| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Puwakkatiya Lokuge Indrani Wimalaratne | -- | 2465 | 2023-11-23 05:31:18 | | | |

| 2 | Peter Tang | -1 word(s) | 2464 | 2023-11-23 06:11:25 | | |

Video Upload Options

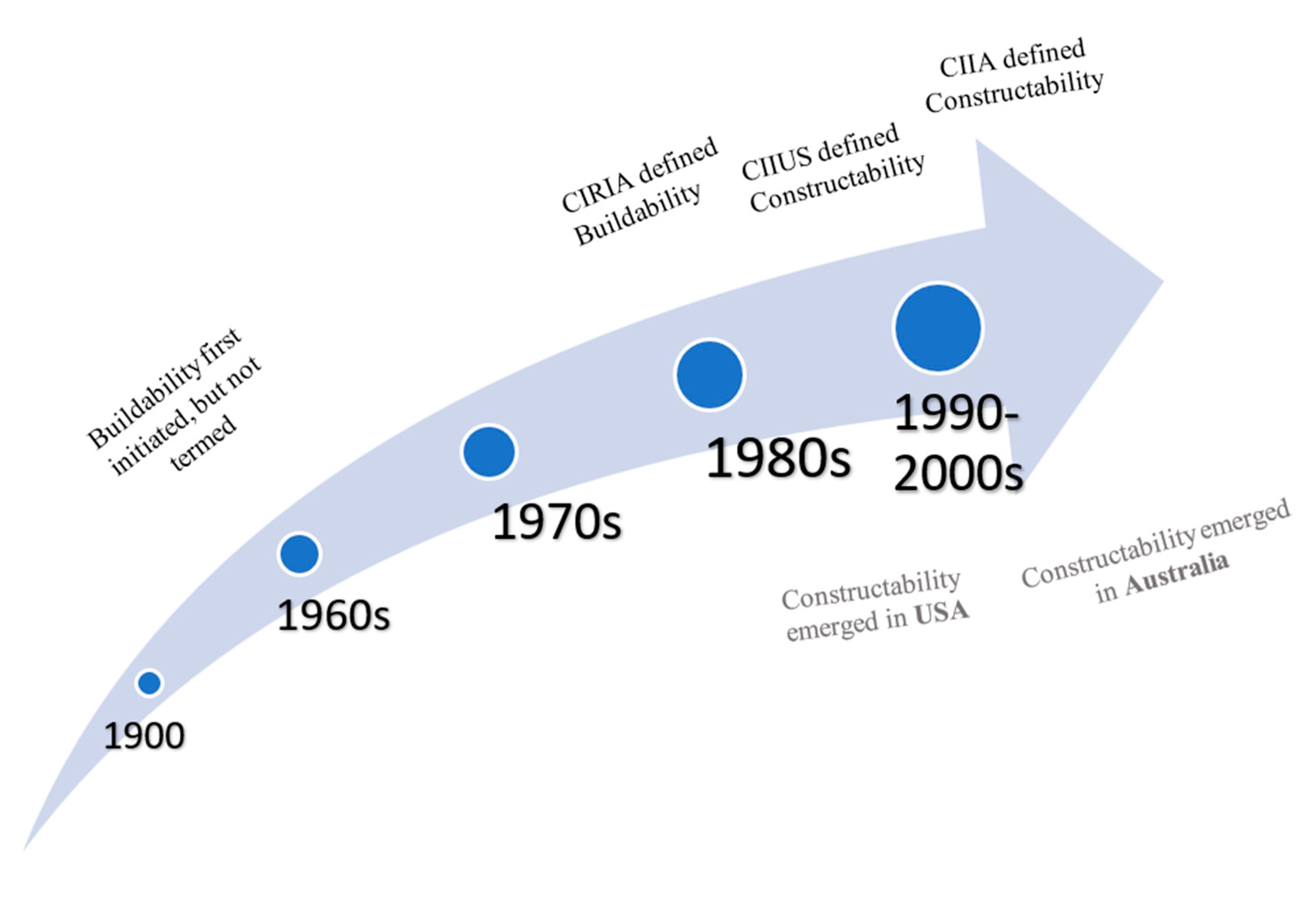

Since the emergence of the concept of “buildability” in 1983, numerous studies have focused on improving project performance through buildability. Initially, the buildability discourse was based on narrow definitions and focused on aspects that could improve construction performance.

1. Introduction

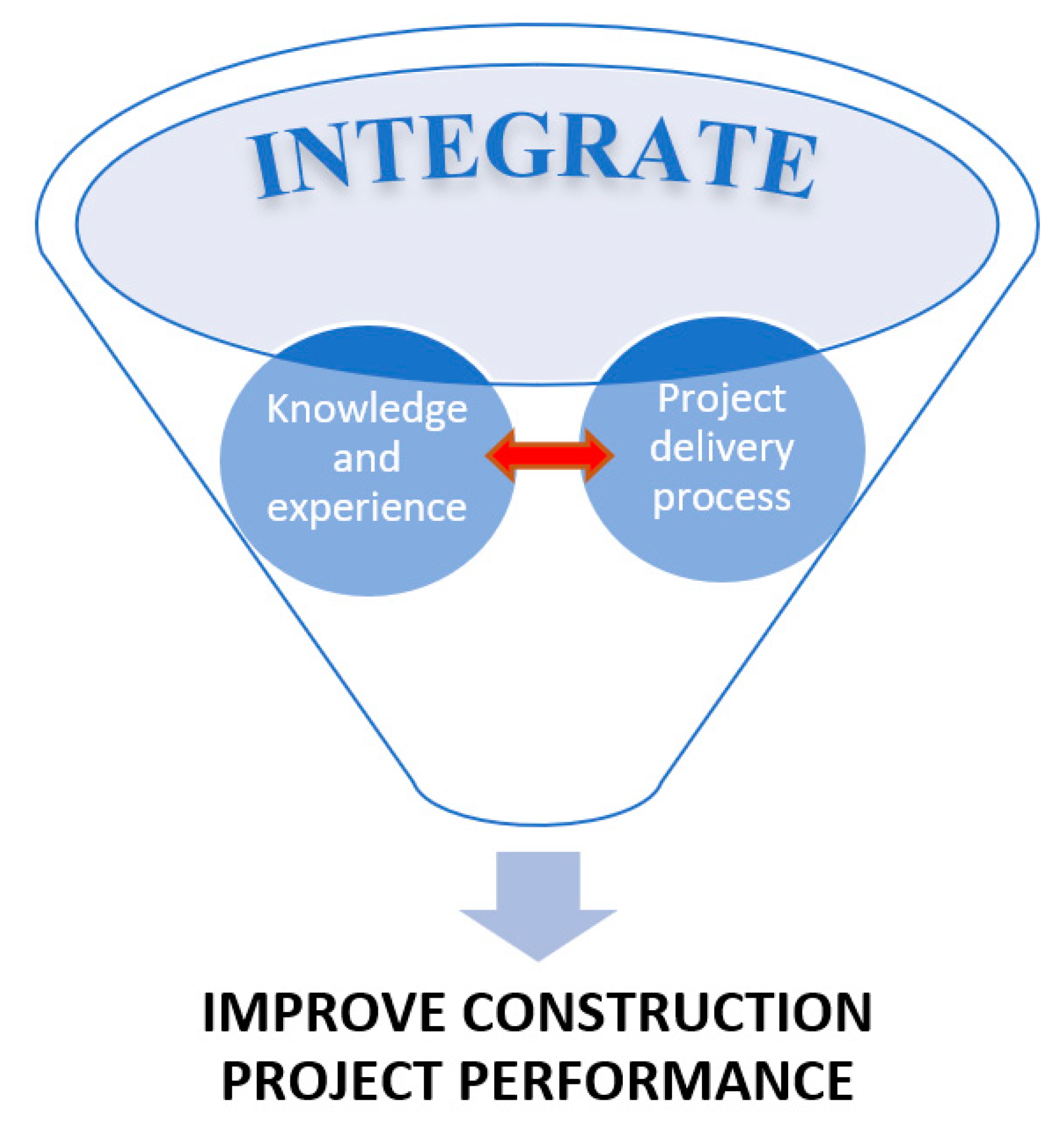

2. Constructability and Buildability

3. Evolution of Buildability

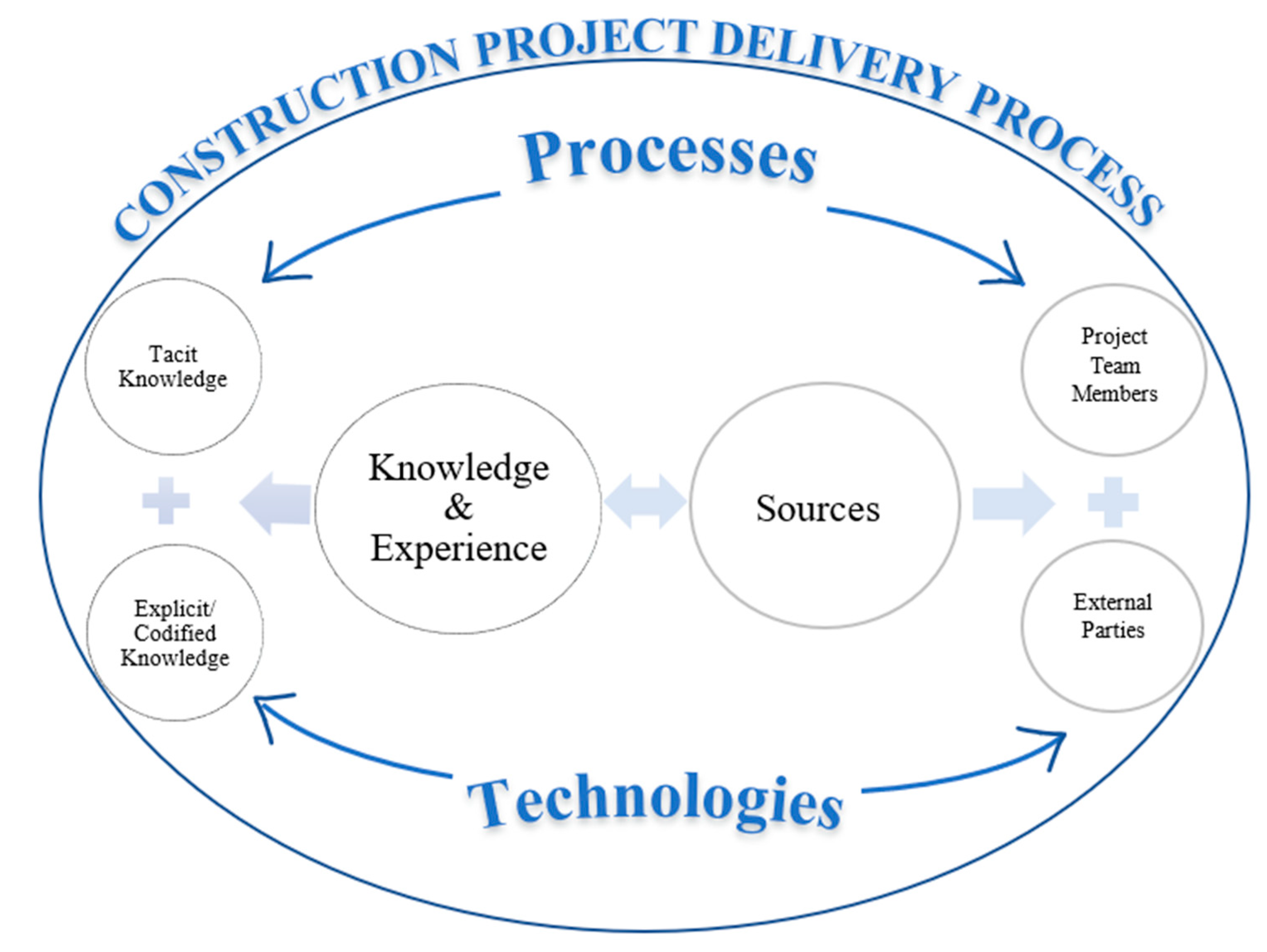

4. Key Constructs of Buildability

|

Year of Publication and Reference |

Publication Title |

Major Focus |

Definition Referenced |

|

|---|---|---|---|---|

|

2012 |

[37] |

Critical success factors to limit constructability issues on a net-zero energy home |

Design & Construction |

(CII, 1986) |

|

2014 |

[38] |

The evaluation of constructability towards construction safety |

Design |

(CII, 1986) |

|

2015 |

[39] |

Modelling a decision support tool for buildable and sustainable building envelope designs |

Design |

(CIRIA, 1983) |

|

2017 |

[40] |

AR (augmented reality) based 3D workspace modelling for quality assessment using as-built on-site conditions in remodeling construction project |

Design & Construction |

(CII, 1993) |

|

2017 |

[41] |

Beamless or beam-supported building floors: Is buildability knowledge the missing link to improving productivity? |

Design |

(CIRIA, 1983) |

|

2018 |

[24] |

Enhancing off-site manufacturing through early contractor involvement (ECI) in New Zealand |

Early Design |

(CIIA, 1992) |

|

2019 |

[42] |

Concepts of constructability for project construction in Indonesia |

All Stages |

(CII, 1986) (CIRIA, 1983) |

|

2019 |

[43] |

An early-design stage assessment method based on constructability for building performance evaluation |

Early Design |

(CIRIA, 1983) (CII,1986) |

|

2020 |

[44] |

A systematic review of prerequisites for constructability implementation in infrastructure projects |

Early Design & Design |

(CIRIA, 1983) (CII, 1986) |

|

2021 |

[27] |

Constructability obstacles: An exploratory factor analysis approach |

Design |

(CII, 1986) |

|

2022 |

[44] |

Assessing design buildability through virtual reality from the perspective of construction students |

Design |

(CIRIA, 1983) |

|

2022 |

[17] |

Buildability in the construction industry: A systematic review |

N/A |

(CIRIA, 1983) |

|

2023 |

[10] |

Buildability attributes for improving the practice of construction management in Nigeria |

Design & Construction |

(CIRIA, 1983) |

|

2023 |

[20] |

Measures for improving the buildability of building designs in construction industry |

Design |

(CIRIA, 1983) |

5. Deconstruction of the Key Constructs of Buildability

References

- Rathnayake, I.; Wedawatta, G.; Tezel, A. Smart Contracts in the Construction Industry: A Systematic Review. Buildings 2022, 12, 2082.

- Masoetsa, T.G.; Ogunbayo, B.F.; Aigbavboa, C.O.; Awuzie, B.O. Assessing Construction Constraint Factors on Project Performance in the Construction Industry. Buildings 2022, 12, 1183.

- Abal-Seqan, M.H.; Pokharel, S.; Naji, K.K. Key Success Factors and Their Impact on the Performance of Construction Projects: Case in Qatar. Sustainability 2023, 15, 3700.

- Memon, A.H.; Memon, A.Q.; Khahro, S.H.; Javed, Y. Investigation of Project Delays: Towards a Sustainable Construction Industry. Sustainability 2023, 15, 1457.

- Ogbu, C.P.; Adindu, C.C. Direct Risk Factors and Cost Performance of Road Projects in Developing Countries: Contractors’ Perspective. J. Eng. Des. Technol. 2019, 18, 326–342.

- Vilkonis, A.; Antucheviciene, J.; Kutut, V. Construction Contracts Quality Assessment from the Point of View of Contractor and Customer. Buildings 2023, 13, 1154.

- Ashtari, M.A.; Ansari, R.; Hassannayebi, E.; Jeong, J. Cost Overrun Risk Assessment and Prediction in Construction Projects: A Bayesian Network Classifier Approach. Buildings 2022, 12, 1660.

- Gebrehiwet, T.; Luo, H. Analysis of Delay Impact on Construction Project Based on RII and Correlation Coefficient: Empirical Study. Procedia Eng. 2017, 196, 366–374.

- Kabirifar, K.; Mojtahedi, M. The Impact of Engineering, Procurement and Construction (EPC) Phases on Project Performance: A Case of Large-Scale Residential Construction Project. Buildings 2019, 9, 15.

- Osuizugbo, I.C.; Oshodi, O.S. Buildability Attributes for Improving the Practice of Construction Management in Nigeria. Built Environ. Proj. Asset Manag. 2023, 13, 270–289.

- CIRIA Buildability: An Assessment; Construction Industry Research and Information Association: London, UK, 1983.

- Adams, S. Practical Buildability; Butterworths: London, UK, 1989.

- CIIA. Research Report 1—The Development of Constructability Principles for the Australian Construction Industry; Construction Industry Institute: Adelaide, Australia, 1996; ISBN 1876189010.

- Construction Industry Institute (CII). Buildability: A Primer; University of Texas: Austin, TX, USA, 1986.

- Nima, M.A.; Abdul-Kadir, M.R.; Jaafar, M.S.; Alghulami, R.G. Constructability Implementation: A Survey in the Malaysian Construction Industry. Constr. Manag. Econ. 2001, 19, 819–829.

- Kifokeris, D.; Xenidis, Y. Constructability: Outline of Past, Present, and Future Research. J. Constr. Eng. Manag. 2017, 143, 04017035.

- Osuizugbo, I.C.; Okolie, K.C.; Oshodi, O.S.; Oyeyipo, O.O. Buildability in the Construction Industry: A Systematic Review. Constr. Innov. 2022; ahead-of-print.

- Wimalaratne, P.L.I.; Kulatunga, U. A Methodology to Study the Complexity of Buildability In Construction Projects. In Proceedings of the 10th World Construction Symposium, Moratuwa, Sri Lanka, 24–26 June 2022; pp. 24–26.

- Kalsaas, B.T.; Hannås, G.; Frislie, G.; Skaar, J. Transformation from Design-Bid-Build to Design-Build Contracts in Road Construction. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction (IGLC), Chennai, India, 16–22 July 2018; Volume 1, pp. 34–45.

- Samimpey, R.; Saghatforoush, E. A systematic review of prerequisites for constructability implementation in infrastructure projects. Civ. Eng. J. 2020, 6, 576–590.

- Ding, C.S.; Salleh, H.; Kho, M.Y. Critical Constructability Principles for Girder Bridge Construction in Malaysia. Int. J. Sustain. Constr. Eng. Technol. 2019, 10, 41–51.

- Finnie, D.; Ali, N.A.; Park, K. Design Development Post Contract Signing in New Zealand: Client’s or Contractor’s Cost? Proc. Inst. Civ. Eng. Manag. Procure. Law 2019, 172, 146–156.

- Wong, F.W.H.; Lam, P.T.I.; Chan, E.H.W.; Shen, L.Y. A Study of Measures to Improve Constructability. Int. J. Qual. Reliab. Manag. 2007, 24, 586–601.

- Finnie, D.; Ali, N.A.; Park, K. Enhancing Off-Site Manufacturing through Early Contractor Involvement (ECI) in New Zealand. Proc. Inst. Civ. Eng. Manag. Procure. Law 2018, 171, 176–185.

- BCA. Code of Practice on Buildability 2022 Edition; Building and Construction Authority: Singapore, 2022.

- Wimalaratne, P.L.I.; Kulatunga, U.; Gajendran, T. Comparison between the Terms Constructability and Buildability: A Systematic Literature Review. In Proceedings of the 9th World Construction Symposium, Moratuwa, Sri Lanka, 9–10 July 2021; pp. 196–207.

- JadidAlEslami, S.; Saghatforoush, E.; Ravasan, A.Z. Constructability Obstacles: An Exploratory Factor Analysis Approach. Int. J. Constr. Manag. 2021, 21, 312–325.

- Emmerson, H. Survey of Problems before the Construction Industries, A Report Prepared for the Ministry of Works; HMSO: London, UK, 1962.

- Banwell, H. The Placing and Management Ofcontracts for Building and Civil Engineering Work; HMSO: London, UK, 1964.

- Illingworth, J.R. Buildability—Tomorrow’s Need. Build. Technol. Manag. 1984, 16–19.

- Ferguson, I. Buildability in Practice; Batsford: London, UK, 1989.

- Moore, D. Buildability Assessment and the Development of an Automated Design Aid for Managing the Transfer of Construction Process Knowledge. Eng. Constr. Archit. Manag. 1996, 3, 29–46.

- Wong, F.W.H.; De Saram, D.D.; Lam, P.T.I.; Chan, D.W.M. A Compendium of Buildability Issues from the Viewpoints of Construction Practitioners. Archit. Sci. Rev. 2006, 49, 81–90.

- Osuizugbo, I.C. The Need for and Benefits of Buildability Analysis: Nigeria as a Case Study. J. Eng. Des. Technol. 2020, 19, 1207–1230.

- Jarkas, A.M. Analysis and Measurement of Buildability Factors Affecting Edge Formwork Labour Productivity Engineering Science and Technology Review. J. Eng. Sci. Technol. Rev. 2010, 3, 142–150.

- Aina, O.O.A.; Wahab, A.B. An Assessment of Build Ability Problems In The Nigerian Construction Industry. Glob. J. Res. Eng. 2011, 11, 42–52.

- Aktas, C.B.; Ryan, K.C.; Sweriduk, M.E.; Bilec, M.M. Critical Success Factors to Limit Constructability Issues on a Net-Zero Energy Home. J. Green Build. 2012, 7, 100–115.

- Yustisia, H. The Evaluation of Constructability towards Construction Safety (Case Study: Kelok-9 Bridge Project, West Sumatera). Proc. Procedia Eng. 2014, 95, 552–559.

- Singhaputtangkul, N.; Low, S.P. Modeling a Decision Support Tool for Buildable and Sustainable Building Envelope Designs. Buildings 2015, 5, 521–535.

- Lee, S.Y.; Kwon, S.W.; Ko, T.K. AR(Augmented Reality) Based 3D Workspace Modeling for Quality Assessment Using as-Built on-Site Condition in Remodeling Construction Project. In Proceedings of the ISARC 2017—34th International Symposium on Automation and Robotics in Construction, Taipei, Taiwan, 28 June–1 July 2017; International Association for Automation and Robotics in Construction I.A.A.R.C.: Edinburgh, UK, 2017; pp. 181–188.

- Jarkas, A.M. Beamless or Beam-Supported Building Floors: Is Buildability Knowledge the Missing Link to Improving Productivity? Eng. Constr. Archit. Manag. 2017, 24, 537–552.

- Ansyorie, M.M.A. Concepts of Constructability for Project Construction in Indonesia. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Malang, East Java, Indonesia, 4–6 September 2019; Institute of Physics Publishing: Bristol, UK, 2019; Volume 669, p. 012062.

- Contrada, F.; Kindinis, A.; Caron, J.-F.; Gobin, C. An Early-Design Stage Assessment Method Based on Constructibility for Building Performance Evaluation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 609, 072070.

- Samarasinghe, D.A.S.; Piri, I.S. Assessing Design Buildability through Virtual Reality from the Perspective of Construction Students. Built Environ. Proj. Asset Manag. 2022, 12, 823–836.

- Osuizugbo, I.C. Measures for Improving the Buildability of Building Designs in Construction Industry. Constr. Innov. 2023; ahead-of-print.

- Osuizugbo, I.C.; Okolie, K.C.; Oshodi, O.S. Factors Supporting the Implementation of Buildability Assessment as a Tool for Buildability Improvement. J. Eng. Des. Technol. 2022; ahead-of-print.

- Tsoukas, H.; Vladimirou, E. What Is Organizational Knowledge? J. Manag. Stud. 2001, 38, 972–993.

- Nonaka, I.; Von Krogh, G.; Voelpel, S. Organizational Knowledge Creation Theory: Evolutionary Paths and Future Advances. Organ. Stud. 2006, 27, 1179–1208.

- Hoe, S.L.; McShane, S. Structural and Informal Knowledge Acquisition and Dissemination in Organizational Learning: An Exploratory Analysis. Learn. Organ. 2010, 17, 364–386.

- Nonaka, I.; Takeuchi, H. The Knowledge-Creating Company: How Japanese Companies Create the Dynamics of Innovation; Oxford University Press: New York, NY, USA, 1995; ISBN 0195092694.

- Nonaka, I. The Knowledge-Creating Company. Harv. Bus. Rev. 2007, 85, 162–171.

- Eslami, M.H.; Lakemond, N.; Brusoni, S. The Dynamics of Knowledge Integration in Collaborative Product Development: Evidence from the Capital Goods Industry. Ind. Mark. Manag. 2018, 75, 146–159.

- Hoe, S.L. Tacit Knowledge, Nonaka and Takeuchi Seci Model and Informal Knowledge Processes. Int. J. Organ. Theory Behav. 2006, 9, 490–502.

- Zhao, N.; Ying, F.J.; Tookey, J. Knowledge Visualisation for Construction Procurement Decision-Making: A Process Innovation. Manag. Decis. 2021; ahead-of-print.

- O’Meara, M.; Kelliher, F. Knowledge Codification. Knowl. Manag. Learn. Organ. 2021, 25–50.

- Rahmani, F. Challenges and Opportunities in Adopting Early Contractor Involvement (ECI): Client’s Perception. Archit. Eng. Des. Manag. 2020, 17, 67–76.

- Wang, D.; Jia, J.; Jiang, S.; Liu, T.; Ma, G. How Team Voice Contributes to Construction Project Performance: The Mediating Role of Project Learning and Project Reflexivity. Buildings 2023, 13, 1599.

- Sergeeva, N.; Roehrich, J.K. Temporary Multi-Organizations: Constructing Identities to Realize Performance Improvements. Ind. Mark. Manag. 2018, 75, 184–192.

- Basten, D.; Haamann, T. Approaches for Organizational Learning: A Literature Review. SAGE Open 2018, 8.

- Kesavan, M.; Gobidan, N.N.; Dissanayake, P.B.G. Analysis of Factors Contributing Civil Engineering Project Delays in Sri Lanka. In Proceedings of the 6th International Conference on Structural Engineering and Construction Management 2015, Kandy, Sri Lanka, 11–13 December 2015; pp. 40–46.

- Latham, M. Constructing the Team: Joint Review of Procurement and Contractual Arrangements in the United Kingdom Construction Industry; HMSO: London, UK, 1994.

- Low, S.P. Building and Sustainability Controls in Singapore: A Journey in Time. Procedia Eng. 2011, 20, 22–40.

- Griffith, A.; Sidwell, A.C. Development of Constructability Concepts, Principles and Practices. Eng. Constr. Archit. Manag. 1997, 4, 295–310.

- Dulaimi, M.F.; Ling, F.Y.Y.; Ofori, G. Engines for Change in Singapore’s Construction Industry: An Industry View of Singapore’s Construction 21 Report. Build. Environ. 2004, 39, 699–711.

- Jadidoleslami, S.; Saghatforoush, E.; Heravi, A.; Preece, C. A Practical Framework to Facilitate Constructability Implementation Using the Integrated Project Delivery Approach: A Case Study. Int. J. Constr. Manag. 2019, 22, 1225–1239.

- Laryea, S.; Samuel, L. Procurement Strategy and Outcomes of a New Universities Project in South Africa. Eng. Constr. Archit. Manag. 2019, 26, 2060–2083.

- Wong, F.W.H.; Lam, P.T.I.; Shen, L.Y. A Dynamic Design Management System for Improving Buildability of Construction. Assoc. Res. Constr. Manag. 2004, 1, 1–3.