| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Filipe Telmo Jeremias | -- | 4210 | 2023-10-18 11:42:53 | | | |

| 2 | Lindsay Dong | Meta information modification | 4210 | 2023-10-19 02:42:05 | | | | |

| 3 | Lindsay Dong | Meta information modification | 4210 | 2023-10-19 02:42:55 | | |

Video Upload Options

Mudrocks are fine-grained clay-rich rocks that comprise different lithotypes forming more than 60% of all sedimentary rocks, and thus, they occur frequently in engineering projects either as natural ground or as made ground. These rocks may display a range of engineering behaviours controlled mostly by their composition and structural features. Due to rapid breakdown and susceptibility to volume changes, they may cause problems both during and after construction. Research into the susceptibility of mudrocks to breakdown aims to predict problematic behaviour and provide guidance for avoiding or mitigating these effects. Low-durability materials that disintegrate during sampling and testing can be especially difficult to assess.

1. Introduction

2. Laboratory Testing of Mudrocks

2.1. Mineralogical, Textural, and Chemical Characterization

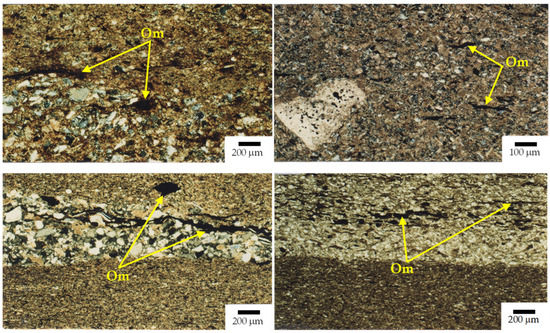

2.1.1. Polarizing Microscopy

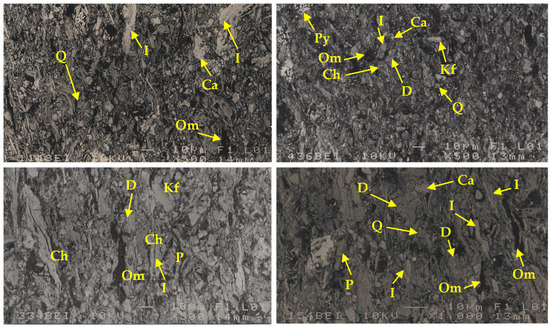

2.1.2. Scanning Electron Microscopy

2.1.3. X-ray Diffraction

2.1.4. Porosimetry

2.1.5. Chemical Analyses

2.2. Identification Test

2.2.1. Density and Porosity

2.2.2. Natural Water Content

2.2.3. Particle Size and Atterberg Limits

2.2.4. Methylene Blue Adsorption

2.3. Strength and Deformability

2.3.1. Uniaxial Compressive Strength Tests

2.3.2. Tensile Strength Tests

2.3.3. Point Load Test

2.3.4. Schmidt Rebound Test-Hammer

2.3.5. National Coal Board Cone Indenter (NCB)

2.4. Swelling

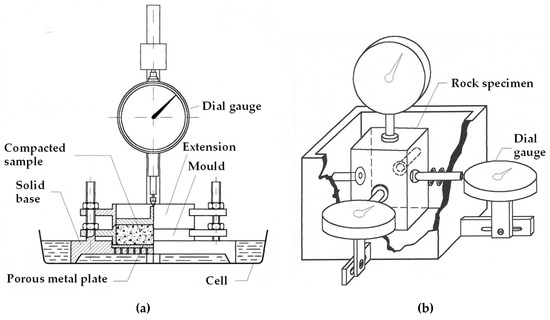

2.4.1. Swelling Strain

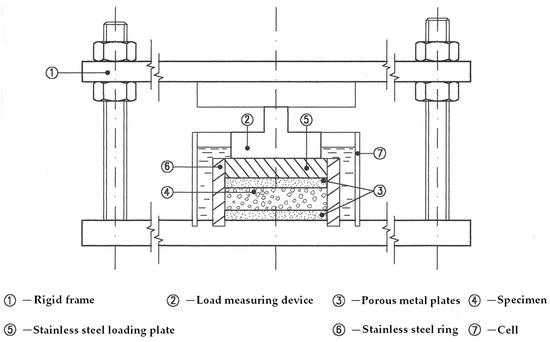

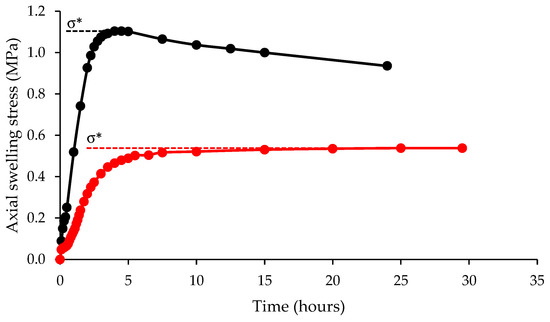

2.4.2. Swelling Stress

2.5. Durability

2.5.1. Ageing Tests

2.5.2. Slake Durability Test

2.5.3. Static Slake Test

2.6. Compaction Tests

3. Mudrock Classifications

3.1. Geological Classifications

The descriptive schemes used for mudrock geological classification are based on features with some genetic significance. Table 1 shows the guidance given by Czerewko and Cripps [35] for the description of mudrock key features. Colour, mineralogy, fossil content, fracture type, and induration state are descriptive modifiers that complement the root names for a better mudrock characterization.

| Attribute | Descriptive Adjectives |

|---|---|

| Induration | Enables decision on description as soil or rock. If resistant to slaking in water and hard, it is rock; if susceptible to slaking in water, deformable, and ‘earthy consistency, it is soil. Strength depends on moisture state; dry sediment is stronger than wet, and rock strength varies with moisture content; sampling may impair strength. |

| Strength | Strength is designated based on the degree of induration. For soil, use field consistency values based on manual assessment, e.g., stiff; when shear strength measurements are made, use strength terms, e.g., high strength. For rock, a definition based principally on manual field assessment using geological hammer and knife may be confirmed with UCS measurement: indurated mudrocks range from extremely weak to medium strong; metamudrocks are stronger depending on weathering. |

| Structure | Standard terms for beds, laminae, and parting are provided by Potter et al. [1]. Include description of lithology and textural inter-relationship, as complex features may be present with structured strata such as ‘thin beds of cross bedded’ mudstone. |

| Colour | Use Munsell colour chart for consistency. Important for correlation; likely environment of formation and indication of likely behaviour of material, i.e., red colour—likely formation under oxidizing continental environment. Most important to mudrocks is relationship between colour on the Fe3+/Fe2+ ratio. A decrease in this ratio gives an increase in colour from red → green → grey (more Fe2+ indicates the presence of pyrite). Organic carbon controls colour: <0.2–0.3%C = light-grey to olive grey; 0.3–0.5%C = mid-grey; >0.5%C = dark-grey to black. |

| Accessory minerals | Calcareous (slightly to very, based on level of effervescence when assessed with HCl, carbonaceous, dolomitic, ferruginous, glauconitic, gypsiferous, pyritic, micaceous, sideritic, phosphatic. |

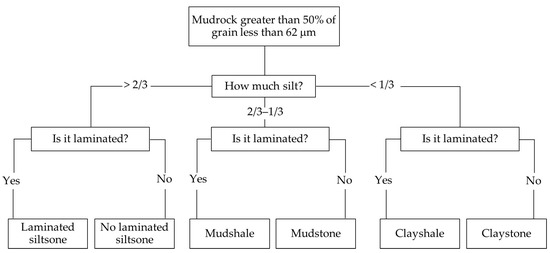

| Rock name | See classification of Figure 1. |

| Additional information | Presence of fossils—record type (generic such as bivalve and retain for identification), abundance, condition, orientation. Inclusions—nodules (with mineral type and details); gravel, sand, silt partings or pockets, etc. |

| State of weathering | Alteration seen as distinct discoloration, significant strength reduction to discontinuities, and presence of lithorelicts (note orientation). |

| Fractures | Use ISO 14689:2017 standard terms and procedures [36]. For rock supplements with details such as nature of fragmentation, e.g., conchoidal, hackly, brittle, splintery, slabby, fissile. |

3.2. Engineering Geological Classifications

4. Conclusions

References

- Potter, P.E.; Maynard, J.B.; Pryor, W.A. The Sedimentology of Shale: A Study Guide and Reference Source; Springer: New York, NY, USA, 1980; 306p.

- Picard, M.D. Classification of fine-grained sedimentary rocks. J. Sediment. Res. 1971, 41, 179–195.

- Taylor, R.K.; Spears, D.A. Laboratory investigation of mudrocks. Q. J. Eng. Geol. Hydrogeol. 1981, 14, 291–309.

- Tucker, M.E. Sedimentary Petrology, 2nd ed.; Blackwell: Oxford, UK, 1994; 260p.

- Stow, D.A. Fine-grained sediments: Terminology. Q. J. Eng. Geol. 1981, 14, 243–244.

- Lundegard, P.D.; Samuels, N.D. Field classification of fine-grained sedimentary rocks. J. Sediment. Res. 1980, 50, 781–786.

- Cripps, J.C.; Taylor, R.K. The engineering properties of mudrocks. Q. J. Eng. Geol. 1981, 14, 325–346.

- Shakoor, A.; Broch, D. Relationship between Fissility, composition and engineering properties of selected shales from northeast Ohio. Bull. Assoc. Eng. Geol. 1987, 24, 363–379.

- Jeremias, F.T.; Olarte, J.M.; Pinho, A.B.; Duarte, I.M.; Saroglou, H.; Torres-Suárez, M.C. Mudrocks as soft rocks—Properties and characteristics. In Soft Rock Mechanics and Engineering; Kanji, M., He, M., Sousa, L.R., Eds.; Springer Nature: Cham, Switzerland, 2020; pp. 37–108.

- BS 1377+A1 2021; Methods of Test for Soils for Civil Engineering Purposes—Part 3: Chemical and Electrochemical Tests. British Standards Institution: London, UK, 2018.

- ISRM. Determining water content, porosity, density, and related properties and swelling and slake-durability index properties. In The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974–2006, 1st ed.; Ulusay, R., Hudson, J., Eds.; ISRM Turkish National Group: Ankara, Turkey, 2007; pp. 83–98.

- ISO 17892-4; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 4: Determination of Particle Size Distribution. ISO: Geneva, Switzerland, 2016; 31p.

- ISO 17892-12; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 12: Determination of Liquid and Plastic Limits. ISO: Geneva, Switzerland, 2018; 27p.

- NF P94-068; Détermination de la Valeur de Blue de Méthylène d’un sol ou d’un Matériau Rocheux par I’essai à la Tache. Association Française de Normalisation (AFNOR): Paris, France, 1998; p. 8.

- ISRM. Determining uniaxial compressive strength and deformability of rock materials. In The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974–2006, 1st ed.; Ulusay, R., Hudson, J., Eds.; ISRM Turkish National Group: Ankara, Turkey, 2007; pp. 151–156.

- ASTM D7012; Standard Test Methods for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens under Varying States of Stress and Temperatures. ASTM International: West Conshohocken, PA, USA, 2014.

- ISRM. Determining tensile strength of rock materials. In The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974–2006, 1st ed.; Ulusay, R., Hudson, J., Eds.; ISRM Turkish National Group: Ankara, Turkey, 2007; pp. 177–184.

- ISRM. Determining point load strength. In The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974–2006, 1st ed.; Ulusay, R., Hudson, J., Eds.; ISRM Turkish National Group: Ankara, Turkey, 2007; pp. 121–132.

- ISRM. Determination of the Schmidt rebound hardness. In The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974–2006, 1st ed.; Ulusay, R., Hudson, J., Eds.; ISRM Turkish National Group: Ankara, Turkey, 2007; pp. 107–108.

- Carter, P.G.; Sneddon, M. Comparison of Schmidt hammer, point load and unconfined compression tests in carboniferous strata. In Rock Engineering; Attewell, P., Ed.; British Geotechnical Society: Newcastle-upon-Tyne, UK, 1977; pp. 197–220.

- National Coal Board. NCB cone indenter. In Mining Research and Development Establishment Handbook No. 5; National Coal Board: London, UK, 1977; 5p.

- LNEC Standard No. 200; Soils. Soil Swelling Test. LNEC: Lisboa, Portugal, 1967; 5p. (In Portuguese)

- Jeremias, F.T. Geological Controls on the Engineering Properties of Mudrocks of the North Lisbon Area. Unpublished. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2000; 464p.

- ISRM. Laboratory testing of swelling rocks. In The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974–2006, 1st ed.; Ulusay, R., Hudson, J., Eds.; ISRM Turkish National Group: Ankara, Turkey, 2007; pp. 199–216.

- Jeremias, F.T. Importância da Expansibilidade na Durabilidade dos Materiais Rochosos e Técnicas Laboratoriais Para a sua Avaliação. Master’s Thesis, Nova University Lisbon, Lisbon, Portugal, 1991; 220p. Unpublished(In Portuguese).

- Shakoor, A.; Gautam, T.P. Influence of geologic and index properties on disintegration behavior of clay-bearing rocks. Environ. Eng. Geosci. 2015, 21, 197–209.

- Franklin, J.A.; Chandra, R. The slake-durability test. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1972, 9, 325–341.

- ASTM D4644; Standard Test Method for Slake Durability of Shales and Other Similar Weak Rocks. ASTM International: West Conshohocken, PA, USA, 2016.

- Czerewko, M.A.; Cripps, J.C. Assessing the durability of mudrocks using the modified jar slake index test. Q. J. Eng. Geol. Hydrogeol. 2001, 34, 153–163.

- Lutton, R.J. Design and Construction of Compacted Shales Embankments: Vol. 3—Slaking Indexes for Design; Report No. FHWA-RD-77-1; Federal Highway Administration, US Department of Transportation: Washington, DC, USA, 1977; 94p.

- Dusseault, M.B.; Cimolini, P.; Soderberg, H.; Scafe, D.W. Rapid index tests for transitional materials. Geotech. Test. J. 1988, 15, 281–346.

- Hopkins, T.C.; Deen, R.C. Identification of shales. Geotech. Test. J. 1984, 7, 10–18.

- Santi, P.M. Improving the jar slake, slake index, and slake durability tests for shales. Environ. Eng. Geosci. 1998, 4, 385–396.

- NF P94-066; Coefficient de Fragmentabilité des Matériaux Rocheux. Association Française de Normalisation (AFNOR): Paris, France, 1992; p. 7.

- Czerewko, M.A.; Cripps, J.C. Mudrocks, clays and pyrite. In ICE Manual of Geotechnical Engineering; Burland, J., Chapman, T., Hilary, S., Michael, B., Eds.; Thomas Telford: London, UK, 2012; Volume 36, pp. 481–516.

- ISO 14689; Geotechnical Investigation and Testing—Identification, Description and Classification of Rock. ISO: Geneva, Switzerland, 2017; 21p.

- ISO 14688-1; Geotechnical Investigation and Testing—Identification and Classification of Soil—Part 1: Identification and Description. ISO: Geneva, Switzerland, 2017; 23p.

- ISO 14688-2; Geotechnical Investigation and Testing—Identification and Classification of Soil—Part 2: Principles for a Classification. ISO: Geneva, Switzerland, 2017; 11p.

- Grainger, P. The classification of mudrocks for engineering purposes. Q. J. Eng. Geol. 1984, 17, 381–387.

- Taylor, R.K. Coal measures mudrocks: Composition, classification and weathering processes. Q. J. Eng. Geol. 1988, 21, 85–99.

- Mead, W.J. Engineering geology of dam sites. In Transactions, 2nd International Congress on Large Dams; International Committee on Large Damas: Paris, France, 1936; Volume 4, pp. 183–198.

- Underwood, L.B. Classification and identification of shales. J. Soil Mech. Found. Div. 1967, 93, 97–116.

- Morgenstern, N.R.; Eigenbrod, K.D. Classification of argillaceous soils and rocks. J. Geotech. Eng. 1974, 100, 1137–1156.

- IAEG. Rock and soil description and classification for engineering geological mapping. Bull. Eng. Geol. 1981, 24, 235–274.

- ISRM. Basic geotechnical description of rock masses. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1981, 18, 8–110.

- Hencher, S.R. Conference summary. In The Engineering Geology of Weak Rock; Cripps, J., Coulthard, J., Culshaw, M., Forster, A., Hencher, S., Moon, C., Eds.; Balkema: Rotterdam, The Netherlands, 1993; pp. 499–504.

- Erguler, Z.A.; Shakoor, A. Quantification of fragment size distribution of clay-bearing rocks after slake durability testing. Environ. Eng. Geosci. 2009, 15, 81–89.

- Ulusay, R.; Erguler, Z.A. Assessment of physical disintegration characteristics of clay-bearing rocks: Disintegration index test and a new durability classification chart. Eng. Geol. 2009, 105, 11–19.

- Spears, D.A. Towards a classification of shale. J. Geol. Soc. 1980, 137, 125–129.