Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | YUSUF ZIYA ERDIL | -- | 4617 | 2023-11-27 06:56:47 | | | |

| 2 | Jason Zhu | Meta information modification | 4642 | 2023-11-28 02:31:54 | | | | |

| 3 | Jason Zhu | + 38 word(s) | 4680 | 2023-12-29 06:37:40 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Liu, Y.; Hu, W.; Kasal, A.; Erdil, Y.Z. Biomechanics Applied in Ergonomic Furniture Design. Encyclopedia. Available online: https://encyclopedia.pub/entry/52078 (accessed on 15 January 2026).

Liu Y, Hu W, Kasal A, Erdil YZ. Biomechanics Applied in Ergonomic Furniture Design. Encyclopedia. Available at: https://encyclopedia.pub/entry/52078. Accessed January 15, 2026.

Liu, Yan, Wengang Hu, Ali Kasal, Yusuf Ziya Erdil. "Biomechanics Applied in Ergonomic Furniture Design" Encyclopedia, https://encyclopedia.pub/entry/52078 (accessed January 15, 2026).

Liu, Y., Hu, W., Kasal, A., & Erdil, Y.Z. (2023, November 27). Biomechanics Applied in Ergonomic Furniture Design. In Encyclopedia. https://encyclopedia.pub/entry/52078

Liu, Yan, et al. "Biomechanics Applied in Ergonomic Furniture Design." Encyclopedia. Web. 27 November, 2023.

Copy Citation

Furniture as a functional object must satisfy both artistic and scientific requirements. In particular, ergonomic factors are very important in furniture design in terms of human health and productivity. To make furniture designs at the ideal intersection of science and art, it is necessary to approach furniture design with a scientific systematic.

furniture

biomechanics

ergonomics

1. Introduction

Furniture occupies an important place in today’s consumer culture because it satisfies both the physiological and psychological needs of people. The history of woodworking and furniture is intertwined with the development of civilization. From the ceremonial chair of Tutankhamun to the rococo armchair and from the Louis XV center table to the postmodern Carlton bookcase, the furniture used homes has consistently reflected the aspirations, fashions, and technology of its time. Human beings have been utilizing furniture since ancient times in order to address basic needs, such as sitting, lying, eating, etc.

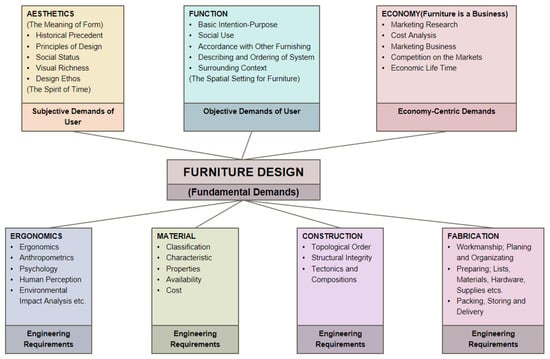

There are three key design elements to consider when creating any kind of furniture. The first is functional design, which involves determining the intended function of furniture and identifying the primary benefits it is expected to provide (Figure 1) [1]. Aesthetic design, on the other hand, focuses on the artistic aspects of furniture design, encompassing features such as form, texture, color, and shape, while taking into consideration the influence of relevant cultures or fashion trends, as well as the demands of consumers [2][3][4][5]. Engineering design, which is the last key element of design, is the process of determining the most appropriate ergonomic criteria, materials, construction techniques, and manufacturing technologies [6][7][8][9][10][11][12].

Figure 1. Considerations that affect furniture design.

Ergonomics is a crucial engineering factor that affects furniture design and has a significant impact on human health and productivity. Ergonomics can be defined as the discipline of studying the design of working and living environments in accordance with human characteristics. The human body has certain physical limitations in the structural sense. Products designed for use interact with the human body under certain conditions during use. This interaction is especially present in the form of one-to-one in seating furniture. In other words, various parts of the human body and some parts of the seating furniture are in contact during the sitting action. When using a piece of furniture, it is important to ensure that the physical dimensions of the user and the product are compatible with each other. This compatibility can only be achieved by understanding the physical characteristics of the human body. To create ergonomic furniture, it is necessary to recognize the anthropometric dimensions, anatomical properties, and the biomechanical structure of the human body. Furniture that does not comply with human anthropometry and anatomical structure is uncomfortable and can cause long-term health problems. The ergonomics of furniture play a crucial role in its suitability for the human body’s physical structure.

Biomechanics is often defined as the application of mechanical principles to the study of living organisms [13][14]. In the early 1970s, the term biomechanics was adopted by scientists worldwide to refer to the study of the mechanics of living organs.

2. Biomechanics Utilized in Different Types of Furniture

To obtain a comprehensive understanding of the biomechanics used in furniture design, it is necessary to characterize the typical studies investigating the use of biomechanics. The following is a summary of typical studies on the application of biomechanics in furniture according to the type of furniture, classified as common furniture, special furniture, and transportation vehicle seats.

2.1. Common Furniture

Seating furniture is a commonly used and highly interactive type of furniture in daily life. This interaction is typically experienced on a one-to-one basis with the furniture. Therefore, the application of biomechanics in furniture design is mainly focused on seating furniture. Many efforts have been made to improve the anthropometry and ergonomics of seating furniture from the perspective of human–furniture interactions to improve the comfort of sitting and human health [15]. The subjective evaluation of the user can only provide qualitative information. Analyzing the human–seat interface and understanding the influence of body weight distribution on seat comfort are beneficial for ergonomic and functional seat design [16]. A method for measuring the pressure distribution on the contact surface is one of the most widely used means to analyze the biomechanics of human sitting from an objective point of view [17]. The design of the seat support can decrease the user’s muscle fatigue level during extended use, suggesting that biomechanical analysis of the subject can account for the level of comfort experienced. [18]. A study showed that the most important design parameter affecting seat comfort is the backrest angle and that the inclination of the seat pan and the friction coefficient have a complex combination of effects on muscle activity and spinal joint forces [15][19][20][21][22]. Increasing the backrest angle from 90° to 105° decreases the reaction forces between L5 and the sacrum. As a result, muscle activation is significantly reduced, which is an important factor in increasing the overall comfort value [15][22][23]. This also showed that women are more suitable than men to use lightweight armchairs. A synchronized seat significantly reduces lumbar lordosis when the backrest is tilted [19]. However, continuous lordosis sitting is more detrimental to lumbar spine health than anterior lordosis sitting and may lead to cumulative damage to the soft tissues of the spine [15][24]. Similarly, studies have shown a linear relationship (or correlation) between upholstery thickness and seat comfort [16]. To obtain more qualitative information about what is happening inside the participant’s body, Mahantesh et al. [25] conducted human digital modeling and rapid upper limb assessment (RULA) analysis of office chairs, with the aim of improving the safety of office seating and improving the user’s physical health and well-being at work. However, sitting comfortably is not the same as sitting healthily, and sitting at a computer for long periods can lead to static loading on the body [26]. Therefore, by monitoring posture, muscle activity, and spinal contraction in women typing on an office chair with armrests and an exercise ball, it was found that the advantages of the body load sitting on an exercise ball may not outweigh the disadvantages [27].

Furthermore, researchers with expertise in biomechanics have examined common household furniture to better understand its impact in daily life. Lifting a child into or out of a motorized seat, bathtub, crib, infant carrier, and highchair has been reported to be a stressful activity for mothers [28][29]. Therefore, when designing furniture for infants and toddlers, it is important to consider not only the suitability for infants and toddlers but also the health and comfort of their caregivers. One researcher analyzed the lumbar joint reaction forces and muscle activation in mothers as they lifted their babies out of the baby cribs designed with varying bed heights. The study established a milestone for the implementation of computer-aided ergonomic methods in furniture design [30]. In addition, the team evaluated the musculoskeletal stress levels associated with the use of two different types of kitchen furniture cabinets [31]. The results showed that kitchen base cabinets with drawers were more ergonomic than kitchen base cabinets with doors.

As an important group in the world, the physical health and comfort of students while studying has also received much scientific attention. Based on the RULA, it was found that most preschool students experience mismatch between the anthropometric dimensions of the students and the dimensions of the chair and desk [32][33]. This issue is present in primary and secondary schools as well as universities. The primary reason for this is that the furniture provided is largely modular and the classroom areas are limited, leading to a considerable decrease in overall comfort and functionality [34][35]. Therefore, some researchers aim to find the ideal design parameter dimensions of student desks and chairs based on relevant anthropometric information and considering the biomechanics of students in the sitting position and the design of relevant desks and chairs [36]. The proper design of desks and chairs based on ergonomics increases efficiency, promotes the quality of education, leads to correct posture in students, and reduces the risk of musculoskeletal disorders [37].

Most of the studies above analyze and examine the biomechanics of common furniture from a comfort-oriented perspective, which is advantageous for designing ergonomic and practical furniture. Nevertheless, much of the research still concentrates on seating design. Furniture, in fact, has a vast range of applications, and biomechanics can have broad applications in the furniture design procedure. In future research, biomechanics can be conducted to study the human–furniture interactions of various other pieces of furniture, including tables and beds. Previous scientific studies have mainly examined the biomechanics of static postures during use. However, a biomechanical approach that analyzes dynamic movements in relation to the actions performed during use is necessary for a comprehensive understanding.

2.2. Special Furniture

Approximately 1% of the world’s population uses wheelchairs [38]. A wheelchair is a type of specialized furniture product for people with physical disabilities that is used for mobility, social participation, and healthy living. For manual wheelchair users, maneuvers such as turning, going uphill, and passing curbs are difficult, and they use their upper extremities for prolonged periods, putting them at risk of injury from upper extremity use [39][40][41]. Therefore, the primary goal of incorporating biomechanical principles in the design of specialized furniture, such as wheelchairs, is to mitigate the risk of physical harm to users and enable them to independently perform daily activities. Differences between surfaces highlighted the importance of assessing wheelchair propulsion capabilities on a range of surfaces through a kinetic analysis of manual wheelchair propulsion during activation on selected indoor and outdoor surfaces [40]. Wearable sensors were installed on the wheelchair to track the wheelchair user throughout their weekly motion. Based on the monitoring results, the efficiency of wheelchair use can be optimized in future wheelchair design in terms of wheelchair–user interaction principles [41][42]. Dubowsky et al. [43] validated an upper extremity model for manual wheelchair users to reduce upper extremity injuries during use. The use of electric drives has become a new development in personal transportation. The wheelchair with cam-thread drive (WCD) is a new type of electric wheelchair. Field tests, laboratory measurements, and biomechanical analysis of the WCD and comparison with a typical wheelchair with push-rim drive (WPD) revealed that the WCD is a sustainable form of personal transportation that requires less human biological force to propel and exerts less stress on the human motor system, and therefore, can be used for rehabilitation [44].

The world’s population is aging at an irreversible rate. For most elderly people, daily activities such as sit-to-stand transitions and walking pose significant challenges for most elderly individuals. Previous commercially available sit-to-stand assistive devices are relatively large and require sufficient upper limb strength for use, making them unsuitable for elderly people with declining physical functions [15][45]. The utilization of biomechanics, such as the abovementioned research on wheelchairs, can reduce upper extremity injuries and help users perform independent behaviors such as sit-to-stand transitions in daily living. To this end, some researchers have developed active walker systems [46], user-adaptive support systems [47], etc. The parameters of this user adaptive support system are determined according to the user’s physical dimensions and disability and illustrate the effectiveness of the method of adjusting the position of the handrail, the height of the bed and the position of the feet. According to the survey, falls are the leading cause of accidental injury and death among older adults. Nearly 24% of falls in the elderly are caused by falling out of bed. According to biomechanical evaluation, protective floor mats can reduce the risk of injury from falls bed to some extent [48][49]. The increase in the elderly population has led to a significant increase in the number of nursing homes and an increase in the demand for caregivers. Wearable lower extremity assistive devices and stretchers with assistive features aim to reduce the physical burden on caregivers and family members of patients [50][51].

As stated above, the primary objective of using specialized furniture in biomechanics is to aid users in reducing upper limb injuries and facilitating their fundamental daily activities in a secure setting [26]. At the same time, it reduces the physical burden on caregivers when caring for the patient. The use of biomechanics in the design of special furniture is relatively mature. In future research, the design of specialized furniture can simultaneously focus on enhancing its practicality and aesthetic value at the same time. In addition, further studies should explore the design of furniture that enhances the indoor mobility and quality of life for wheelchair users from a biomechanical perspective.

2.3. Transportation Vehicle Seats

In the automotive industry, customer demand for vehicle performance and comfort is increasing. As a result, car manufacturers consider car seats or interior comfort as an important selling point and as a way to differentiate themselves from their competitors [52][53]. However, these seats are currently designed mainly based on user experience, traditional knowledge, and extensive, time-consuming, and expensive prototyping and experimental or field testing [54][55]. For example, experimental tests are first conducted to obtain a fatigue analysis view. Road tests are then conducted using seat pressure distribution (SPD) and electromyography (EMG) to elaborate the fatigue process [56]. Comfort in mass-produced vehicles can be measured using digital human models (DHMs) [54]. The advent of the human hip finite element (FE) model enables the prediction of the pressure distribution between the human body and the seat surface through its detailed and realistic geometric description [52]. Biomechanical methods have emerged to analyze fatigue more accurately and to design more comfortable car seats. Grujicic et al. [53] utilized musculoskeletal modeling and simulation techniques to investigate the primary factors contributing to fatigue in long-distance truck drivers. The study finds that interaction factors between the driver and the car seat, including the backrest angle, coefficient of friction at the interface between the body and the car seat, longitudinal track position, and availability of lumbar support, impact both driver fatigue and comfort [53][56]. The use of biomechanical knowledge is more scientific and objective than subjective comfort assessment and less costly and more efficient than experimental testing. In addition, torso posture and biomechanical logic should be introduced into seat design and evaluation, incorporating seat geometry into comfort, safety and ergonomic design solutions. As the market shifts from human driven to autonomous vehicles, the need to account for postural variation in seat design increases [57][58][59].

As in the automotive seat industry, comfort has been an important factor for passengers in choosing an airline and the aircraft for many years, and it makes sense to design a comfortable interior and seat to attract passengers. Some studies show that a seat pan design using spring–foam technology can be lighter and more comfortable than conventional foam cushion materials [55][60]. Comfort is established by six factors: anthropometry, climate, sound, vibration, illumination, and smell. “Anthropometry” was the most important factor influencing comfort, meaning that the legroom and seat width are inadequate for the size of different parts of the human body [61]. The seat and inclination need attention in relation to anthropometrics [62]. Simulation of passengers’ perceived comfort at different launch angles is one of the approaches. The results of such analysis could be explained by embedding a discomfort triggered adjustment (DTA) process in existing comfort models to address the cycle of discomfort development, the trigger, and the friction between movement desire and the practical constraints until the joy of comfort [63]. Some studies have found that staggered seats were significantly better in terms of comfort and privacy based on short-term evaluations [64][65]. In summary, research on aircraft seats is mainly carried out by means of experimental simulations, which are costly, and the object of their study is mainly the comfort of the seats.

In conclusion, the above research clearly indicates that there is a lack of research performed on the biomechanics of furniture design, with the main focus being on comfort, human health, and ergonomics for seating furniture. When designing special furniture, reducing upper limb injuries, and ensuring applicability are the primary design considerations. Future research can consider the conceptual design and styling of furniture from the perspective of human–furniture interaction using biomechanical knowledge.

3. Biomechanical Analysis and Testing Methods

According to the literature review and summary, it can be inferred that research on human biomechanics concentrates on sports biomechanics, musculoskeletal biomechanics, and ergonomic biomechanics [49][66][67]. Commonly used research methods and tools include mechanical models, computer-aided ergonomics, experimental testing, and other methods.

3.1. Mechanical Models

At present, most research on human movement biomechanics is based on the establishment of simplified mathematical–mechanical models, or the establishment of complex multibody dynamics models, including multiple parts of the human skeleton and muscle [68][69]. What to include in a model depends on the intended use of the model [70]. The simplest biomechanical motion models typically reduce the human body to a mass and do not take into account its own rotation and deformation. For example, the simplest model used to study walking is the inverted pendulum [71]. For complex motions, mathematical models are simplified compared to the real body, but they generate a formidable number of equations [72]. According to GB/T 17245 [73]; a regression equation can be established to predict the body segment mass and center of mass, expressed as Equation (1):

𝑌=𝐵0+𝐵1𝑋1+𝐵2𝑋2

is the regression coefficient of the body height.

GB/T 17245 specifies the coefficients of the binary regression equation coefficients for calculating the body segment mass, the center of the mass position, and the overall center of the mass position of the human body based on body weight and height. A model for calculating the center of the mass position of the human body based on the mass of the body segments can be established. According to theoretical mechanics, if the object consists of several parts, and its i-th part mass is mi and the center of mass is (xi, yi, zi), the center of mass of the object (xc, yc, zc) is shown in Equation (2):

According to Equation (2), the equation for calculating the center of mass of the human body based on the geometric model of the body center of mass calculation can be expressed as Equation (3):

where n is the number of human body segments divided by Equation (3). The human body mass center coordinates can be obtained.

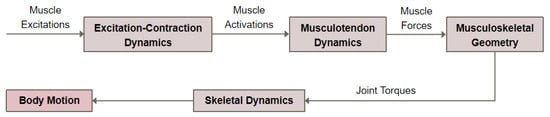

The model of the human center of mass provides a basic description of the principles governing human movement, enabling people to comprehend the trajectory, velocity, acceleration, and other factors associated with motion [68]. Human motion biomechanics problems are more analyzed by a multi-rigid body model. According to the actual needs, a multi-rigid body model can be a simple local joint model or a complex whole body model [74]. As shown in Figure 5 [70][75], a more complete model for human motion simulation should include: (1) a skeleton model; (2) a muscle path model; (3) a musculotendon actuation model; (4) a muscle excitation–contraction coupling model; and (5) a motor task goal model.

Figure 5. Diagram components included in a multi-joint model of movement.

- (1)

-

Skeleton model

If the human musculoskeletal system under consideration has n degrees of freedom (DoF) and the corresponding joint angles are generalized displacements, the relationship between the motion and muscle forces in this musculoskeletal system can be expressed by the following matrix Equation (4):

However, Equation (4) is often redundant because the number of muscles with unknown contractile forces is more than the number of equations (m > n). Equation (4) can be simplified so that each degree of freedom corresponds to a muscle moment, yielding an equation in the form of Equation (5):

- (2)

-

Muscle path model

The position of the start and end points of a muscle affects the force arm that the muscle exerts across the joint. The multiplication of this force arm by the muscle force is the magnitude of that muscle’s contribution to the combined moment that produces the joint motion. As shown in Equation (4), the force arm is usually a function of the angle of the joint.

- (3)

-

Musculotendon actuation model

The current widely used Hill-type muscle model can be represented by two differential equations in Equation (6):

- (4)

-

Muscle excitation–contraction coupling model

Muscles cannot be activated or relaxed instantaneously. The delay between muscle excitation (u, which represents the net neural drive) and muscle activation (am) is usually modeled as a first-order process in Equation (8):

Implicit in the formulation of Equation (8) is the assumption that muscle activation relies solely on a single variable u. However, there may be other forms of coupled muscle excitation–contraction models.

- (5)

-

Motor task goal model

Equations (1)–(3) can be combined to form a model of the neuromusculoskeletal system. The inputs to this system are the muscle excitations, and the outputs are the body motions. Measurements of the muscle EMG and body motions can be used to estimate muscle forces during movement. Alternatively, the goal of the motor task can be modeled and used together with dynamic optimization theory to calculate the set of muscle excitations needed for optimal performance.

The above multiphysical model is generally driven by joint torque, and is only suitable for analyzing motion rules. Some mature dynamic analysis software has established a typical musculoskeletal model, which greatly facilitates the user to conduct biomechanical simulation analysis [74][75][76][77][78][79].

3.2. Computer-Aided Ergonomics

Due to the complexity of human body systems, simple models often have difficulty explaining complex problems in practical applications. This has led to the development of human biomechanical models in the direction of complexity and detail, with simulation playing an increasingly important role as a necessary means to solve the described complex problems [68]. In recent years, computer modeling and simulation technology have developed to a new high level, and this approach can provide a more quantitative explanation of how the neuromuscular and musculoskeletal systems interact to produce motion. In particular, simulations of standing, walking, jumping, and pedaling can provide insight into how the leg muscles work together in each task to achieve a common goal [26][70]. The primary simulation software utilized comprises LifeMOD, OpenSim, AnyBody Technology, VIMS, SIMM, and ANSYS finite element software [74][75][76][77][78][79][80]. Among them, the skeletal muscle model of VIMS software cannot define the muscle unit that generates the key dynamic force, so it is mainly used for kinematic analysis. SIMM software is mainly used to study joint kinematics and the characteristics of muscle forces and moments, and it can represent the kinematic characteristics of joints, but the kinematic model of joints is not directly available in SIMM. LifeMOD, Opensim, and AnyBody Technology are the three most widely used human simulation software programs.

LifeMOD is a common simulation software for gait analysis [81][82][83], which can study the changes in human biomechanical parameters and the coupling between human and mechanical systems [84][85] under different working environments [81][86][87][88].

Opensim has fine control over muscle morphological parameters, low computational error, and fast computation [89][90], and it is used in many other fields, such as walking dynamics analysis [91], motion performance studies [92][93][94][95], surgical procedure simulation [87][96], and medical device design [82][83][89][97].

AnyBody Technology is the most complex but most functional muscle and bone modeling software tool currently available [43][44][45][70][92][98], which can customize the parameters related to the human body model and directly invoke the human body model from the model database. It can model the environment in the simulation and interface with the presence of other software (such as SolidWorks, ANSYS, Abaqus, etc.) [99][100]. It is widely used in research fields, such as clinical medicine [43][101][102], automotive industrial design [53], aerospace, rehabilitation medical engineering [87][103], product design [19][20][21][31], work environment design [30][44], and sports and equipment [104][105][106].

In addition to the abovementioned simulation software, software such as MATLAB and FEM are used in furniture design [51][52][93]. The main technical challenges faced in current human biomechanics-based modeling and simulation research are (1) how to accurately calculate joint muscle forces and accuracy verification problems; (2) kinetic parameters in human motion derived from kinematic data; and (3) neuromuscular multistructural hierarchy and multiscale control of motion biomechanics modeling. In the future, the following directions are likely to be the key directions for sports biomechanics modeling and simulation research: (1) Personalized musculoskeletal modeling and analysis—with the rapid development of new sensor technologies, the research of personalized musculoskeletal modeling means and analysis and evaluation methods that reflect individual differences will become a trend. (2) Neuromuscular control simulation—with the continuous development of computer technology, the study of neuromuscular model control based on deep learning and reinforcement learning strategies is expected to become a research hot topic in the crossover field.

3.3. Experimental Test Methods

Compared to the mechanical model and computer-aided ergonomics mentioned above, experimental testing of human biomechanics is more mature. Researchers have developed test methods such as kinematic parameter monitoring [27][39][43][47][99][100][105][106], physiological parameter monitoring [22][27][38][41][44][56][106], and kinetic parameter monitoring [16][18][39][44][46][56][103][104][105] by combining advanced experimental techniques from computer, medical, biological, and mechanical disciplines to study the motion characteristics of the human body.

At present, the primary technical challenges in human biomechanics for the experimental testing of furniture design include (1) the challenge of detecting the internal motion of the skeletal system, and (2) the challenge of obtaining precise measurements across different time and space scales. In the foreseeable future, the research and development of intelligent, flexible, biobased electronic measurement instruments and special dynamic test system development will be the key development directions of new test equipment research and development. In terms of testing technology, non-interference-based motion posture recognition based on image or video deep learning models and the inversion of kinetic parameters through kinematic data combined with mechanical models will also be research directions that need to focus on breakthroughs. Additionally, expanding the range of measurable metrics is a crucial aspect of the current experimental sports body testing. For instance, by examining and analyzing kinematic, kinetic, electromyographic, and electrocardiographic parameters together, a more comprehensive understanding of the athletes’ technical, physical, fatigue, and psychological state can be obtained.

Most of the current research combines mechanical models, computer-aided ergonomics, and experimental tests for biomechanical analysis. First, the human motion is simplified and analyzed by the mechanical model. Then, biomechanical simulation software is used to simulate the human–machine coupling model [26]. Finally, the results are verified using experimental tests. As mentioned above, the accuracy of computer-aided ergonomics and experimental testing should be further improved in future research so that biomechanics can be improved and applied to furniture design more often.

References

- Yu, N.; Ouyang, Z.W.; Wang, H.H.; Tao, D.; Jing, L. The effects of smart home interface touch button design features on performance among young and senior users. Int. J. Environ. Res. Public Health 2022, 4, 2391.

- Sang, R.; Yang, F.; Fan, Z. The Effect of Water-Based Primer Pretreatment on the Performance of Water-Based Inkjet Coatings on Wood Surfaces. Coatings 2023, 13, 1649.

- Zhou, C.M.; Li, Z.Y.; Kaner, J.; Leng, C.X. Development of a selection system for the colour of wardrobe furniture. BioResources 2022, 3, 3912.

- Yu, S.L.; Zheng, Q.; Chen, T.Y.; Zhang, H.L.; Chen, X.R. Consumer personality traits vs. their preferences for the characteristics of wood furniture products. BioResources 2023, 4, 7443–7459.

- Jiang, L.L.; Cheung, V.; Westland, S.; Rhodes, P.A.; Shen, L.M.; Xu, L. The impact of color preference on adolescent children’s choice of furniture. Color. Res. Appl. 2020, 4, 754–767.

- Efe, H. Mechanical Behavior Characteristics of Traditional and Alternative Connection Techniques in Modern Furniture Frame Construction Design. Ph.D Thesis, IInstitute of Science and Technology, Karadeniz Technical University, Trabzon, Turkey, 1994.

- Zhao, Z.; Zhang, X.; Lin, Q.; Zhu, N.; Gui, C.; Yong, Q. Development and investigation of a two-component adhesive composedof soybean flour and sugar solution for plywood manufacturing. Wood Mater. Sci. Eng. 2022, 17, 2086067.

- Miao, Y.; Pan, S.; Xu, W. Staple holding strength of furniture frame joints constructed of plywood and solid wood. Forests 2022, 13, 2006.

- Wu, Q.L.; Li, W.B.; Yan, X.X. Effect of microcapsules on mechanical, optical, self-healing and electromagnetic wave absorption in waterborne wood paint coatings. Coatings 2023, 13, 1478.

- Zhu, Y.; Huang, N.; Yan, X. Effect of three kinds of aloe emodin microcapsules prepared by SDBS, OP-10 and TWEEN-80 emulsifiers on antibacterial, optical and mechanical properties of water-based coating for MDF. Coatings 2023, 13, 1477.

- Wang, Y.; Pan, P.; Yan, X. Preparation of chitosan-modified nano-silver solution microcapsules and their effects on antibacterial properties of waterborne coatings. Coatings 2023, 13, 1433.

- Ding, T.T.; Huang, N.; Yan, X. Effect of different emulsifiers on the preparation process of aloe-emodin microcapsules and waterborne coating properties. Coatings 2023, 13, 1355.

- Fung, Y.C.; Skalak, R. Biomechanics: Mechanical properties of living tissues. J. Biomech. Eng. 1981, 103, 231–298.

- Huston, R.L. Fundamentals of Biomechanics; CRC Press: Boca Raton, FL, USA, 2013; pp. 17–20.

- Zhou, C.M.; Huang, T.; Luo, X.; Kaner, J.; Fu, X.M. Recognition and analysis of an age-friendly intelligent sofa design based on skeletal key-points. Int. J. Environ. Res. Public Health 2022, 19, 11522.

- Kasal, A.; Yüksel, M.; Acar, M.; Özcan, C.; Efe, H.; Erdil, Y. Determination of load distribution on a seating surface by using pressure mat for different upholster thickness. In Proceedings of the 4th International Furniture Congress (UMDK 2017), Düzce, Turkey, 19–21 October 2017; pp. 647–651.

- Chao, Y.; Shen, L.M.; Liu, M.P. Mechanical characteristic and analytical model of novel air spring for ergonomic mattress. Mech. Ind. 2021, 22, 37.

- Yüksel, M.; Kasal, A.; Erdil, Y.; Kilic, H.; Özcan, C. Study on single seat armchairs in terms of ergonomics and comfort. In Proceedings of the 4th International Furniture and Decoration Congress, Duzce, Turkey, 7 December 2017.

- Rasmussen, J.; Tørholm, S.; de Zee, M. Computational analysis of the influence of seat pan inclination and friction on muscle activity and spinal joint forces. Int. J. Ind. Erogonom. 2009, 1, 52–57.

- Efe, H.; Kasal, A.; Kilic, H.; Özcan, C. Effect of the critical ergonomics parameters on domestic chairs for comfort using the human based product development software. In Proceedings of the XXVIIth International Conference Research for Furniture Industry, Ankara, Turkey, 21 September 2015.

- Kasal, A.; Yüksel, M.; Kilic, H.; Ergün, M.; Özcan, C. Oturma mobilyası tasarımında bilgisayar destekli ergonomik analiz. Selcuk. Univ. J. Eng. Sci. 2015, 2, 26–44.

- Zhou, C.M.; Huang, T.; Zhang, Z.X.; Wu, Z.H.; Ye, Y.Z.; Cao, Z.Q. Investigation of ageing suitability of sofa backrest angle using EEG and EMG multi-signals. J. For. Eng. 2022, 6, 202–210.

- Yüksel, M.; Erdil, Y.; Kasal, A.; Acar, M. Evaluation of various lightweight armchairs in terms of ergonomics. Innov. Woodwork. Ind. Eng. Des. 2020, 1, 60–67.

- Pynt, J.; Mackey, M.; Higgs, J. Kyphosed seated postures: Extending concepts of postural health beyond the office. J. Occup. Rehabil. 2008, 1, 35–45.

- Mahantesh, M.M.; Rao, K.R.; Mandal, J. Human digital modeling and RULA analysis for an office chair user in computer work environment—A case study in Indian context. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2021; Volume 2316, p. 030013.

- Fang, J.J.; Shen, L.M.; Chen, H. Mechanical properties of TPEE and its influence on pressure distribution of mattress. J. For. Eng. 2021, 05, 191–197.

- Kingma, I.; Van Dieën, J.H. Static and dynamic postural loadings during computer work in females: Sitting on an office chair versus sitting on an exercise ball. Appl. Ergon. 2009, 2, 199–205.

- Vincent, R.; Hocking, C. Factors that might give rise to musculoskeletal disorders when mothers lift children in the home. Physiother. Res. Int. 2013, 2, 81–90.

- Yu, N.; Yu, C.; Li, H.; Li, M. Effects of mattress firmness on infant body pressure distribution. Int. J. Ind. Ergonom. 2021, 83, 103101.

- Kilic, H.; Özcan, C.; Efe, H.; Kasal, A. Computer aided ergonomics in furniture design: Baby crib case study. In Proceedings of the XXVIIITH International Conference Research for Furniture Industry, Poznań, Poland, 22 September 2017.

- Kilic, H.; Özcan, C.; Efe, H.; Kasal, A. Computer aided ergonomics in furniture design: Case study for kitchen bottom cupboards. In Proceedings of the V. International Furniture Congress, Eskişehir, Turkey, 1–4 November 2018.

- Tunay, M.; Melemez, K. An analysis of biomechanical and anthropometric parameters on classroom furniture design. Afr. J Biotechnol. 2008, 7, 1081–1086.

- Godilano, E.C.; Galang, M.K.G.; Ramilo, H.E.O.; Velayo, K.R.F. Design of an ergonomie classroom chair and desk for preschool students of selected public schools in Cabuyao City, Laguna. In Proceedings of the 2018 5th International Conference on Industrial Engineering and Applications (ICIEA), Singapore, 26–28 April 2018; pp. 420–423.

- Pérez-Gosende, P. Anthropometry-based approach for side-mounted desktop chairs design evaluation for university students in Ecuador. In Proceedings of the 2017 IEEE Second Ecuador Technical Chapters Meeting (ETCM), Salinas, Ecuador, 16–20 October 2017; pp. 1–5.

- Naddeo, A.; Califano, R.; Vink, P. The effect of posture, pressure and load distribution on (dis) comfort perceived by students seated on school chairs. Int. J. Interact. Des. Manuf. IJIDeM 2018, 12, 1179–1188.

- Mokarami, H.; Ansari, S.; Cousins, R.; Varmazyar, S. Assessing the ergonomic status of commonly used chairs in Iran’s universities based on combinational equations and anthropometric indices. Work 2022, 71, 1087–1095.

- Ansari, S.; Nikpay, A.; Varmazyar, S. Design and development of an ergonomic chair for students in educational settings. Health Scope 2018, 7, e60531.

- WHO. Assistive Technology. Available online: https://www.who.int/news-room/fact-sheets/detail/assistive-technology (accessed on 24 September 2021).

- Van Drongelen, S.; Van Der Woude, L.H.; Janssen, T.W.; Angenot, E.L.; Chadwick, E.K.; Veeger, D.H. Mechanical load on the upper extremity during wheelchair activities. Arch. Phys. Med. Rehabil. 2005, 6, 1214–1220.

- Koontz, A.M.; Cooper, R.A.; Boninger, M.L.; Yang, Y.; Impink, B.G.; Van Der Woude, L.H. A kinetic analysis of manual wheelchair propulsion during start-up on select indoor and outdoor surfaces. J. Rehabil. Res. Dev. 2005, 4, 447–458.

- Togni, R.; Kilchenmann, A.; Proffe, A.; Mullarkey, J.; Demkó, L.; Taylor, W.R.; Zemp, R. Turning in circles: Understanding manual wheelchair use towards developing User-Friendly steering systems. Front. Bioeng. Biotech. 2022, 10, 831528.

- Lin, Q.; Zhang, X.; Zhu, N.; Kusumah, S.; Umemura, K.; Zhao, Z. Preparation and investigation of an eco-friendly plywoodadhesive composed of sucrose and ammonium polyphosphate. Wood Mater. Sci. Eng. 2022, 17, 2121176.

- Dubowsky, S.R.; Rasmussen, J.; Sisto, S.A.; Langrana, N.A. Validation of a musculoskeletal model of wheelchair propulsion and its application to minimizing shoulder joint forces. J. Biomech. 2008, 14, 2981–2988.

- Gabryelski, J.; Kurczewski, P.; Sydor, M.; Szperling, A.; Torzyński, D.; Zabłocki, M. Development of transport for disabled people on the example of wheelchair propulsion with cam-thread drive. Energies 2021, 23, 8137.

- Yu, N.; Hong, L.; Guo, J. Analysis of upper-limb muscle fatigue in the process of rotary handling. Int. J. Ind. Ergonom. 2021, 83, 103109.

- Chugo, D.; Asawa, T.; Kitamura, T.; Jia, S.; Takase, K. A rehabilitation walker with standing and walking assistance. In Proceedings of the 2008 IEEE/RSJ International Conference on Intelligent Robots and Systems, Nice, France, 22–26 September 2008; pp. 260–265.

- Hirata, Y.; Higuchi, J.I.; Hatsukari, T.; Kosuge, K. Sit-to-stand assist system by using handrail and electric bed moving up and down. In Proceedings of the 2008 2nd IEEE RAS & EMBS International Conference on Biomedical Robotics and Biomechatronics, Scottsdale, AZ, USA, 19–22 October 2008; pp. 187–192.

- Raymond, D.E.; Catena, R.D.; Vaughan, T.R. Biomechanics and injury risk assessment of falls onto protective floor mats. Rehabil. Nurs. 2011, 6, 248–254.

- Li, X.X.; Zhou, B.; Shen, L.M.; Wu, Z.H. Exploring the effect of mattress cushion materials on human-mattress interface temperatures, pre-sleep thermal state and sleep quality. Indoor. Built. Environ. 2021, 5, 650–664.

- Hasegawa, Y.; Muramatsu, M. Wearable lower-limb assistive device for physical load reduction of caregiver on transferring support. In Proceedings of the 2013 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Wollongong, NSW, Australia, 9–12 July 2013; pp. 1027–1032.

- Xiong, Y.; Tang, X.; Shi, C.; Yang, Y. A design of stretcher with auxiliary functions of lateral positioning and transferring for immobilized patients. MATEC Web of Conferences. EDP Sci. 2021, 336, 02014.

- Verver, M.M.; Van Hoof, J.; Oomens, C.W.J.; Wismans, J.S.H.M.; Baaijens, F.P.T. A finite element model of the human buttocks for prediction of seat pressure distributions. Comput. Method. Biomec. 2004, 4, 193–203.

- Grujicic, M.; Pandurangan, B.; Xie, X.; Gramopadhye, A.K.; Wagner, D.; Ozen, M. Musculoskeletal computational analysis of the influence of car-seat design/adjustments on long-distance driving fatigue. Int. J. Ind. Ergonom. 2010, 3, 345–355.

- Reynolds, H.M.; Scataglini, S. Driver comfort and gender inequality measured with DHMs. In Digital Human Modeling and Applied Optimization, Proceedings of the 13th AHFE International Conference on Digital Human Modeling and Applied Optimization, New York, NY, USA, 24–28 July 2022; AHFE: Nice, France, 2022.

- Vink, P.; Lips, D. Sensitivity of the human back and buttocks: The missing link in comfort seat design. Appl. Ergon. 2017, 58, 287–292.

- Michida, N.; Okiyama, H.; Nishikawa, K.; Nouzawa, T. A study of Drivers’ fatigue mechanisms during long hour driving. SAE Trans. 2001, 110, 284–292.

- Reynolds, H.M.; Brodeur, R.; Wehrle, J.H. ERL seat Design-Occupied specifications for the unoccupied deliverable seat. SAE Trans. 2006, 115, 1096–1101.

- Reynolds, H.M.; Paul, G. Systems anthropometry of digital human models for seat design. In Advances in Physical Ergonomics and Human Factors, Proceedings of the AHFE 2017 International Conference on Physical Ergonomics and Human Factors, The Westin Bonaventure Hotel, Los Angeles, CA, USA, 17–21 July 2017; Springer: Cham, Switzerland, 2017.

- Reynolds, H.M. ERL seat design and digital human models. In DHM and Posturography; Scataglini, S., Paul, G., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 125–137.

- Dangal, S.; Smulders, M.; Vink, P. Implementing spring-foam technology to design a lightweight and comfortable aircraft seat-pan. Appl. Ergon. 2021, 91, 103174.

- Anjani, S.; Song, Y.; Hou, T.; Ruiter, I.A.; Vink, P. The effect of 17-inch-wide and 18-inch-wide airplane passenger seats on comfort. Int. J. Ind. Ergonom. 2021, 82, 103097.

- Vink, P.; Vledder, G.; Song, Y.; Herbig, B.; Reichherzer, A.S.; Mansfield, N. Aircraft interior and seat design: Priorities based on passengers' opinions. Int. J. Aviat. Aeronaut. 2022, 9, 3.

- Yao, X.; Ping, Y.; Song, Y.; Vink, P. Sitting Comfort in an Aircraft Seat with Different Seat Inclination Angles. Int. J. Ind. Ergon. 2023, 96, 103470.

- Vink, P.; Anjani, S.; Percuoco, C.; Vos, R.; Vanacore, A. A Staggered Seat is Beneficial for the Flying V Aircraft. In Proceedings of the 21st Congress of the International Ergonomics Association (IEA 2021) Volume III: Sector Based Ergonomics; Springer International Publishing: Cham, Switzerland, 2021; pp. 184–190.

- Liu, Z.; Rotte, T.; Anjani, S.; Vink, P. Seat pitch and comfort of a staggered seat configuration. Work 2021, 68, S151–S159.

- Chao, Y.; Shen, L.M.; Liu, M.P.; Zhang, H.Y. Static characteristics and calculation model of air spring with vertical variable stiffness for mattress. J. For. Eng. 2021, 6, 197–204.

- Qi, Y.; Sun, Y.; Zhou, Z.; Huang, Y.; Li, J.; Liu, G. Response surface optimization based on freeze-thaw cycle pretreatment of poplar wood dyeing effect. Wood Research 2023, 68, 293–305.

- Liu, C.L.; Hao, W.Y.; Huo, B. Advances and challenges in sports biomechanics. Adv. Mech. 2022, 52, 1–41.

- Li, X.X.; Shen, L.M.; Califano, R. The comparative study of thermal comfort and sleep quality for innovative designed mattress in hot weather. Sci. Technol. Build. En. 2020, 5, 643–657.

- Pandy, M.G. Computer modeling and simulation of human movement. Annu. Rev. Biomed. Eng. 2001, 1, 245–273.

- Wagner, D.W.; Reed, M.P.; Rasmussen, J. Assessing the importance of motion dynamics for ergonomic analysis of manual materials handling tasks using the AnyBody modeling system. SAE Trans. 2007, 116, 2092–2101.

- Alexander, R.M.N. Modelling approaches in biomechanics. Proc. R. Soc. Lond. Ser. B. 2003, 1437, 1429–1435.

- GB/T 17245-2004; Inertial Parameters of Adult Human Body. National Standard of the People’s Republic of China: Beijing, China, 2004.

- Liu, Y.S.; Tsay, T.S.; Wang, T.C. Muscles force and joints load simulation of bicycle riding using multibody models. Proc. Eng. 2011, 13, 81–87.

- Cao, E.; Inoue, Y.; Liu, T.; Shibata, K. Analysis of muscle forces in lower limbs based on wearable sensors. In Proceedings of the 2010 IEEE International Conference on Information and Automation, Harbin, China, 20–23 June 2010; pp. 185–190.

- Bandera, C.; Filippi, S.; Motyl, B. Survey on virtual prototyping technologies for orthopedic implants and prosthesis design. World Conf. Innov. Virtual Real. 2011, 44328, 199–206.

- Raabe, M.E.; Chaudhari, A.M.W. An investigation of jogging biomechanics using the full-body lumbar spine model: Model development and validation. J. Biomech. 2016, 7, 1238–1243.

- OpenSIM. Available online: https://simtk.org/frs/index.php?group_id=91 (accessed on 8 August 2023).

- AnyBody. Available online: https://anyscript.org/tutorials/index.html (accessed on 8 August 2023).

- Rong, K.; Qian, J.G. Comparison of LifeMOD and OpenSim. J. Nanjing Sports Inst. 2015, 5, 38–42.

- Liu, Y.; Gao, Y.; Zhu, Y. A novel cable-pulley underactuated lower limb exoskeleton for human load-carrying walking. J. Mech. Ech. Med. Biol. 2017, 7, 1740042.

- Andersen, M.S.; Rasmussen, J. Total knee replacement musculoskeletal model using a novel simulation method for non-conforming joints. In Proceedings of the International Society of Biomechanics Conference, Brussels, Belgium, 3 July 2011.

- Richards, R.E.; Andersen, M.S.; Harlaar, J.; Van Den Noort, J.C. Relationship between knee joint contact forces and external knee joint moments in patients with medial knee osteoarthritis: Effects of gait modifications. Osteoarthr. Cartil. 2018, 9, 1203–1214.

- Zhang, B.J.; Liu, C.; Liu, G.; Jia, C. A study of dynamics to solve the human Initial gesture based on the known information of the Man-Rifle system. In Proceedings of the 4th International Conference on Computer, Mechatronics, Control and Electronic Engineering; Atlantis Press: Amsterdam, The Netherlands, 2015; pp. 529–534.

- Chen, Y.S.; Sun, W.W. R&D strategy study of customized furniture with film-laminated wood-based panels based on an analytic hierarchy process/quality function deployment integration approach. BioResources 2023, 18, 8249–8263.

- Mizu-Uchi, H.; Ma, Y.; Ishibashi, S.; Colwell, C.W., Jr.; Nakashima, Y.; D’Lima, D.D. Tibial sagittal and rotational alignment reduce patellofemoral stresses in posterior stabilized total knee arthroplasty. Sci. Rep. 2022, 1, 12319.

- Zhang, J.X.; Gao, K.; Xie, B. Review of gait analysis. Packag. Eng. 2022, 10, 41–53.

- Zhang, L.; Song, D.; Wang, B.; Xue, F. Hip motion analysis using parametric mathematical modeling in middle aged to elderly adults during walking. J. Mech. Med. Biol. 2018, 7, 1840004.

- Munoz, D.; Gizzi, L.; De Marchis, C.; Severini, G. Predictive simulation of Sit-to-Stand movements. In Wearable Robotics: Challenges and Trends: Proceedings of the 5th International Symposium on Wearable Robotics; Springer International Publishing: Cham, Switzerland, 2020; pp. 263–267.

- Sessa, S.; Zecca, M.; Lin, Z.; Bartolomeo, L.; Ishii, H.; Takanishi, A. A methodology for the performance evaluation of inertial measurement units. J. Intell. Robot. Syst. 2013, 2, 143–157.

- Kim, W.; Kim, H.; Lim, D.; Moon, H.; Han, C. Design and kinematic analysis of the hanyang exoskeleton assistive robot (HEXAR) for human synchronized motion. In Wearable Robotics: Challenges and Trends: Proceedings of the 2nd International Symposium on Wearable Robotics, Segovia, Spain, 18–21 October 2016; Springer International Publishing: Cham, Switzerland; pp. 275–279.

- Qian, J.; Mao, Y.; Tang, X.; Li, Z.; Wen, C.; Zhang, S. A finite element model for estimation of contact dynamics during a jumping movement on a trampoline. J. Hum. Kinet. 2020, 1, 59–72.

- Savonnet, L.; Duprey, S.; Wang, X. Coupling rigid multi-body and deformable finite element human models for assessing seat discomfort. In Proceedings of the 4th International Digital Human Modeling Conference, Montreal, QC, Canda, 15–17 June 2016; 7p.

- De Roeck, J.; Duquesne, K.; Van Houcke, J.; Audenaert, E.A. Statistical-Shape prediction of lower limb kinematics during cycling, squatting, lunging, and stepping-are bone geometry predictors helpful? Front. Bioeng. Biotech. 2021, 9, 696360.

- Felsner, E.M.; Litzenberger, S.; Mally, F.; Sabo, A. Musculoskeletal modelling of elite handcycling motion: Evaluation of muscular on-and offset. Proc. Eng. 2016, 147, 168–174.

- Wolbert, F.A.; Peters, M.; Viellehner, J.; Funken, J.; Potthast, W. Musculoskeletal modelling of handcycling motion on an erogometer: Influence of crank position on training purposes. ISBS Proc. Arch. 2017, 1, 22.

- Morrow, M.M.; Cutti, A.G.; Vidt, M.E. Trends and advancements in shoulder biomechanics research. J. Electromyogr. Kinesiol. 2020, 62, 102409.

- Jurkojć, J.; Michnik, R.; Czapla, K. Mathematical modelling as a tool to assessment of loads in volleyball player’s shoulder joint during spike. J. Sport. Sci. 2017, 12, 1179–1186.

- Fasel, B.; Favre, J.; Chardonnens, J.; Gremion, G.; Aminian, K. An inertial sensor-based system for spatio-temporal analysis in classic cross-country skiing diagonal technique. J. Biomech. 2015, 12, 3199–3205.

- Gellaerts, J.; Bogdanov, E.; Dadashi, F.; Mariani, B. In-field validation of an inertial sensor-based system for movement analysis and classification in ski mountaineering. Sensors 2018, 3, 885.

- Dupré, T.; Funken, J.; Müller, R.; Mortensen, K.R.; Lysdal, F.G.; Braun, M.; Potthast, W. Does inside passing contribute to the high incidence of groin injuries in soccer? A biomechanical analysis. J. Sport. Sci. 2018, 16, 1827–1835.

- Van Houcke, J.; Galibarov, P.E.; Van Acker, G.; Fauconnier, S.; Allaert, E.; Van Hoof, T.; Audenaert, E.A. Personalized hip joint kinetics during deep squatting in young, athletic adults. Comput. Method. Biomec. 2020, 1, 23–32.

- Dupré, T.; Tryba, J.; Potthast, W. Muscle activity of cutting manoeuvres and soccer inside passing suggests an increased groin injury risk during these movements. Sci. Rep. 2021, 1, 72223.

- Si, W.; Yan, Z.; Li, Y.; Liu, S. The crouch start modeling and simulation based on AnyBody Technology. JDCTA 2010, 8, 8–14.

- Larson, R.E.; Ridge, S.T.; Bruening, D.; Johnson, A.W.; Mitchell, U.H. Healthcare worker choice and low back force between self-chosen and highest bed height when boosting a patient up in bed. Ergonomics 2022, 10, 1373–1379.

- Fritzsche, L.; Galibarov, P.E.; Gärtner, C.; Bornmann, J.; Damsgaard, M.; Wall, R.; Babič, J. Assessing the efficiency of exoskeletons in physical strain reduction by biomechanical simulation with AnyBody Modeling System. Wearable Technol. 2021, 2, 6.

More

Information

Subjects:

Ergonomics

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.6K

Revisions:

3 times

(View History)

Update Date:

29 Dec 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No