| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Dukhyun Choi | -- | 6275 | 2023-11-09 08:57:11 | | | |

| 2 | Lindsay Dong | + 91 word(s) | 6366 | 2023-11-12 13:16:56 | | | | |

| 3 | Dukhyun Choi | + 17 word(s) | 6383 | 2023-11-20 19:34:47 | | |

Video Upload Options

The quality of human life has improved thanks to the rapid development of wearable electronics. Previously, bulk structures were usually selected for the fabrication of high performance electronics, but these are not suitable for wearable electronics due to mobility limitations and comfortability. Fibrous material-based triboelectric nanogenerators (TENGs) can provide power to wearable electronics due to their advantages such as light weight, flexibility, stretchability, wearability, etc. Fiber materials, multiple fabrication methods, and fundamentals of TENGs are described. Moreover, advances in functional fiber-based wearable TENGs are introduced. Furthermore, the challenges to functional fiber-based TENGs are discussed, and possible solutions are suggested. Finally, the use of TENGs in hybrid devices is introduced for a broader introduction of fiber-based energy harvesting technologies.

1. Introduction

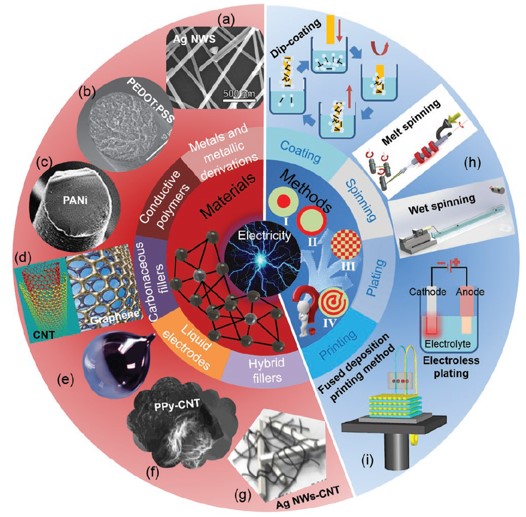

Figure 1. Commonly adopted conductive material systems and fabrication methods of electronic textiles. The frequently used conductive materials for textiles are broadly divided into five categories, i.e., metals and metallic derivations, conductive polymers, carbonaceous fillers, liquid electrodes, and their hybrid fillers. (a) Ag NWs. (b) PEDOT:PSS. (c) PANI. (d) CNT and graphene. (e) liquid metal. (f) PPy−CNT. (g) Ag NWs−CNT. The main preparation methods for conductive textile materials include coating, spinning, plating, and printing. There are four main types of compounding structures between conductive materials and other functional materials, i.e., inner embedding (I), outer covering (II), homogenous blending (III), and spiral cladding (IV). (h) Melt spinning and wet spinning. (i) Fused deposition printing. Reprinted with permission from Ref [44]. Copyright 2019 John Wiley & Sons.

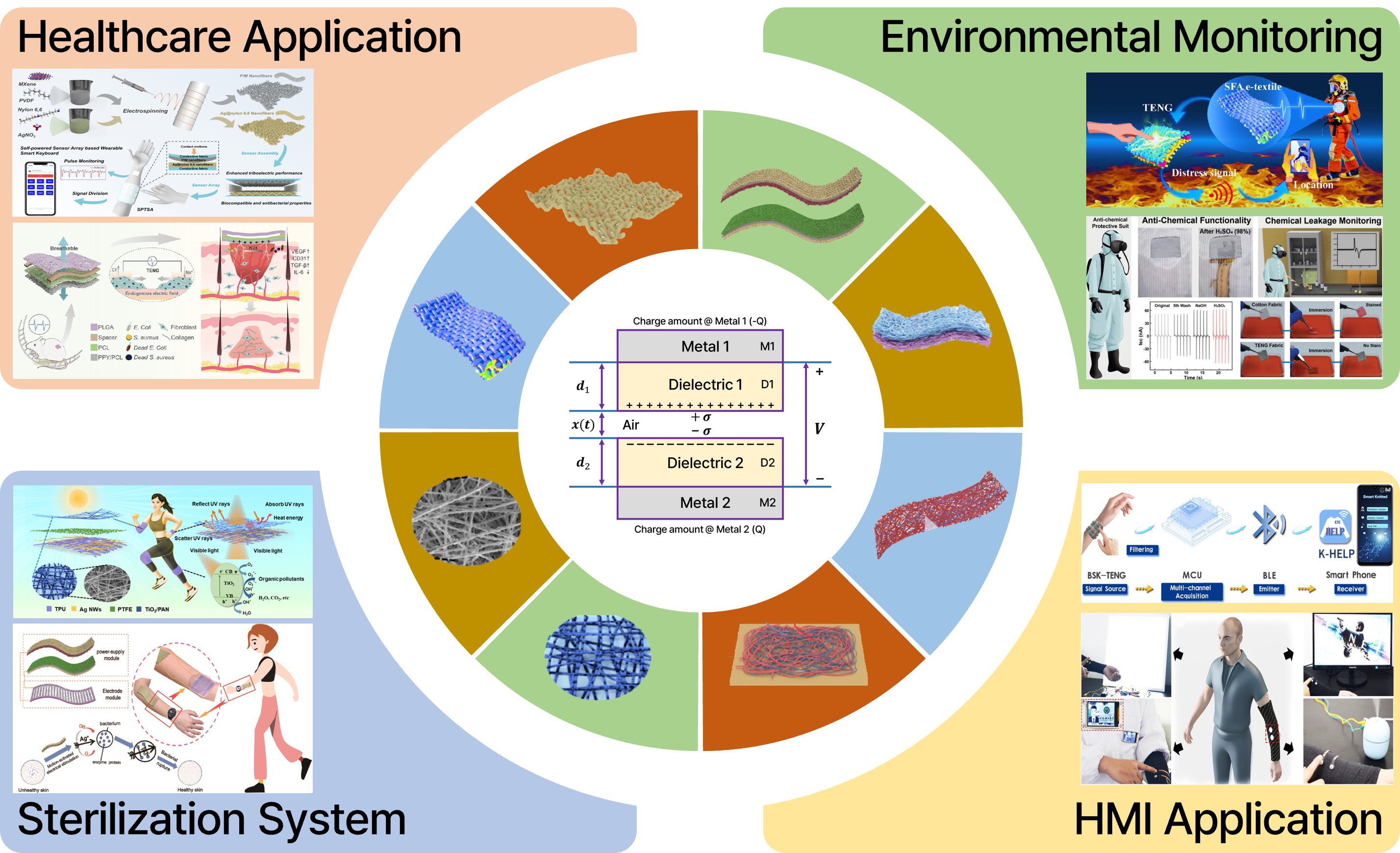

Figure 1. Commonly adopted conductive material systems and fabrication methods of electronic textiles. The frequently used conductive materials for textiles are broadly divided into five categories, i.e., metals and metallic derivations, conductive polymers, carbonaceous fillers, liquid electrodes, and their hybrid fillers. (a) Ag NWs. (b) PEDOT:PSS. (c) PANI. (d) CNT and graphene. (e) liquid metal. (f) PPy−CNT. (g) Ag NWs−CNT. The main preparation methods for conductive textile materials include coating, spinning, plating, and printing. There are four main types of compounding structures between conductive materials and other functional materials, i.e., inner embedding (I), outer covering (II), homogenous blending (III), and spiral cladding (IV). (h) Melt spinning and wet spinning. (i) Fused deposition printing. Reprinted with permission from Ref [44]. Copyright 2019 John Wiley & Sons. Figure 2. Functional fiber−based wearable triboelectric nanogenerators for use in healthcare applications, environmental monitoring, sterilization systems, and human−machine interfaces. Reprinted with permission from Ref. [55]. Copyright 2023 Elsevier. Reprinted with permission from Ref. [56]. Copyright 2023 American Chemical Society. Reprinted with permission from Ref. [57]. Copyright 2022 American Chemical Society. Reprinted with permission from Ref. [58]. Copyright 2021 John Wiley & Sons. Reprinted with permission from Ref. [59]. Copyright 2023 American Chemical Society. Reprinted with permission from Ref. [60]. Copyright 2021 American Chemical Society. Reprinted with permission from Ref. [61]. Copyright 2021 Elsevier. Reprinted with permission from Ref. [62]. Copyright 2022 Elsevier. Reprinted with permission from Ref. [63]. Copyright 2023 Springer Nature.

Figure 2. Functional fiber−based wearable triboelectric nanogenerators for use in healthcare applications, environmental monitoring, sterilization systems, and human−machine interfaces. Reprinted with permission from Ref. [55]. Copyright 2023 Elsevier. Reprinted with permission from Ref. [56]. Copyright 2023 American Chemical Society. Reprinted with permission from Ref. [57]. Copyright 2022 American Chemical Society. Reprinted with permission from Ref. [58]. Copyright 2021 John Wiley & Sons. Reprinted with permission from Ref. [59]. Copyright 2023 American Chemical Society. Reprinted with permission from Ref. [60]. Copyright 2021 American Chemical Society. Reprinted with permission from Ref. [61]. Copyright 2021 Elsevier. Reprinted with permission from Ref. [62]. Copyright 2022 Elsevier. Reprinted with permission from Ref. [63]. Copyright 2023 Springer Nature.2. Triboelectric Nanogenerator

2.1 Four Fundamental Modes of TENGs

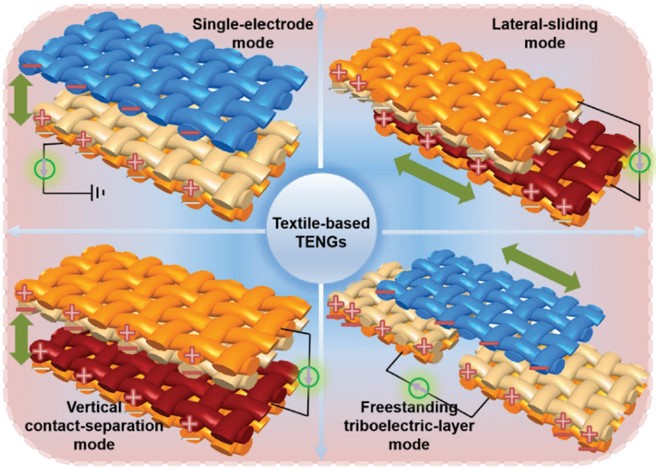

Figure 3. The four operation modes of textile−based TENGs, which take the fabric−based TENGs as examples. The yellow models refer to conductive fabrics, while the gray, crimson, and blue models represent dielectric fabrics. Reprinted with permission from Ref. [44]. Copyright 2019 John Wiley & Sons.

Figure 3. The four operation modes of textile−based TENGs, which take the fabric−based TENGs as examples. The yellow models refer to conductive fabrics, while the gray, crimson, and blue models represent dielectric fabrics. Reprinted with permission from Ref. [44]. Copyright 2019 John Wiley & Sons.2.2 The Working Principle of TENGs

2.3 Triboelectric Series

3. Functional Fiber based Wearable TENGs

3.1 Healthcare Applications

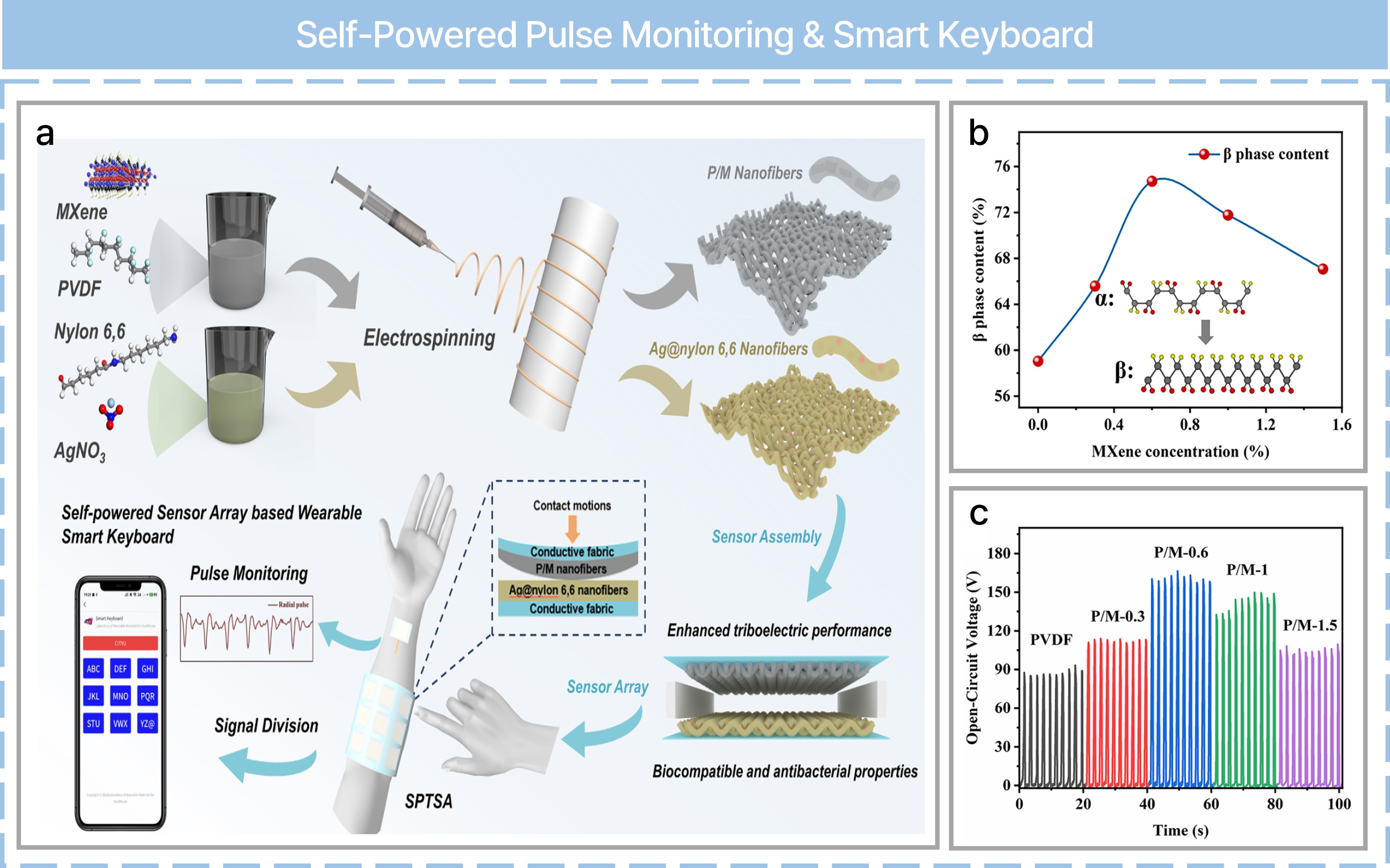

Figure 4. A biocompatible and antibacterial all−textile structured triboelectric nanogenerator for a self−powered tactile sensing apparatus (SPTSA). (a) Schematic of the fabrication and application of the SPTSA. (b) The β-phase content of the P/M nanofibers. (c) The open-circuit voltage variations of different P/M nanofibers. Reprinted with permission from Ref. [55]. Copyright 2023 Elsevier.

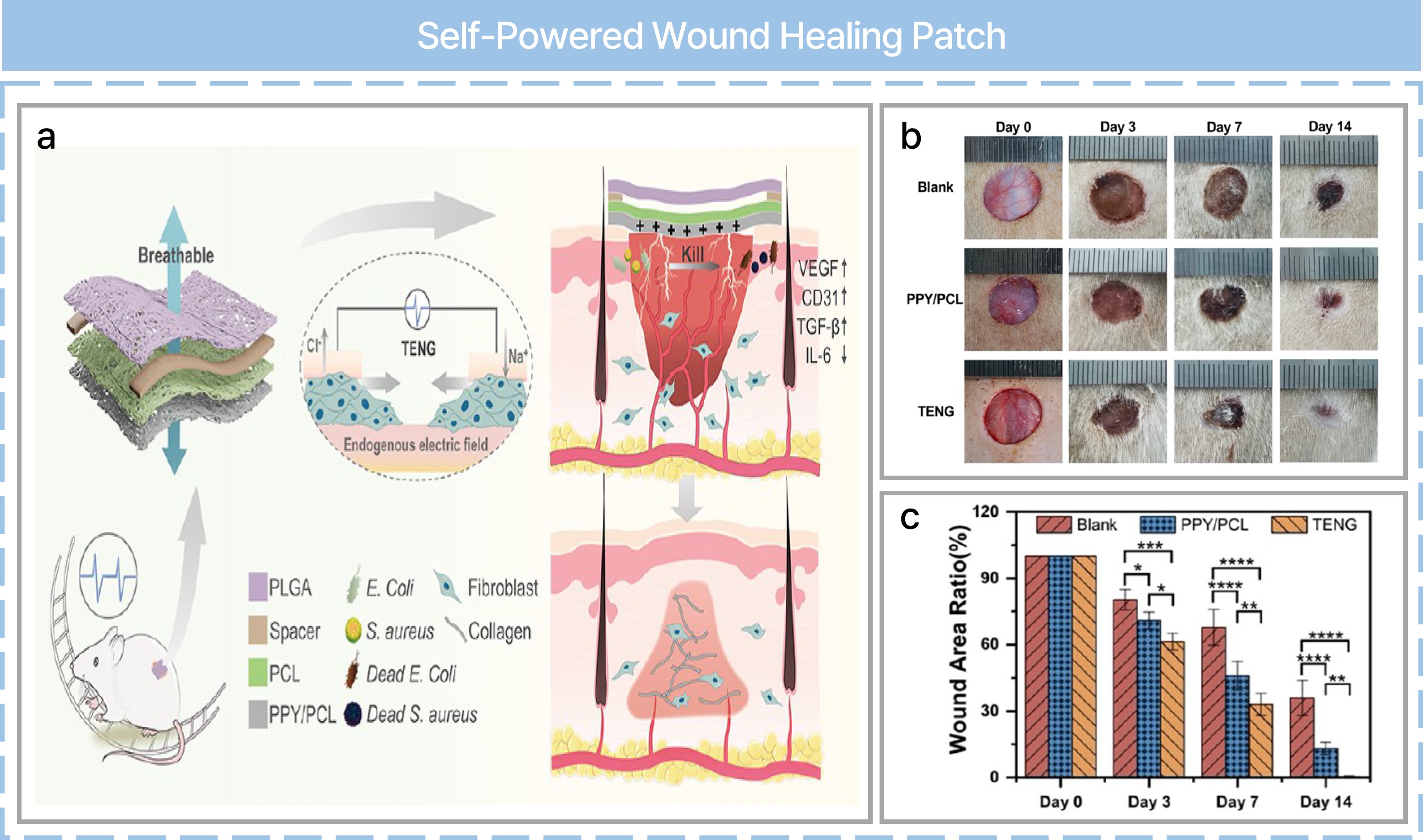

Figure 4. A biocompatible and antibacterial all−textile structured triboelectric nanogenerator for a self−powered tactile sensing apparatus (SPTSA). (a) Schematic of the fabrication and application of the SPTSA. (b) The β-phase content of the P/M nanofibers. (c) The open-circuit voltage variations of different P/M nanofibers. Reprinted with permission from Ref. [55]. Copyright 2023 Elsevier. Figure 5. Flexible, breathable, and self-powered patch assembled from electrospun polymer triboelectric layers and a polypyrrole-coated electrode for infected chronic wound healing. (a) Schematic illustration of self−powered multifunctional wound−healing patch. (b) Photographs of wounds at different periods. (c) Wound-area statistics at different periods. All experiments were conducted with at least three sample sizes, and the experimental results were expressed as mean ± standard deviation. Differences between groups were analyzed by one−way analysis of variance (ANOVA), with p-values less than 0.05 considered statistically significant (* p < 0.05, ** p < 0.01, *** p < 0.001, and **** p < 0.0001). Reprinted with permission from Ref. [56]. Copyright 2023 American Chemical Society.

Figure 5. Flexible, breathable, and self-powered patch assembled from electrospun polymer triboelectric layers and a polypyrrole-coated electrode for infected chronic wound healing. (a) Schematic illustration of self−powered multifunctional wound−healing patch. (b) Photographs of wounds at different periods. (c) Wound-area statistics at different periods. All experiments were conducted with at least three sample sizes, and the experimental results were expressed as mean ± standard deviation. Differences between groups were analyzed by one−way analysis of variance (ANOVA), with p-values less than 0.05 considered statistically significant (* p < 0.05, ** p < 0.01, *** p < 0.001, and **** p < 0.0001). Reprinted with permission from Ref. [56]. Copyright 2023 American Chemical Society.3.2 Environmental Monitoring

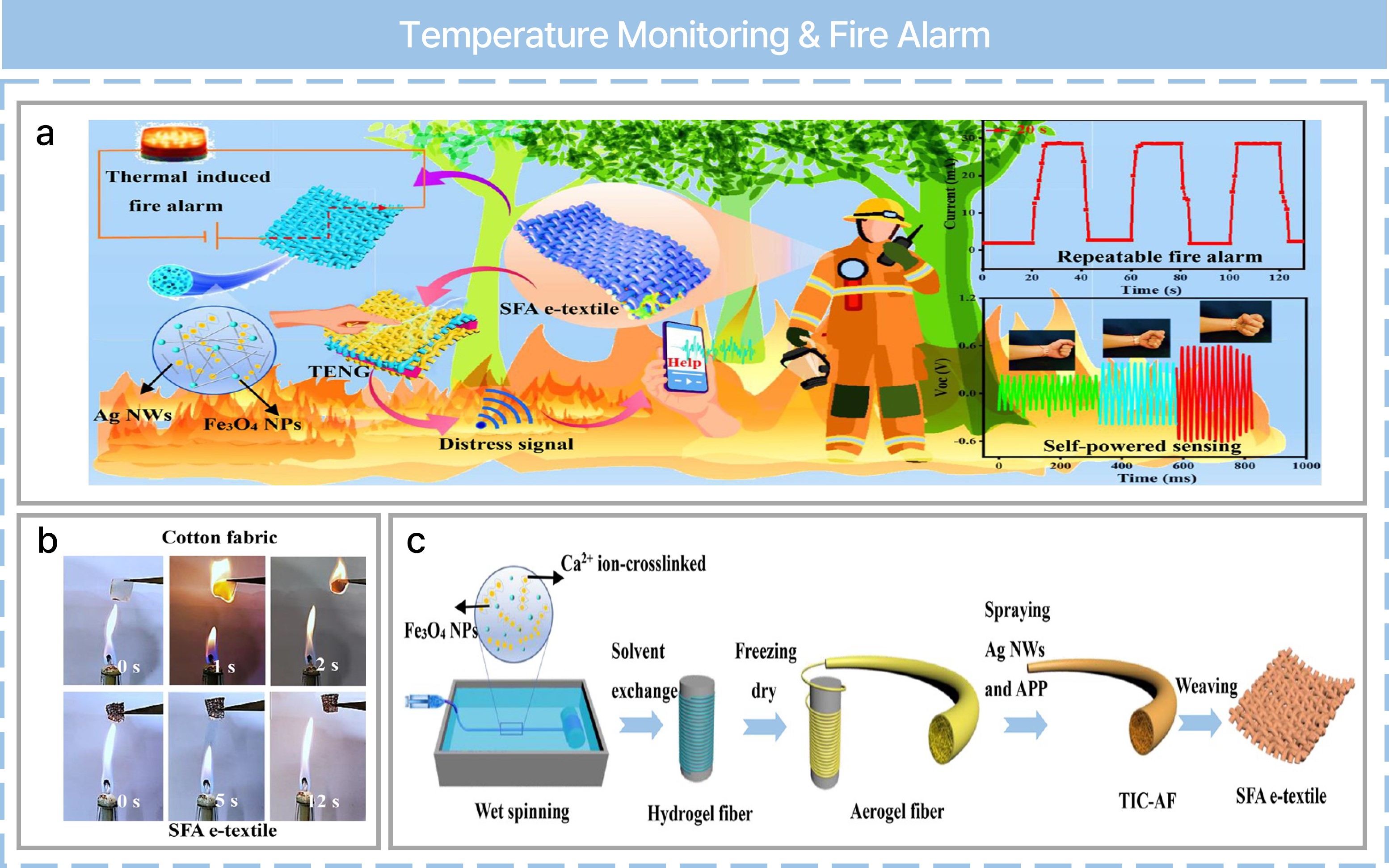

Figure 6. Ultralight self−powered fire alarm e−textile based on a conductive aerogel fiber with repeatable temperature monitoring performance used in firefighting clothing. (a) Applications of the SFA e−textile in smart firefighting clothing for energy harvesting, real−time fire warning, and precise rescue location. (b) Vertical burning test processes of the SFA e−textile under an alcohol lamp flame. (c) Schematic description of the fabrication of the TIC−AF and SFA e−textile. Reprinted with permission from Ref. [57]. Copyright 2022 American Chemical Society.

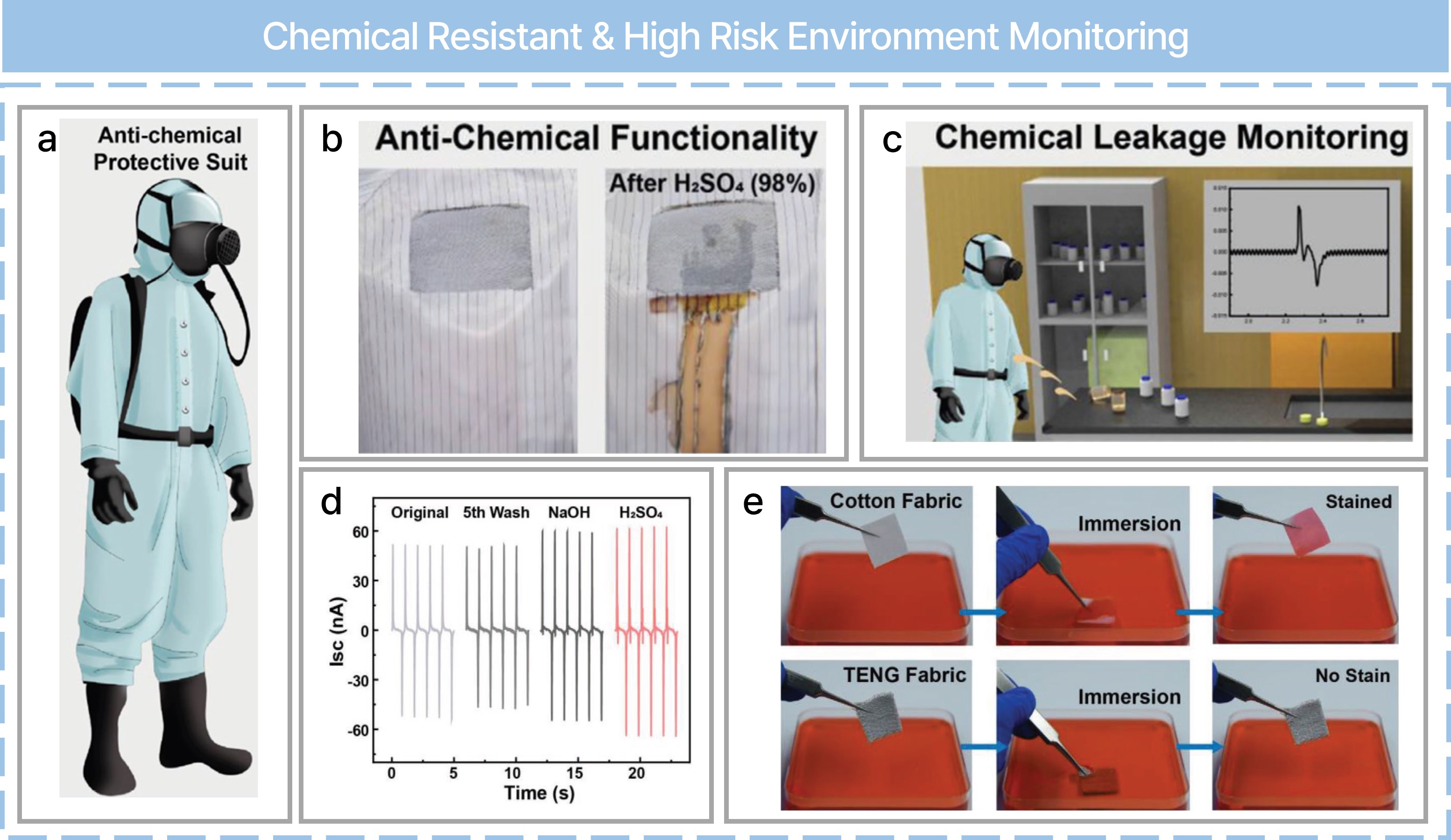

Figure 6. Ultralight self−powered fire alarm e−textile based on a conductive aerogel fiber with repeatable temperature monitoring performance used in firefighting clothing. (a) Applications of the SFA e−textile in smart firefighting clothing for energy harvesting, real−time fire warning, and precise rescue location. (b) Vertical burning test processes of the SFA e−textile under an alcohol lamp flame. (c) Schematic description of the fabrication of the TIC−AF and SFA e−textile. Reprinted with permission from Ref. [57]. Copyright 2022 American Chemical Society. Figure 7. Acid− and alkali−resistant textile triboelectric nanogenerator as a smart protective suit for liquid energy harvesting and self−powered monitoring in high−risk environments. (a) Schematic of an anti-chemical protective suit. (b) Anti-chemical functionality. (c) Chemical leakage monitoring. (d) Electrical output performance after water washing and acid and alkali soaking. (e) Photographs showing the dipping of F−TENG and cotton fabric into colored water. Reprinted with permission from Ref. [58]. Copyright 2021 John Wiley & Sons.

Figure 7. Acid− and alkali−resistant textile triboelectric nanogenerator as a smart protective suit for liquid energy harvesting and self−powered monitoring in high−risk environments. (a) Schematic of an anti-chemical protective suit. (b) Anti-chemical functionality. (c) Chemical leakage monitoring. (d) Electrical output performance after water washing and acid and alkali soaking. (e) Photographs showing the dipping of F−TENG and cotton fabric into colored water. Reprinted with permission from Ref. [58]. Copyright 2021 John Wiley & Sons.3.3 Sterilization Systems

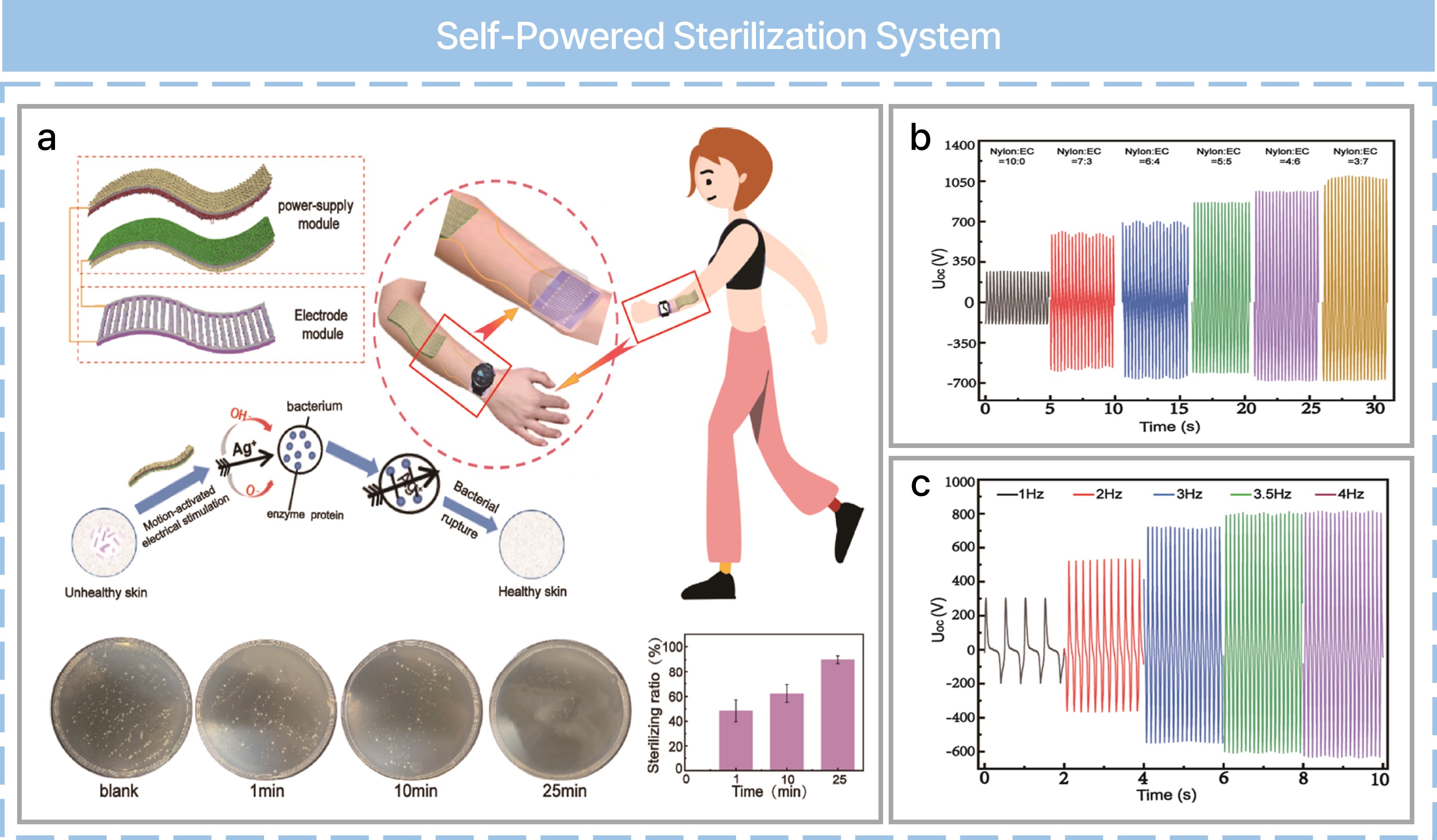

Figure 8. Self−powered sterilization system for wearable devices based on biocompatible materials and a triboelectric nanogenerator. (a) Schematic of motion−activated self−powered sterilization. (b) Open−circuit voltage of NMF-TENGs constructed from PA66/EC nanofiber membranes with different mass ratios. (c) Open−circuit voltage of NMF-TENGs under different impact frequencies at PA66 and EC at the best quality (PA66/EC = 5:5). Reprinted with permission from Ref [59]. Copyright 2023 American Chemical Society.

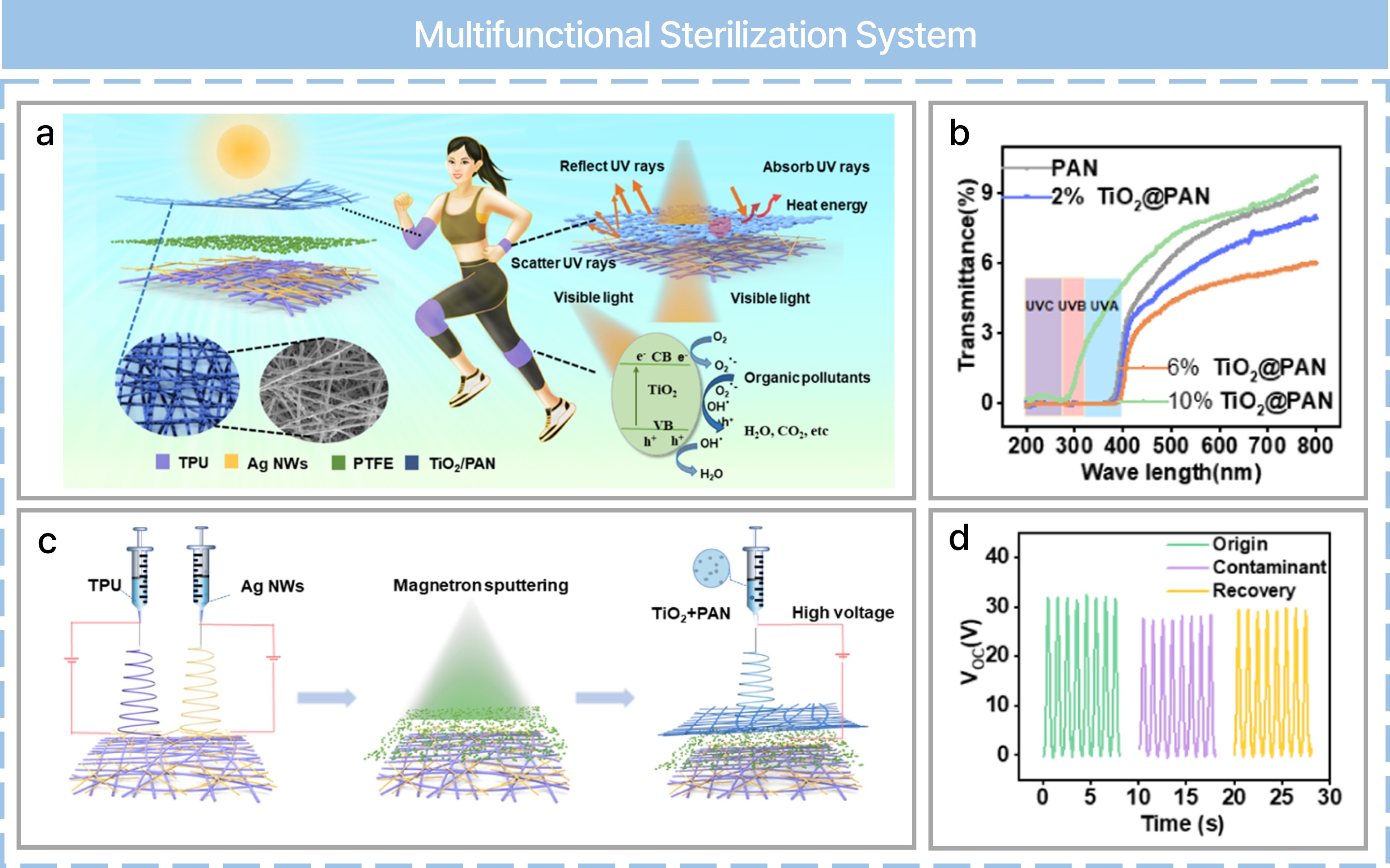

Figure 8. Self−powered sterilization system for wearable devices based on biocompatible materials and a triboelectric nanogenerator. (a) Schematic of motion−activated self−powered sterilization. (b) Open−circuit voltage of NMF-TENGs constructed from PA66/EC nanofiber membranes with different mass ratios. (c) Open−circuit voltage of NMF-TENGs under different impact frequencies at PA66 and EC at the best quality (PA66/EC = 5:5). Reprinted with permission from Ref [59]. Copyright 2023 American Chemical Society.Multifunctional wearable electronics and TENG-based wearable electronics can be applied to various functions. For example, an ultraviolet (UV)-protective, self-cleaning, antibacterial nanofiber-based TENG has been reported, as shown in Figure 9a [60]. Titanium dioxide (TiO2) is known for its UV resistance, stability, and lack of toxicity. However, the content of TiO2 was selected based on UV transmittance, absorption, and its protective performance and mechanical properties, as shown in Figure 9b. TiO2 and polyacrylonitrile (PAN) can be used to fabricate nanofibers, which provide UV protection and electrification (Figure 9c). Thermoplastic polyurethane (TPU) and AgNWs are used to fabricate other nanofibers and serve as an electrode. PTFE is sputtered onto the middle film via magnetron sputtering technology for enhanced hydrophobicity. A multifunctional wearable TENG is composed of three parts: a TiO2@PAN nanofiber, PTFE, and TPU/AgNWs. Three fabrication procedures were compared in terms of UV protection: electrospinning PAN nanofibers and electrospraying TiO2 (TiO2/PAN); electrospinning PAN and coating with a pre-dispersed TiO2 NPs immersion (TiO2-PAN); and electrospinning of a solution based on TiO2 and PAN (TiO2 + PAN). As a result, TiO2 + PAN nanofibers from one-step electrospinning achieved the best UV protective properties considering the UV protection factor, transmittance of UVA, and transmittance of UVB. Silver and TiO2 are anti-microbial agents with a wide range of biocidal properties. When the anti-bacterial performance was evaluated, TiO2/Ag NW/PAN nanofibers demonstrated the best anti-bacterial properties compared with the control groups due to the free radicals from TiO2 and rapidly released silver ions. Furthermore, TiO2 can be used for self-cleaning under UV light as it is a semiconductor material. The electrical output recovery was evaluated when polluted by organic contaminants (Figure 9d). Samples containing TiO2 recovered to near-original values.

Figure 9. UV−protective, self−cleaning, and antibacterial nanofiber−based triboelectric nanogenerators for self-powered human motion monitoring. (a) Schematic of a TENG. (b) UV transmittance spectra of nanofibers at different TiO2 concentrations. (c) An illustration of the fabrication process of the TiO2 + PAN nanofibers. (d) Comparison of Voc among the original, polluted, and self−cleaned TENGs. Reprinted with permission from Ref. [60]. Copyright 2021 American Chemical Society.

Figure 9. UV−protective, self−cleaning, and antibacterial nanofiber−based triboelectric nanogenerators for self-powered human motion monitoring. (a) Schematic of a TENG. (b) UV transmittance spectra of nanofibers at different TiO2 concentrations. (c) An illustration of the fabrication process of the TiO2 + PAN nanofibers. (d) Comparison of Voc among the original, polluted, and self−cleaned TENGs. Reprinted with permission from Ref. [60]. Copyright 2021 American Chemical Society.3.4 Human-Machine Interface Applications

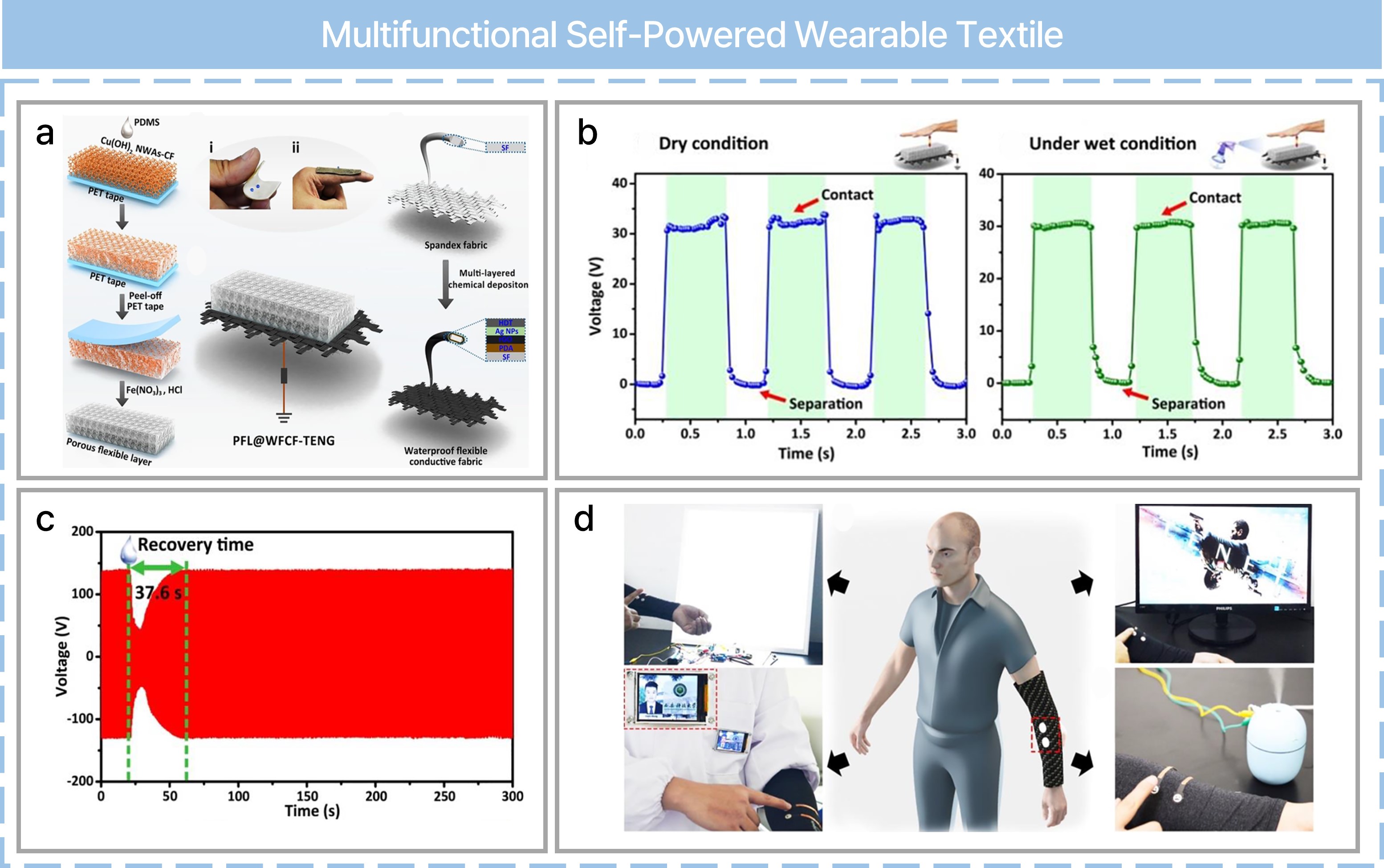

Figure 10. A humidity−resistant, stretchable, and wearable textile−based triboelectric nanogenerator for mechanical energy harvesting and multifunctional self−powered haptic sensing. (a) Fabrication process of PFL@WFCF−TENG. (b) Comparison of the sensing performance of PFL@WFCF−TENG on finger touching between dry and wet conditions. (c) The output signal recovery process curve of the t-TENG after spray dampness adopts triboelectric layers’ PFL. (d) Schematic multi−functional HMI systems based on wearable haptic controllers such as controlling light switch states, electronic badges, slides, and humidifiers. Reprinted with permission from Ref. [61]. Copyright 2021 Elsevier.

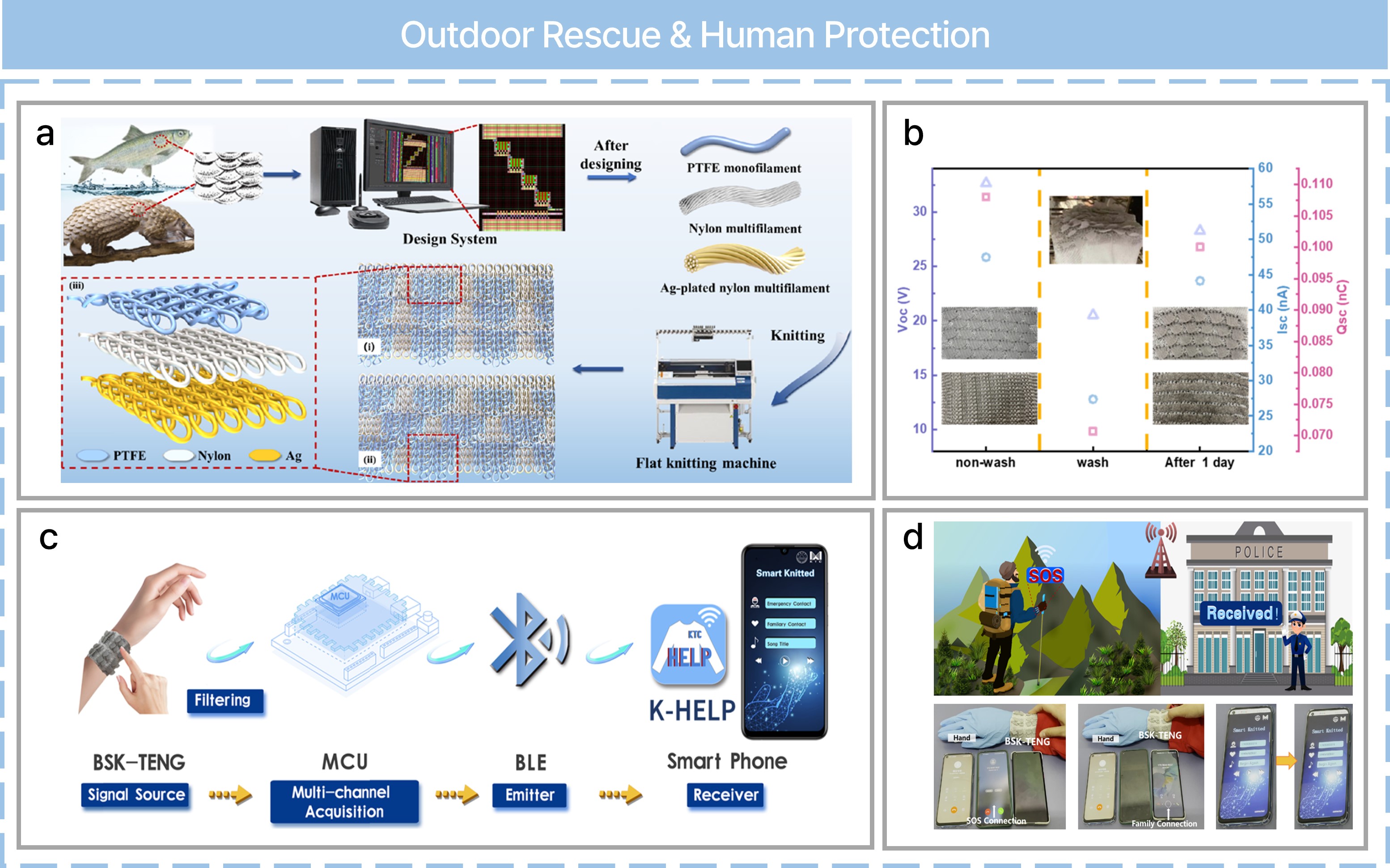

Figure 10. A humidity−resistant, stretchable, and wearable textile−based triboelectric nanogenerator for mechanical energy harvesting and multifunctional self−powered haptic sensing. (a) Fabrication process of PFL@WFCF−TENG. (b) Comparison of the sensing performance of PFL@WFCF−TENG on finger touching between dry and wet conditions. (c) The output signal recovery process curve of the t-TENG after spray dampness adopts triboelectric layers’ PFL. (d) Schematic multi−functional HMI systems based on wearable haptic controllers such as controlling light switch states, electronic badges, slides, and humidifiers. Reprinted with permission from Ref. [61]. Copyright 2021 Elsevier. Figure 11. Industrial production of a bionic-scale knitting fabric-based triboelectric nanogenerator for outdoor rescue and human protection. (a) Structural design and fabrication of a BSK−TENG. (b) The output performance of BSK−TENGs before washing, after washing, and one day after washing. (c) A schematic of a BSK−TENG as a self-powered sensor for a wireless personal outdoor rescue system. (d) Demonstration of the personal outdoor rescue system with wireless signal transmission using a BSK-TENG as a self−powered sensor and specific functions of the personal outdoor rescue system. Reprinted with permission from Ref. [62]. Copyright 2022 Elsevier.

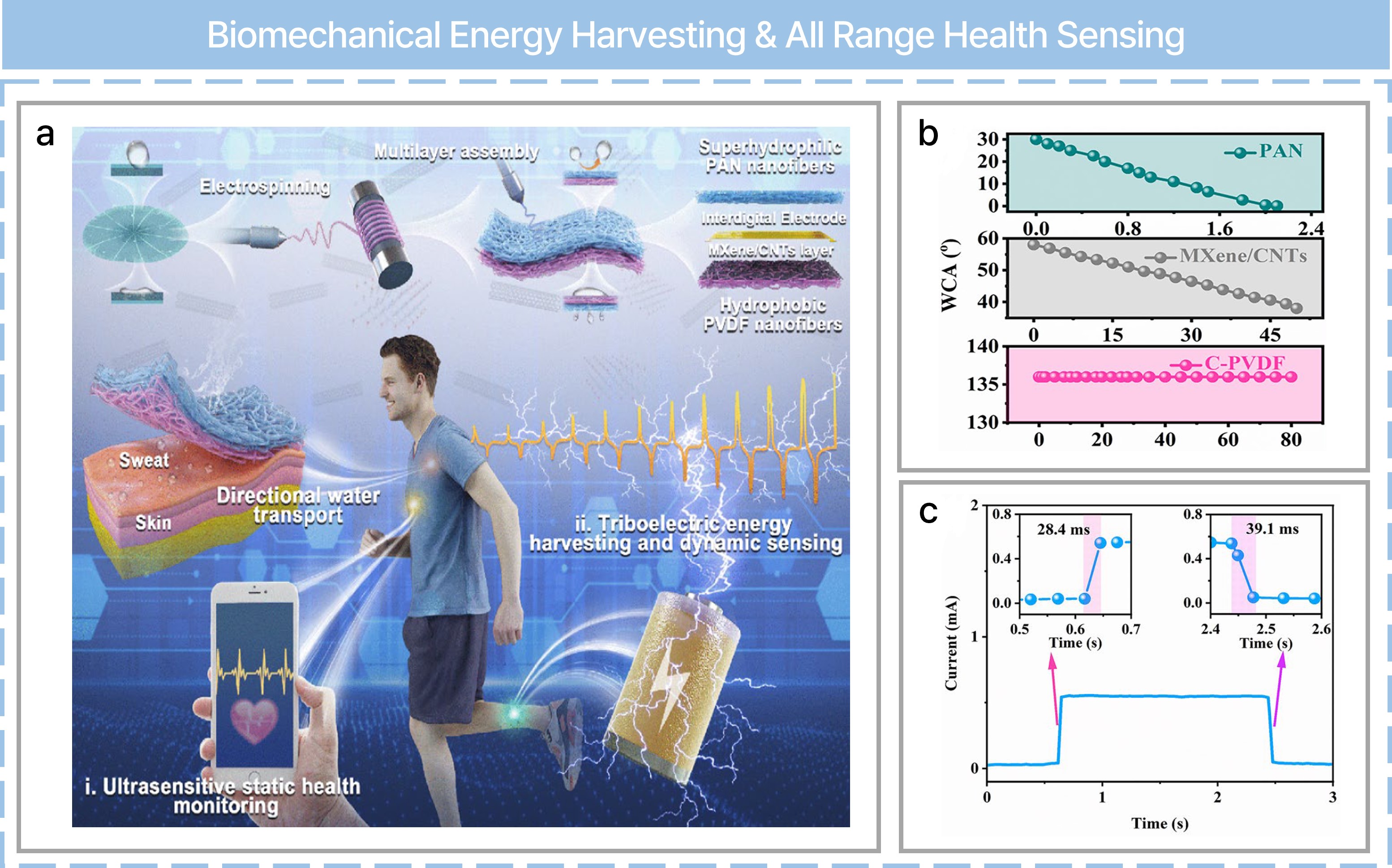

Figure 11. Industrial production of a bionic-scale knitting fabric-based triboelectric nanogenerator for outdoor rescue and human protection. (a) Structural design and fabrication of a BSK−TENG. (b) The output performance of BSK−TENGs before washing, after washing, and one day after washing. (c) A schematic of a BSK−TENG as a self-powered sensor for a wireless personal outdoor rescue system. (d) Demonstration of the personal outdoor rescue system with wireless signal transmission using a BSK-TENG as a self−powered sensor and specific functions of the personal outdoor rescue system. Reprinted with permission from Ref. [62]. Copyright 2022 Elsevier. Figure 12. Bioinspired all−fibrous directional moisture−wicking electronic skins for biomechanical energy harvesting and all−range health sensing. (a) Schematic of the fabrication and application of the DMWES membrane. (b) Water contact angle change with time. (c) Response and recovery time of the DMWES. Reprinted with permission from Ref. [63]. Copyright 2023 Springer Nature.

Figure 12. Bioinspired all−fibrous directional moisture−wicking electronic skins for biomechanical energy harvesting and all−range health sensing. (a) Schematic of the fabrication and application of the DMWES membrane. (b) Water contact angle change with time. (c) Response and recovery time of the DMWES. Reprinted with permission from Ref. [63]. Copyright 2023 Springer Nature.4. Hybrid System Based on TENGs

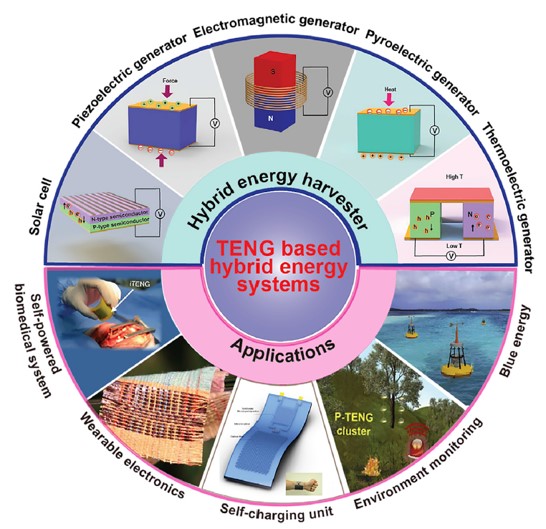

Figure 13. Outline illustration of hybrid energy harvesting systems using triboelectric nanogenerators. The hybrid energy harvesters are integrating triboelectric nanogenerators (TENGs) with other major energy harvesting techniques including electromagnetic generators, piezoelectric generators, thermoelectric generators, pyroelectric generators, and solar cells. They can be used for a variety of applications such as a self−charging power system, self-powered biomedical system, wearable electronics, environment monitoring, and wave energy harvesting. Reprinted with permission from Ref. [85]. Copyright 2021 Elsevier.

Figure 13. Outline illustration of hybrid energy harvesting systems using triboelectric nanogenerators. The hybrid energy harvesters are integrating triboelectric nanogenerators (TENGs) with other major energy harvesting techniques including electromagnetic generators, piezoelectric generators, thermoelectric generators, pyroelectric generators, and solar cells. They can be used for a variety of applications such as a self−charging power system, self-powered biomedical system, wearable electronics, environment monitoring, and wave energy harvesting. Reprinted with permission from Ref. [85]. Copyright 2021 Elsevier.5. Future Perspectives

References

- Majid, M.; Habib, S.; Javed, A.R.; Rizwan, M.; Srivastava, G.; Gadekallu, T.R.; Lin, J.C. Applications of Wireless Sensor Networks and Internet of Things Frameworks in the Industry Revolution 4.0: A Systematic Literature Review. Sensors 2022, 22, 2087.

- Stolojescu-Crisan, C.; Crisan, C.; Butunoi, B.P. An IoT-Based Smart Home Automation System. Sensors 2021, 21, 3784.

- Damadam, S.; Zourbakhsh, M.; Javidan, R.; Faroughi, A. An Intelligent IoT Based Traffic Light Management System: Deep Reinforcement Learning. Smart Cities 2022, 5, 1293–1311.

- Li, D.; Zhou, J.; Yao, K.; Liu, S.; He, J.; Su, J.; Qu, Q.; Gao, Y.; Song, Z.; Yiu, C.; et al. Touch IoT enabled by wireless self-sensing and haptic-reproducing electronic skin. Sci. Adv. 2022, 8, eade2450.

- Manas, M.; Sinha, A.; Sharma, S.; Mahboob, M.R. A novel approach for IoT based wearable health monitoring and messaging system. J. Ambient. Intell. Human. Comput. 2019, 10, 2817–2828.

- Yao, L.P.; Zeng, Q.; Qi, T.; Li, J. An environmentally friendly discharge technology to pretreat spent lithium-ion batteries. J. Clean. Prod. 2020, 245, 118820.

- Mrozik, W.; Rajaeifar, M.A.; Heidrich, O.; Christensen, P. Environmental impacts, pollution sources and pathways of spent lithium-ion batteries. Energy Environ. Sci. 2021, 14, 6099–6121.

- Lv, W.; Wang, Z.; Cao, H.; Sun, Y.; Zhang, Y.; Sun, Z. A Critical Review and Analysis on the Recycling of Spent Lithium-Ion Batteries. ACS Sustain. Chem. Eng. 2018, 6, 1504–1521.

- Arshad, F.; Li, L.; Amin, K.; Fan, E.; Manurkar, N.; Ahmad, A.; Yang, J.; Wu, F.; Chen, R. A Comprehensive Review of the Advancement in Recycling the Anode and Electrolyte from Spent Lithium Ion Batteries. ACS Sustain. Chem. Eng. 2020, 8, 13527–13554.

- Luo, J.; Wang, Z.L. Recent progress of triboelectric nanogenerators: From fundamental theory to practical applications. EcoMat 2020, 2, e12059.

- Liu, H.; Zhong, J.; Lee, C.; Lee, S.-W.; Lin, L. A comprehensive review on piezoelectric energy harvesting technology: Materials, mechanisms, and applications. Appl. Phys. Rev. 2018, 5, 041306.

- Wu, Z.; Zhang, S.; Liu, Z.; Mu, E.; Hu, Z. Thermoelectric converter: Strategies from materials to device application. Nano Energy 2022, 91, 106692.

- Ryu, H.; Yoon, H.J.; Kim, S.W. Hybrid Energy Harvesters: Toward Sustainable Energy Harvesting. Adv. Mater. 2019, 31, 1802898.

- Kim, W.; Yasmeen, S.; Nguyen, C.T.; Lee, H.B.; Choi, D. Toward Enhanced Humidity Stability of Triboelectric Mechanical Sensors via Atomic Layer Deposition. Nanomaterials 2021, 11, 1795.

- Ra, Y.; Choi, J.H.; La, M.; Park, S.J.; Choi, D. Development of a highly transparent and flexible touch sensor based on triboelectric effect. Funct. Compos. Struct. 2019, 1, 045001.

- Son, J.H.; Chung, S.H.; Cha, K.; Kim, S.; Lin, Z.H.; Hong, J.; Chung, J.; Lee, S. Ultrahigh Performance, Serially Stackable, Breeze Driven Triboelectric Generator via Ambient Air Ionizing Channel. Adv. Mater. 2023, 35, 2300283.

- Hwang, H.J.; Choi, D. The coupled effects of an electron blocking layer beneath tribomaterials for boosted triboelectric nanogenerators. Funct. Compos. Struct. 2021, 3, 025004.

- Jeong, S.-H.; Lee, Y.; Lee, M.-G.; Song, W.J.; Park, J.-U.; Sun, J.-Y. Accelerated wound healing with an ionic patch assisted by a triboelectric nanogenerator. Nano Energy 2021, 79, 105463.

- Song, K.Y.; Kim, S.W.; Nguyen, D.C.; Park, J.Y.; Luu, T.T.; Choi, D.; Baik, J.M.; An, S. Recent progress on nature-derived biomaterials for eco-friendly triboelectric nanogenerators. EcoMat 2023, 5, e12357.

- Wang, C.; Shi, Q.; Lee, C. Advanced Implantable Biomedical Devices Enabled by Triboelectric Nanogenerators. Nanomaterials 2022, 12, 1366.

- Menge, H.G.; Huynh, N.D.; Hwang, H.J.; Han, S.; Choi, D.; Park, Y.T. Designable Skin-like Triboelectric Nanogenerators Using Layer-by-Layer Self-Assembled Polymeric Nanocomposites. ACS Energy Lett. 2021, 6, 2451–2459.

- Chang, K.-B.; Parashar, P.; Shen, L.-C.; Chen, A.-R.; Huang, Y.-T.; Pal, A.; Lim, K.-C.; Wei, P.-H.; Kao, F.-C.; Hu, J.-J.; et al. A triboelectric nanogenerator-based tactile sensor array system for monitoring pressure distribution inside prosthetic limb. Nano Energy 2023, 111, 108397.

- Choi, D.; Lee, Y.; Lin, Z.H.; Cho, S.; Kim, M.; Ao, C.K.; Soh, S.; Sohn, C.; Jeong, C.K.; Lee, J.; et al. Recent Advances in Triboelectric Nanogenerators: From Technological Progress to Commercial Applications. ACS Nano 2023, 17, 11087–11219.

- Karan, S.K.; Maiti, S.; Lee, J.H.; Mishra, Y.K.; Khatua, B.B.; Kim, J.K. Recent Advances in Self-Powered Tribo-/Piezoelectric Energy Harvesters: All-In-One Package for Future Smart Technologies. Adv. Funct. Mater. 2020, 30, 2004446.

- Qin, Q.; Cao, X.; Wang, N. Ball-Mill-Inspired Durable Triboelectric Nanogenerator for Wind Energy Collecting and Speed Monitoring. Nanomaterials 2023, 13, 939.

- Ahn, J.; Kim, J.S.; Jeong, Y.; Hwang, S.; Yoo, H.; Jeong, Y.; Gu, J.; Mahato, M.; Ko, J.; Jeon, S.; et al. All-Recyclable Triboelectric Nanogenerator for Sustainable Ocean Monitoring Systems. Adv. Energy Mater. 2022, 12, 2201341.

- Maiti, S.; Karan, S.K.; Kim, J.K.; Khatua, B.B. Nature Driven Bio-Piezoelectric/Triboelectric Nanogenerator as Next-Generation Green Energy Harvester for Smart and Pollution Free Society. Adv. Energy Mater. 2019, 9, 1803027.

- Zhang, X.; Zhao, J.; Fu, X.; Lin, Y.; Qi, Y.; Zhou, H.; Zhang, C. Broadband vibration energy powered autonomous wireless frequency monitoring system based on triboelectric nanogenerators. Nano Energy 2022, 98, 107209.

- Yang, Y.; Chen, L.; He, J.; Hou, X.; Qiao, X.; Xiong, J.; Chou, X. Flexible and Extendable Honeycomb-Shaped Triboelectric Nanogenerator for Effective Human Motion Energy Harvesting and Biomechanical Sensing. Adv. Mater. Technol. 2021, 7, 2100702.

- Paria, S.; Bera, R.; Karan, S.K.; Maitra, A.; Das, A.K.; Si, S.K.; Halder, L.; Bera, A.; Khatua, B.B. Insight into Cigarette Wrapper and Electroactive Polymer Based Efficient TENG as Biomechanical Energy Harvester for Smart Electronic Applications. ACS Appl. Energy Mater. 2018, 1, 4963–4975.

- Gao, C.; Liu, T.; Luo, B.; Cai, C.; Zhang, W.; Zhao, J.; Yuan, J.; Fatehi, P.; Qin, C.; Nie, S. Cellulosic triboelectric materials for stable energy harvesting from hot and humid conditions. Nano Energy 2023, 111, 108426.

- Lu, D.; Liu, T.; Meng, X.; Luo, B.; Yuan, J.; Liu, Y.; Zhang, S.; Cai, C.; Gao, C.; Wang, J.; et al. Wearable Triboelectric Visual Sensors for Tactile Perception. Adv. Mater. 2023, 35, 2209117.

- Wang, W.; Sun, W.; Du, Y.; Zhao, W.; Liu, L.; Sun, Y.; Kong, D.; Xiang, H.; Wang, X.; Li, Z.; et al. Triboelectric Nanogenerators-Based Therapeutic Electrical Stimulation on Skin: From Fundamentals to Advanced Applications. ACS Nano 2023, 17, 9793–9825.

- Zhang, S.; Chi, M.; Mo, J.; Liu, T.; Liu, Y.; Fu, Q.; Wang, J.; Luo, B.; Qin, Y.; Wang, S.; et al. Bioinspired asymmetric amphiphilic surface for triboelectric enhanced efficient water harvesting. Nat. Commun. 2022, 13, 4168.

- Arief, I.; Zimmermann, P.; Hait, S.; Park, H.; Ghosh, A.K.; Janke, A.; Chattopadhyay, S.; Nagel, J.; Heinrich, G.; Wiessner, S.; et al. Elastomeric microwell-based triboelectric nanogenerators by in situ simultaneous transfer-printing. Mater. Horiz. 2022, 9, 1468–1478.

- Zhang, Y.; Wang, H.; Lu, H.; Li, S.; Zhang, Y. Electronic fibers and textiles: Recent progress and perspective. iScience 2021, 24, 102716.

- Dong, K.; Hu, Y.; Yang, J.; Kim, S.-W.; Hu, W.; Wang, Z.L. Smart textile triboelectric nanogenerators: Current status and perspectives. MRS Bull. 2021, 46, 512–521.

- Yang, B.; Xiong, Y.; Ma, K.; Liu, S.; Tao, X. Recent advances in wearable textile-based triboelectric generator systems for energy harvesting from human motion. EcoMat 2020, 2, e12054.

- Shi, Q.; Sun, J.; Hou, C.; Li, Y.; Zhang, Q.; Wang, H. Advanced Functional Fiber and Smart Textile. Adv. Fiber Mater. 2019, 1, 3–31.

- Fan, C.; Zhang, Y.; Liao, S.; Zhao, M.; Lv, P.; Wei, Q. Manufacturing Technics for Fabric/Fiber-Based Triboelectric Nanogen-erators: From Yarns to Micro-Nanofibers. Nanomaterials 2022, 12, 2703.

- Yin, Z.; Lu, H.; Gan, L.; Zhang, Y. Electronic Fibers/Textiles for Health-Monitoring: Fabrication and Application. Adv. Mater. Technol. 2022, 8, 2200654.

- Li, L.; Hao, R.; Qin, J.; Song, J.; Chen, X.; Rao, F.; Zhai, J.; Zhao, Y.; Zhang, L.; Xue, J. Electrospun Fibers Control Drug Delivery for Tissue Regeneration and Cancer Therapy. Adv. Fiber Mater. 2022, 4, 1375–1413.

- Zhu, C.; Wu, J.; Yan, J.; Liu, X. Advanced Fiber Materials for Wearable Electronics. Adv. Fiber Mater. 2022, 5, 12–35.

- Dong, K.; Peng, X.; Wang, Z.L. Fiber/Fabric-Based Piezoelectric and Triboelectric Nanogenerators for Flexible/Stretchable and Wearable Electronics and Artificial Intelligence. Adv. Mater. 2020, 32, 1902549.

- Ge, X.; Hu, N.; Yan, F.; Wang, Y. Development and applications of electrospun nanofiber-based triboelectric nanogenerators. Nano Energy 2023, 112, 108444.

- Wang, W.; Yu, A.; Zhai, J.; Wang, Z.L. Recent Progress of Functional Fiber and Textile Triboelectric Nanogenerators: Towards Electricity Power Generation and Intelligent Sensing. Adv. Fiber Mater. 2021, 3, 394–412.

- Bhatta, T.; Maharjan, P.; Cho, H.; Park, C.; Yoon, S.H.; Sharma, S.; Salauddin, M.; Rahman, M.T.; Rana, S.M.S.; Park, J.Y. High-performance triboelectric nanogenerator based on MXene functionalized polyvinylidene fluoride composite nanofibers. Nano Energy 2021, 81, 105670.

- Cheon, S.; Kang, H.; Kim, H.; Son, Y.; Lee, J.Y.; Shin, H.-J.; Kim, S.-W.; Cho, J.H. High-Performance Triboelectric Nanogenerators Based on Electrospun Polyvinylidene Fluoride-Silver Nanowire Composite Nanofibers. Adv. Funct. Mater. 2018, 28, 1703778.

- Shi, L.; Jin, H.; Dong, S.; Huang, S.; Kuang, H.; Xu, H.; Chen, J.; Xuan, W.; Zhang, S.; Li, S.; et al. High-performance triboelectric nanogenerator based on electrospun PVDF-graphene nanosheet composite nanofibers for energy harvesting. Nano Energy 2021, 80, 105599.

- Rana, S.M.S.; Rahman, M.T.; Salauddin, M.; Sharma, S.; Maharjan, P.; Bhatta, T.; Cho, H.; Park, C.; Park, J.Y. Electrospun PVDF-TrFE/MXene Nanofiber Mat-Based Triboelectric Nanogenerator for Smart Home Appliances. ACS Appl. Mater. Interfaces 2021, 13, 4955–4967.

- Chen, G.; Au, C.; Chen, J. Textile Triboelectric Nanogenerators for Wearable Pulse Wave Monitoring. Trends Biotechnol. 2021, 39, 1078–1092.

- Pu, X.; An, S.; Tang, Q.; Guo, H.; Hu, C. Wearable triboelectric sensors for biomedical monitoring and human-machine interface. iScience 2021, 24, 102027.

- Xiong, X.; Liang, J.; Wu, W. Principle and recent progress of triboelectric pressure sensors for wearable applications. Nano Energy 2023, 113, 108542.

- Lama, J.; Yau, A.; Chen, G.; Sivakumar, A.; Zhao, X.; Chen, J. Textile triboelectric nanogenerators for self-powered biomon-itoring. J. Mater. Chem. A 2021, 9, 19149–19178.

- Zhi, C.; Shi, S.; Meng, S.; Wu, H.; Si, Y.; Zhang, K.; Zhang, S.; Hu, J. A biocompatible and antibacterial all-textile structured triboelectric nanogenerator for self-powered tactile sensing. Nano Energy 2023, 115, 108734.

- Tang, Q.; Ke, Q.; Chen, Q.; Zhang, X.; Su, J.; Ning, C.; Fang, L. Flexible, Breathable, and Self-Powered Patch Assembled of Electrospun Polymer Triboelectric Layers and Polypyrrole-Coated Electrode for Infected Chronic Wound Healing. ACS Appl. Mater. Interfaces 2023, 15, 17641–17652.

- He, H.; Liu, J.; Wang, Y.; Zhao, Y.; Qin, Y.; Zhu, Z.; Yu, Z.; Wang, J. An Ultralight Self-Powered Fire Alarm e-Textile Based on Conductive Aerogel Fiber with Repeatable Temperature Monitoring Performance Used in Firefighting Clothing. ACS Nano 2022, 16, 2953–2967.

- Ma, L.; Wu, R.; Patil, A.; Yi, J.; Liu, D.; Fan, X.; Sheng, F.; Zhang, Y.; Liu, S.; Shen, S.; et al. Acid and Alkali-Resistant Textile Triboelectric Nanogenerator as a Smart Protective Suit for Liquid Energy Harvesting and Self-Powered Monitoring in High-Risk Environments. Adv. Funct. Mater. 2021, 31, 2102963.

- Lei, D.; Wu, J.; Zi, Y.; Pan, C.; Cui, H.; Li, X. Self-Powered Sterilization System for Wearable Devices Based on Biocompatible Materials and Triboelectric Nanogenerator. ACS Appl. Electron. Mater. 2023, 5, 2819–2828.

- Jiang, Y.; Dong, K.; An, J.; Liang, F.; Yi, J.; Peng, X.; Ning, C.; Ye, C.; Wang, Z.L. UV-Protective, Self-Cleaning, and Antibacterial Nanofiber-Based Triboelectric Nanogenerators for Self-Powered Human Motion Monitoring. ACS Appl. Mater. Interfaces 2021, 13, 11205–11214.

- Wang, J.; He, J.; Ma, L.; Yao, Y.; Zhu, X.; Peng, L.; Liu, X.; Li, K.; Qu, M. A humidity-resistant, stretchable and wearable tex-tile-based triboelectric nanogenerator for mechanical energy harvesting and multifunctional self-powered haptic sensing. Chem. Eng. J. 2021, 423, 130200.

- Niu, L.; Peng, X.; Chen, L.; Liu, Q.; Wang, T.; Dong, K.; Pan, H.; Cong, H.; Liu, G.; Jiang, G.; et al. Industrial production of bionic scales knitting fabric-based triboelectric nanogenerator for outdoor rescue and human protection. Nano Energy 2022, 97, 107168.

- Zhi, C.; Shi, S.; Zhang, S.; Si, Y.; Yang, J.; Meng, S.; Fei, B.; Hu, J. Bioinspired All-Fibrous Directional Moisture-Wicking Elec-tronic Skins for Biomechanical Energy Harvesting and All-Range Health Sensing. Nano-Micro Lett. 2023, 15, 60.

- Fan, F.-R.; Tian, Z.-Q.; Wang, Z.L. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334.

- Niu, S.; Wang, S.; Lin, L.; Liu, Y.; Zhou, Y.S.; Hu, Y.; Wang, Z.L. Theoretical study of contact-mode triboelectric nanogenerators as an effective power source. Energy Environ. Sci. 2013, 6, 3576.

- Wang, Z.L. On the expanded Maxwell’s equations for moving charged media system – General theory, mathematical solutions and applications in TENG. Mater. Today 2022, 52, 348–363.

- Huynh, N.D.; Choi, D. Mechanical Conversion and Transmission Systems for Controlling Triboelectric Nanogenerators. Nanoenergy Adv. 2022, 2, 29–51.

- Liu, Y.; Mo, J.; Fu, Q.; Lu, Y.; Zhang, N.; Wang, S.; Nie, S. Enhancement of Triboelectric Charge Density by Chemical Func-tionalization. Adv. Funct. Mater. 2020, 30, 2004714.

- Yoo, D.; Jang, S.; Cho, S.; Choi, D.; Kim, D.S. A Liquid Triboelectric Series. Adv. Mater. 2023, 35, 2300699.

- Cao, X.; Xiong, Y.; Sun, J.; Xie, X.; Sun, Q.; Wang, Z.L. Multidiscipline Applications of Triboelectric Nanogenerators for the Intelligent Era of Internet of Things. Nano-Micro Lett. 2023, 15, 14.

- Kim, J.; Campbell, A.S.; De Avila, B.E.; Wang, J. Wearable biosensors for healthcare monitoring. Nat. Biotechnol. 2019, 37, 389–406.

- Zou, Y.; Raveendran, V.; Chen, J. Wearable triboelectric nanogenerators for biomechanical energy harvesting. Nano Energy 2020, 77, 105303.

- Yang, Y.; Guo, X.; Zhu, M.; Sun, Z.; Zhang, Z.; He, T.; Lee, C. Triboelectric Nanogenerator Enabled Wearable Sensors and Electronics for Sustainable Internet of Things Integrated Green Earth. Adv. Energy Mater. 2022, 13, 2203040.

- Tat, T.; Libanori, A.; Au, C.; Yau, A.; Chen, J. Advances in triboelectric nanogenerators for biomedical sensing. Biosens. Bioelectron. 2021, 171, 112714.

- Su, Y.; Chen, G.; Chen, C.; Gong, Q.; Xie, G.; Yao, M.; Tai, H.; Jiang, Y.; Chen, J. Self-Powered Respiration Monitoring Enabled By a Triboelectric Nanogenerator. Adv. Mater. 2021, 33, 2101262.

- Fan, W.; He, Q.; Meng, K.; Tan, X.; Zhou, Z.; Zhang, G.; Yang, J.; Wang, Z.L. Machine-knitted washable sensor array textile for precise epidermal physiological signal monitoring. Sci. Adv. 2020, 6, eaay2840.

- Guo, J.; He, J.; Yuan, Z.; Tao, J.; Liu, X.; Song, Z.; Gao, W.; Wang, C.; Pan, C. Self-powered angle-resolved triboelectric nano-generator for underwater vibration localization. Nano Energy 2023, 110, 108392.

- Zou, Y.; Tan, P.; Shi, B.; Ouyang, H.; Jiang, D.; Liu, Z.; Li, H.; Yu, M.; Wang, C.; Qu, X.; et al. A bionic stretchable nanogenerator for underwater sensing and energy harvesting. Nat. Commun. 2019, 10, 2695.

- Das, N.K.; Ravipati, M.; Badhulika, S. Nickel Metal-Organic Framework/PVDF Composite Nanofibers based Self-Powered Wireless Sensor for Pulse Monitoring of Underwater Divers via Triboelectrically Generated Maxwell-Displacement Current. Adv. Funct. Mater. 2023, 33, 2303288.

- Xiao, X.; Xiao, X.; Nashalian, A.; Libanori, A.; Fang, Y.; Li, X.; Chen, J. Triboelectric Nanogenerators for Self-Powered Wound Healing. Adv. Healthc. Mater. 2021, 10, 2100975.

- Chang, A.; Uy, C.; Xiao, X.; Xiao, X.; Chen, J. Self-powered environmental monitoring via a triboelectric nanogenerator. Nano Energy 2022, 98, 107282.

- Feng, L.; Xu, S.; Sun, T.; Zhang, C.; Feng, J.; Yao, L.; Ge, J. Fire/Acid/Alkali-Resistant Aramid/Carbon Nanofiber Triboelectric Nanogenerator for Self-Powered Biomotion and Risk Perception in Fire and Chemical Environments. Adv. Fiber Mater. 2023, 5, 1478–1492.

- Sun, Z.; Zhu, M.; Lee, C. Progress in the Triboelectric Human–Machine Interfaces (HMIs)-Moving from Smart Gloves to AI/Haptic Enabled HMI in the 5G/IoT Era. Nanoenergy Adv. 2021, 1, 81–120.

- Padha, B.; Verma, S.; Mahajan, P.; Sundramoorthy, A.K.; Arya, S. An Insight into the Wearable Technologies Based on Novel Hybrid Piezoelectric-Triboelectric Nanogenerators. Energy Technol. 2023, 11, 2300224.

- Pang, Y.; Cao, Y.; Derakhshani, M.; Fang, Y.; Wang, Z.L.; Cao, C. Hybrid Energy-Harvesting Systems Based on Triboelectric Nanogenerators. Matter 2021, 4, 116–143.

- Meena, K.K.; Arief, I.; Ghosh, A.K.; Liebscher, H.; Hait, S.; Nagel, J.; Heinrich, G.; Fery, A.; Das, A. 3D-printed stretchable hybrid piezoelectric-triboelectric nanogenerator for smart tire: Onboard real-time tread wear monitoring system. Nano Energy 2023, 115, 108707.

- Mariello, M. Recent Advances on Hybrid Piezo-Triboelectric Bio-Nanogenerators: Materials, Architectures and Circuitry. Nanoenergy Adv. 2022, 2, 64–109.

- Lee, D.; Cho, S.; Jang, S.; Ra, Y.; Jang, Y.; Yun, Y.; Choi, D. Toward effective irregular wind energy harvesting: Self-adaptive mechanical design strategy of triboelectric-electromagnetic hybrid wind energy harvester for wireless environmental monitoring and green hydrogen production. Nano Energy 2022, 102, 107638.

- Chen, J.; Gong, S.; Gong, T.; Yang, X.; Guo, H. Stackable Direct Current Triboelectric-Electromagnetic Hybrid Nanogenerator for Self-Powered Air Purification and Quality Monitoring. Adv. Energy Mater. 2023, 13, 2203689.

- Lee, D.; Kim, I.; Kim, D. Hybrid tribo-thermoelectric generator for effectively harvesting thermal energy activated by the shape memory alloy. Nano Energy 2021, 82, 105696.

- Wang, Z.L.; Song, J. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 2006, 312, 242–246.

- Sun, J.; Yang, A.; Zhao, C.; Liu, F.; Li, Z. Recent progress of nanogenerators acting as biomedical sensors in vivo. Sci. Bull. 2019, 64, 1336–1347.

- Zhang, C.; Tang, W.; Han, C.; Fan, F.; Wang, Z.L. Theoretical comparison, equivalent transformation, and conjunction operations of electromagnetic induction generator and triboelectric nanogenerator for harvesting mechanical energy. Adv. Mater. 2014, 26, 3580–3591.

- Yang, Y.; Zhang, H.; Lin, Z.-H.; Liu, Y.; Chen, J.; Lin, Z.; Zhou, Y.S.; Wong, C.P.; Wang, Z.L. A hybrid energy cell for self-powered water splitting. Energy Environ. Sci. 2013, 6, 2429–2434.

- He, W.; Zhang, G.; Zhang, X.; Ji, J.; Li, G.; Zhao, X. Recent development and application of thermoelectric generator and cooler. Appl. Energy 2015, 143, 1–25.