Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Lin-Qing Zhang | -- | 2550 | 2023-10-22 12:38:51 | | | |

| 2 | Lindsay Dong | -1 word(s) | 2549 | 2023-10-23 05:13:42 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Zhang, L.; Miao, W.; Wu, X.; Ding, J.; Qin, S.; Liu, J.; Tian, Y.; Wu, Z.; Zhang, Y.; Xing, Q.; et al. Source/Drain Ohmic Contact with β-Ga2O3. Encyclopedia. Available online: https://encyclopedia.pub/entry/50646 (accessed on 07 February 2026).

Zhang L, Miao W, Wu X, Ding J, Qin S, Liu J, et al. Source/Drain Ohmic Contact with β-Ga2O3. Encyclopedia. Available at: https://encyclopedia.pub/entry/50646. Accessed February 07, 2026.

Zhang, Lin-Qing, Wan-Qing Miao, Xiao-Li Wu, Jing-Yi Ding, Shao-Yong Qin, Jia-Jia Liu, Ya-Ting Tian, Zhi-Yan Wu, Yan Zhang, Qian Xing, et al. "Source/Drain Ohmic Contact with β-Ga2O3" Encyclopedia, https://encyclopedia.pub/entry/50646 (accessed February 07, 2026).

Zhang, L., Miao, W., Wu, X., Ding, J., Qin, S., Liu, J., Tian, Y., Wu, Z., Zhang, Y., Xing, Q., & Wang, P. (2023, October 22). Source/Drain Ohmic Contact with β-Ga2O3. In Encyclopedia. https://encyclopedia.pub/entry/50646

Zhang, Lin-Qing, et al. "Source/Drain Ohmic Contact with β-Ga2O3." Encyclopedia. Web. 22 October, 2023.

Copy Citation

β-Ga2O3, with excellent bandgap, breakdown field, and thermal stability properties, is considered to be one of the most promising candidates for power devices including field-effect transistors (FETs) and for other applications such as Schottky barrier diodes (SBDs) and solar-blind ultraviolet photodetectors. Ohmic contact is one of the key steps in the β-Ga2O3 device fabrication process for power applications.

β-Ga2O3

Ohmic contact

ion implantation

interface

1. Introduction

Si-based devices are the dominant devices used for power applications. However, with the increasing demand for much faster and more convenient network communication, Si-based device techniques cannot meet these requirements due to their physical properties. Thus, new-material devices should be investigated for operating at high temperatures, at high power, and in harsh environments. In recent years, wide-bandgap semiconductors including GaN (3.4 eV) and SiC (3.25 eV) have been developed, and they have replaced Si-based techniques in many fields due to their advantages in terms of their material properties [1][2][3][4][5]. Recently, β-Ga2O3, which is mostly thermally and chemically stable in five polymorphs [6][7][8], has attracted more and more attention for power applications because β-Ga2O3 has a wide bandgap of 4.6–4.9 eV and a breakdown field strength as high as 8 MV/cm [9][10][11]. In addition, for the Baliga figure and Johnson’s figure of merit, when evaluating its application potential in power devices, β-Ga2O3 exhibits the best performance [9][10][11].

2. Basic Metal–Ga2O3 Contact Physical Theory

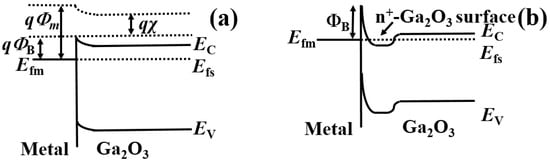

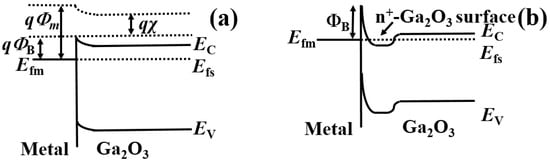

Metal–semiconductor contact is a critical part of β-Ga2O3 power devices. A device’s performance is mainly limited by the Ohmic contact property. Two types of contacts (Schottky and Ohmic) can be formed due to the differences in the work functions of contact metals [12][13][14]. For wide-bandgap β-Ga2O3, the contacts always exhibit Schottky behavior. When metal and Ga2O3 come into contact, the energy band of the Ga2O3 side bends up to make their Fermi levels equal. As shown in Figure 1, the Schottky barrier height from the metal side (ΦB) can be described as

ΦB = Φm − χ,

where χ represents the semiconductor’s electron affinity (4 eV for Ga2O3 in thecase [15]) and Φm represents the metal work function. Therefore, it is desirable to select a metal with a Φm lower than 4 eV to realize a negative ΦB, which allows electrons to flow freely across it to form an Ohmic contact. Unfortunately, the lack of suitable metal materials with lower work functions makes Ohmic contact formation challenging. Generally, researchers have proposed Ohmic contact schemes to form a lower ΦB or an n+-doped Ga2O3 region for electron tunneling. When a semiconductor is heavily doped (ND > 1018 cm−3), field emission (FE) dominates the electron tunneling [16][17]. In order to obtain a low RC or ρc, a higher ND is expected.

Figure 1. Energy-band diagrams of metal–Ga2O3 Schottky contacts with (a) a lower Φbn and (b) an n+-doped Ga2O3 region.

The Ohmic contact resistance (RC, measured in Ω·mm) and specific contact resistance (ρc, measured in Ω·cm−2) are always determined using the transmission line model (TLM) method [18][19]. Details concerning the TLM measurement technique can be seen in the references mentioned above.

The metal work function, metal schemes, interfacial reactions between metal and a semiconductor during the annealing process, and the doping concentration of Ga2O3 in the source/drain region are significant influencing factors for the Ohmic contact property. Until now, researchers from universities and research institutes have proposed Ohmic contact schemes involving optimizing the metal materials, annealing condition, source/drain doping method and concentration, and source/drain etching as well as adding an interlayer in the source/drain region.

3. Approaches to Metal–Ga2O3 Ohmic Contact

3.1. Metal Electrode

From the metal–semiconductor contact theory, the work function of the selected metal material crucially affects the Ohmic contact quality. Thus, in the early period, Yao et al. [20] investigated the Ohmic contact properties and surface morphologies of nine metal materials, including Ti, In, Ag, Sn, W, Mo, Sc, Zn, and Zr with Sn-doped (2̲ 01) β-Ga2O3. From their results, the work function is not the main factor influencing the contact quality. Sc, with the lowest work function, cannot form Ohmic contacts under different annealing conditions. Ti/Au metal schemes with a 400 °C annealing process exhibited the lowest RC values. Cross-sectional transmission electron microscopy (TEM) and energy-dispersive X-ray spectroscopy (EDX) mapping showed that Ga and O diffused into the Ti layer during the annealing process. They concluded that interfacial reactions during the annealing process played a crucial part in Ohmic contact formation.

Other groups have reported Mg/Au and Cr/Au metal schemes for Ohmic contact formation [21][22]. In the Mg (3.66 eV)/Au method, the ρc of 2.2 × 10−4~2.1 × 10−5 Ω·cm−2 was achieved with an annealing process at temperatures varying from 300 °C to 500 °C. Until now, the most common metallization schemes of Ohmic contact for β-Ga2O3 have used Ti/Au. Ti is used as an adhesion layer with a low work function. Au serves as a cap layer to prevent the oxidation of metal stacks during the high-temperature process.

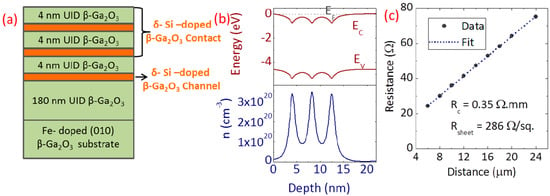

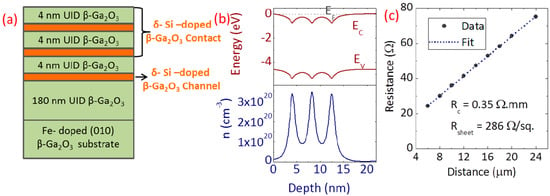

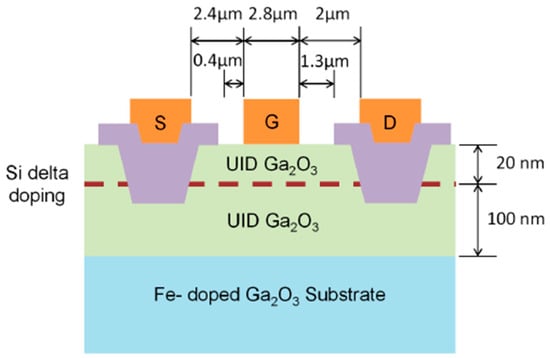

Also, multilayer metal contact schemes were proposed for obtaining lower RC values, such as Ti/Al/Au [23][24], Ti/Al/Ni/Au [25][26], and Ti/Au/Ni [27][28]. As can be seen in Figure 2, Krishnamoorthy et al. formed a δ-doped β-Ga2O3 structure in the source/drain region to form a heavily doped contact area. After Ti/Au/Ni deposition, a 470 °C RTA process was employed for 1 min for Ohmic contact formation. The extracted RC and ρc were 0.35 Ω·mm and 4.3 × 10−6 Ω·cm−2, respectively. In addition, the fabricated β-Ga2O3 FET exhibited excellent ID and gm results. By using Ti/Al/Au contact metals, Zhou et al. [24] achieved a low RC of 0.75 Ω·mm by adopting a highly Sn-doped channel.

Figure 2. (a) Device structure, (b) equilibrium band diagram and charge profile, and (c) TLM results. Reproduced from Ref. [28].

In 2022, Tetzner et al. [29] used a TiW alloy instead of the traditional Ti/Au metal schemes, and a low ρc of 1.5 × 10−5 Ω·cm−2 was extracted after a 700 °C RTA process. The temperature was 200 °C higher than that of the Ti/Au schemes. To understand the Ohmic contact formation mechanism, STEM HAADF and EDX were employed. The STEM HAADF image showed that a 3–5 nm TiOX interlayer was formed, which was confirmed with the STEM EDX. They suspected that vacancies, defects, or Ga impurities that exist in the interlayer are beneficial for electrons flowing freely to reduce the RC.

Thermal stability is another important index of contact quality. For Ti/Au electrodes, the most commonly used annealing temperatures are between 400 °C to 500 °C. Above 500 °C, Yao et al. [20] found that the Ohmic contacts degraded in their results. In 2022, Lee et al. [30] systematically investigated the influence of temperature on Ohmic contact quality. In their results, when the annealing temperature increased from 470 °C to 520 °C, aggressive Au diffused into the interface and reacted with Ga that diffused out, resulting in a much thicker Ti–TiOx layer due to GaAu2 formation, which accounted for the contact degradation.

3.2. Surface Treatment

A surface treatment before metal deposition can also help improve the Ohmic contact property (dry etching, plasma bombardment, etc.). In 2012, Higashiwaki et al. [31] compared the I–V results of Ga2O3 devices with and without the RIE treatment. The RIE process was implemented by using a BCl3/Ar mixing gas for 1 min before Ti/Au (20/230 nm) deposition. The samples with the RIE treatment exhibited Ohmic contact characteristics, while without the RIE process the samples showed Schottky contact features. They speculated that the Ohmic contact formation was due to the large number of oxygen-vacancy surface defects formed during the RIE process. The defects acted as donors for Ohmic contact realization. Combined with Si ion implantation [32], they achieved a ρc of 4.6 × 10−6 Ω·cm−2 with a doping concentration of 5 × 1019 cm−3.

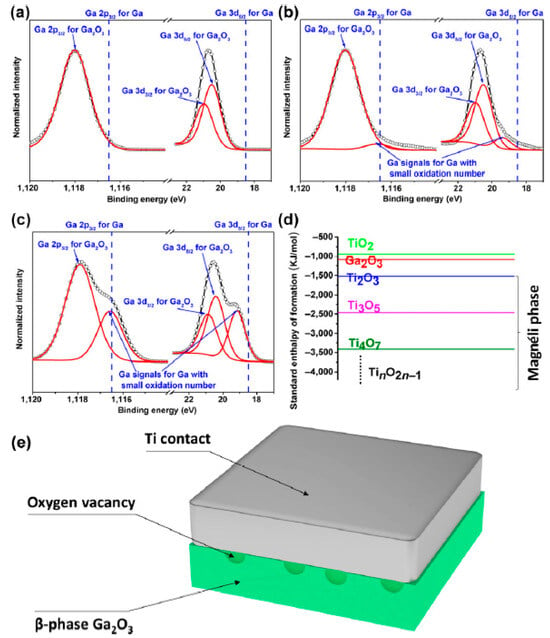

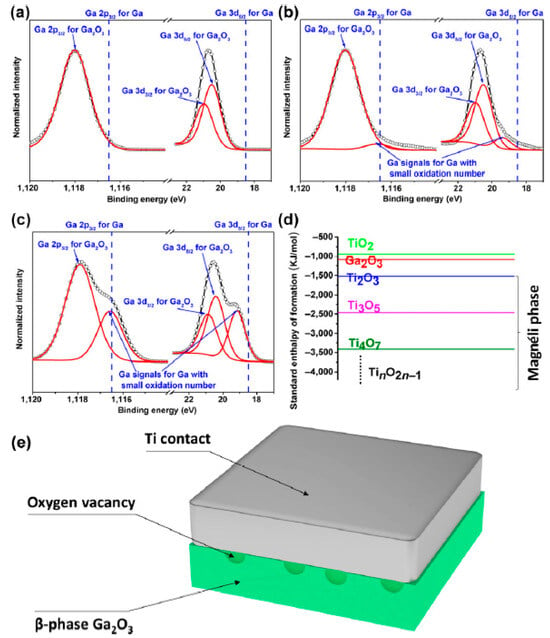

Also, the annealing temperature and atmosphere may affect the interfacial reactions that dominate Ohmic contact formation. Bae et al. [33] compared the electrical results of the fabricated β-Ga2O3 nanobelts under different atmospheres with various temperatures. The samples treated under a N2 atmosphere exhibited better characteristics that the ones treated in an air environment. Under an Ar atmosphere, Li et al. [34] reduced the RC to 0.387 Ω·mm by optimizing the annealing temperature and the durations. In their results, a large drain current density of ~3.1 mA/μm (Vds = 100 V) was achieved due to the low RC. To fully understand the influence of an Ar atmosphere on improving the β-Ga2O3 device’s I–V characteristics, XPS was used to show the material changes during the RTA process. From the results, as can be seen in Figure 33, they deduced that Ti reduced β-Ga2O3 and generated large numbers of oxygen vacancies at the interface during the annealing process, which served as effective electron donors. For this reason, the depletion layer was narrower, resulting in Ohmic behavior and a low RC for β-Ga2O3 FETs. The annealing temperature is another element that affects the interface reactions to determine the Ohmic contact property.

Figure 3. XPS results from β-Ga2O3. (a) Normalized Ga 2p3/2 XPS spectra and Ga 3d XPS spectra from pure β-Ga2O3, (b) β-Ga2O3 after annealing in argon at 300 °C for 180 min, and (c) Ti-coated (1 nm) β-Ga2O3 after annealing in argon at 300 °C for 180 min. Black dots show experimental data, and red curves show simulated fitting curves. (d) Free energy scheme of different metal oxides. (e) Schematic diagram of the proposed oxygen vacancy model at the Ti/β-Ga2O3 interface. Reproduced from Ref. [34].

3.3. Ion Implantation

The ion-implantation doping technique (including Si, Sn, etc.) is another effective way for Ga2O3 to realize low-contact-resistance Ohmic electrodes by forming a heavily doped n+ region that facilitates electron flow. In 2013, Sasaki et al. [32] successfully fabricated Ohmic electrodes with a low contact resistance via Si implantation, which requires the MOVPE method in β-Ga2O3. They optimized the Si doping concentration to 5 × 1019 cm−3, which was activated by annealing at a temperature of 950 °C. The RC and ρc in their results were as low as 1.4 mΩ·cm and 4.6 × 10−6 Ω·cm−2, respectively. In other results, Zhou et al. [23] doped β-Ga2O3 with Sn at a concentration of 2.7 × 1018 cm−3. Combined with Ar plasma bombardment, the RC was dramatically reduced to 0.95 Ω·mm. The fabricated devices also exhibited an excellent on/off ratio and output characteristics and a low SS value. In addition, Ge and Sn were also studied for doping β-Ga2O3 [35]. In that study, the samples were treated under the same annealing condition (925 °C for 30 min). The efficiencies of Sn, Ge, and Si were calculated to be 28.2%, 40.3%, and 64.7%, respectively, using SIMS measurements. The same activation annealing condition for Ge and Sn with Si resulted in low activation efficiencies for Ge and Sn. The heavier Ge and Sn ions also created more implant damage than the Si ions due to the greater momentum transfer required to achieve the same implant depth, likely contributing to decreased implant activation and increasing both the contact and sheet resistances.

3.4. Epitaxial Regrowth

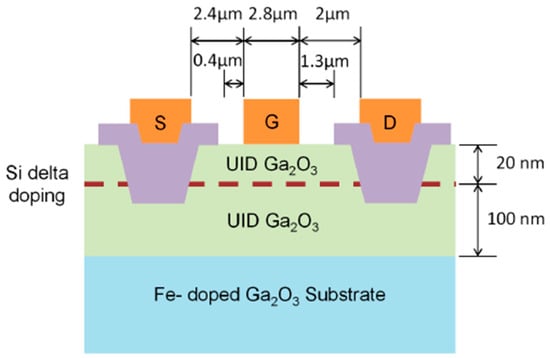

To further reduce the contact resistance, regrown contacts have been reported to fabricate Ohmic contacts. Ion implantation and spin-on-glass techniques need a high annealing temperature around 900–1200 °C and potentially deteriorate the material quality in the active region. However, the regrowth process, which is performed at a much lower temperature of about 600 °C can avoid this potential problem. In 2018, Xia et al. [27] used a molecular-beam epitaxy (MBE) method to form a heavily doped n-type Ga2O3 with a doping concentration of 2 × 1020 cm−3. The device’s structure can be seen in Figure 4. An extracted RC of 1.5 Ω·mm was obtained from the TLM structure. The regrowth technique avoids gate recessing and potential damage associated with etching, which may degrade the carrier mobility. The fabricated devices exhibited a peak drain current of 140 mA/mm and an excellent transconductance of 34 mS/mm.

Figure 4. Device schematic of delta-doped β-Ga2O3 MESFET. Reproduced from Ref. [27].

The existing results that have been reported in recent years demonstrate that regrown contact is an effective approach to achieve an ultralow RC. Epitaxial regrowth obtains a high-quality crystalline film and can be versatile. However, there are also several constraints, such as low throughput, high expense, strict material compatibility, and the need for selective growth or subsequent etchings, as mentioned in Refs. [36][37].

3.5. Adding the Interlayer

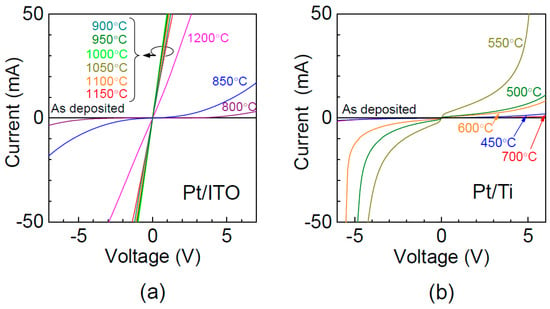

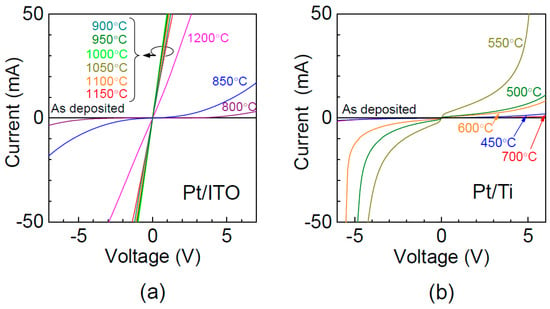

The Ti/Au schemes always form a 3–5 nm interlayer, which facilitates electron transport for Ohmic contact formation. Another approach is inserting an intermediate semiconductor layer (ISL) with a low work function and a narrower bandgap. In 2016, Oshima et al. [38] proved the insertion of indium tin oxide (ITO) for forming Ohmic contact with β-Ga2O3. In their results, as shown in Figure 5, the ITO method exhibited Ohmic behavior at temperatures from 900 °C to 1150 °C. However, Pt/β-Ga2O3 maintained Schottky contact, even at the RTA temperature of 500 °C. They also confirmed the existence of an intermediate semiconductor layer (ISL) at the interface using TEM and EDS analyses.

Figure 5. Typical I–V characteristics of (a) Pt/ITO and (b) Pt/Ti electrodes annealed at various temperatures. Reproduced from Ref. [38].

Other elements such as substrate orientation have also been reported to influence the Ohmic contact property. To form Ohmic contact, Ti/Au contacts were deposited, followed by an RTA process at 450 °C for 5 min, which was employed on both (2̲

01) and (010) Sn-doped Ga2O3. The former sample exhibited Ohmic characteristics compared to the rectifying behavior of the (010) sample. Related content has also been investigated and reported by other groups [39][40][41][42].

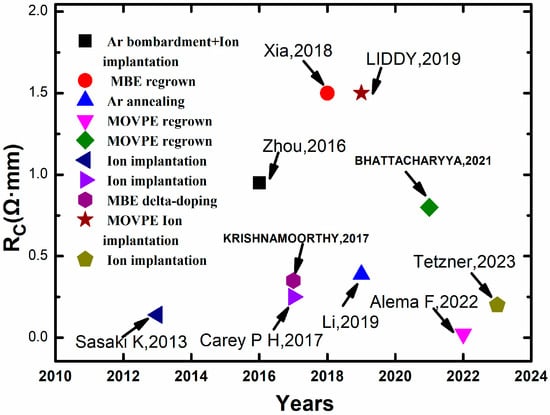

In recent years, researchers have investigated and optimized the Ohmic contact property of β-Ga2O3 by choosing a metal with a proper work function and investigating metal schemes, interfacial reactions between metal and semiconductors during the annealing process, and the doping concentration of Ga2O3 in the source/drain region, and they have achieved excellent results. Representative results with excellent Ohmic contact quality are summarized in Figure 6 [23][27][28][32][34][43][44][45][46][47]. Despite the significant improvement in the Ohmic contact techniques for β-Ga2O3, there are also some questions that need to be solved before commercializing the devices. (1) For power device applications, contact performance in high-temperature, -current, and -voltage environments is another concern. Failure analyses of the electrical stress/cycling of Ohmic electrodes have been investigated for other WBG semiconductor systems [48][49][50], while for β-Ga2O3, the research is lacking and efforts should be made to understand the degradation mechanism of Ohmic contacts under electrical stress. (2) To realize the integration of β-Ga2O3 semiconductors into Si CMOS technology, Au-free metal schemes should be investigated and proposed. The commonly used Ti/Au layer for Ga2O3 is not CMOS-compatible due to the existence of Au, which is a contaminant for Si fabrication lines [51][52]. Au is used for oxidation protection. Some oxidation-resistant capping materials, such as TiN, which has been proven to realize low-RC Ohmic contact in AlGaN/GaN HEMT [53], can be substitutes for Ohmic contact realization in β-Ga2O3 devices. Related investigations should be carried out to prove the feasibility of Au-free schemes. (3) RIE, ion implantation, and epitaxial regrowth are used to achieve a low RC. For the RIE process, the influences of plasma gas (including BCl3/Ar, Ar, and CF4 [54]), plasma power, bias power, etc., should be fully understood. For ion implantation, the high-temperature annealing used for impurity activation and damage recovery may cause unwanted effects, which should be noticed and further studied. In addition, the effect of substrate orientation should also be investigated. Other annealing techniques can also be used for Ohmic contact formation in β-Ga2O3 devices [55][56].

References

- Sonnenberg, T.; Verploegh, S.; Pinto, M.; Popović, Z. W-Band GaN HEMT Frequency Multipliers. IEEE Trans. Microw. Theory Tech. 2023, 71, 4327–4336.

- Akso, E.; Collins, H.; Clymore, C.; Li, W.; Guidry, M.; Romanczyk, B.; Wurm, C.; Liu, W.; Hatui, N.; Hamwey, R.; et al. First Demonstration of Four-Finger N-polar GaN HEMT Exhibiting Record 712 mW Output Power With 31.7% PAE at 94 GHz. IEEE Microw. Wirel. Technol. Lett. 2023, 33, 683–686.

- Han, L.; Tang, X.; Wang, Z.; Gong, W.; Zhai, R.; Jia, Z.; Zhang, W. Research Progress and Development Prospects of Enhanced GaN HEMTs. Crystals 2023, 13, 911.

- Li, H.; Zhao, S.; Wang, X.; Ding, L.; Mantooth, A.H. Parallel Connection of Silicon Carbide MOSFETs Challenges, Mechanism, and Solutions. IEEE Trans. Power Electron. 2023, 38, 9731–9749.

- Lyu, G.; Sun, J.; Wei, J.; Chen, K.J. Static and Dynamic Characteristics of a 1200 V/22 mΩ Normally-Off SiC/GaN Cascode Device Built with Parallel-Connected SiC JFETs Controlled by a Single GaN HEMT. IEEE Trans. Power Electron. 2023, 38, 12648–12658.

- Roy, R.; Hill, V.G.; Osborn, E.F. Polymorphism of Ga2O3 and the system Ga2O3-H2O. J. Am. Chem. Soc. 1952, 74, 719–722.

- Yoshioka, S.; Hayashi, H.; Kuwabara, A.; Oba, F.; Matsunaga, K.; Tanaka, I. Structures and energetics of Ga2O3 polymorphs. J. Phys. Condens. Matter 2007, 19, 346211.

- Bechstedt, F.; Furthmüller, J. Influence of screening dynamics on excitons in Ga2O3 polymorphs. Appl. Phys. Lett. 2019, 114, 122101.

- Pearton, S.J.; Yang, J.; Cary, P.H.; Ren, F.; Kim, J.; Tadjer, M.J.; Mastro, M.A. A review of Ga2O3 materials, processing, and devices. Appl. Phys. Rev. 2018, 5, 011301.

- Wang, C.; Zhang, J.; Xu, S.; Zhang, C.; Feng, Q.; Zhang, Y.; Ning, J.; Zhao, S.; Zhou, H.; Hao, Y. Progress in state-of-the-art technologies of Ga2O3 devices. J. Phys. D Appl. Phys. 2021, 54, 243001.

- Sheoran, H.; Kumar, V.; Singh, R. A comprehensive review on recent developments in ohmic and Schottky contacts on Ga2O3 for device applications. ACS Appl. Electron. Mater. 2022, 4, 2589–2628.

- Mott, N.F. Note on the contact between a metal and an insulator or semi-conductor. In Mathematical Proceedings of the Cambridge Philosophical Society; Cambridge University Press: Cambridge, UK, 1938; pp. 568–572.

- Sze, S.M.; Ng, K.K. Physics of Semiconductor Devices; John Wiley & Sons: Hoboken, NJ, USA, 2006.

- Neamen, D. Semiconductor Physics and Devices; McGraw-Hill, Inc.: New York, NY, USA, 2002.

- Mohamed, M.; Irmscher, K.; Janowitz, C.; Galazka, Z.; Manzke, R.; Fornari, R. Schottky barrier height of Au on the transparent semiconducting oxide β-Ga2O3. Appl. Phys. Lett. 2012, 101, 132106.

- Sze, S.M. Physics of Semiconductor Devices, 2nd ed.; Wily: New York, NY, USA, 1982.

- Rideout, V.L. A review of the theory and technology for ohmic contacts to group III-V compound semiconductors. Solid-State Electron. 1975, 18, 541–550.

- Reeves, G.K.; Harrison, H.B. Obtaining the specific contact resistance from transmission line model measurements. IEEE Electron. Device Lett. 1982, 3, 111–113.

- Schroder, D.K. Contact Resistance and Schottky Barriers; Wiley: New York, NY, USA, 2006.

- Yao, Y.; Davis, R.F.; Porter, L.M. Investigation of different metals as ohmic contacts to β-Ga2O3: Comparison and analysis of electrical behavior, morphology, and other physical properties. J. Electron. Mater. 2017, 46, 2053–2060.

- Shi, J.; Xia, X.; Liang, H.; Abbas, Q.; Liu, J.; Zhang, H.; Liu, Y. Low resistivity ohmic contacts on lightly doped n-type β-Ga2O3 using Mg/Au. J. Mater. Sci. Mater. Electron. 2019, 30, 3860–3864.

- Ma, J.; Yoo, G. Low Subthreshold Swing Double-Gate β-Ga2O3 Field-Effect Transistors with Polycrystalline Hafnium Oxide Dielectrics. IEEE Electron. Device Lett. 2019, 40, 1317–1320.

- Zhou, H.; Si, M.; Alghamdi, S.; Qiu, G.; Yang, L.; Ye, P. High-Performance Depletion/Enhancement-mode β-Ga2O3 on Insulator (GOOI) Field-Effect Transistors with Record Drain Currents of 600/450 mA/mm. IEEE Electron. Device Lett. 2016, 38, 103–106.

- Zhou, H.; Maize, K.; Qiu, G.; Shakouri, A.; Ye, P. β-Ga2O3 on insulator field-effect transistors with drain currents exceeding 1.5 A/mm and their self-heating effect. Appl. Phys. Lett. 2017, 111, 092102.

- Chabak, K.D.; Moser, N.; Green, A.; Jr, D.; Tetlak, S.; Heller, E.; Crespo, A.; Fitch, R.; McCandless, J.; Leedy, K.; et al. Enhancement-mode Ga2O3 wrap-gate fin field-effect transistors on native (100) β-Ga2O3 substrate with high breakdown voltage. Appl. Phys. Lett. 2016, 109, 213501.

- Chen, J.; Li, X.; Ma, H.; Huang, W.; Ji, Z.; Xia, C.; Lu, H.; Zhang, W. Investigation of the mechanism for Ohmic contact formation in Ti/Al/Ni/Au contacts to β-Ga2O3 nanobelt field-effect transistors. ACS Appl. Mater. Interfaces 2019, 11, 32127–32134.

- Xia, Z.; Joishi, C.; Krishnamoorthy, S.; Bajaj, S.; Zhang, Y.; Brenner, M.; Lodha, S.; Rajan, S. Delta Doped β-Ga2O3 Field Effect Transistors with Regrown Ohmic Contacts. IEEE Electron. Device Lett. 2018, 39, 568–571.

- Krishnamoorthy, S.; Xia, Z.; Bajaj, S.; Brenner, M.; Rajan, S. Delta-doped β-gallium oxide field-effect transistor. Appl. Phys. Express 2017, 10, 051102.

- Tetzner, K.; Schewski, R.; Popp, A.; Anooz, S.; Chou, T.; Ostermay, I.; Kirmse, H.; Würfl, J. Refractory metal-based ohmic contacts on β-Ga2O3 using TiW. APL Mater. 2022, 10, 071108.

- Lee, M.H.; Chou, T.S.; Bin Anooz, S.; Galazka, Z.; Popp, A.; Peterson, R. Effect of post-metallization anneal on (100) Ga2O3/Ti-Au ohmic contact performance and interfacial degradation. APL Mater. 2022, 10, 091105.

- Higashiwaki, M.; Sasaki, K.; Kuramata, A.; Masui, T.; Yamakoshi, S. Gallium oxide (Ga2O3) metal-semiconductor field-effect transistors on single-crystal β-Ga2O3 (010) substrates. Appl. Phys. Lett. 2012, 100, 013504.

- Sasaki, K.; Higashiwaki, M.; Kuramata, A.; Masui, T.; Yamakoshi, S. Si-ion implantation doping in β-Ga2O3 and its application to fabrication of low-resistance ohmic contacts. Appl. Phys. Express 2013, 6, 086502.

- Bae, J.; Kim, H.Y.; Kim, J. Contacting mechanically exfoliated β-Ga2O3 nanobelts for (opto) electronic device applications. ECS J. Solid State Sci. Technol. 2016, 6, Q3045.

- Li, Z.; Liu, Y.; Zhang, A.; Liu, Q.; Shen, C.; Wu, F.; Xu, C.; Chen, M.; Fu, H.; Zhou, C. Quasi-two-dimensional β-Ga2O3 field effect transistors with large drain current density and low contact resistance via controlled formation of interfacial oxygen vacancies. Nano Res. 2019, 12, 143–148.

- Spencer, J.A.; Tadjer, M.J.; Jacobs, A.G.; Mastro, M.A.; Lyons, J.L.; Freitas, J.A., Jr.; Gallagher, J.C.; Thieu, Q.T.; Sasaki, K.; Kuramata, A.; et al. Activation of implanted Si, Ge, and Sn donors in high-resistivity halide vapor phase epitaxial β-Ga2O3: N with high mobility. Appl. Phys. Lett 2022, 121, 192102.

- Lee, M.H.; Peterson, R.L. Process and characterization of ohmic contacts for beta-phase gallium oxide. J. Mater. Res. 2021, 36, 4771–4789.

- Kim, H. Control and understanding of metal contacts to β-Ga2O3 single crystals: A review. SN Appl. Sci. 2022, 4, 27.

- Oshima, T.; Wakabayashi, R.; Hattori, M.; Hashiguchi, A.; Kawano, N.; Sasaki, K.; Masui, T.; Kuramata, A.; Yamakoshi, S.; Yoshimatsu, K. Formation of indium-tin oxide ohmic contacts for β-Ga2O3. Jpn. J. Appl. Phys. 2016, 55, 1202B7.

- Deng, Y.; Yang, Z.; Xu, T.; Jiang, H.; Ng, K.; Liao, C.; Su, D.; Pei, Y.; Chen, Z.; Wang, G. Band alignment and electrical properties of NiO/β-Ga2O3 heterojunctions with different β-Ga2O3 orientations. Appl. Surf. Sci. 2023, 622, 156917.

- Ingebrigtsen, M.E.; Vines, L.; Alfieri, G. Bulk β-Ga2O3 with (010) and (201) surface orientation: Schottky contacts and point defects. Mater. Sci. Forum 2017, 897, 755–758.

- Yatskiv, R.; Tiagulskyi, S.; Grym, J. Influence of crystallographic orientation on Schottky barrier formation in gallium oxide. J. Electron. Mater. 2020, 49, 5133–5137.

- Wong, M.H.; Nakata, Y.; Kuramata, A.; Yamakoshi, S.; Higashiwaki, M. Enhancement-mode Ga2O3 MOSFETs with Si-ion-implanted source and drain. Appl. Phys. Express 2017, 10, 041101.

- Bhattacharyya, A.; Roy, S.; Ranga, P.; Shoemaker, D.; Song, Y.; Lundh, J.; Choi, S.; Krishnamoorthy, S. 130 mA mm−1 β-Ga2O3 metal semiconductor field effect transistor with low-temperature metalorganic vapor phase epitaxy-regrown ohmic contacts. Appl. Phys. Express 2021, 14, 076502.

- Liddy, K.J.; Green, A.; Hendricks, N.; Heller, E.; Moser, N.; Leedy, K.; Popp, A.; Lindquist, M.; Tetlak, S.; Wagner, G.; et al. Thin channel β-Ga2O3 MOSFETs with self-aligned refractory metal gates. Appl. Phys. Express 2019, 12, 126501.

- Tetzner, K.; Thies, A.; Seyidov, P.; Chou, T.; Rehm, J.; Ostermay, J.; Galazka, Z.; Fiedler, A.; Popp, A.; Würfl, J. Ge-ion implantation and activation in (100) β-Ga2O3 for ohmic contact improvement using pulsed rapid thermal annealing. J. Vac. Sci. Technol. A 2023, 41, 043102.

- Alema, F.; Peterson, C.; Bhattacharyya, A.; Roy, S.; Krishnamoorthy, S.; Osinsky, A. Low resistance Ohmic contact on epitaxial MOVPE grown β-Ga2O3 and β-(AlxGa1-x)2O3 films. IEEE Electron. Device Lett. 2022, 43, 1649–1652.

- Carey, P.H.; Yang, J.; Ren, F.; Hays, D.; Pearton, S.; Kuramata, A.; Kravchenko, I. Improvement of Ohmic contacts on Ga2O3 through use of ITO-interlayers. J. Vac. Sci. Technol. B 2017, 35, 061201.

- Downey, B.P.; Mohney, S.E.; Clark, T.E.; Flemish, J. Reliability of aluminum-bearing ohmic contacts to SiC under high current density. MicroElectron. Reliab. 2010, 50, 1967–1972.

- Liu, L.; Ling, M.; Yang, J.; Xiong, W.; Jia, W.; Wang, G. Efficiency degradation behaviors of current/thermal co-stressed GaN-based blue light emitting diodes with vertical-structure. J. Appl. Phys. 2012, 111, 093110.

- Moens, P.; Banerjee, A.; Constant, A.; Coppens, P.; Caesar, M.; Li, Z.; Vandeweghe, W.; Declercq, F.; Padmanabhan, B.; Jeon, W. Intrinsic reliability assessment of 650V rated AlGaN/GaN based power devices: An industry perspective. ECS Trans. 2016, 72, 65.

- Li, Y.; Ng, G.I.; Arulkumaran, S.; Kumar, C.; Ang, K.; Anand, M.; Wang, H.; Hofstetter, R.; Ye, G. Low-contact-resistance non-gold Ta/Si/Ti/Al/Ni/Ta Ohmic contacts on undoped AlGaN/GaN high-electron-mobility transistors grown on silicon. Appl. Phys. Express 2013, 6, 116501.

- Piazza, M.; Dua, C.; Oualli, M.; Morvan, E.; Carisetti, D.; Wyczisk, F. Degradation of TiAlNiAu as ohmic contact metal for GaN HEMTs. MicroElectron. Reliab. 2009, 49, 1222–1225.

- Zhang, J.; Kang, X.; Wang, X.; Huang, S.; Chen, C.; Kei, K.; Zheng, Y.; Zhou, Q.; Chen, W.; Zhang, B.; et al. Ultralow-Contact-Resistance Au-Free Ohmic Contacts With Low Annealing Temperature on AlGaN/GaN Heterostructures. IEEE Electron. Device Lett. 2018, 39, 847–850.

- Jeong, Y.J.; Yang, J.Y.; Lee, C.H.; Park, R.; Lee, G.; Chung, R.; Yoo, G. Fluorine-based plasma treatment for hetero-epitaxial β-Ga2O3 MOSFETs. Appl. Surf. Sci. 2021, 558, 149936.

- Zhang, L.Q.; Shi, J.S.; Huang, H.F.; Liu, X.; Zhao, S.; Wang, P.; Zhang, W. Low-temperature Ohmic contact formation in GaN high electron mobility transistors using microwave annealing. IEEE Electron. Device Lett. 2015, 36, 896–898.

- Hou, M.; Xie, G.; Sheng, K. Improved device performance in AlGaN/GaN HEMT by forming ohmic contact with laser annealing. IEEE Electron. Device Lett. 2018, 39, 1137–1140.

More

Information

Subjects:

Physics, Applied

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.2K

Revisions:

2 times

(View History)

Update Date:

23 Oct 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No