2012, 28, 73–82.

- Nazari, A.; Riahi, S.; Riahi, S.; Fatemeh Shamekhi, S.; Khademno, A. Benefits of Fe2O3 Nanoparticles in Concrete Mixing Matrix. J. Am. Sci. 2010, 6, 102–106.

- Joshaghani, A.; Balapour, M.; Mashhadian, M.; Ozbakkaloglu, T. Effects of Nano-TiO2, Nano-Al2O3, and Nano-Fe2O3 on Rheology, Mechanical and Durability Properties of Self-Consolidating Concrete (SCC): An Experimental Study. Constr. Build. Mater. 2020, 245, 118444.

- Vipulanandan, C.; Mohammed, A. Smart Cement Modified with Iron Oxide Nanoparticles to Enhance the Piezoresistive Behavior and Compressive Strength for Oil Well Applications. Smart Mater. Struct. 2015, 24, 125020.

- Knetsch, M.L.W.; Koole, L.H. New Strategies in the Development of Antimicrobial Coatings: The Example of Increasing Usage of Silver and Silver Nanoparticles. Polymers 2011, 3, 340–366.

- Guo, L.; Yuan, W.; Lu, Z.; Li, C.M. Polymer/Nanosilver Composite Coatings for Antibacterial Applications. Colloids Surf. A Physicochem. Eng. Asp. 2013, 439, 69–83.

- Cui, J.; Shao, Y.; Zhang, H.; Zhang, H.; Zhu, J. Development of a Novel Silver Ions-Nanosilver Complementary Composite as Antimicrobial Additive for Powder Coating. Chem. Eng. J. 2021, 420, 127633.

- Kumar, A.; Vemula, P.K.; Ajayan, P.M.; John, G. Silver-Nanoparticle-Embedded Antimicrobial Paints Based on Vegetable Oil. Nat. Mater. 2008, 7, 236–241.

- Li, H.; Zhang, M.; Ou, J. Abrasion Resistance of Concrete Containing Nano-Particles for Pavement. Wear 2006, 260, 1262–1266.

- Yu, X.; Kang, S.; Long, X. Compressive Strength of Concrete Reinforced by TiO2 Nanoparticles. AIP Conf. Proc. 2018, 2036, 030006.

- Paz, Y.; Luo, Z.; Rabenberg, L.; Heller, A. Photooxidative Self-Cleaning Transparent Titanium Dioxide Films on Glass. J. Mater. Res. 1995, 10, 2842–2848.

- Allen, N.S.; McIntyre, R.; Kerrod, J.M.; Hill, C.; Edge, M. Photo-Stabilisation and UV Blocking Efficacy of Coated Macro and Nano-Rutile Titanium Dioxide Particles in Paints and Coatings. J. Polym. Environ. 2018, 26, 4243–4257.

- van Broekhuizen, P.; van Broekhuizen, F.; Cornelissen, R.; Reijnders, L. Use of Nanomaterials in the European Construction Industry and Some Occupational Health Aspects Thereof. J. Nanoparticle Res. 2011, 13, 447–462.

- Otero, J.; Starinieri, V.; Charola, A.E. Nanolime for the Consolidation of Lime Mortars: A Comparison of Three Available Products. Constr. Build. Mater. 2018, 181, 394–407.

- Masi, G.; Sassoni, E. Air Lime Mortar Consolidation by Nanolimes and Ammonium Phosphate: Compatibility, Effectiveness and Durability. Constr. Build. Mater. 2021, 299, 123999.

- Normand, L.; Duchêne, S.; Vergès-Belmin, V.; Dandrel, C.; Giovannacci, D.; Nowik, W. Comparative in Situ Study of Nanolime, Ethyl Silicate and Acrylic Resin for Consolidation of Wall Paintings with High Water and Salt Contents at the Chapter Hall of Chartres Cathedral. Int. J. Archit. Herit. 2020, 14, 1120–1133.

- Odgers, D. Nanolime: A Practical Guide to Its Use for Consolidating Weathered Limestone. Historic England Guidance; Liverpool University Press: Liverpool, UK, 2017.

- Baglioni, P.; Chelazzi, D.; Giorgi, R. Nanotechnologies in the Conservation of Cultural Heritage. A Compendium of Materials and Techniques, 1st ed.; Springer: Dordrecht, The Netherlands, 2015; ISBN 978-94-017-9303-2.

- Borsoi, G.; Santos Silva, A.; Menezes, P.; Candeias, A.; Mirão, J. Analytical Characterization of Ancient Mortars from the Archaeological Roman Site of Pisões (Beja, Portugal). Constr. Build. Mater. 2019, 204, 597–608.

- Borsoi, G.; Lubelli, B.; van Hees, R.; Veiga, R.; Santos Silva, A. Evaluation of the Effectiveness and Compatibility of Nanolime Consolidants with Improved Properties. Constr. Build. Mater. 2017, 142, 385–394.

- García-Vera, V.E.; Tenza-Abril, A.J.; Solak, A.M.; Lanzón, M. Calcium Hydroxide Nanoparticles Coatings Applied on Cultural Heritage Materials: Their Influence on Physical Characteristics of Earthen Plasters. Appl. Surf. Sci. 2020, 504, 144195.

- Jang, J.; Matero, F.G. Performance Evaluation of Commercial Nanolime as a Consolidant for Friable Lime-Based Plaster. J. Am. Inst. Conserv. 2018, 57, 95–111.

- Baglioni, P.; Chelazzi, D.; Giorgi, R. Deacidification of Paper, Canvas and Wood. In Nanotechnologies in the Conservation of Cultural Heritage; Springer Netherlands: Dordrecht, The Netherlands, 2015; pp. 117–144.

- Chelazzi, D.; Poggi, G.; Jaidar, Y.; Toccafondi, N.; Giorgi, R.; Baglioni, P. Hydroxide Nanoparticles for Cultural Heritage: Consolidation and Protection of Wall Paintings and Carbonate Materials. J. Colloid. Interface Sci. 2013, 392, 42–49.

- Girginova, P.I.; Galacho, C.; Veiga, R.; Santos Silva, A.; Candeias, A. Study of Mechanical Properties of Alkaline Earth Hydroxide Nanoconsolidants for Lime Mortars. Constr. Build. Mater. 2020, 236, 117520.

- Karozou, A.; Pavlidou, E.; Stefanidou, M. Enhancing Properties of Clay Mortars Using Nano-Additives. Solid State Phenom. 2019, 286, 145–155.

- Hassan, A.; Elkady, H.; Shaaban, I.G. Effect of Adding Carbon Nanotubes on Corrosion Rates and Steel-Concrete Bond. Sci. Rep. 2019, 9, 6285.

- Sharma, S.K.; Ali, K. (Eds.) Solar Cells, 1st ed.; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; ISBN 978-3-030-36353-6.

- Chiranjiakumari Devi, S.; Ahmad Khan, R. Influence of Graphene Oxide on Sulfate Attack and Carbonation of Concrete Containing Recycled Concrete Aggregate. Constr. Build. Mater. 2020, 250, 118883.

- Liu, C.; Huang, X.; Wu, Y.-Y.; Deng, X.; Zheng, Z. The Effect of Graphene Oxide on the Mechanical Properties, Impermeability and Corrosion Resistance of Cement Mortar Containing Mineral Admixtures. Constr. Build. Mater. 2021, 288, 123059.

- Yu, L.; Wu, R. Using Graphene Oxide to Improve the Properties of Ultra-High-Performance Concrete with Fine Recycled Aggregate. Constr. Build. Mater. 2020, 259, 120657.

- Liu, C.; Hunag, X.; Wu, Y.-Y.; Deng, X.; Zheng, Z.; Yang, B. Studies on Mechanical Properties and Durability of Steel Fiber Reinforced Concrete Incorporating Graphene Oxide. Cem. Concr. Compos. 2022, 130, 104508.

- Jena, G.; Anandkumar, B.; Vanithakumari, S.C.; George, R.P.; Philip, J.; Amarendra, G. Graphene Oxide-Chitosan-Silver Composite Coating on Cu-Ni Alloy with Enhanced Anticorrosive and Antibacterial Properties Suitable for Marine Applications. Prog. Org. Coat. 2020, 139, 105444.

- Arun, T.; Verma, S.K.; Panda, P.K.; Joseyphus, R.J.; Jha, E.; Akbari-Fakhrabadi, A.; Sengupta, P.; Ray, D.K.; Benitha, V.S.; Jeyasubramanyan, K.; et al. Facile Synthesized Novel Hybrid Graphene Oxide/Cobalt Ferrite Magnetic Nanoparticles Based Surface Coating Material Inhibit Bacterial Secretion Pathway for Antibacterial Effect. Mater. Sci. Eng. C 2019, 104, 109932.

- Al-Jethelah, M.; Tasnim, S.H.; Mahmud, S.; Dutta, A. Nano-PCM Filled Energy Storage System for Solar-Thermal Applications. Renew. Energy 2018, 126, 137–155.

- Biswas, K.; Lu, J.; Soroushian, P.; Shrestha, S. Combined Experimental and Numerical Evaluation of a Prototype Nano-PCM Enhanced Wallboard. Appl. Energy 2014, 131, 517–529.

- Li, D.; Ma, Y.; Zhang, S.; Yang, R.; Zhang, C.; Liu, C. Photothermal and Energy Performance of an Innovative Roof Based on Silica Aerogel-PCM Glazing Systems. Energy Convers. Manag. 2022, 262, 115567.

- Pedroso, M.; Flores-Colen, I.; Silvestre, J.D.; Gomes, M.G.; Silva, L.; Ilharco, L. Physical, Mechanical, and Microstructural Characterisation of an Innovative Thermal Insulating Render Incorporating Silica Aerogel. Energy Build. 2020, 211, 109793.

- Soares, A.; de Fátima Júlio, M.; Flores-Colen, I.; Ilharco, L.M.; de Brito, J. EN 998-1 Performance Requirements for Thermal Aerogel-Based Renders. Constr. Build. Mater. 2018, 179, 453–460.

- Gomes, M.G.; Flores-Colen, I.; da Silva, F.; Pedroso, M. Thermal Conductivity Measurement of Thermal Insulating Mortars with EPS and Silica Aerogel by Steady-State and Transient Methods. Constr. Build. Mater. 2018, 172, 696–705.

- Talebi, Z.; Soltani, P.; Habibi, N.; Latifi, F. Silica Aerogel/Polyester Blankets for Efficient Sound Absorption in Buildings. Constr. Build. Mater. 2019, 220, 76–89.

- Nocentini, K.; Achard, P.; Biwole, P.; Stipetic, M. Hygro-Thermal Properties of Silica Aerogel Blankets Dried Using Microwave Heating for Building Thermal Insulation. Energy Build. 2018, 158, 14–22.

- Lee, K.-J.; Choe, Y.-J.; Kim, Y.H.; Lee, J.K.; Hwang, H.-J. Fabrication of Silica Aerogel Composite Blankets from an Aqueous Silica Aerogel Slurry. Ceram. Int. 2018, 44, 2204–2208.

- Berardi, U. Development of Glazing Systems with Silica Aerogel. Energy Procedia 2015, 78, 394–399.

- Buratti, C.; Moretti, E. Glazing Systems with Silica Aerogel for Energy Savings in Buildings. Appl. Energy 2012, 98, 396–403.

- Zinzi, M.; Rossi, G.; Anderson, A.M.; Carroll, M.K.; Moretti, E.; Buratti, C. Optical and Visual Experimental Characterization of a Glazing System with Monolithic Silica Aerogel. Solar Energy 2019, 183, 30–39.

- Wang, J.; Zou, Z.; Geng, G. Construction of Superhydrophobic Copper Film on Stainless Steel Mesh by a Simple Liquid Phase Chemical Reduction for Efficient Oil/Water Separation. Appl. Surf. Sci. 2019, 486, 394–404.

- Ali, S.I.A.; Ismail, A.; Karim, M.R.; Yusoff, N.I.; Al-Mansob, R.A.; Aburkaba, E. Performance Evaluation of Al2O3 Nanoparticle-Modified Asphalt Binder. Road Mater. Pavement Des. 2017, 18, 1251–1268.

- Chanda, S.; Bajwa, D.S. A Review of Current Physical Techniques for Dispersion of Cellulose Nanomaterials in Polymer Matrices. Rev. Adv. Mater. Sci. 2021, 60, 325–341.

- Papanikolaou, I.; Ribeiro de Souza, L.; Litina, C.; Al-Tabbaa, A. Investigation of the Dispersion of Multi-Layer Graphene Nanoplatelets in Cement Composites Using Different Superplasticiser Treatments. Constr. Build. Mater. 2021, 293, 123543.

- Ali, R.A.; Kharofa, O.H. The Impact of Nanomaterials on Sustainable Architectural Applications Smart Concrete as a Model. Mater. Today Proc. 2021, 42, 3010–3017.

- Gamal, H.A.; El-Feky, M.S.; Alharbi, Y.R.; Abadel, A.A.; Kohail, M. Enhancement of the Concrete Durability with Hybrid Nano Materials. Sustainability 2021, 13, 1373.

- Kant, R.; Sundriyal, P. Carbon-Based Nanomaterials for Perovskite Solar Cells: A Review. In Carbon Nanostructures; AIP Publishing: Melville, NY, USA, 2021; pp. 1–32.

- Adeleye, A.S.; Conway, J.R.; Garner, K.; Huang, Y.; Su, Y.; Keller, A.A. Engineered Nanomaterials for Water Treatment and Remediation: Costs, Benefits, and Applicability. Chem. Eng. J. 2016, 286, 640–662.

- Ajith, S.; Arumugaprabu, V. Environmental and Occupational Health Hazards of Nanomaterials in Construction Sites. In Handbook of Consumer Nanoproducts; Springer: Singapore, 2021; pp. 1–12.

- Singh, D.; Marrocco, A.; Wohlleben, W.; Park, H.-R.; Diwadkar, A.R.; Himes, B.E.; Lu, Q.; Christiani, D.C.; Demokritou, P. Release of Particulate Matter from Nano-Enabled Building Materials (NEBMs) across Their Lifecycle: Potential Occupational Health and Safety Implications. J. Hazard. Mater. 2022, 422, 126771.

- Santhosh, G.; Nayaka, G.P. Nanoparticles in Construction Industry and Their Toxicity. In Ecological and Health Effects of Building Materials; Springer International Publishing: Cham, Switzerland, 2022; pp. 133–146.

- Gkika, D.A.; Vordos, N.; Nolan, J.W.; Mitropoulos, A.C.; Vansant, E.F.; Cool, P.; Braet, J. Price Tag in Nanomaterials? J. Nanoparticle Res. 2017, 19, 177.

- Rodrigues, P.; Silvestre, J.D.; Flores-Colen, I.; Viegas, C.A.; de Brito, J.; Kurad, R.; Demertzi, M. Methodology for the Assessment of the Ecotoxicological Potential of Construction Materials. Materials 2017, 10, 649.

- López-Alonso, M.; Díaz-Soler, B.; Martínez-Rojas, M.; Fito-López, C.; Martínez-Aires, M.D. Management of Occupational Risk Prevention of Nanomaterials Manufactured in Construction Sites in the EU. Int. J. Environ. Res. Public Health 2020, 17, 9211.

- Kurwadkar, S.; Pugh, K.; Gupta, A.; Ingole, S. Nanoparticles in the Environment: Occurrence, Distribution, and Risks. J. Hazard. Toxic Radioact. Waste 2015, 19, 04014039.

- Lowry, G.V.; Gregory, K.B.; Apte, S.C.; Lead, J.R. Transformations of Nanomaterials in the Environment. Environ. Sci. Technol. 2012, 46, 6893–6899.

- Arsenov, D.; Beljin, J.; Jović, D.; Maletić, S.; Borišev, M.; Borišev, I. Nanomaterials as Endorsed Environmental Remediation Tools for the next Generation: Eco-Safety and Sustainability. J. Geochem. Explor. 2023, 253, 107283.

- Corsi, I.; Venditti, I.; Trotta, F.; Punta, C. Environmental Safety of Nanotechnologies: The Eco-Design of Manufactured Nanomaterials for Environmental Remediation. Sci. Total Environ. 2023, 864, 161181.

- Jones, W.; Gibb, A.; Goodier, C.; Bust, P. Managing the Unknown—Addressing the Potential Health Risks of Nanomaterials in the Built Environment. Constr. Manag. Econ. 2017, 35, 122–136.

- Handy, R.D.; Shaw, B.J. Toxic Effects of Nanoparticles and Nanomaterials: Implications for Public Health, Risk Assessment and the Public Perception of Nanotechnology. Health Risk Soc. 2007, 9, 125–144.

- Lee, J.; Mahendra, S.; Alvarez, P.J.J. Nanomaterials in the Construction Industry: A Review of Their Applications and Environmental Health and Safety Considerations. ACS Nano 2010, 4, 3580–3590.

- Hallock, M.F.; Greenley, P.; DiBerardinis, L.; Kallin, D. Potential Risks of Nanomaterials and How to Safely Handle Materials of Uncertain Toxicity. J. Chem. Health Saf. 2009, 16, 16–23.

- Lynch, I.; Weiss, C.; Valsami-Jones, E. A Strategy for Grouping of Nanomaterials Based on Key Physico-Chemical Descriptors as a Basis for Safer-by-Design NMs. Nano Today 2014, 9, 266–270.

- Ganguly, P.; Breen, A.; Pillai, S.C. Toxicity of Nanomaterials: Exposure, Pathways, Assessment, and Recent Advances. ACS Biomater. Sci. Eng. 2018, 4, 2237–2275.

- Wigger, H.; Kägi, R.; Wiesner, M.; Nowack, B. Exposure and Possible Risks of Engineered Nanomaterials in the Environment—Current Knowledge and Directions for the Future. Rev. Geophys. 2020, 58.

- Keller, A.A.; Lazareva, A. Predicted Releases of Engineered Nanomaterials: From Global to Regional to Local. Environ. Sci. Technol. Lett. 2014, 1, 65–70.

- Gottschalk, F.; Sun, T.; Nowack, B. Environmental Concentrations of Engineered Nanomaterials: Review of Modeling and Analytical Studies. Environ. Pollut. 2013, 181, 287–300.

- Hincapié, I.; Caballero-Guzman, A.; Hiltbrunner, D.; Nowack, B. Use of Engineered Nanomaterials in the Construction Industry with Specific Emphasis on Paints and Their Flows in Construction and Demolition Waste in Switzerland. Waste Manag. 2015, 43, 398–406.

- OECD. Nanomaterials in Waste Streams: Current Knowledge on Risks and Impacts; OECD Publishing: Paris, France, 2016; ISBN 9789264240612.

- EUON (European Union Observatory for Nanomaterials). How Nanomaterials Change in the Environment. Available online: https://euon.echa.europa.eu/how-nanomaterials-change-in-the-environment (accessed on 2 January 2023).

- Ray, P.C.; Yu, H.; Fu, P.P. Toxicity and Environmental Risks of Nanomaterials: Challenges and Future Needs. J. Environ. Sci. Health Part C 2009, 27, 1–35.

- Vareda, J.P.; García-González, C.A.; Valente, A.J.M.; Simón-Vázquez, R.; Stipetic, M.; Durães, L. Insights on Toxicity, Safe Handling and Disposal of Silica Aerogels and Amorphous Nanoparticles. Environ. Sci. Nano 2021, 8, 1177–1195.

- Rücker, C.; Kümmerer, K. Environmental Chemistry of Organosiloxanes. Chem. Rev. 2015, 115, 466–524.

- Karatum, O.; Bhuiya, M.M.H.; Carroll, M.K.; Anderson, A.M.; Plata, D.L. Life Cycle Assessment of Aerogel Manufacture on Small and Large Scales: Weighing the Use of Advanced Materials in Oil Spill Remediation. J. Ind. Ecol. 2018, 22, 1365–1377.

- Arvidsson, R.; Molander, S.; Sandén, B.A. Particle Flow Analysis. J. Ind. Ecol. 2012, 16, 343–351.

- Buchman, J.T.; Hudson-Smith, N.V.; Landy, K.M.; Haynes, C.L. Understanding Nanoparticle Toxicity Mechanisms to Inform Redesign Strategies to Reduce Environmental Impact. Acc. Chem. Res. 2019, 52, 1632–1642.

- Gupta, D.; Boora, A.; Thakur, A.; Gupta, T.K. Green and Sustainable Synthesis of Nanomaterials: Recent Advancements and Limitations. Environ. Res. 2023, 231, 116316.