1. Introduction

In recent years, the global greenhouse horticulture field has always focused on “energy and water resources”, especially when the continuous increase in energy prices has brought tremendous operational pressure to the growers

[1]. Meanwhile, the implementation of the Kyoto Protocol and the Paris Climate Agreement has increased the pressure on the production of greenhouses in terms of environmental and ecological protection. Energy conservation and the broadening of the renewable energy range have become the subjects of greenhouse energy research

[2]. Since 2006, renewable energy sources, such as solar energy, wind energy, biomass energy, etc., have been put into commercial operation in part of the greenhouses in Europe and America

[3]. Related application research is also being comprehensively developed. In the “New energy greenhouse design contest” of 2007 in the Netherlands, a total of three schemes were awarded, including a Sunwind greenhouse and two other greenhouses designed by the universities of Wageningen and Benk

[4]. These three greenhouses used solar energy, geothermal energy, and wind energy with related technologies to explore the technical mechanism and commercialization approach of reducing the future dependence on fossil energy in greenhouses. Related projects have been demonstrated in Bleiswijk with the government’s support.

Facility horticulture in China started relatively late, due to strong and rigid demand for agricultural products (particularly vegetables) in the northern regions during the winter. The facility horticulture area in China has developed rapidly over the past 30 years, and the current facility horticulture area reaches 3.7 million hectares, which makes it the country with the largest facility horticulture area in the world

[5]. In facility horticulture, the development of plastic greenhouses and Chinese solar greenhouses (CSGs) is the most rapid, while the multi-span greenhouse is slow. The light-transmitting covering material of the multi-span greenhouse comprises a film, glass, and a plastic plate. Research showed that the coal consumption of the multi-span greenhouse is about 90–150 kg/m

2 in a year, and the coal cost accounts for 30–50% of the whole production cost

[6]. Therefore, the multi-span greenhouse is difficult to develop on a large scale, even if the economy of the century develops to a certain level. The plastic-covered tunnel mostly uses bamboo and steel as a framework and is a simple arched greenhouse covered with plastic film. It is built when in use and dismantled when not in use. The little requirement for additional energy makes it mostly used in southern areas of China

[7].

Chinese agriculture is changing from traditional agriculture to modern agriculture. Although plastic-covered tunnels and CSGs are still important production facilities

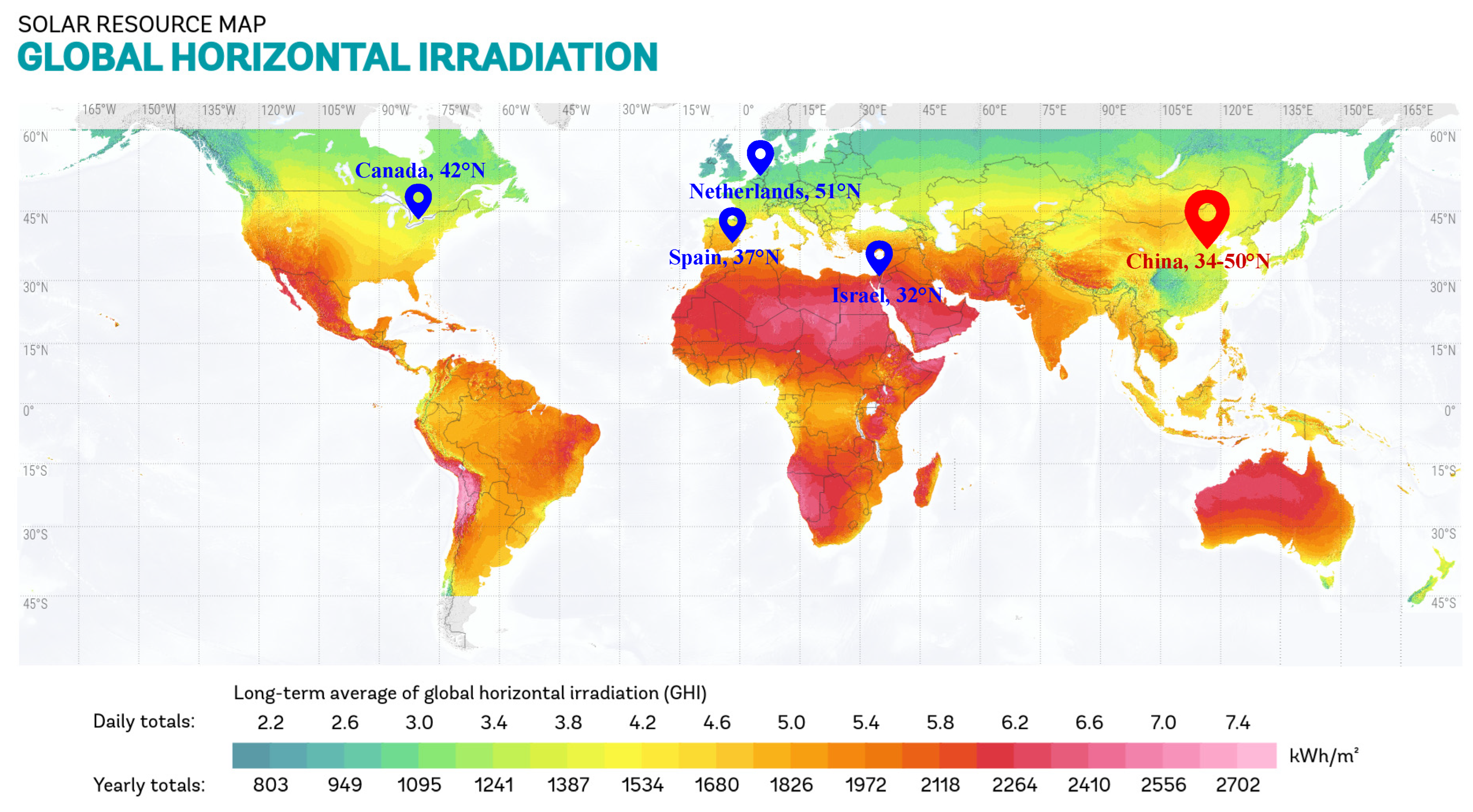

[8], high-yield and high-efficiency modern greenhouses are one of the directions of future Chinese agriculture development. With the continuous promotion of the modernization and industrialization of agriculture in China, the degree of dependence of agricultural production on energy has continuously increased. Compared with traditional agriculture, facility agriculture has a stronger dependence on energy. As shown in

Figure 1, the climate and energy use patterns of agricultural facilities in China are very different from those in countries with advanced facility horticulture (

http://solargis.com/maps-and-gis-data/download (accessed on 12 January 2023)). It is difficult to reduce energy consumption under complicated climate conditions in China without modifying Venlo-type multi-span greenhouses introduced from abroad.

Figure 1. Overview of global horizontal solar radiation and typical regional facility agriculture distribution. This map is published by the World Bank Group, funded by ESMAP, and prepared by Solargis (

http://globalsolaratlas.info), the time of browsing this page is March of 2023.

A CSG is a facility type independently developed in China. It is a passive greenhouse with three wall sides and one light-transmitting side. Generally, solar energy is its only source of heat. At present, the overwintering production of vegetables in the northern regions of China completely depends on greenhouses, but the heat accumulated by the north walls of traditional CSGs is very limited

[9]. Therefore, most CSGs need to be heated by coal. However, this heated mode faces problems of low efficiency, high pollution, and high investment and operation costs. Thus, the economic benefit of greenhouse cultivation is restricted. Especially in recent years, many cities in the north of China have come up with relevant policies to cope with haze disasters. As a result, the traditional coal-fired small boiler is banned. In this regard, it is important to select solar energy to replace coal for heating greenhouses

[10]. Generally, illumination and temperature are considered the main environmental factors of the CSG, so the future development trend focuses on the research of structural optimization and heat insulation performance of the CSG.

In China today, the capacity of solar water heaters and photovoltaic cells ranks first in the world. In recent years, the solar cell industry has faced the problem of excess capacity under the anti-dumping complaints of Europe and America on Chinese photovoltaic export products. The solar cell industry in China develops diversified consumption markets for destocking by combining related industries. The application demonstration of distributed photovoltaic power generation and the photovoltaic poverty relief policy promoted by the National Energy Bureau make the solar energy and agriculture industries complement each other

[11]. After combining photovoltaic cells with CSG, the power generated by the solar energy system can be used for the functions of intelligent temperature control, irrigation, and light supplementation. Moreover, the residual electric quantity can be sold back to a power grid company to create additional benefits

[12]. In addition, the photovoltaic CSG can effectively utilize land resources and avoid the problem of farmland occupation. In the critical period of vigorously promoting the development of modern agriculture in China, the development of the photothermal/photovoltaic CSG not only facilitates agricultural production, but also improves the agricultural technology level to a great extent.

2. Basic Conditions of Chinese Solar Greenhouses

2.1. Conditions Related to Solar Greenhouses in the Representative Area

At present, in North China, vegetables consumed in winter are mainly supplied by means of facility agriculture, while in all the facilities, more than 90% are produced from CSGs

[13]. The continuous popularization and construction of CSGs can increase the labor income of farmers, playing an important role in supplying fresh vegetables in northern areas in the winter. However, the distribution of the CSGs in China is extremely unbalanced; the CSGs in North China, Northeast China, and the Huanghuai area develop faster, while the CSGs in Shandong, Henan, and Liaoning account for the vast majority of the CSGs in China. The proportions of the provinces of Xinjiang, Qinghai, Gansu, Ningxia, and Shaanxi in the northwest are very small compared with the eastern region of China. However, the northwest regions are vast, and the undeveloped, uncultivated land has abundant resources and sufficient photothermal.

The distribution of Chinese solar energy resources has obvious geographical characteristics. Except for the two autonomous regions of Tibet and Xinjiang, the western region is higher than the eastern region, and the southern region is substantially lower than the northern region. The distribution characteristic reflects the restriction of solar energy resources by conditions such as climate and geography. The Chinese Academy of Meteorological Science divides China into four bands of solar resources,

[14]. The climate is partitioned according to the requirements of the thermal engineering design. The climate factors of the air temperature, the average temperature of the coldest month (January), and the hottest month (July) are taken as the main indexes. The annual average temperature between 5 °C and 25 °C is taken as the auxiliary index. Thus, China is divided into five zones: severe cold; cold; hot in summer and cold in winter; hot in summer and warm in winter; and temperate regions

[15]. Compared with Lanzhou and Shenyang, Shouguang has better temperature and illumination resources, which ensure the basic photothermal environment requirements in the CSG.

2.2. Solar Technology for Chinese Solar Greenhouses

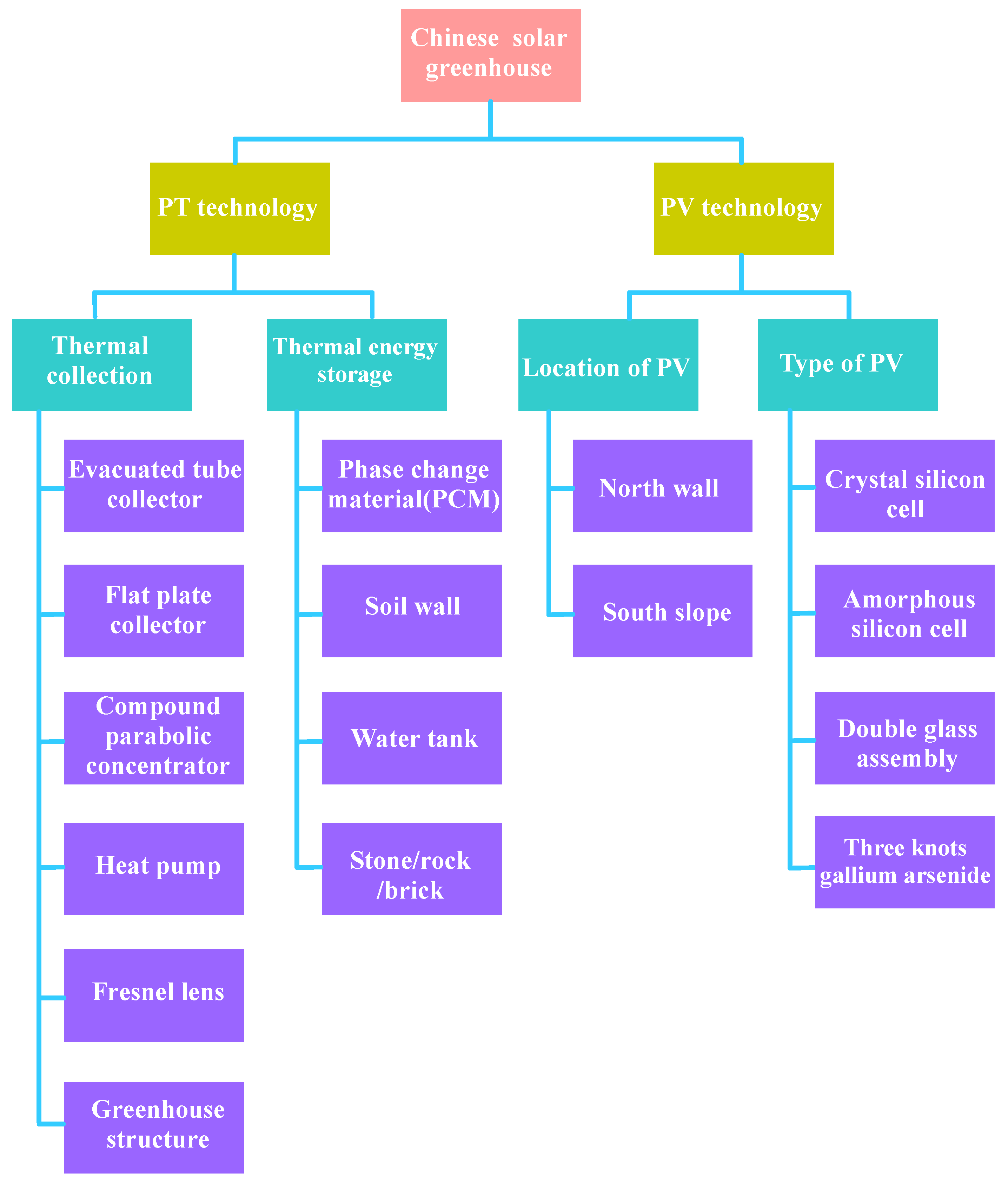

The poor heat-preserving performance of the current Chinese solar greenhouses and the shadowing effect in PV greenhouses have directed a series of studies in academia on utilizing advanced solar technology for PT (photothermic) and PV utilization technology, which are the main subjects studied by Chinese scholars, as shown in Figure 2.

Figure 2. Classification of photothermal and photovoltaic technology for a Chinese solar greenhouse.

3. Application of Photovoltaic Technology in Chinese Solar Greenhouses

3.1. Development of Photovoltaic Technology in Chinese Solar Greenhouses

In photovoltaic applications combined with buildings, the photovoltaic system can be combined with various buildings, structures, and envelope structures that can receive solar illumination. Photovoltaic technologies are widely used in production in conjunction with various agricultural infrastructures, such as photovoltaic systems, integrated glasshouses, and tunnel greenhouses

[16]. In view of the special conditions of strong light during the day and low temperatures at night in most areas in northwest China, the solar greenhouse is suitable for photovoltaic applications. Currently, photovoltaic systems are still in the startup and exploration phases for CSGs

[17]. The CSG is usually located in a suburban county or a remote area away from the town. Generally, the cost of power transmission and supply is high, and some remote areas even have no power supply. Power utilization facilities in the advanced CSG are numerous, so a stable power supply is needed if the economic and efficient operation of the CSG is to be satisfied

[18]. Related technologies are applied to traditional CSGs, such as illumination, temperature and humidity regulation, ventilation, CO

2 regulation, and irrigation spraying systems. Photovoltaic cell panels covered on the south slope surface of the CSG are usually thick and heavy, and the greenhouse is required to be supported by better stand columns and beam frames. The southern slope angle of the existing CSG is gentle, and the generating efficiency of the photovoltaic cell panel is influenced to a certain degree.

The sunlight incident on the surface of the CSG film comprises three types: ultraviolet light, visible light, and infrared light. Visible light is the most suitable for plant growth, wherein the blue light within 400~520 nm and the red orange light within 610~720 nm are effective energy regions for photosynthesis

[19]. Meanwhile, the greenhouse structure absorbs NIR more than the plants. As a result, the temperature of the greenhouse air increases, and this leads to a reduction in crop production. Thus, NIR is better utilized by semi-transparent photovoltaic modules to produce electricity.

In common solar photovoltaic cells (

Table 1), the light transmittance of the thin-film cell can be customized to any percentage, such as 10%, 20%, and 30%. The light-transmitting principle is realized by laser scribing and the small-hole imaging principle. The power of the film assembly decreases with increasing light transmission, and the size of the assembly can be selected or customized based on the original structural features and modulus

[20]. Most photovoltaic components used in the current Chinese photovoltaic agricultural greenhouse are thin-film components, with the advantages of good weak light properties, low cost, long power generation time, and a light transmission spectrum beneficial to plant growth. However, the thin-film components have low photoelectric conversion efficiency and a large annual attenuation rate, so the thin-film components have a short service life, generally 10~15 years. Compared with other related component materials, polysilicon has higher economy and practicability due to its advantages of maintenance-free properties, long service life, and low cost.

The dual-glass assembly is composed of three raw materials: glass, ethylene vinyl acetate (EVA) film, and polysilicon. EVA is a kind of thermosetting adhesive film with the advantages of adhesive force, durability, and optical characteristics. So, the EVA adhesive film is increasingly being applied to novel photovoltaic assemblies. The photovoltaic cell glass adopts toughened glass with the advantages of high strength, impact resistance, and bending resistance. Its bending strength is 3~5 times that of common glass. It has good thermal stability and light transmission. One of the features of the dual-glass assembly is variable optical transmission. Therefore, different light transmittances can be customized according to the illumination requirements of different plants in the greenhouse. It can prevent ultraviolet rays from damaging plants in the daytime and excessive heat from entering a greenhouse, while at night it can also prevent indoor infrared heat from radiating outwards for heat preservation and insulation

[21].

In order to assess the impact of transparent solar cells on plant growth, the average action spectrum of 27 herbaceous plants (including common greenhouse crops such as tomatoes, lettuce, and cucumbers) was used.

The impact of the absorption by the organic photovoltaic (OPV) device on crop growth was determined by calculating a crop growth factor,

G(

x), as a function of active layer thickness,

x, which can be defined as

where

T(

x, λ) is the total transmission of the complete simulated solar cell stack. The rate of photosynthesis in a crop is governed by the integral of the solar spectrum and action spectra.

G(

x) therefore represents the ratio of the rate of photosynthesis under a clear sky to the rate under a greenhouse material (such as an OPV covering) with spectrally dependent transparency,

T(

x, λ).

𝑏𝑠(𝜆) is AM1.5 spectrum irradiance.

𝑎(𝜆) represents the average action spectrum of 27 herbaceous plants (including common greenhouse crops such as tomatoes, lettuce, and cucumbers). The growth of crops in the greenhouse is subsequently assumed to be reduced by 1% for every 1% reduction in the rate of photosynthesis

[22].

In order to achieve a certain light transmittance, photovoltaic assemblies of solar greenhouses have the following two options

[20]. First, by adjusting the interval between the opaque solar cells, which can be realized by silica-based thin-film solar cells and crystalline silicon solar cells. The shortage lies in the fact that the solar cell part is sheltered from the sunlight of the full wave band, which has a certain influence on vegetation. In addition, the silicon-based thin-film solar cells can achieve certain light transmittance through laser scribing or a transparent back electrode to satisfy the lighting requirements of the photovoltaic greenhouse. Moreover, plants can uniformly receive light through this application mode. In addition, the silicon-based thin-film solar cells can reduce ultraviolet rays, which are unfavorable for plant growth. If the transparent back electrode assembly is adopted, unijunction silicon-based thin-film solar cells can be selected. In this way, the defect that the silicon-based thin-film solar cells have strong absorptivity for light with a wavelength of 440 nm can be overcome, which is active in photosynthesis.

Combining the above two modes, the best solution is to install the silicon-based film light-transmitting assembly according to the former, so that the photovoltaic greenhouse can generate electricity without influencing the growth of crops. So, the income of farmers is increased

[23]. Solar power generation is combined with shade-tolerant crop production, and the economic value exceeds 30% compared with that of traditional agriculture

[24]. The investment recovery period of the photovoltaic greenhouse is estimated using the electric energy generated by the photovoltaic assembly, so that the sustainable production of greenhouse crops can be better promoted. The calculated recovery period for the dynamic photovoltaic greenhouse under clear air conditions in Italy is 6 years

[25]. The annual return rate of photovoltaic CSGs varies from 9% to 20%, and the investment return period is less than 9 years

[26]. With the development of photovoltaic technology, the combination of photovoltaic assembly and CSGs will be a mature choice in the near future.

3.2. Photovoltaic Cell on the Top of the North Wall

Taking the combined benefits of the shading of the adjacent greenhouse on the southern side with the solar panels into account, solar panels are usually placed on top of the broad north wall of CSG. To ensure the lighting interval between the north and south adjacent CSGs, the photovoltaic assembly bracket and the CSG structure are completely independent. Photovoltaic power generation and greenhouse production can be simultaneously performed

[27]. However, due to the height of the photovoltaic panels, the interval between adjacent CSGs is correspondingly increased. This reduces the effective utilization of the land by agricultural production compared to conventional CSGs. Therefore, in order to improve the land utilization rate, the greenhouse is designed in the form of a synergy CSG, with vegetables planted in the south and mushrooms planted in the north. The shorter photovoltaic panels above the north wall can avoid shading the plants inside the north greenhouse. The installation can make full use of the north wall passageway or skeleton. The mode has a north wall-enclosing channel, so the cleaning and the appearance inspection are convenient and fast, with low maintenance costs

[28].

3.3. Photovoltaic Cells on the South Slope of Chinese Solar Greenhouses

3.3.1. Coverage Area of the Photovoltaic Assembly

The design mode of combining the photovoltaic panel with the front roof framework of the CSG is adopted, with the greenhouse structure fully utilized and structural materials reduced

[29]. The greenhouse roof correspondingly increases the area of the photovoltaic panel and the photovoltaic power generation amount. However, because the photovoltaic panel blocks the lighting of crops in the greenhouse while generating power

[30], the light becomes a competitive resource required by both photovoltaic power generation and agricultural production, besides planting shade-loving crops (such as mushrooms), which do not need light or need weak light in the greenhouse.

When the solar radiation is strong in the summer, the photovoltaic assembly can play a good role in shading sunlight. In order to ensure that crop growth is not affected as much as possible, the Italian government stipulates that the installation ratio of photovoltaic assemblies on the roof of the greenhouse must not exceed 50% for different coverage rates of crystalline silicon solar cells on the glass greenhouse

[31][32]. Compared to foreign countries, Chinese scholars have less research on the combination of crystalline silicon photovoltaics and CSGs. Zan et al. use ECOTECT software to establish models of monocrystalline silicon photovoltaic greenhouses with roof coverage rates of 7.61%, 15.22%, 22.83%, and 30.44%, respectively, based on Kunming climate characteristics. Compared with CSGs without photovoltaic assembly coverage, the lighting coefficient is reduced by about 16%, 38%, 49%, and 58%, respectively

[33].

In terms of the effect of the amorphous silicon photovoltaic assembly coverage area on the CSG, Zhao et al. monitored the light environment and tomato growth conditions in a thin-film photovoltaic CSG and a plastic-film CSG in Yanan city (36° N, 108° E). Under the layout with a ratio of 1:1 between the area of the film photovoltaic and the PC board, the total radiation transmittance within 2 h before and after noon on a clear day in the summer is 38.7%, and the photosynthetic effective light quantum flux density transmittance is 38.9%. They are, respectively, 30.3% and 17.6% lower than that of a plastic-film solar greenhouse. And during this period, the thin-film photovoltaic solar greenhouse can block 3949.8 kJ/m

2 more heat into the room than the plastic thin-film solar greenhouse on a clear day

[20]. Zhao et al. also experimented on the southern slope of a CSG in Yangling, Shaanxi (34°16′ N, 108°04′ E). Every three rows of film photovoltaic assemblies and PC sunlight plates are laid from west to east at intervals of 1:2 and 1:3. It is found that the total solar radiation with the 1:3 ratio in winter is increased by 50.3 W/m

2, and the average transmittance of the total solar radiation is increased by 9.1%, but the transmittance of the average photosynthetic active quantum flux density is almost unchanged. The average light transmittance of the inclined plane formed by the amorphous silicon cell assembly and the PC board is changed within a range of 34.7~41.7%

[34].

The research shows that the film photovoltaic assembly can significantly block solar radiation and reduce indoor temperatures in the summer. This has little influence on the photosynthesis of plants and light transmittance compared with a PC plate. However, the coverage rate of the photovoltaic assembly of less than 50% is determined according to specific planting objects. When the coverage rate of the crystalline silicon photovoltaic greenhouse is 30%, the crystalline silicon photovoltaic greenhouse has an obvious inhibition effect on photosynthetic effective radiation, but the adverse effect of a thin-film photovoltaic CSG with the same coverage rate is much smaller

[31]. The coverage area of the photovoltaic assembly can directly influence the power generation amount, so the photovoltaic coverage areas can be designed in a photovoltaic CSG that does not take power generation as its main purpose. For example, if the electricity generated is only used by the system itself and the coverage rate is low, the quality and yield of agricultural production can be ensured with reductions in the investment of grid-connected equipment and the energy loss in the grid-connected process.

3.3.2. Arrangement of the Photovoltaic Assembly

On the premise of the same coverage area, the influence of the arrangement mode on the environment in the greenhouse is very important. Zan et al. establish a monocrystalline silicon photovoltaic CSG model with one row of compact, two rows of compact, two rows of chessboard, and four rows of chessboard arrangements and compare the one row of compact and two rows of chessboard type greenhouses, respectively, under the condition that the roof solar cell coverage rate is 7.61%

[33]. The results show that during the winter daytime, the temperature in one row of a compact greenhouse is higher than that in two rows of a chessboard-type greenhouse, with a maximum temperature difference of 2.5 °C. The results are close to those of the two rows of compact and four rows of chessboard-type greenhouses, with a coverage rate of 15.22% for roof photovoltaic cells. The lighting coefficients of the bottoms of the two rows of compact and four rows of chessboard-type greenhouse are, respectively, superior to those of one row of compact and two rows of compact type.

The comparisons between the compact type and the chessboard type show that the sealed heat preservation effect of the compact greenhouse is better than that of the chessboard-type arrangement. However, chessboard-type arrangement lighting is better than the compact type of arrangement. This is more favorable for the uniform irradiation of illumination because the photosynthesis and quality of crops are less influenced

[35].

In the aspect of research on the arrangement of the amorphous silicon thin-film photovoltaic assemblies, Zhao et al. find that the average light transmittance of the thin-film photovoltaic CSG is 33.0% in January, which is 11.6% lower than that of the plastic thin-film CSG. By counting the days of lowest temperature during the test period, it was found that the number of days below 8℃ in the photovoltaic greenhouse (2 days) was significantly less than that in the plastic-film greenhouse (10 days, 33%)

[20]. The film photovoltaic assembly covering 9.8% of the roof area of the CSG cannot influence the yield and quality of tomatoes. However, in the crystalline silicon photovoltaic CSG, the light transmittance of the checkerboard-arranged film solar sun is obviously better than that of a straight-line arrangement to improve the quality of crops. So, the checkerboard arrangement of the photovoltaic assembly can enable the illumination in the CSG to be more uniform and more suitable for the growth of crops. In addition, the low-temperature days in winter show that the winter temperature environment of the photovoltaic CSG is obviously better than that of a plastic-film CSG, and the photovoltaic CSG is more favorable for fruit and vegetable cultivation in winter.

The whole greenhouse roof area is often covered with opaque conventional PV panels to maximize energy production

[36]. However, this scenario is unsuitable for green plant cultivation. In fact, on average, among the most common PV greenhouse types, the annual global radiation decreases by 0.8% for each additional 1.0% of PV coverage on the roof. The greenhouse internal light environment varies greatly according to whether the PV modules are concentrated as a single array or dispersed over the roof when the roof is partially covered with PV modules. PV panel shadows are dissected and scattered on the wider area of greenhouse interior space when the PV modules are distributed in a dispersed manner on the roof. Stripe or checkerboard arrangements of PV arrays using conventional opaque PV panels have been studied. An important implication exists related to the stripe direction. Straight lines of PV modules aligned east–west, mounted on the south roof of an east–west oriented greenhouse, are suitable for electricity production

[30]. The inclination of south-facing roofs of east–west-oriented greenhouses in the northern hemisphere usually contributes to PV electricity production. By contrast, all plants in the greenhouse receive direct sunlight frequently during a sunny day when the strings of PV modules are aligned north–south, irrespective of the greenhouse orientation or if the PV modules are placed in a checkerboard arrangement

[37][38].