Advanced nanomaterials (NMs) have been widely used in several sectors, from medicine to electronics, aerospace, biotechnology, textiles, agriculture, and, most importantly, in the construction sector. Over the past two decades, the application of nanostructured materials in construction, such as concrete, paint, coatings, glass, renders, plasters, thermal insulation, steel, and even sensors, has become increasingly prevalent. However, previous studies and reports have raised concerns about the ecotoxicity and long-term impact of nanomaterials on human health and the environment. National and international legislation and regulations are struggling to keep up with the rapid development of nanomaterials, taking into account their unique characteristics and essential requirements for application and commercialization. This paper, based on existing standards for conventional materials and bibliometric networks of papers focused on nanomaterials, conducts a critical review and proposes relevant indicators for the application of nanomaterials in the construction sector. These indicators should be mandatory and are divided into environmental, human health, and economic perspectives, providing a risk assessment framework for applying nanomaterial-based constructive solutions oriented to environmental, social, and economic sustainability.

- nanomaterials

- environment

- human health

- economic

1. Overview

| Nanomaterial | Synthesis or Production Method | Applications | Functionality/Improvement | References |

|---|---|---|---|---|

| Nanosilica | Sol-gel | Mortars, concrete | Abrasion resistance; Acceleration on cement hydration; Concrete-to-steel bonding; Improved freeze–thaw resistance; Mechanical improvement; Pozzolanic activity; Paste–aggregate bonding; Permeability reduction | [33,34,35,36,37,38,39,40,41,42] |

| Coatings | Corrosion inhibition efficiency | [43] | ||

| Roads, footpaths | Mechanical improvement | [44,45] | ||

| Iron oxide | Mechanical milling; electro explosion; laser ablation; sol-gel; atomic condensation; template-assisted | Mortars, concrete | Electrical conductivity; Enhanced ductility; Mechanical improvement; Piezoresistive property; Permeability reduction; Self-sensing | [46,47,48,49] |

| Nanosilver | Electro-explosion | Paints, coatings | Biocidal activity | [50,51,52,53] |

| Titanium dioxide | Sol-gel; chemical vapor deposition; template-assisted | Mortars, concrete | Abrasion resistance; Acceleration on cement hydration; Increased durability; Mechanical improvement; Self-cleaning | [48,54,55] |

| Glass | Anti-fogging; Fouling resistance; Self-cleaning | [56] | ||

| Paints, coatings | Antimicrobial; Anti-pollution; Air-purifying surfaces; Coolant; Hydrophobic; UV resistance | [57,58] | ||

| Calcium hydroxide and alkoxides | Colloidal; microemulsion; micelle-assisted; solvothermal reaction; sol-gel | Wall paintings | Biocidal activity; De-acidification; Protection of cultural heritage | [59,60,61,62,63,64,65] |

| Limestone | ||||

| Lime-based mortars | ||||

| Renders and plaster | [66,67] | |||

| Cellulose-based materials (canvas/wood) | [68] | |||

| Magnesium or barium hydroxides | Colloidal; sol solutions | Wall paintings, Lime-based mortars |

Biocidal activity; Protection of cultural heritage | [69,70] |

| Nanoclay | Mechanical milling | Mortars, concrete | Mechanical improvement | [71] |

| Carbon nanotubes | Mechanical milling; laser ablation; chemical vapor deposition; template-assisted | Mortars, concrete | Crack prevention; Concrete-to-steel bonding; Decreased porosity; Mechanical improvement; Self-sensing | [38,40,72] |

| Sensors | Health monitoring in construction | [16] | ||

| Solar cells | Electrical conductivity | [73] | ||

| Graphene oxide | Mechanical milling; chemical vapor deposition | Mortars, concrete | Mechanical improvement | [74,75,76,77] |

| Paints, coatings | Biocidal activity; Corrosion inhibition efficiency | [78,79] | ||

| Phase change materials | Sol-gel | Building components, thermal insulation materials, wallboards | Thermal resistance | [80,81,82] |

| Silica aerogel |

Sol-gel | Mortars, concrete, renders | Decreased thermal conductivity | [83,84,85] |

| Blanket | Acoustic insulation; Thermal resistance | [86,87,88] | ||

| Glazing, window | Dispersion of the incident light | [82,89,90,91] | ||

| Nano copper | Colloidal methods | Steel mesh | Corrosion inhibition efficiency; Formability; Weldability | [92] |

| Aluminum oxide | Sol-gel | Asphalt concrete | Increased serviceability | [93] |

| Concrete | Acceleration on cement hydration; Mechanical improvement | [33,42,48] |

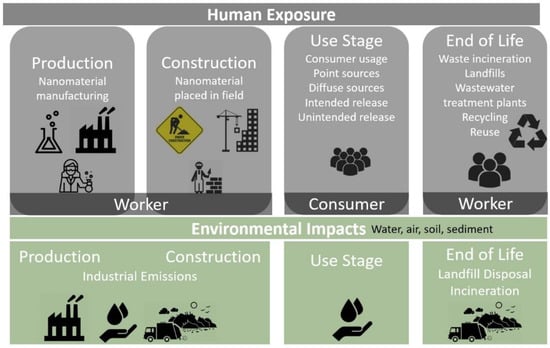

2. Impact on Human Health and on the Environment

3. Conclusions

This work intended to address the current concerns, evaluate the sustainability (environmental, social, economic) and viability, and thus contribute to the implementation of regulations on NMs, which are often commercialized and categorized similarly to regular construction materials. Based on an extensive literature review for nanomaterials and European standards for regular building materials, environmental, human health, and economic indicators were proposed as mandatory for nanomaterials to be applied in the construction sector.

A particular focus on toxicity (ecotoxicity and human toxicity), soil impacts (land-use-related impacts / soil quality), and emissions into the air (particulate matter emissions) was identified. The use of these indicators should be considered for nanomaterials such as copper, aluminum oxide, titanium nanoparticles, or carbon nanotubes which have significant levels of toxicity and are widely used in the construction sector.

Regarding the economic indicators, it was concluded that the evaluation of the cost impact throughout the various stages of the whole life cycle is essential, focusing not only on the initial cost but also on optimizing the less economically viable stages. These indicators would be particularly relevant for nanomaterials which are generally incorporated in large quantities (e.g., silica-aerogel in thermal insulation composites) and may cause economic problems during recycling processes. Furthermore, the lack of data on durability and end-of-life processes hinders the applicability on a larger scale of nanomaterials such as carbon nanotubes, iron oxide, and graphene oxide.

These proposed indicators could be a good basis for their integration into a risk assessment framework of nanomaterials to be applied in construction.

Limitations of the proposed indicators can be identified in terms of their applicability to certain nanomaterials, functionalized and designed according to specific applications, presenting different physicochemical properties and thus environmental risks. Although the evaluation of the physicochemical properties of nanomaterials that may affect human health, and aquatic and terrestrial ecotoxicology, has been widely debated, the categorization of a small number of nanomaterial groups was identified, which often resulted in specific tests being waived, creating consistent data gaps.

This entry is adapted from the peer-reviewed paper 10.3390/app132312896