Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Nyasha Geoffrey Matsanga | -- | 4084 | 2023-11-23 11:29:27 | | | |

| 2 | Lindsay Dong | Meta information modification | 4084 | 2023-11-24 07:31:25 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Matsanga, N.; Nheta, W.; Chimwani, N. Grinding Media in Ball Mills for Mineral Processing. Encyclopedia. Available online: https://encyclopedia.pub/entry/51989 (accessed on 08 February 2026).

Matsanga N, Nheta W, Chimwani N. Grinding Media in Ball Mills for Mineral Processing. Encyclopedia. Available at: https://encyclopedia.pub/entry/51989. Accessed February 08, 2026.

Matsanga, Nyasha, Willie Nheta, Ngonidzashe Chimwani. "Grinding Media in Ball Mills for Mineral Processing" Encyclopedia, https://encyclopedia.pub/entry/51989 (accessed February 08, 2026).

Matsanga, N., Nheta, W., & Chimwani, N. (2023, November 23). Grinding Media in Ball Mills for Mineral Processing. In Encyclopedia. https://encyclopedia.pub/entry/51989

Matsanga, Nyasha, et al. "Grinding Media in Ball Mills for Mineral Processing." Encyclopedia. Web. 23 November, 2023.

Copy Citation

The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles. Grinding media play an important role in the comminution of mineral ores in these mills.

grinding media

ball mill

comminution

1. Introduction

The mining industry has been battling decreased head grades and increasing mineralogy complexity over the years, owing to the rapid depletion of high-grade ores. This has seen the processing of low-grade ores taking center stage and now almost dominating the industry, forcing many mines to upgrade the size of their tumbling mills to increase the mill throughput.

Tumbling mills convert electrical energy into mechanical energy, generating many fracture opportunities in the process. They all effect particle breakage using the same basic principle, regardless of the grinding media used. The grinding media impart the forces required for size reduction [1] and determine the category of tumbling mills: autogenous, rod mills and ball mills. Autogenous and semi-autogenous mills are used in primary grinding whilst rod and ball mills are used in secondary grinding, with the ball mills being the most commonly used. The ball mills are either used in a dry-milling or wet-milling set-up depending on the needs of the industry in which they are utilised. The cement and pharmaceutical industries normally use dry grinding whereas the mineral processing industry mostly resorts to wet-milling. In mineral processing, grinding, which is key to the liberation of valuable minerals from gangue, is achieved in primary, secondary and tertiary applications as well as regrind mills. These mills are further categorized by the nature of the discharge configuration: trunnion overflow mills operated in open or closed circuits or grate discharge mills [2].

On the one hand, the grate discharge mill, as the name implies, is fitted with a discharge diaphragm or grates between the cylindrical shell of the mill and the discharge trunnion so that particles greater than the openings of the grate are not discharged. In this mill, particles are barely overground, resulting in the discharge of a larger percentage of coarse particles. On the other hand, the overflow discharge mill, which is most widely used due to its simplicity, has material fed through the trunnion at one end and discharged through another trunnion at the other end as overflowing pulp. In both types of mills, a portion of the charge is lifted along the perimeter of the shell during the mill rotation and, after exceeding the angle of repose, part of it slides down while the other part cataracts and drops to the toe of the shell, imparting the grinding action in the process. The impacts resulting from the falling balls are considerably significant in the grate discharge owing to the continuous draining of the slurry during the grinding process, whereas the presence of a slurry pool in the overflow mill gives rise to very insignificant impacts between the balls and particles. This therefore translates to different media wear dynamics in these mills and, eventually, media consumption. In a grate discharge mill, the impact is a major player in the media consumption, followed by abrasion and corrosion, which are considerably lower because there is limited slurry pooling. However, in overflow mills, the wear mechanisms are mostly dominated by abrasion and corrosion, which is an offspring of the frictional force from slurry [3].

Therefore, the grinding action is achieved by attrition, abrasion, and impact between the ore itself and between the ore particles and grinding media [4]. Factors that influence the grinding efficiency include mill design, liner design, mill speed, mineralogical composition of the ore, charge ratio, and grinding media properties [5]. The grinding efficiency of a ball mill is determined by the product size distribution, energy consumption, and the grinding costs. According to Hassanzadeh [6], about 37% of the costs are used for grinding media only,13% for liners, and about 50% is used for energy in an industrial ball mill. This is evidence that media consumption has its fair share of the operating costs of the beneficiation process of ore. Thus, it became a fertile field of research, with many grinding-media-related papers produced.

It is important to mention that the media wear phenomenon is complicated in both mills and is also influenced by the operational parameters, which are complex and interactive in nature. These parameters are the fractional ball filling (J), the fraction of critical speed (fc), the fraction of the mill volume filled by powder (fc), powder filling (U), solids concentration, and ball and feed size distributions. For instance, Gupta and Yuan [1] observed that a corresponding 2% of ball grinding media is consumed for every 1% change in mill speed. At a low mill rotational speed, Soni and Mishra [7] perceived that bigger balls move near the periphery of the mill and smaller balls clutter around the kidney of the charge, in which very little grinding work is performed. The small media in the kidney rub against each other and wear into cubic shapes. At higher mill rotational speeds, Soni and Mishra [7] observed that it is the bigger balls which occupy the kidney area, while smaller balls move closer to the periphery. However, at intermediate speed, the charge dynamics attain a perfect transition state, representing the uniform distribution of contacts.

2. Grinding Media Materials and the Applicability of Grinding Media

Grinding media are the main components of the grinding process involving a ball mill. Research has been carried out to select the most suitable materials to manufacture improved grinding media [8][9][10][11]. Although the selection of grinding media is generally based on wear, it is also influenced by other parameters, such as the mineralogy, the water chemistry, and the mill characteristics. Good grinding media should have high hardness, fracture toughness, wear resistance and corrosion resistance, but at the same time, should have adequate ductility to minimize sudden ruptures and chipping. Grinding media can be classified according to the materials used to manufacture them (cast iron or steel), according to the process used to make them (forged or cast, rolled) or according to shape (cubes, spheres ellipsoids, cylinders). It is interesting to note that although iron, steel, chromium alloys (Cr 15%–30%), ceramic and pebble are used to make various grinding media used in industry, iron, and steel balls, grinding media are widely used in various grinding applications on account of their low cost [12]. The grinding media significantly influence the downstream process behaviour through the grinding chemistry, such as the floatation of the PGMs and, eventually, the recovery of the minerals in UG2 ores [13]. Although there are several types of grinding media, which include inert grinding media such as ceramic, zirconia, agate, and glass, this section is going to focus on cast iron and steel grinding media, together with their applicability in ball mills. Cast iron carbon content is generally between 2 and 4 wt. %, whereas steels contain a carbon content of less than 2 wt. %. Alloys are made by the addition of alloying elements like chromium, nickel, molybdenum, and manganese.

2.1. Cast Iron Grinding Media

Cast iron can be grey or white, but white cast irons are commonly used in abrasive wear applications in the comminution process. Cast iron grinding media are one of the ancient media, which were first used in mineral processing and can be grouped into cast low-chrome and high-chrome white iron [14]. The cast irons are heat-treated to adjust the amount of retained austenite and vary the carbide size and distribution, resulting in a microstructure with superior hardness and abrasion resistance. High-chromium cast iron is ferrous-based, and alloyed with 11–35 wt.% chromium and 1.8–7.5 wt.% carbon. Thus, their excellent wear resistance is due to the high-volume fraction of hard chromium carbides, which forms in a softer ductile matrix. The chrome carbides in the matrix provide superior corrosion resistance.

Zhang et al. [15], conducted a comprehensive study comparing the performance of cast iron and ceramic-based media. Their results show that a higher recovery of chalcopyrite was achieved with the use of ceramic-based media. This was among other factors caused by the lower pH and Fe3+ concentration in the pulp obtained by the ceramic media compared to cast-iron-based media. The cast-iron-based media also produced products with a high surface roughness and serious corrosion, in contrast to those yielded by the ceramic-based media, which had more even and smoother surfaces that led to better hydrophobicity and floatability. This aligns with Nie et al. [16], who found that grinding sphalerite with ceramic media produced a weaker electrochemical interaction than that with cast iron media, and they attributed this to the existence of the only local cell action of sphalerite for ceramic balls.

2.2. Steel Grinding Media

Steel grinding media are usually forged, and water-quenched. Their properties are governed by their carbon content, alloying element content, and heat treatment. Most commercial grinding media at present are produced from martensitic low-alloy steels. The grinding media can adapt to most milling conditions and have a favourable cost-to-wear ratio. Low-alloy high-carbon steels are the strongest, hardest, and least ductile; therefore, they offer high resistance to abrasive wear compared to other steels when used in the tempered form [17][18]. Their hardened and tempered form render them extensive strength against abrasive wear as compared to other steels. High-chrome steel-grinding media are an economical media based on their wear performance and the positive change they provide in pulp chemistry, which may affect subsequent processes. The results obtained by Cullinan et al. [19] showed that the floatation recovery of galena using high-chrome steel balls (26% chromium) was higher than that obtained using high-carbon steel balls (1% chromium) during floatation.

A comparison of steel balls with other media has shown that they are outperformed for some ores by other grinding media. For sulfide ore, inert grinding media such as ceramic ball or pebbles have shown a superior performance to steel pebbles. This is due to the sulfide mineral surface being covered by the iron hydroxides produced by oxidation, which then negatively influence the floatation behavior during the downstream process [15].

3. Mechanisms of Grinding Media Wear in Ball Mills

The performance of grinding media in a ball mill is measured in terms of wear rate, which is a function of the media composition, hardness, phase structure, and corrosive–abrasive characteristics of the slurry. The wear mechanisms involved in a ball mill are impact, abrasion, corrosion, and erosion. Their individual contributions are difficult to assess during the grinding process owing to their complex interactions and thus have not yet been perfectly established [20]. Over the years, various methods of assessing grinding media wear rate have been developed, including pin abrasion tests, rubber wheel tests, or dry wheel tests, but the marked ball test is the most used. In that test, several balls are loaded in the mill, with unique marks for each ball, and the average mass loss during grinding is determined by weighing the balls before and after grinding [21]. However, the marked ball test can result in marked ball anomaly when interpreting the results, especially when the marked ball is more durable than other balls of the same type.

3.1. Corrosion Wear

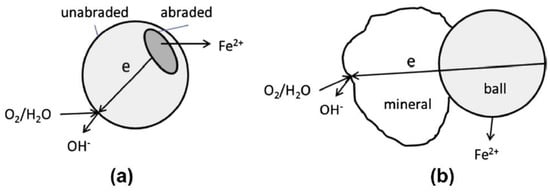

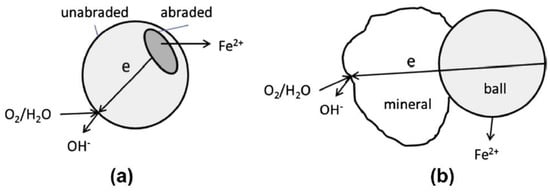

Corrosion wear is the loss of material on the grinding media surface due to galvanic interactions between the ore (cathode) and the grinding media (anode) or between the abraded and unabraded points on the surface of the grinding media due to differences in electrochemical potentials, as shown in Figure 1 [22]. Mass loss by corrosion is due to oxidative electrochemical reactions where oxygen is reduced and iron is oxidised. Iwasaki and Rajagopal [20] outlined that corrosion wear depends on the abrasion and corrosion resistance of the grinding media, the presence of oxygen in the mill and the abrasiveness and electroactive nature of the ore. Corrosive wear is greatly dominant in wet grinding when using ferrous grinding media and is responsible for up to 50% of ferrous grinding media consumption [23]. Despite the widely accepted phenomenon that wet grinding is a fertile environment for corrosion wear regardless of the chromium content of the balls, studies to verify its importance are few and far between [24].

Figure 1. Showing corrosion wear for (a) differential abrasion cell (b) ball—mill galvanic cell. Adapted from [22].

The extent of grinding media wear is governed by ore mineralogy, media characteristics and process conditions, such as pH, among other operational parameters. Iwasaki and Rajagopal [20] proposed a direct proportionality relationship between the corrosion resistance of ball materials of any composition and the pH of the slurry. The pH, along with the metal solution potential and the composition of the metal solution, plays an important role in maintaining a thin passive layer with low electrical conductivity that is stable on the media surface, thus strengthening the corrosion resistance.

In some instances, corrosion is accelerated by abrasion when it generates products that weakly attach to the surface and are easily abraded away. Abrasion achieves this by breaking the fragile superficial passivation film that protects the metallic alloys against corrosion. The wear rate would then tend to depend on the re-passivation rate and the intensity of wear [24].

Chromium grinding media possess a high corrosion resistance in the presence of oxygen. An increase in chromium content augments corrosion resistance but the resistance is somehow compromised by the formation of chromium carbides, which consume a large proportion of the chromium. Rajagopal and Iwaski [20] found that there is a critical chromium level above which no pitting corrosion is observed. Allahkarami et al. [25] also found that the galvanic interaction between galena and the grinding media significantly decreased with an increase in chromium content.

3.2. Abrasion Wear

Abrasion wear is the removal of material on the grinding media surface due to scratching by hard particles [26]. Ores have different abrasiveness owing to their mineralogical composition. Quartz is one of the most pervasive abrasive materials in mineral processing. The chemical composition, microstructure and hardness of grinding media influence the extent of abrasion wear during milling. Abrasion wear also depends on the rheology of the slurry, which is dependent on the viscosity and the percent solids of the pulp [27]. Martensite has good abrasion resistance compared to pearlite and ferrite. Generally, materials with high hardness are more abrasion-resistant but the microstructure also plays a vital role; therefore, hardness cannot fully describe wear resistance alone [28]. Microstructural parameters such as retained austenite, inclusions, carbides, matrix structures and notches must be considered.

3.3. Impact Damage Mechanism

Impact results in the loss of grinding media material due to repeated high-energy tangential impacts. Some impacts that crack the hardened surface layer and/or lead to the transformation of austenite to martensite that cracks locally cause spalling, which can generally be controlled at the heat treatment stage through the phase composition of the grinding media.

Impact on the grinding media is influenced by the surface hardening of the ball, the spalling tendency, which usually affects larger balls, and the resistance to breakage under the repeated impacts it must experience [20]. The degree of impact is affected by parameters such as mill speed, ball size, mill diameter, mill filling volume, interstitial filling, and particle size. Impact, among other wearing mechanisms, causes spherical balls to wear into non-spherical fragments [29].

Grinding media with nearly noo retained austenite and a purely pearlitic structure through the cross-section have excellent impact toughness but inferior hardness. Higher amounts of retained austenite of above 15% lead to macro-spalling and fracture owing to the transformation from austenite to martensite [30].

It is commonly assumed that increasing the mill speed would lead to more impact-related damage mechanisms, which cause grinding media such as cast irons to perform poorly. A recent study by Ali et al. [31] revealed that increasing the impact severity index (ISI), which is a relative average measure of the degree of impact inside the mill, increased the performance of white cast irons using ores of different abrasiveness levels (quartz, basalt, Tumbulgum quartzite, copper ore). The ISI was manipulated using rotation speed, mill-filling volume and feed particle size. To explain the unexpected observations, a hypothesis formulated by the authors was that the microfracture of the chromium carbides is more promoted by tensile stresses due to tangential sliding interactions rather than the compressive forces caused by high-angle impingement. The authors concluded that ball mills with a diameter of less than 600 mm do not have impact effects because all the wear occurring will be abrasive in nature. Thus, it is yet to be determined whether the impact levels in industrial mills that cannot cause macro-scale fractures in white cast irons do or do not promote microfracture wear mechanisms.

4. Effect of Grinding Media Size, Shape, and Density on Mill Performance

4.1. Effect of Grinding Media Size on Mill Perfomance

Different sizes of grinding media have different influences on the grinding performance [32]. Ball sizes that are used in grinding should be large enough to break the largest and hardest ore particles. Optimal ball sizes depend on the feed/product size ratio, mill dimensions, and breakage kinetics parameters. Usually, larger balls grind coarser ore particles efficiently and smaller balls grind fine particles more efficiently [33]. Larger balls break particles through impact, whilst smaller balls break through attrition. Sometimes, the smaller balls do not have sufficient impact energy to break an ore particle; therefore, both media sizes are vital. An optimal ball size range should provide sufficient energy to break coarse ore particles, but at the same time should not produce unnecessary ultrafine particles.

From the experiments conducted by Lameck [34], larger balls were effective for large feed sizes due to their impact, although they had a reduced surface area, whilst small balls were effective on small feed sizes because of their attrition and higher surface area. Kabezya and Motjotji [35] observed that 30 mm diameter balls were better than 10 mm and 20 mm diameter balls in grinding a quartzite ore of a feed size from −8 to +5.6 mm. However, there was an increase in efficiency when the feed size from −2 mm to +1.4 mm was ground by 20 mm diameter balls.

4.2. Effect of Grinding Media Shape on Mill Performance

Grinding media shape, among other parameters, has been reported as essential during grinding and has a significant influence on downstream processes such as flotation [32]. It is also an influential parameter in mass transport, and research has shown that power draw is sensitive to media shape at different charge filling levels. The difference in media shape results in different surface areas, bulk densities, and contact mechanisms during grinding. Different grinding media shapes have different toe and shoulder positions in the mill, resulting in different power draws and load behaviours. Toe and shoulder positions are the angular positions at which the liner comes into contact with the charge and when the charge departs from the liners, respectively. According to Shahbazi et al. [36], friction coefficients between media and lifter and media–media affect the media position in the mill. Also, the surface area, which is affected by media shape, causes the charge to become more defiant and move between media layers, hence effectively lifting the load.

Spherical balls are mostly used for ball mill processes but are associated with high foundry production costs when compared to other types of media [36]. They change their shape over time due to the wearing away of the outer layer. According to experiments conducted by Dökme et al. [37], spherical balls produced 27% finer particles and consumed 5% less power than worn balls, which suggests that worn balls should be constantly removed from the mill since they affect the breakage kinetics of ore particles. Worn balls reduce the grinding surface area compared with spherical balls. However, there is a need to investigate the relationship between worn balls and mill speed, liner profiles, or filling ratios.

Findings from Lameck [34] showed that cylpebs have the highest shoulder position and lowest toe position compared to spherical and worn balls, at a critical speed of more than 60%. The higher shoulder positions of cylpebs compared to other media shapes are due to cataracting and premature centrifuging. The lower toe positions for the cylpebs were due to the close packing and locking of the media such that their cascading speed was less than the mill speed. The shoulder positions of spherical and worn balls increased with charge filling, but the toe positions for all media shapes were similar for speeds below 70% of the critical speed. Cylpebs showed a small variation in shoulder positions with a change in mill speed. Cylpebs drew more power at speeds less than 72% of the critical speed, followed by worn balls, and lastly spherical balls.

4.3. Effect of Grinding Media Density on Mill Perfomance

In order to increase the efficiency of the grinding mill, Stoimenov et al. [38] suggested that the grinding media density should be increased. The author discovered that low-density balls are less efficient than high-density balls when grinding material is subjected to the ultrasonic milling method. Harriss et al. [39] also included grinding media density as one of the variables that affect power consumption. Yildinm et al. [40] found that mill power draw was linearly proportional to media density using grinding media of different densities. Cleary [41] found agreeing results; however, the difference in specific power consumption was negligible for grinding media of the density 4000 kg/m3 and 7800 kg/m3.

5. Effect of Grinding Media on the Mineral’s Liberation

Inside the ball mill, the enhanced liberation of the valuable mineral provides a homogenous product particle size, improves the technical index of the classification circuit, and improves the concentration in subsequent processes. The grinding media, such as steel balls, generate a breakage force that causes fractures on the mineral interface. The ore should not be underground or overground as this will cause inefficient separation in concentration processes. Different grinding media sizes and shapes, and different media filling rates, have different effects on the liberation degree of the valuable minerals.

The variation in grinding media sizes produces a dissimilar extent of mineral liberation. In experiments performed by Si et al. [42] using eight different sizes of steel balls, i.e., 10 mm, 13 mm, 16 mm, 19 mm, 22 mm, 25 mm, 28 mm, and 32 mm, the mineral liberation analyser showed that some magnetite particles were incompletely liberated whilst others were still intergrown. The 10 mm and 13 mm steel balls had reduced efficiency due to their small diameter, but their mineral liberation degree was better compared to other ball sizes. However, they were rendered inappropriate, and 22 mm steel balls were found to provide a better liberation and the desired product size. As the ball diameter increased from 25 mm to 28 mm, the mineral liberation decreased. This was confirmed by Nava et al. [43], who found that the liberation degree decreased with increasing ball size.

The grinding media shape used can affect downstream processes such as floatation due to the different degrees of mineral liberation. Li et al. [44] found that rod-milled scheelite was more liberated than ball-milled scheelite because the amount of oversized particles generated by rods was less than that produced by balls. The rod-milled product had a higher adsorption and floatation recovery using oleate as the collector.

6. Conclusions

Over the years, research has been conducted to improve the quality of grinding media so that they can withstand the highly abrasive and corrosion environments in the ball mill. Grinding media have also been improved to minimise slurry contamination such that downstream processes such as floatation are not affected. High-chrome white cast irons are used in highly abrasive environments, whilst high-chrome steel balls are used where slurry contamination should be minimised. Studies have been conducted on the methods of production, be they forging or casting, and the heat treatment processes to determine the effect on the micro-structure of the grinding media. However, there is still ongoing research on grinding media that can be both abrasion- and impact-wear-resistant with a prolonged service life. Various shapes of grinding media have been manufactured, including cylpebs, ellipsoids, cubes, and truncated cones, which have the ability to compete with the commonly used spherical grinding media. The grinding media properties affect the overall performance of the grinding process, with grinding media size distribution being more significant than the density, shape, and hardness. Operational parameters such as grinding media filling, pH, mill speed and wear also affect ball mill efficiency. Grinding media with low wear rates are the most appropriate, as they serve for longer and produce less debris, which affects downstream processes. However, there are still many areas concerning the ball mill operation as a function of the grinding media that still need to be studied to obtain a profound understanding of the grinding process. The properties of grinding media, such as shape, hardness, and size, should be further exploited to increase mill efficiency. Since most grinding media that are currently in use, such as high-chromium cast iron and high-carbon low-alloy steel, have certain levels of both martensite and austenite. In the ball structure, martensite with high hardness and austenite should be used to minimize grinding wear. Some ores, such as gold and copper, which are abrasive, produce high grinding media wear rates.

References

- Gupta, A.; Yan, D.S. Mineral Processing Design and Operation: An Introduction; Elsevier: Amsterdam, The Netherlands, 2006.

- Wills, B.A.; Napier-Munn, T.J. Wills’ Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery, 7th ed.; Elsevier: London, UK, 2005; ISBN 0750644508.

- King, J.; Li, Q.; He, C.; Zhou, J.; Deng, H.; Xu, R. Evaluation of grinding media wear-rate by a combined grinding method. Miner. Eng. 2015, 73, 39–43.

- Hinsberg, V. Wills’ Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery; Wills, B.A., Napier-Munn, T.J., Eds.; Butterworth-Heinemann (Elsevier): Burlington, MA, USA, 2008; 456p, ISBN 978-0-7506-4450-1.

- Conger, W.; DuPont, J.F.; McIvor, R.E.; Weldum, T.P. Ball mill media optimization. Min. Eng. 2018, 70, 28–37.

- Hassanzadeh, A. The Effect of Make-up Ball Size Regime on Grinding Effciency of Full-scale Ball Mill Fine, coarse and fine/coarse particle processing in mineral processing systems View project A Study on Batch and Industrial Flotation of Copper Porphyry Ores View project. In Proceedings of the XVII Balkan Mineral Processing Congress (BMPC), Antalya, Turkey, 1–3 November 2017; pp. 117–123. Available online: https://www.researchgate.net/publication/320864487 (accessed on 5 July 2022).

- Soni, R.; Mishra, B.K. Understanding Size Segregation in Tumbling Mills. In Proceedings of the International Conference on Discrete Element Methods, Phoenix, AZ, USA, 25–28 September 2016; pp. 1153–1168.

- Huang, Q.; Noble, A.; Talan, D. Exploratory investigation on the use of low-cost alternative media for ultrafine grinding of coal. Int. J. Coal Prep. Util. 2020, 42, 2127–2144.

- Prziwara, P.; Hamilton, L.D.; Breitung-Faes, S.; Kwade, A. Impact of grinding aids and process parameters on dry stirred media milling. Powder Technol. 2018, 335, 114–123.

- Simba, K.P.; Hlabangana, N.; Hildebrandt, D. Fineness of the Grind produced by Mixtures of Grinding media of Different shapes. In Proceedings of the 16th International Mineral Processing Symposium, Belek, Turkey, 23–25 October 2018; pp. 388–393. Available online: https://www.researchgate.net/publication/339400451 (accessed on 7 August 2022).

- Koval, A.D.; Efremenko, V.G.; Brykov, M.N.; Andrushchenko, M.I.; Kulikovskii, R.A.; Efremenko, A.V. Principles of development of grinding media with increased wear resistance. Part 2. Optimization of steel composition to suit conditions of operation of grinding media. J. Frict. Wear 2012, 33, 153–159.

- Wang, X.; Xie, Y. The Effect of Grinding Media and Environment on the Surface Properties and Flotation Behaviour of Sulfide Minerals. Miner. Procesing Extr. Metall. Rev. 1990, 7, 49–79.

- Greet, C.; Bruckard, W.J.; MacKay, D. Collector–Addition point and consumption. Miner. Process. Extr. Metall. 2010, 119, 235–241.

- Remark, J.F.; Wick, O.J. Corrosion Control in Ball and Rod Mills; NACE: Bruxelles, Belgium, 1976; Volume 76.

- Zhang, X.; Han, Y.; Kawatra, S.K. Effects of Grinding Media on Grinding Products and Flotation Performance of Sulfide Ores. Miner. Process. Extr. Metall. Rev. 2020, 42, 172–183.

- Nie, M.; Han, Y.; Li, Y. Effects of grinding media on the flotation behaviors of sphalerite. Met. Mine 2019, 512, 163–167. (In Chinese)

- Usman, H.; Fonna, S.; Huzni, S.; Ramadhan, T.I. The Effect of Hardening on Mechanical Properties of Low Alloy Steel Grinding Media. In Proceedings of the 2nd International Conference on Experimental and Computational Mechanics in Engineering: ICECME 2020, Banda Aceh, Indonesia, 13–14 October 2021; Akhyar, Ed.; Springer: Singapore, 2021; pp. 459–469.

- Tanaka, Y.; Pahlevani, F.; Kitamura, S.Y.; Privat, K.; Sahajwalla, V. Behaviour of Sulphide and Non-alumina-Based Oxide Inclusions in Ca-Treated High-Carbon Steel. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2020, 51, 1384–1394.

- Cullinan, V.J.; Grano, S.R.; Greet, C.J.; Johnson, N.W.; Ralston, J.; Wark, I. Investigating fine galena recovery problems in the lead circuit of mount isa mines lead/zinc concentrator part 1: Grinding media effects. Miner. Eng. 1999, 12, 147–163.

- Rajagopal, V.; Iwasaki, I. The Properties and Performance of Cast Iron Grinding Media. Miner. Process. Extr. Metall. Rev. 1992, 11, 75–106.

- Vermeulen, L.A.; Howat, D.D.; Gough, C. Theories of ball wear and the results of a marked-ball test in ball milling. J. S. Afr. Inst. Min. Metall. 1983, 83, 189–197.

- Aldrich, C. Consumption of steel grinding media in mills—A review. Miner. Eng. 2013, 49, 77–91.

- Chelgani, S.C.; Parian, M.; Parapari, P.S.; Ghorbani, Y.; Rosenkranz, J. A comparative study on the effects of dry and wet grinding on mineral flotation separation—A review. J. Mater. Res. Technol. 2019, 8, 5004–5011.

- Massola, C.P.; Chaves, A.P.; Albertin, E. A discussion on the measurement of grinding media wear. J. Mater. Res. Technol. 2016, 5, 282–288.

- Allahkarami, E.; Zarepoor, A.; Rezai, B. Studies of Grinding Media Corrosion from Galvanic Interaction on Galena Flotation. Int. J. Nonferrous Metall. 2014, 3, 29–34.

- Pourasiabi, H.; Gates, J.D. Ball mill abrasion test (BMAT): Method development and statistical evaluations. MethodsX 2022, 9, 101900.

- Awuye, D.E.; Amankwah, R.K.; Kwofie, S.; Owusu, C.; Agorhom, E.A. Selection of Grinding Media for Use in the Gold Processing Industry. In Proceedings of the 7th UMaT Biennial International Mining and Mineral Conference, Tarkwa, Ghana, 2 August 2022; pp. 1–8.

- Chandrasekaran, T.; Kishore. Effect of microstructure and hardness on the grinding abrasive wear resistance of a ball bearing steel. Wear 1993, 161, 105–109.

- Banisi, S.; Langari-Zadeh, G.; Pourkani, M.; Kargar, M.; Laplante, A. Measurement of ball size distribution and wear kinetics in an 8 m by 5 m primary mill of Sarcheshmeh copper mine. CIM Bullet. 2000, 93, 145–149.

- Moema, J.S.; Papo, M.J.; Slabbert, G.A.; Zimba, J. Grinding media quality assurance for the comminution of gold ores. In Proceedings of the World Gold Conference, Johannesburg, South Africa, 26–30 October 2009; The Southern African Institute of Mining and Metallurgy: Newtown, Johannesburg; pp. 27–34.

- Ali, Y.; Garcia-Mendoza, C.D.; Gates, J.D. Effects of ‘impact’ and abrasive particle size on the performance of white cast irons relative to low-alloy steels in laboratory ball mills. Wear 2019, 426–427, 83–100.

- Shi, F. Comparison of grinding media–Cylpebs versus balls. Miner. Eng. 2004, 17, 1259–1268.

- Cho, H.; Kwon, J.; Kim, K.; Mun, M. Optimum choice of the make-up ball sizes for maximum throughput in tumbling ball mills. Powder Technol. 2013, 246, 625–634.

- Nistlaba, N.; Lameck, S. Effects of Grinding Media Shapes on Ball Mill Performance. Master’s Thesis, University of the Witwatersrand, Witwatersrand, Johannesburg, 2005; pp. 1–146.

- Kabezya, K.M.; Motjotji, H. The effect of ball size diameter on milling performance. J. Mater. Sci. Eng. 2014, 4, 1–3.

- Shahbazi, B.; Jafari, M.; Parian, M.; Rosenkranz, J.; Chelgani, S.C. Study on the impacts of media shapes on the performance of tumbling mills—A review. Miner. Eng. 2020, 157, 106490.

- Dökme, F.; Kimyasallar, Ş.; Soda, G.; Fabrikası, S.A.Ş.K. Investigation of Effects of Grinding Media Shapes to the Grinding Efficiency in Ball. Sisecam Chem. 2015, 1, 1–2.

- Stoimenov, N.; Karastoyanov, D.; Klochkov, L. Study of the factors increasing the quality and productivity of drum, rod and ball mills. AIP Conf. Proc. 2018, 2020, 020024.

- Harris, C.C.; Schnock, E.M.; Arbiter, N. Grinding Mill Power Consumption. Miner. Process. Extr. Metall. Rev. 1985, 1, 297–345.

- Yildinm, K.; Silica, U.S.; Austin, L.G.; Cho, H. A study of mill power as a function of media type and shape. Part. Sci. Technol. 1997, 15, 179.

- Cleary, P. Modelling comminution devices using DEM. Int. J. Numer. Anal. Methods Geomech. 2000, 25, 83–105.

- Si, L.; Cao, Y.; Fan, G. The Effect of Grinding Media on Mineral Breakage Properties of Magnetite Ores. Geofluids 2021, 2021, 1575886.

- Nava, J.V.; Llorens, T.; Menéndez-Aguado, J.M. Kinetics of Dry-Batch Grinding in a Laboratory-Scale Ball Mill of Sn–Ta–Nb Minerals from the Penouta Mine (Spain). Metals 2020, 10, 1687.

- Li, C.-W.; Gao, Z. Effect of grinding media on the surface property and flotation behavior of scheelite particles. Powder Technol. 2017, 322, 386–392.

More

Information

Subjects:

Metallurgy & Metallurgical Engineering

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

3.3K

Revisions:

2 times

(View History)

Update Date:

24 Nov 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No