| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Mohammadreza Bagheri | -- | 18013 | 2023-10-09 11:11:06 | | | |

| 2 | Mohammadreza Bagheri | -2892 word(s) | 15121 | 2023-10-10 12:48:50 | | | | |

| 3 | Sirius Huang | -6470 word(s) | 8651 | 2023-10-13 06:11:54 | | |

Video Upload Options

As a rapidly evolving technology, carbon capture and storage (CCS) can potentially lower the levels of greenhouse gas emissions from the oil and gas industry. A comprehensive review of different aspects of CCS technology is presented herein, including its key components, the methods and stages of carbon storage, implied environmental effects, and its pros and cons. It also investigates the utilization of CCS as an alternative method to water injection into oil reservoirs. It also probes the technical and operational challenges of implementing CCS technology in the oil and gas industry. Additionally, it examines the regulatory and policy issues associated with CCS, including incentives and frameworks for promoting the deployment of CCS technology. Finally, the potential benefits of CCS are discussed, including reducing the carbon footprint of the oil and gas industry, enhancing energy security, and supporting the transition to a low-carbon economy.

1. Introduction

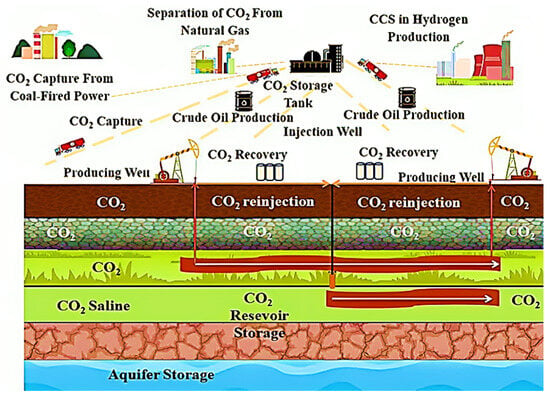

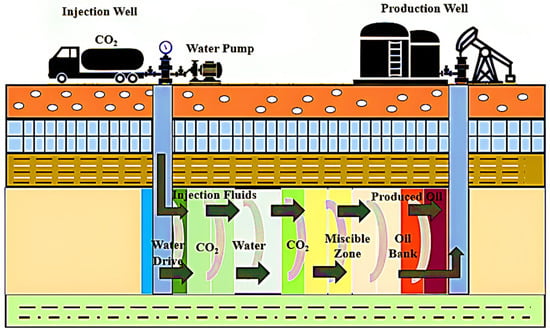

This text provides a systematic review of the application of CCS technology in different aspects of the oil and gas industry. The key components of CCS, including capture, transport, and storage, as well as the different methods and challenges associated with each stage, have been discussed. The different methods of carbon storage, such as geological storage, ocean storage, and mineralization, have been investigated, as has how they work in different industries, especially the oil and gas industry. The stages of carbon storage, including site characterization, injection, and monitoring, and post-closure activities have been outlined, along with the technical and operational challenges associated with each stage. The potential benefits and challenges associated with using the CCS method as an alternative method for water injection in oil reservoirs have been discussed. The environmental impacts of CCS, such as potential risks to groundwater resources and local ecosystems, have also been considered, along with the measures that can be taken to mitigate these risks. Additionally, the technologies used in the CCS method, especially in petroleum engineering, have been investigated, as has the potential for innovation in and the improvement of these technologies. The advantages and disadvantages of the carbon storage method have been discussed, including its potential benefits for reducing greenhouse gas emissions and enhancing energy security, as well as the potential risks and uncertainties associated with the long-term storage of carbon. Finally, CCS and EOR, as well as the potential for combining these technologies to enhance oil production while reducing greenhouse gas emissions, have been explored. The policy and regulatory issues associated with CCS deployment, including the need for supportive policies and incentives, as well as the potential for international cooperation and collaboration in promoting CCS technology, have also been considered.

2. Background

2.1. The Purpose of CCS in the Oil and Gas Industry

2.2. Key Components of CCS

- EOR: The captured CO2 is injected into oil reservoirs to enhance oil production. CO2 helps reduce the viscosity of the oil, making it easier to extract.

- Industrial processes: CO2 can be used as a raw material in various industrial processes, such as chemical manufacturing or the production of synthetic fuels.

- Mineralization: CO2 can be reacted with certain minerals to form stable carbonates, which can be used in construction materials or other applications.

- Agricultural applications: CO2 can be used in agricultural practices, such as greenhouse farming or enhancing plant growth.

- Direct air capture (DAC): Using this technique, CO2 is extracted from the air and utilized for different purposes, such as carbon-neutral fuel production or carbon removal [60][61][62].

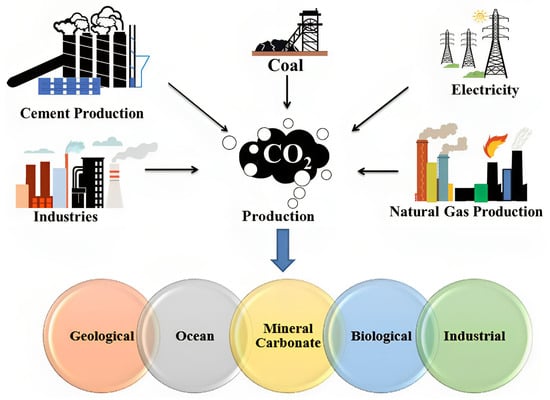

2.3. Different Methods of Carbon Storage

There are several methods with which to accomplish a carbon storage project, which are listed below:

- Geological storage: CO2 is stored in this method in formations such as depleted oil and gas reservoirs, saline aquifers, and coal beds [58].

- Ocean storage: This method involves storing CO2 in deep ocean water, where it can be dissolved and stored for long periods [63].

- Mineral carbonation: This method involves converting CO2 into stable carbonates through chemical reactions with minerals [64][65].

- BECCS: This method involves capturing CO2 emissions from biomass power plants and storing them in geological formations [66].

- DAC: This method involves capturing CO2 directly from the air using specialized equipment and storing it in geological formations [67].

- Industrial use: This is another important component of carbon dioxide utilization. CO2 can be used as a raw material in various industrial processes, such as chemical manufacturing or the production of synthetic fuels. This enables the conversion of CO2 into useful products, lowering emissions and fostering the development of a more sustainable future [67].

These methods, as shown in Figure 2, have their advantages and disadvantages and require careful consideration when implementing carbon storage projects [68].

2.3.1. Geological Storage

Geological storage involves injecting CO2 into geological formations such as depleted oil and gas reservoirs, aquifers, and coal seams [69]. This method is considered to be the most viable and widely used method for carbon storage due to the abundance of geological formations that can be used for storage [70].

Capturing CO2 from industrial processes, compressing it, and injecting it into underground geological formations are steps involved in the process of geological storage. Once trapped by cap rock or other geological features that prevent it from escaping into the atmosphere, the CO2 is permanently stored in the geological formations [1]. After this process, the storage location is monitored to make sure the CO2 is kept in place and does not escape into the environment.

Advantages of geological storage include the following:

- Large storage capacity: Geological formations have the potential to store large amounts of CO2, making them ideal for large-scale carbon storage projects [71].

- Proven technology: Geological storage has been used for decades to store natural gas and other substances, making it a proven and reliable technology [72].

- Permanent storage: CO2 stored in geological formations is trapped permanently, reducing the risk of emissions into the atmosphere [73].

- Synergies with existing infrastructure: Geological formations used for carbon storage are often located near existing oil and gas infrastructure, making it easier to transport and store CO2 [74][75].

Disadvantages of geological storage include the following:

- Potential for leakage: While geological formations are designed to trap CO2, there is a risk of leakage that could result in environmental damage and health risks [76].

- Limited availability of suitable sites: Not all geological formations are suitable for carbon storage, and finding suitable sites can be challenging [77].

- High costs: Geological storage can be expensive due to the costs of capturing, compressing, and transporting CO2, as well as the costs of monitoring and maintaining storage sites [73].

Geological storage has a larger capacity than other methods, such as ocean storage and mineral carbonation [78][79][80]; however, the decision to use this approach will be influenced by several considerations, including the cost of the process, the accessibility of storage locations, and the environmental concerns associated with this method [5][81].

2.3.2. Ocean Storage

Ocean storage involves capturing CO2 from industrial processes, compressing it, and transporting it to the sea. CO2 is then injected into deep ocean water, where it can be dissolved and stored for long periods [63]. The stored CO2 is then monitored to ensure that it remains dissolved and prevent it from escaping into the atmosphere [82]. This method is still in the experimental phase and requires further research to determine its feasibility and potential environmental impacts [83].

Advantages of ocean storage include the following:

- Large storage capacity: The deep ocean has the potential to store vast amounts of CO2, making it an attractive option for large-scale carbon storage projects [63].

- Natural carbon sinks: The ocean is a natural carbon sink, and storing CO2 in ocean water could potentially enhance the ocean’s ability to adsorb carbon from the atmosphere [84][85].

- Reduced risk of leakage: Unlike geological formations, the ocean is constantly in motion, which reduces the risk of CO2 leakage [86].

Disadvantages of ocean storage include the following:

- Environmental risks: Injecting large amounts of CO2 into the ocean could potentially have negative environmental impacts, such as ocean acidification and harm to marine life [63].

- Technological challenges: Injecting CO2 into the ocean requires specialized equipment and infrastructure, which can be expensive and challenging to implement [87].

- Uncertainty: The long-term effects of ocean storage on the environment and marine life are not yet fully understood, and further research is needed to determine its feasibility [88].

Compared to other methods of carbon storage, ocean storage has the advantages of a large storage capacity and reduced risk of leakage [79]. Nevertheless, the choice of this method will depend on a variety of factors, including the accessibility of suitable storage locations, the cost of the process, and the environmental risks associated with each method [89][90].

2.3.3. Mineral Carbonation

-

Permanent storage: Carbonates formed by the carbonation of minerals are stable and can be stored permanently in geological formations [71].

-

Potential for carbon-negative processes: Mineral carbonation has the potential to be a carbon-negative process, i.e., it removes more CO2 from the atmosphere than it emits [92].

-

Use of abundant minerals: The minerals used in mineral carbonation are abundant and widely available, reducing the cost and environmental impact of the technology [93].

-

Technological challenges: Mineral carbonation requires specialized equipment and infrastructure, which can be expensive and challenging to implement [65].

-

Slow reaction rates: The reaction rates involved in mineral carbonation are slow, which can limit the storage capacity and efficiency of the technology [94].

-

Uncertainty: The long-term effects of mineral carbonation on the environment and geological formations are not yet fully understood, and further research is needed to determine its feasibility [79].

2.3.4. Bioenergy with Carbon Capture and Storage (BECCS)

2.3.5. Direct Air Capture (DAC)

2.4. CCS Deployment Projects through Time

Table 1. An overview of the deployment of CCS projects over time.

| Early development (2000s) [2][3] |

|

| Expansion and demonstration (2010s) [109] |

|

| Government support and initiatives [6][44] |

|

| International collaboration [2][3] |

|

| Current developments [3][14] |

|

2.5. Leading Countries in the Field of CCS

Table 2 provides a list of countries that are considered leaders in the field of CCS, along with their storage methods and storage capacity.

Table 2. Leading countries in the field of CCS.

| Country | Storage Method | Storage Capacity |

|---|---|---|

| Norway [6] | Norway primarily focuses on offshore storage in geological formations, specifically within the North Sea. | Norway has significant storage potential, with an estimated offshore storage capacity of up to 70 billion tons of CO2. |

| Canada [42] | Canada has been exploring both onshore and offshore storage options. Onshore storage involves utilizing deep saline aquifers, while offshore storage is being studied in depleted oil and gas reservoirs. | Canada has substantial potential for CO2 storage, with an estimated storage capacity exceeding 600 billion tones. |

| Australia [63] | Australia has been investigating various storage options, including onshore storage in deep saline aquifers and offshore storage in depleted oil and gas fields. | Australia has significant storage potential, with an estimated capacity exceeding 400 billion tones. |

| United States [69] | The United States has been actively studying both onshore and offshore storage options. Onshore storage primarily focuses on deep saline aquifers, while offshore storage is being explored in depleted oil and gas fields. | The U.S. has substantial storage potential, with an estimated capacity exceeding 13,000 billion tones. |

| United Kingdom [15] | The UK has been investigating offshore storage in depleted oil and gas fields beneath the North Sea. | The UK has significant storage potential, with an estimated offshore storage capacity exceeding 70 billion tones. |

| China [59] | China has been increasing its efforts in CCS deployment and has several ongoing projects. | The volume of CO2 storage in China is expected to reach approximately 8 million tons per year. |

| Saudi Arabia [2] | Saudi Arabia has also started investing in CCS technology and has plans for underground CO2 storage facilities. | The volume of CO2 storage in Saudi Arabia is estimated to be around 5 million tons per year. |

| Japan [54] | Japan has been exploring CCS technology and has initiated pilot projects for underground CO2 storage. | The volume of CO2 storage in Japan is projected to be approximately 4 million tons per year. |

| South Korea [3] | South Korea has shown interest in CCS and has started implementing pilot projects for underground CO2 storage. | The volume of CO2 storage in South Korea is expected to be around 3 million tons per year. |

| United Arab Emirates [74] | The United Arab Emirates has also joined the CCS movement and has plans for underground CO2 storage facilities. | The volume of CO2 storage in the United Arab Emirates is estimated to be approximately 2 million tons per year. |

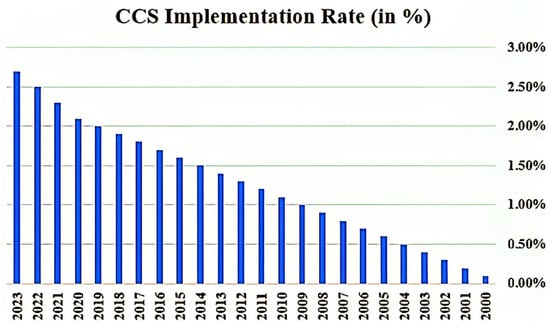

2.6. Historical Data on CCS Capacity

Figure 3 shows the historical data on CCS between the years 2000 and 2023. The implementation rate is calculated by dividing the number of CCS projects implemented to develop a field by the total number of projects. The increasing trend suggests an improved general perception regarding CCS technology.

Figure 3. Historical data on CCS capacity.

| Year | CCS Implementation Rate (in %) | Applications in Petroleum Engineering |

|---|---|---|

| 2000 | 0.10% | Limited implementation in CO2-EOR [2]. |

| 2001 | 0.20% | Continued use in CO2-EOR projects, with a slight increase in implementation [4]. |

| 2002 | 0.30% | Further utilization of captured CO2 for enhanced oil recovery application [3]. |

| 2003 | 0.40% | Ongoing use in CO2-EOR projects, contributing to increased oil production [14]. |

| 2004 | 0.50% | The gradual growth of CCS implementation in CO2-EOR projects positively impacts oil production [6]. |

| 2005 | 0.60% | Continued utilization of captured CO2 for enhanced oil recovery applications [74]. |

| 2006 | 0.70% | Application of CCS in CO2-EOR projects, aiding in increased oil extraction from reservoirs [12]. |

| 2007 | 0.80% | The steady growth of CCS usage in CO2-EOR operations supports enhanced oil recovery efforts [65]. |

| 2008 | 0.90% | Continued implementation of CCS for enhanced oil production in certain reservoirs [44]. |

| 2009 | 1.00% | The cumulative increase in CCS application contributes to enhanced oil recovery and carbon management [5]. |

| 2010 | 1.10% | Further integration of CCS in CO2-EOR projects, aiding in sustainable oil production and emission reductions [1]. |

| 2011 | 1.20% | Increasing implementation of CCS in CO2-EOR projects, supporting oil recovery and carbon mitigation strategies [104]. |

| 2012 | 1.30% | Continued adoption of CCS in CO2-EOR for enhanced production and carbon management in petroleum engineering [103]. |

| 2013 | 1.40% | Steady utilization of CCS for enhanced oil recovery, enabling sustainable oil production and reducing emissions [85]. |

| 2014 | 1.50% | The growing incorporation of CCS in CO2-EOR projects to optimize reservoir management and reduce carbon footprints [78]. |

| 2015 | 1.60% | Increasing implementation of CCS in CO2-EOR projects, supporting oil recovery and carbon mitigation strategies [7]. |

| 2016 | 1.70% | Increased deployment of CCS technology, facilitating efficient CO2 utilization and improved reservoir performance [9]. |

| 2017 | 1.80% | Advancements in CCS methods for reservoir monitoring, optimizing CO2-EOR projects in petroleum engineering [2]. |

| 2018 | 1.90% | Continued integration of CCS in CO2-EOR, enhancing oil production and minimizing the environmental impact [6]. |

| 2019 | 2.00% | Expanding the use of CCS for sustainable oil recovery, addressing emissions, and maximizing reservoir potential [44]. |

| 2020 | 2.10% | Growing global focus on CCS for CO2-EOR, fostering sustainable practices in petroleum engineering [14]. |

| 2021 | 2.30% | Increasing adoption of CCS to optimize oil recovery, meet emission targets, and support responsible petroleum operations [109]. |

| 2022 | 2.50% | Maturing technology and wider implementation of CCS in petroleum engineering to ensure sustainable oil production [22]. |

| 2023 | 2.70% | Continued growth of CCS in CO2-EOR projects, enhancing production efficiency and mitigating greenhouse gas emissions [86]. |

Moving towards 2050, the future of CCS in petroleum engineering is projected to be increasingly vital. As the industry strives for decarbonization and sustainable practices, CCS is expected to see further advancements and wider deployment. The integration of CCS with various reservoir management techniques, together with enhanced monitoring and innovative CO2 utilization methods, will contribute to maximizing oil recovery while minimizing the environmental impact. This comprehensive approach is anticipated to drive the development of efficient and sustainable petroleum engineering practices [108].

3. Typical Global CCS Science and Technology Infrastructures

Some typical global CCS science and technology infrastructures include the following:

- CCS research centers: These infrastructures focus on conducting scientific research and technological development related to CCS. They typically have advanced laboratories equipped with state-of-the-art equipment for analyzing and testing various aspects of CCS technologies.

- Large-scale CCS demonstration projects: These infrastructures are designed to showcase the viability and effectiveness of CCS technologies at a commercial scale. They involve capturing CO2 emissions from power plants or industrial facilities and storing them underground. These projects often involve collaborations between governments, research institutions, and industry partners.

- CCS monitoring networks: These infrastructures consist of a network of sensors and monitoring stations that track the movement and behavior of stored CO2 They provide real-time data on factors such as CO2 leakage, pressure changes, and geological stability to ensure the safety and effectiveness of CCS operations.

- CCS simulation and modeling facilities: These infrastructures utilize advanced computer simulations and modeling techniques to predict the behavior and performance of CCS systems under different scenarios. They help optimize design parameters, assess potential risks, and guide decision making in the deployment of CCS technologies.

- CO2 transport infrastructure: This infrastructure includes pipelines and transportation networks specifically designed for the efficient and safe transport of captured CO2 from capture sites to storage sites. It requires careful planning and engineering to ensure the integrity of the pipelines and minimize leakage during transportation.

- Geological storage sites: These infrastructures consist of suitable underground formations where captured CO2 can be safely stored for long periods. They require detailed geological surveys and assessments to identify appropriate storage sites with characteristics such as permeability, porosity, and containment capacity.

- CO2 utilization facilities: In addition to storage, some infrastructures focus on developing technologies for utilizing captured CO2 in various industrial processes. These facilities explore avenues such as converting CO2 into valuable products or using it for enhanced oil recovery.

Characteristics of these infrastructures include the following:

- Interdisciplinary collaboration: CCS infrastructures often involve collaboration between scientists, engineers, policymakers, and industry experts to address the complex challenges associated with CCS technologies.

- Long-term planning: Developing and maintaining these infrastructures require long-term planning and funding commitments due to the scale and complexity of CCS projects.

- Regulatory compliance: CCS infrastructures need to adhere to strict environmental and safety regulations to ensure the protection of human health and the environment.

- International cooperation: Many CCS infrastructures involve international collaboration and knowledge sharing to accelerate technology development and deployment globally.

- Continuous improvement: CCS infrastructures focus on continuous improvement and innovation to enhance the efficiency, cost-effectiveness, and environmental performance of CCS technologies [109][110].

4. Applicability of Carbon Storage Methods in the Oil and Gas Industry

Methods of carbon storage have been discussed in Section 2.3. This section focuses on the applicability of these methods in the oil and gas industry.

-

Geological storage: This method can be used to enhance oil and gas recovery, a process known as EOR [24]. By injecting CO2 into depleted reservoirs, the CO2 can help mobilize and extract remaining oil and gas reserves that would otherwise be difficult to recover. This process can also help reduce the carbon footprint of the oil and gas industry by storing CO2 underground [111].

-

Ocean storage: This method is not commonly used due to the environmental risks and technological challenges involved in ocean storage [54].

-

Mineral carbonation: This method is not commonly used due to the technological challenges and slow reaction rates involved in mineral carbonation [94].

-

BECCS: This method can be used to generate renewable energy and reduce the carbon footprint of oil and gas operations [112]. Biomass can be produced from different sources, including agricultural waste and dedicated energy crops, and the resulting energy can be used to power oil and gas operations [113].

5. Advantages and Disadvantages of the Carbon Storage Method

6. CCS and EOR

-

Reduced water usage: CCS does not require large amounts of water, which can be a significant cost-saving method for oil producers in regions with water scarcity [141].

-

Improved oil recovery: Oil recovery could be improved with the injection of CO2 through a reduction in oil viscosity and an increase in reservoir pressure [142].

-

Reduced environmental impact: Climate change can be mitigated through CCS by lowering the amount of CO2 emissions into the atmosphere [2].

-

High costs: CCS involves significant upfront costs for capturing, compressing, and transporting CO2, making it more expensive than other water injection methods [145].

-

Logistics and infrastructure requirements: CCS requires significant infrastructure and transportation systems, which can make its implementation difficult in some locations [146].

-

Environmental risks: Any potential risks to the environment, such as CO2 leakage, must be carefully considered and mitigated [147].

6.1. Potential Use of CCS and EOR as a Combined Approach

6.2. Economic Feasibility of CCS and EOR

6.3. Technical Challenges and Opportunities Associated with CCS and EOR

6.4. Environmental Impacts of CCS and EOR

6.5. Regulatory and Policy Landscape Surrounding CCS and EOR

6.6. Role of Public Perception and Stakeholder Engagement in the Successful Implementation of CCS and EOR

6.7. Application of CCS and EOR in Different Geological Settings

6.8. Integration of CCS and EOR with Other Renewable Energy Sources

References

- Zhang, Z.; Huisingh, D. Carbon dioxide storage schemes: Technology, assessment, and deployment. J. Clean. Prod. 2017, 142, 1055–1064.

- Gambhir, A.; Tavoni, M. Direct Air Carbon Capture and Sequestration: How It Works and How It Could Contribute to Climate-Change Mitigation. One Earth 2019, 1, 405–409.

- Tan, Y.; Nookuea, W.; Li, H.; Thorin, E.; Yan, J. Property impacts on Carbon Capture and Storage (CCS) processes: A review. Energy Convers. Manag. 2016, 118, 204–222.

- Michaelides, E.E. Thermodynamic analysis and power requirements of CO2 capture, transportation, and storage in the ocean. Energy 2021, 230, 120804.

- Aminu, M.D.; Nabavi, S.A.; Rochelle, C.A.; Manovic, V. A review of developments in carbon dioxide storage. Appl. Energy 2017, 208, 1389–1419.

- Ajayi, T.; Gomes, J.S.; Bera, A. A review of CO2 storage in geological formations emphasizing modeling, monitoring, and capacity estimation approaches. Pet. Sci. 2019, 16, 1028–1063.

- Lau, H.C.; Ramakrishna, S.; Zhang, K.; Radhamani, A.V. The Role of Carbon Capture and Storage in the Energy Transition. Energy Fuels 2021, 35, 7364–7386.

- Zou, C.; Xue, H.; Xiong, B.; Zhang, G.; Pan, S.; Jia, C.; Wang, Y.; Ma, F.; Sun, Q.; Guan, C.; et al. Connotation, Innovation and Vision of “Carbon Neutrality”. Nat. Gas Ind. B 2021, 8, 523–537.

- Gilmore, T.; Bonneville, A.; Sullivan, C.; Kelley, M.; Appriou, D.; Vermeul, V.; White, S.; Zhang, F.; Bjornstad, B.; Cornet, F.; et al. Characterization and Design of the FutureGen 2.0 Carbon Storage Site. Int. J. Greenh. Gas Control 2016, 53, 1–10.

- Suicmez, V.S. Feasibility study for carbon capture utilization and storage (CCUS) in the Danish North Sea. J. Nat. Gas Sci. Eng. 2019, 68, 102924.

- Lei, H.; Yang, S.; Zu, L.; Wang, Z.; Li, Y. Oil recovery performance and CO2 storage potential of CO2 water-alternating-gas injection after continuous CO2 injection in a multilayer formation. Energy Fuels 2016, 30, 8922–8931.

- Eldardiry, H.; Habib, E. Carbon Capture and Sequestration in Power Generation: Review of Impacts and Opportunities for Water Sustainability. Energy. Sustain. Soc. 2018, 8, 1–15.

- Lee, S.-Y.; Park, S.-J. A review on solid adsorbents for carbon dioxide capture. J. Ind. Eng. Chem. 2015, 23, 1–11.

- McLaughlin, H.; Littlefield, A.A.; Menefee, M.; Kinzer, A.; Hull, T.; Sovacool, B.K.; Bazilian, M.D.; Kim, J.; Griffiths, S. Carbon capture utilization and storage in review: Sociotechnical implications for a carbon reliant world. Renew. Sustain. Energy Rev. 2023, 177, 113215.

- Luo, J.; Xie, Y.; Hou, M.Z.; Xiong, Y.; Wu, X.; Lüddeke, C.T.; Huang, L. Advances in subsea carbon dioxide utilization and storage. Energy Rev. 2023, 2, 100016.

- Kapitonov, I.A. Development of low-carbon economy as the base of sustainable improvement of energy security. Environ. Dev. Sustain. 2020, 23, 3077–3096.

- Prasad, S.; Venkatramanan, V.; Singh, A. Renewable Energy for a Low-Carbon Future: Policy Perspectives BT—Sustainable Bioeconomy: Pathways to Sustainable Development Goals; Venkatramanan, V., Shah, S., Prasad, R., Eds.; Springer: Singapore, 2021; pp. 267–284. ISBN 978-981-15-7321-7.

- Seixas, J.; Fortes, P.; Dias, L.; Carneiro, J.; Boavida, D.; Aguiar, R.; Marques, F.; Fernandes, V.; Helseth, J.; Ciesielska, J.; et al. CO2 Capture and Storage in Portugal A Bridge to A Low Carbon Economy; Universidade Nova de Lisboa: Lisbon, Spain, 2015.

- Romasheva, N.; Ilinova, A. CCS Projects: How Regulatory Framework Influences Their Deployment. Resources 2019, 8, 181.

- Chen, S.; Liu, J.; Zhang, Q.; Teng, F.; McLellan, B.C. A critical review on deployment planning and risk analysis of carbon capture, utilization, and storage (CCUS) toward carbon neutrality. Renew. Sustain. Energy Rev. 2022, 167, 112537.

- Jiang, K.; Ashworth, P.; Zhang, S.; Liang, X.; Sun, Y.; Angus, D. China’s carbon capture, utilization and storage (CCUS) policy: A critical review. Renew. Sustain. Energy Rev. 2019, 119, 109601.

- Moomaw, W.R.; Law, B.E.; Goetz, S.J. Focus on the role of forests and soils in meeting climate change mitigation goals: Summary. Environ. Res. Lett. 2020, 15, 045009.

- Cheng, F.; Small, A.A.; Colosi, L.M. The levelized cost of negative CO2 emissions from thermochemical conversion of biomass coupled with carbon capture and storage. Energy Convers. Manag. 2021, 237, 114115.

- Adu, E.; Zhang, Y.; Liu, D. Current situation of carbon dioxide capture, storage, and enhanced oil recovery in the oil and gas industry. Can. J. Chem. Eng. 2019, 97, 1048–1076.

- Xu, Z.; Smyth, C.E.; Lemprière, T.C.; Rampley, G.J.; Kurz, W.A. Climate change mitigation strategies in the forest sector: Biophysical impacts and economic implications in British Columbia, Canada. Mitig. Adapt. Strat. Glob. Chang. 2017, 23, 257–290.

- Budinis, S.; Krevor, S.; Mac Dowell, N.; Brandon, N.; Hawkes, A. An assessment of CCS costs, barriers and potential. Energy Strat. Rev. 2018, 22, 61–81.

- Bashti, S.; Sadeghi, A.; McCoy, S.; Mahinpey, N. Could the Post-SAGD Heat Recovery Supply the Direct Air CO2 Capture (DAC) Energy in a Net Negative Carbon Emission Environment? In Proceedings of the SPE Canadian Energy Technology Conference, Calgary, AB, Canada, 27–30 November 2023; p. D011S007R003.

- Stephanie, N.E.M. The Transition of Fossil Fuel As a Source of Energy to Renewable Energy. Ph.D. Thesis, Centria University of Applied Science, Kokkola, Finland, 2022.

- Yoro, K.O.; Daramola, M.O. CO2 Emission Sources, Greenhouse Gases, and the Global Warming Effect. In Advances in Carbon Capture; Elsevier: Amsterdam, The Netherlands, 2020; pp. 3–28.

- Mikhaylov, A.; Moiseev, N.; Aleshin, K.; Burkhardt, T. Global climate change and greenhouse effect. Entrep. Sustain. Issues 2020, 7, 2897–2913.

- Gabrielli, P.; Gazzani, M.; Mazzotti, M. The role of carbon capture and utilization, carbon capture and storage, and biomass to enable a net-zero-CO2 emissions chemical industry. Ind. Eng. Chem. Res. 2020, 59, 7033–7045.

- Braun, C. Not in My Backyard: CCS Sites and Public Perception of CCS. Risk Anal. 2017, 37, 2264–2275.

- Bai, Y.; Liu, J.; Liu, S.; Xia, Z.; Chen, Y.; Liang, G.; Shen, Y. Experimental Comparative Investigation of Hot Solvent/Steam-Assisted Gravity Drainage in Oil Sand Reservoirs. ACS Omega 2021, 6, 22333–22343.

- Xu, J.; Chen, Z.; Dong, X.; Zhou, W. Effects of Lean Zones on Steam-Assisted Gravity Drainage Performance. Energies 2017, 10, 471.

- Li, S.; Han, R.; Wang, P.; Cao, Z.; Li, Z.; Ren, G. Experimental investigation of innovative superheated vapor extraction technique in heavy oil reservoirs: A two-dimensional visual analysis. Energy 2021, 238, 121882.

- Mosleh, M.H.; Sedighi, M.; Babaei, M.; Turner, M. Geological Sequestration of Carbon Dioxide. In Managing Global Warming; Elsevier: Amsterdam, The Netherlands, 2019; pp. 487–500.

- Soiket, M.; Oni, A.; Kumar, A. The development of a process simulation model for energy consumption and greenhouse gas emissions of a vapor solvent-based oil sands extraction and recovery process. Energy 2019, 173, 799–808.

- Dong, X.; Liu, H.; Chen, Z.; Wu, K.; Lu, N.; Zhang, Q. Enhanced oil recovery techniques for heavy oil and oilsands reservoirs after steam injection. Appl. Energy 2019, 239, 1190–1211.

- Kumar, N.; Sampaio, M.A.; Ojha, K.; Hoteit, H.; Mandal, A. Fundamental Aspects, Mechanisms and Emerging Possibilities of CO2 Miscible Flooding in Enhanced Oil Recovery: A Review. Fuel 2022, 330, 125633.

- Karmaker, A.K.; Rahman, M.M.; Hossain, M.A.; Ahmed, M.R. Exploration and corrective measures of greenhouse gas emission from fossil fuel power stations for Bangladesh. J. Clean. Prod. 2020, 244, 118645.

- Middleton, R.S.; Yaw, S. The cost of getting CCS wrong: Uncertainty, infrastructure design, and stranded CO2. Int. J. Greenh. Gas Control. 2018, 70, 1–11.

- Kheirinik, M.; Ahmed, S.; Rahmanian, N. Comparative Techno-Economic Analysis of Carbon Capture Processes: Pre-Combustion, Post-Combustion, and Oxy-Fuel Combustion Operations. Sustainability 2021, 13, 13567.

- De Guido, G.; Compagnoni, M.; Pellegrini, L.A.; Rossetti, I. Mature versus emerging technologies for CO2 capture in power plants: Key open issues in post-combustion amine scrubbing and in chemical looping combustion. Front. Chem. Sci. Eng. 2018, 12, 315–325.

- Ahmed, A.S.; Rahman, M.R.; Bakri, M.K.B. A Review Based on Low-and High-Stream Global Carbon Capture and Storage (CCS) Technology and Implementation Strategy. J. Appl. Sci. Process Eng. 2021, 8, 722–737.

- Gerbelová, H.; van der Spek, M.; Schakel, W. Feasibility Assessment of CO2 Capture Retrofitted to an Existing Cement Plant: Post-combustion vs. Oxy-fuel Combustion Technology. Energy Procedia 2017, 114, 6141–6149.

- Wang, Y.; Zhao, L.; Otto, A.; Robinius, M.; Stolten, D. A Review of Post-combustion CO2 Capture Technologies from Coal-fired Power Plants. Energy Procedia 2017, 114, 650–665.

- Qureshi, F.; Yusuf, M.; Kamyab, H.; Vo, D.-V.N.; Chelliapan, S.; Joo, S.-W.; Vasseghian, Y. Latest eco-friendly avenues on hydrogen production towards a circular bioeconomy: Currents challenges, innovative insights, and future perspectives. Renew. Sustain. Energy Rev. 2022, 168, 112916.

- Cannone, S.F.; Lanzini, A.; Santarelli, M. A review on CO2 capture technologies with focus on CO2-enhanced methane recovery from hydrates. Energies 2021, 14, 387.

- Negri, V.; Vazquez, D.; Pardo-Sales, M.; Guimera, R.; Guillén-Gosálbez, G. Bayesian symbolic learning to build analytical correlations from rigorous process simulations: Application to CO2 capture technologies. ACS Omega 2022, 7, 41147–41164.

- Shawuti, S.; Difiglio, C.; Esmaeilialiabadi, D.; Gülgün, M.A.; Öncel, Ç.; Yeşilyurt, S. Using Natural Gas as an Environmentally Sustainable Power Source with Solid Oxide Fuel Cells; Sabanci University: Istanbul, Turkey, 2018.

- Singh, R.P.; Singh, S.S.S. Cost-Effective Technologies Used to Curb Air Pollution. In Air Pollution: Sources, Impacts and Controls; CAB International Wallingford: Oxfordshire, UK, 2019.

- Moreno Aguado, B. Carbon Capture and Storage Technology’s Role in CO2 Emissions Reduction and the Energy Cost; Universitat de Barcelona: Barcelona, Spain, 2023.

- Younas, M.; Rezakazemi, M.; Daud, M.; Wazir, M.B.; Ahmad, S.; Ullah, N.; Inamuddin; Ramakrishna, S. Recent progress and remaining challenges in post-combustion CO2 capture using metal-organic frameworks (MOFs). Prog. Energy Combust. Sci. 2020, 80, 100849.

- Wilberforce, T.; Olabi, A.; Sayed, E.T.; Elsaid, K.; Abdelkareem, M.A. Progress in carbon capture technologies. Sci. Total Environ. 2021, 761, 143203.

- Wang, D.; Zhang, Y.D.; Adu, E.; Yang, J.P.; Shen, Q.W.; Tian, L.; Wu, L. Influence of Dense Phase Co2 Pipeline Transportation Parameters. Int. J. Heat Technol. 2016, 34, 479–484.

- Geske, J.; Berghout, N.; Broek, M.v.D. Cost-effective balance between CO2 vessel and pipeline transport. Part I—Impact of optimally sized vessels and fleets. Int. J. Greenh. Gas Control. 2015, 36, 175–188.

- Wei, Y.-M.; Li, X.-Y.; Liu, L.-C.; Kang, J.-N.; Yu, B.-Y. A cost-effective and reliable pipelines layout of carbon capture and storage for achieving China’s carbon neutrality target. J. Clean. Prod. 2022, 79, 134651.

- Tomić, L.; Karović-Maričić, V.; Danilović, D.; Crnogorac, M. Criteria for CO2 storage in geological formations. Podzemn. Rad. 2018, 32, 61–74.

- Fawad, M.; Mondol, N.H. Monitoring geological storage of CO2: A new approach. Sci. Rep. 2021, 11, 5942.

- Abdel-Shafy, H.I.; Kamel, A.H. Groundwater in Egypt issue: Resources, location, amount, contamination, protection, renewal, future overview. Egypt J. Chem. 2016, 59, 321–362.

- Amirthan, T.; Perera, M. Underground hydrogen storage in Australia: A review on the feasibility of geological sites. Int. J. Hydrogen Energy 2023, 48, 4300–4328.

- Omotilewa, O.J.; Panja, P.; Vega-Ortiz, C.; McLennan, J. Evaluation of enhanced coalbed methane recovery and carbon dioxide sequestration potential in high volatile bituminous coal. J. Nat. Gas Sci. Eng. 2021, 91, 103979.

- Arrieta, J.M.; Mayol, E.; Hansman, R.L.; Herndl, G.J.; Dittmar, T.; Duarte, C.M. Dilution limits dissolved organic carbon utilization in the deep ocean. Science 2015, 348, 331–333.

- Woodall, C.M.; McQueen, N.; Pilorgé, H.; Wilcox, J. Cover Picture: Utilization of mineral carbonation products: Current state and potential (Greenhouse Gas Sci Technol 6/2019). Greenh. Gases Sci. Technol. 2019, 9, 1096–1113.

- Neeraj; Yadav, S. Carbon storage by mineral carbonation and industrial applications of CO2. Mater. Sci. Energy Technol. 2020, 3, 494–500.

- Mishra, A.; Kumar, M.; Medhi, K.; Thakur, I.S. Biomass Energy with Carbon Capture and Storage (BECCS). In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2020; pp. 399–427.

- McQueen, N.; Psarras, P.; Pilorgé, H.; Liguori, S.; He, J.; Yuan, M.; Woodall, C.M.; Kian, K.; Pierpoint, L.; Jurewicz, J.; et al. Cost Analysis of Direct Air Capture and Sequestration Coupled to Low-Carbon Thermal Energy in the United States. Environ. Sci. Technol. 2020, 54, 7542–7551.

- Thamo, T.; Pannell, D.J. Challenges in developing effective policy for soil carbon sequestration: Perspectives on additionality, leakage, and permanence. Clim. Policy 2015, 16, 973–992.

- Jafari, M.; Cao, S.C.; Jung, J. Geological CO2 sequestration in saline aquifers: Implication on potential solutions of China’s power sector. Resour. Conserv. Recycl. 2017, 121, 137–155.

- Niemi, A.; Bear, J.; Bensabat, J. Geological Storage of CO2 in Deep Saline Formations; Springer: Berlin/Heidelberg, Germany, 2017.

- Snæbjörnsdóttir, S.Ó.; Sigfússon, B.; Marieni, C.; Goldberg, D.; Gislason, S.R.; Oelkers, E.H. Carbon dioxide storage through mineral carbonation. Nat. Rev. Earth Environ. 2020, 1, 90–102.

- Tarkowski, R. Underground hydrogen storage: Characteristics and prospects. Renew. Sustain. Energy Rev. 2019, 105, 86–94.

- Kearns, D.; Liu, H.; Consoli, C. Technology readiness and costs of CCS. Glob. CCS Inst. 2021, 3, 24.

- Khan, M.H.A.; Daiyan, R.; Neal, P.; Haque, N.; MacGill, I.; Amal, R. A framework for assessing economics of blue hydrogen production from steam methane reforming using carbon capture storage & utilisation. Int. J. Hydrogen Energy 2021, 46, 22685–22706.

- Orr Jr, F.M. Carbon capture, utilization, and storage: An update. SPE J. 2018, 23, 2444–2455.

- Raza, A.; Gholami, R.; Rezaee, R.; Rasouli, V.; Rabiei, M. Significant aspects of carbon capture and storage—A review. Petroleum 2018, 5, 335–340.

- Kaplan, R.; Mamrosh, D.; Salih, H.H.; Dastgheib, S.A. Assessment of desalination technologies for treatment of a highly saline brine from a potential CO2 storage site. Desalination 2016, 404, 87–101.

- Lee, J.H.; Lee, J.H. Techno-economic and environmental feasibility of mineral carbonation technology for carbon neutrality: A Perspective. Korean J. Chem. Eng. 2021, 38, 1757–1767.

- Saran, R.; Arora, V.; Yadav, S. CO2 sequestration by mineral carbonation: A review. Glob. NEST J. 2018, 20, 497–503.

- Veluswamy, H.P.; Kumar, A.; Seo, Y.; Lee, J.D.; Linga, P. A review of solidified natural gas (SNG) technology for gas storage via clathrate hydrates. Appl. Energy 2018, 216, 262–285.

- Samuel, G.; Sims, J.M. Drivers and constraints to environmental sustainability in UK-based biobanking: Balancing resource efficiency and future value. BMC Med. Ethic 2023, 24, 36.

- Flohr, A.; Schaap, A.; Achterberg, E.P.; Alendal, G.; Arundell, M.; Berndt, C.; Blackford, J.; Böttner, C.; Borisov, S.M.; Brown, R.; et al. Towards improved monitoring of offshore carbon storage: A real-world field experiment detecting a controlled sub-seafloor CO2 release. Int. J. Greenh. Gas Control. 2021, 106, 103237.

- Yu, H.; Zahidi, I. Environmental hazards posed by mine dust, and monitoring method of mine dust pollution using remote sensing technologies: An overview. Sci. Total. Environ. 2023, 864, 161135.

- Howard, J.; Sutton-Grier, A.; Herr, D.; Kleypas, J.; Landis, E.; Mcleod, E.; Pidgeon, E.; Simpson, S. Clarifying the role of coastal and marine systems in climate mitigation. Front. Ecol. Environ. 2017, 15, 42–50.

- Hurd, C.L.; Law, C.S.; Bach, L.T.; Britton, D.; Hovenden, M.; Paine, E.R.; Raven, J.A.; Tamsitt, V.; Boyd, P.W. Forensic carbon accounting: Assessing the role of seaweeds for carbon sequestration. J. Phycol. 2022, 58, 347–363.

- Wang, Z.; Li, H.; Liu, S.; Xu, J.; Liu, J.; Wang, X. Risk evaluation of CO2 leakage through fracture zone in geological storage reservoir. Fuel 2023, 342, 127896.

- Suopajärvi, H.; Umeki, K.; Mousa, E.; Hedayati, A.; Romar, H.; Kemppainen, A.; Wang, C.; Phounglamcheik, A.; Tuomikoski, S.; Norberg, N.; et al. Use of biomass in integrated steelmaking—Status quo, future needs and comparison to other low-CO2 steel production technologies. Appl. Energy 2018, 213, 384–407.

- Nauels, A.; Gütschow, J.; Mengel, M.; Meinshausen, M.; Clark, P.U.; Schleussner, C.-F. Attributing long-term sea-level rise to Paris Agreement emission pledges. Proc. Natl. Acad. Sci. USA 2019, 116, 23487–23492.

- Dehghani-Sanij, A.R.; Tharumalingam, E.; Dusseault, M.B.; Fraser, R. Study of energy storage systems and environmental challenges of batteries. Renew. Sustain. Energy Rev. 2019, 104, 192–208.

- Fuss, S.; Lamb, W.F.; Callaghan, M.W.; Hilaire, J.; Creutzig, F.; Amann, T.; Beringer, T.; de Oliveira Garcia, W.; Hartmann, J.; Khanna, T. Negative emissions—Part 2: Costs, potentials and side effects. Environ. Res. Lett. 2018, 13, 063002.

- Galina, N.R.; Arce, G.L.; Ávila, I. Evolution of carbon capture and storage by mineral carbonation: Data analysis and relevance of the theme. Miner. Eng. 2019, 142, 105879.

- Yeo, T.Y.; Bu, J. Mineral Carbonation for Carbon Capture and Utilization BT—An Economy Based on Carbon Dioxide and Water: Potential of Large Scale Carbon Dioxide Utilization; Aresta, M., Karimi, I., Kawi, S., Eds.; Springer: Cham, Switzerland, 2019; pp. 105–153. ISBN 978-3-030-15868-2.

- Shogren, R.; Wood, D.; Orts, W.; Glenn, G. Plant-based materials and transitioning to a circular economy. Sustain. Prod. Consum. 2019, 19, 194–215.

- Yadav, S.; Mehra, A. A review on ex situ mineral carbonation. Environ. Sci. Pollut. Res. 2021, 28, 12202–12231.

- Guo, Q.; Xi, X.; Yang, S.; Cai, M. Technology strategies to achieve carbon peak and carbon neutrality for China’s metal mines. Int. J. Miner. Met. Mater. 2022, 29, 626–634.

- Rivard, E.; Trudeau, M.; Zaghib, K. Hydrogen Storage for Mobility: A Review. Materials 2019, 12, 1973.

- Consoli, C. Bioenergy and carbon capture and storage. Glob. CCS Inst. 2019, 3–4.

- Martens, J.A.; Bogaerts, A.; De Kimpe, N.; Jacobs, P.A.; Marin, G.B.; Rabaey, K.; Saeys, M.; Verhelst, S. The Chemical Route to a Carbon Dioxide Neutral World. ChemSusChem 2016, 10, 1039–1055.

- Tanzer, S.; Blok, K.; Ramirez, A. Decarbonising industry via BECCS: Promising sectors, challenges, and techno-economic limits of negative emissions. Curr. Sustain. Renew. Energy Rep. 2021, 8, 253–262.

- Levihn, F.; Linde, L.; Gustafsson, K.; Dahlen, E. Introducing BECCS through HPC to the research agenda: The case of combined heat and power in Stockholm. Energy Rep. 2019, 5, 1381–1389.

- Kargbo, H.; Harris, J.S.; Phan, A.N. “Drop-in” fuel production from biomass: Critical review on techno-economic feasibility and sustainability. Renew. Sustain. Energy Rev. 2020, 135, 110168.

- Yang, Q.; Zhou, H.; Bartocci, P.; Fantozzi, F.; Mašek, O.; Agblevor, F.A.; Wei, Z.; Yang, H.; Chen, H.; Lu, X.; et al. Prospective contributions of biomass pyrolysis to China’s 2050 carbon reduction and renewable energy goals. Nat. Commun. 2021, 12, 1698.

- Forster, E.J.; Healey, J.R.; Dymond, C.; Styles, D. Commercial afforestation can deliver effective climate change mitigation under multiple decarbonisation pathways. Nat. Commun. 2021, 12, 3831.

- de Jonge, M.M.; Daemen, J.; Loriaux, J.M.; Steinmann, Z.J.; Huijbregts, M.A. Life cycle carbon efficiency of Direct Air Capture systems with strong hydroxide sorbents. Int. J. Greenh. Gas Control. 2018, 80, 25–31.

- Ghiat, I.; Al-Ansari, T. A review of carbon capture and utilisation as a CO2 abatement opportunity within the EWF nexus. J. CO2 Util. 2021, 45, 101432.

- McLaren, D.P.; Tyfield, D.P.; Willis, R.; Szerszynski, B.; Markusson, N.O. Beyond “Net-Zero”: A Case for Separate Targets for Emissions Reduction and Negative Emissions. Front. Clim. 2019, 1, 4.

- Gür, T.M. Carbon dioxide emissions, capture, storage and utilization: Review of materials, processes and technologies. Prog. Energy Combust. Sci. 2022, 89, 100965.

- Ozkan, M.; Nayak, S.P.; Ruiz, A.D.; Jiang, W. Current status and pillars of direct air capture technologies. iScience 2022, 25, 103990.

- Bataille, C.; Åhman, M.; Neuhoff, K.; Nilsson, L.J.; Fischedick, M.; Lechtenböhmer, S.; Solano-Rodriquez, B.; Denis-Ryan, A.; Stiebert, S.; Waisman, H.; et al. A review of technology and policy deep decarbonization pathway options for making energy-intensive industry production consistent with the Paris Agreement. J. Clean. Prod. 2018, 187, 960–973.

- Hanna, R.; Abdulla, A.; Xu, Y.; Victor, D.G. Emergency deployment of direct air capture as a response to the climate crisis. Nat. Commun. 2021, 12, 368.

- Jin, L.; Hawthorne, S.; Sorensen, J.; Pekot, L.; Kurz, B.; Smith, S.; Heebink, L.; Herdegen, V.; Bosshart, N.; Torres, J.; et al. Advancing CO2 Enhanced Oil Recovery and Storage in Unconventional Oil Play—Experimental Studies on Bakken Shales. Appl. Energy 2017, 208, 171–183.

- Choi, Y.Y.; Patel, A.K.; Hong, M.E.; Chang, W.S.; Sim, S.J. Microalgae Bioenergy with Carbon Capture and Storage (BECCS): An emerging sustainable bioprocess for reduced CO2 emission and biofuel production. Bioresour. Technol. Rep. 2019, 7, 100270.

- Welfle, A.; Chingaira, S.; Kassenov, A. Decarbonising Kenya’s domestic & industry Sectors through bioenergy: An assessment of biomass resource potential & GHG performances. Biomass Bioenergy 2020, 142, 105757.

- Al-Mamoori, A.; Krishnamurthy, A.; Rownaghi, A.A.; Rezaei, F. Carbon Capture and Utilization Update. Energy Technol. 2017, 5, 834–849.

- Mikulčić, H.; Skov, I.R.; Dominković, D.F.; Alwi, S.R.W.; Manan, Z.A.; Tan, R.; Duić, N.; Mohamad, S.N.H.; Wang, X. Flexible Carbon Capture and Utilization technologies in future energy systems and the utilization pathways of captured CO2. Renew. Sustain. Energy Rev. 2019, 114, 109338.

- Kramer, D. Negative carbon dioxide emissions. Phys. Today 2020, 73, 44–51.

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-Efficient Cements: Potential Economically Viable Solutions for a Low-CO2 Cement-Based Materials Industry; United Nations Environment Program: Nairobi, Kenya, 2016.

- Darcan, N.K.; Silanikove, N. The advantages of goats for future adaptation to Climate Change: A conceptual overview. Small Rumin. Res. 2018, 163, 34–38.

- Ming, T.; De_Richter, R.; Shen, S.; Caillol, S. Fighting global warming by greenhouse gas removal: Destroying atmospheric nitrous oxide thanks to synergies between two breakthrough technologies. Environ. Sci. Pollut. Res. 2016, 23, 6119–6138.

- Jabbour, A.B.L.d.S.; Vazquez-Brust, D.; Jabbour, C.J.C.; Latan, H. Green supply chain practices and environmental performance in Brazil: Survey, case studies, and implications for B2B. Ind. Mark. Manag. 2017, 66, 13–28.

- Al-Ansari, T.; Korre, A.; Nie, Z.; Shah, N. Integration of greenhouse gas control technologies within the energy, water and food nexus to enhance the environmental performance of food production systems. J. Clean. Prod. 2017, 162, 1592–1606.

- Hanak, D.P.; Manovic, V. Linking renewables and fossil fuels with carbon capture via energy storage for a sustainable energy future. Front. Chem. Sci. Eng. 2019, 14, 453–459.

- Kanwal, S.; Mehran, M.T.; Hassan, M.; Anwar, M.; Naqvi, S.R.; Khoja, A.H. An integrated future approach for the energy security of Pakistan: Replacement of fossil fuels with syngas for better environment and socio-economic development. Renew. Sustain. Energy Rev. 2022, 156, 111978.

- Flamme, S.; Benrath, D.; Glanz, S.; Hoffart, F.; Pielow, C.; Roos, M.; Span, R.; Wagner, H.-J.; Schönauer, A.-L. ELEGANCY: The Interdisciplinary Approach of the German Case Study to Enable a Low Carbon Economy by Hydrogen and CCS. Energy Procedia 2019, 158, 3709–3714.

- Safari, A.; Das, N.; Langhelle, O.; Roy, J.; Assadi, M. Natural gas: A transition fuel for sustainable energy system transformation? Energy Sci. Eng. 2019, 7, 1075–1094.

- Xu, C.; Yang, J.; He, L.; Wei, W.; Yang, Y.; Yin, X.; Yang, W.; Lin, A. Carbon Capture and Storage as a Strategic Reserve against China’s CO2 Emissions. Environ. Dev. 2021, 37, 100608.

- Kang, J.-N.; Wei, Y.-M.; Liu, L.-C.; Wang, J.-W. Observing technology reserves of carbon capture and storage via patent data: Paving the way for carbon neutral. Technol. Forecast. Soc. Chang. 2021, 171, 120933.

- Subraveti, S.G.; Angel, E.R.; Ramírez, A.; Roussanaly, S. Is Carbon Capture and Storage (CCS) Really So Expensive? An Analysis of Cascading Costs and CO2 Emissions Reduction of Industrial CCS Implementation on the Construction of a Bridge. Environ. Sci. Technol. 2023, 57, 2595–2601.

- Lee, J.S.; Choi, E.C. CO2 leakage environmental damage cost—A CCS project in South Korea. Renew. Sustain. Energy Rev. 2018, 93, 753–758.

- Song, Y.; Jun, S.; Na, Y.; Kim, K.; Jang, Y.; Wang, J. Geomechanical challenges during geological CO2 storage: A review. Chem. Eng. J. 2023, 456, 140968.

- Mabon, L.; Kita, J.; Xue, Z. Challenges for social impact assessment in coastal regions: A case study of the Tomakomai CCS Demonstration Project. Mar. Policy 2017, 83, 243–251.

- Swennenhuis, F.; Mabon, L.; Flach, T.A.; de Coninck, H. What role for CCS in delivering just transitions? An evaluation in the North Sea region. Int. J. Greenh. Gas Control. 2020, 94, 102903.

- Zuberi, M.J.S.; Patel, M.K. Bottom-up analysis of energy efficiency improvement and CO2 emission reduction potentials in the Swiss cement industry. J. Clean. Prod. 2017, 142, 4294–4309.

- Saevarsdottir, G.; Kvande, H.; Welch, B.J. Aluminum Production in the Times of Climate Change: The Global Challenge to Reduce the Carbon Footprint and Prevent Carbon Leakage. JOM 2019, 72, 296–308.

- Li, J.; Cheng, W. Comparative life cycle energy consumption, carbon emissions and economic costs of hydrogen production from coke oven gas and coal gasification. Int. J. Hydrogen Energy 2020, 45, 27979–27993.

- Lu, J.; Herremans, I.M. Board gender diversity and environmental performance: An industries perspective. Bus. Strat. Environ. 2019, 28, 1449–1464.

- Obeidat, S.M.; Al Bakri, A.A.; Elbanna, S. Leveraging “green” human resource practices to enable environmental and organiza-tional performance: Evidence from the Qatari oil and gas industry. J. Bus. Ethics 2020, 164, 371–388.

- Wang, L.; Tian, Y.; Yu, X.; Wang, C.; Yao, B.; Wang, S.; Winterfeld, P.H.; Wang, X.; Yang, Z.; Wang, Y.; et al. Advances in improved/enhanced oil recovery technologies for tight and shale reservoirs. Fuel 2017, 210, 425–445.

- Haszeldine, R.S.; Flude, S.; Johnson, G.; Scott, V. Negative emissions technologies and carbon capture and storage to achieve the Paris Agreement commitments. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2018, 376, 20160447.

- Brown, K.; Whittaker, S.; Wilson, M.; Srisang, W.; Smithson, H.; Tontiwachwuthikul, P. The history and development of the IEA GHG Weyburn-Midale CO2 Monitoring and Storage Project in Saskatchewan, Canada (the world largest CO2 for EOR and CCS program). Petroleum 2017, 3, 3–9.

- Luo, X.; Wang, M. Study of solvent-based carbon capture for cargo ships through process modelling and simulation. Appl. Energy 2017, 195, 402–413.

- Wang, C.; Liu, P.; Wang, F.; Atadurdyyev, B.; Ovluyagulyyev, M. Experimental study on effects of CO2 and improving oil recovery for CO2 assisted SAGD in super-heavy-oil reservoirs. J. Pet. Sci. Eng. 2018, 165, 1073–1080.

- Wang, Q.; Yang, S.; Glover, P.W.J.; Lorinczi, P.; Qian, K.; Wang, L. Effect of Pore-Throat Microstructures on Formation Damage during Miscible CO2 Flooding of Tight Sandstone Reservoirs. Energy Fuels 2020, 34, 4338–4352.

- Khurshid, I.; Afgan, I. Geochemical Investigation of CO2 Injection in Oil and Gas Reservoirs of Middle East to Estimate the Formation Damage and Related Oil Recovery. Energies 2021, 14, 7676.

- Wilberforce, T.; Baroutaji, A.; Soudan, B.; Al-Alami, A.H.; Olabi, A.G. Outlook of carbon capture technology and challenges. Sci. Total. Environ. 2018, 657, 56–72.

- Haugen, M.J.; Flynn, D.; Greening, P.; Tichler, J.; Blythe, P.; Boies, A.M. Electrification versus hydrogen for UK road freight: Conclusions from a systems analysis of transport energy transitions. Energy Sustain. Dev. 2022, 68, 203–210.

- Madanhire, I.; Mbohwa, C. Mitigating Environmental Impact of Petroleum Lubricants; Springer: Berlin/Heidelberg, Germany, 2016.

- Farajzadeh, R.; Eftekhari, A.; Dafnomilis, G.; Lake, L.; Bruining, J. On the sustainability of CO2 storage through CO2—Enhanced oil recovery. Appl. Energy 2020, 261, 114467.

- Mavar, K.N.; Gaurina-Međimurec, N.; Hrnčević, L. Significance of Enhanced Oil Recovery in Carbon Dioxide Emission Reduction. Sustainability 2021, 13, 1800.

- Van, S.L.; Chon, B.H. Effective prediction and management of a CO2 flooding process for enhancing oil recovery using artificial neural networks. J. Energy Resour. Technol. 2018, 140, 032906.

- Leeson, D.; Mac Dowell, N.; Shah, N.; Petit, C.; Fennell, P. A Techno-economic analysis and systematic review of carbon capture and storage (CCS) applied to the iron and steel, cement, oil refining and pulp and paper industries, as well as other high purity sources. Int. J. Greenh. Gas Control. 2017, 61, 71–84.

- Miocic, J.M.; Gilfillan, S.M.V.; Frank, N.; Schroeder-Ritzrau, A.; Burnside, N.M.; Haszeldine, R.S. 420,000 year assessment of fault leakage rates shows geological carbon storage is secure. Sci. Rep. 2019, 9, 769.

- Al-Shargabi, M.; Davoodi, S.; Wood, D.A.; Rukavishnikov, V.S.; Minaev, K.M. Carbon Dioxide Applications for Enhanced Oil Recovery Assisted by Nanoparticles: Recent Developments. ACS Omega 2022, 7, 9984–9994.

- Abuov, Y.; Serik, G.; Lee, W. Techno-Economic Assessment and Life Cycle Assessment of CO2-EOR. Environ. Sci. Technol. 2022, 56, 8571–8580.

- Zuloaga-Molero, P.; Yu, W.; Xu, Y.; Sepehrnoori, K.; Li, B. Simulation Study of CO2-EOR in Tight Oil Reservoirs with Complex Fracture Geometries. Sci. Rep. 2016, 6, 33445.

- Nikolova, C.; Tony, G. Use of microorganisms in the recovery of oil from recalcitrant oil reservoirs: Current state of knowledge, technological advances and future perspectives. Front. Microbiol. 2020, 10, 2996.

- Pei, Y.; Zhu, Y.; Wang, N. How do corruption and energy efficiency affect the carbon emission performance of China’s industrial sectors? Environ. Sci. Pollut. Res. 2021, 28, 31403–31420.

- Li, Z.; Kang, W.; Yang, H.; Zhou, B.; Jiang, H.; Liu, D.; Jia, H.; Wang, J. Advances of supramolecular interaction systems for improved oil recovery (IOR). Adv. Colloid Interface Sci. 2022, 301, 102617.

- Cho, J.; Min, B.; Jeong, M.S.; Lee, Y.W.; Lee, K.S. Modeling of CO2-LPG WAG with asphaltene deposition to predict coupled enhanced oil recovery and storage performance. Sci. Rep. 2021, 11, 2082.

- Guo, J.-X.; Huang, C.; Wang, J.-L.; Meng, X.-Y. Integrated operation for the planning of CO2 capture path in CCS–EOR project. J. Pet. Sci. Eng. 2019, 186, 106720.

- Matos, C.R.; Carneiro, J.F.; Silva, P.P. Overview of Large-Scale Underground Energy Storage Technologies for Integration of Renewable Energies and Criteria for Reservoir Identification. J. Energy Storage 2018, 21, 241–258.

- Middleton, R.S.; Yaw, S.P.; Hoover, B.A.; Ellett, K.M. SimCCS: An open-source tool for optimizing CO2 capture, transport, and storage infrastructure. Environ. Model. Softw. 2019, 124, 104560.

- Kolster, C.; Masnadi, M.S.; Krevor, S.; Mac Dowell, N.; Brandt, A.R. CO2 enhanced oil recovery: A catalyst for gigatonne-scale carbon capture and storage deployment? Energy Environ. Sci. 2017, 10, 2594–2608.

- Xian, X.; Mahoutian, M.; Zhang, S.; Shao, Y.; Zhang, D.; Liu, J. Converting industrial waste into a value-added cement material through ambient pressure carbonation. J. Environ. Manag. 2023, 325, 116603.

- Jakobsen, J.; Roussanaly, S.; Anantharaman, R. A techno-economic case study of CO2 capture, transport and storage chain from a cement plant in Norway. J. Clean. Prod. 2016, 144, 523–539.

- Cox, E.; Edwards, N.R. Beyond carbon pricing: Policy levers for negative emissions technologies. Clim. Policy 2019, 19, 1144–1156.

- Talati, S.; Zhai, H.; Morgan, M.G. Viability of Carbon Capture and Sequestration Retrofits for Existing Coal-Fired Power Plants under an Emission Trading Scheme. Environ. Sci. Technol. 2016, 50, 12567–12574.

- Hong, W.Y. A techno-economic review on carbon capture, utilisation and storage systems for achieving a net-zero CO2 emissions future. Carbon Capture Sci. Technol. 2022, 3, 100044.

- Lv, J.; Chi, Y.; Zhao, C.; Zhang, Y.; Mu, H. Experimental study of the supercritical CO2 diffusion coefficient in porous media under reservoir conditions. R. Soc. Open Sci. 2019, 6, 181902.

- Lichtschlag, A.; Pearce, C.R.; Suominen, M.; Blackford, J.; Borisov, S.M.; Bull, J.M.; de Beer, D.; Dean, M.; Esposito, M.; Flohr, A.; et al. Suitability analysis and revised strategies for marine environmental carbon capture and storage (CCS) monitoring. Int. J. Greenh. Gas Control. 2021, 112, 103510.

- Massarweh, O.; Abushaikha, A.S. A review of recent developments in CO2 mobility control in enhanced oil recovery. Petroleum 2022, 8, 291–317.

- Rognmo, A.; Heldal, S.; Fernø, M. Silica nanoparticles to stabilize CO2-foam for improved CO2 utilization: Enhanced CO2 storage and oil recovery from mature oil reservoirs. Fuel 2018, 216, 621–626.

- Farhadi, H.; Riahi, S.; Ayatollahi, S.; Ahmadi, H. Experimental study of nanoparticle-surfactant-stabilized CO2 foam: Stability and mobility control. Chem. Eng. Res. Des. 2016, 111, 449–460.

- Ren, D.; Wang, X.; Kou, Z.; Wang, S.; Wang, H.; Wang, X.; Tang, Y.; Jiao, Z.; Zhou, D.; Zhang, R. Feasibility Evaluation of CO2 EOR and Storage in Tight Oil Reservoirs: A Demonstration Project in the Ordos Basin. Fuel 2023, 331, 125652.

- Kumar, S.; Mandal, A. A comprehensive review on chemically enhanced water alternating gas/CO2 (CEWAG) injection for enhanced oil recovery. J. Pet. Sci. Eng. 2017, 157, 696–715.

- Yekeen, N.; Khan, J.A.; Ali, M.; Elraies, K.A.; Okunde, O.A.; Ridha, S.; Al-Yaseri, A. Impact of nanoparticles–surfactant solutions on carbon dioxide and methane wettabilities of organic-rich shale and CO2/brine interfacial tension: Implication for carbon geosequestration. Energy Rep. 2022, 8, 15669–15685.

- Dong, Y.; Hu, H.; Wang, R.; Wang, S.; Meng, W.; Chen, Z.; Tang, S. Evaluation of the Driving Effect of the CO2 Viscosity Enhancer Composite System in Extra-Low Per-meability Sandstone Reservoirs. ACS Omega 2023, 8, 5625–5633.

- Gbadamosi, A.O.; Junin, R.; Manan, M.A.; Agi, A.; Yusuff, A.S. An overview of chemical enhanced oil recovery: Recent advances and prospects. Int. Nano Lett. 2019, 9, 171–202.

- Wang, Y.; Ren, S.; Zhang, L.; Peng, X.; Pei, S.; Cui, G.; Liu, Y. Numerical study of air assisted cyclic steam stimulation process for heavy oil reservoirs: Recovery performance and energy efficiency analysis. Fuel 2018, 211, 471–483.

- Nowrouzi, I.; Manshad, A.K.; Mohammadi, A.H. Effects of TiO2, MgO and γ-Al2O3 nano-particles on wettability alteration and oil production under carbonated nano-fluid imbibition in carbonate oil reservoirs. Fuel 2019, 259, 116110.

- Pal, N.; Verma, A.; Ojha, K.; Mandal, A. Nanoparticle-modified gemini surfactant foams as efficient displacing fluids for enhanced oil recovery. J. Mol. Liq. 2020, 310, 113193.

- McLaren, D.; Markusson, N. The co-evolution of technological promises, modelling, policies and climate change targets. Nat. Clim. Chang. 2020, 10, 392–397.

- Dunstan, M.T.; Jain, A.; Liu, W.; Ong, S.P.; Liu, T.; Lee, J.; Persson, K.A.; Scott, S.A.; Dennis, J.S.; Grey, C.P. Large scale computational screening and experimental discovery of novel materials for high temperature CO2 capture. Energy Environ. Sci. 2016, 9, 1346–1360.

- Wang, Y.; Han, X.; Li, J.; Liu, R.; Wang, Q.; Huang, C.; Wang, X.; Zhang, L.; Lin, R. Review on Oil Displacement Technologies of Enhanced Oil Recovery: State-of-the-Art and Outlook. Energy Fuels 2023, 37, 2539–2568.

- Gaurina-Međimurec, N.; Mavar, K.N. Depleted hydrocarbon reservoirs and CO2 injection wells–CO2 leakage assessment. Rud. Zb. 2017, 32, 15–26.

- Li, Y.; Yang, C.; Li, Y.; Kumar, A.; Kleeman, M.J. Future emissions of particles and gases that cause regional air pollution in California under different greenhouse gas mitigation strategies. Atmos. Environ. 2022, 273, 118960.

- Xu, C.; Hong, J.; Ren, Y.; Wang, Q.; Yuan, X. Approaches for controlling air pollutants and their environmental impacts generated from coal-based electricity generation in China. Environ. Sci. Pollut. Res. 2015, 22, 12384–12395.

- Mac Dowell, N.; Fennell, P.S.; Shah, N.; Maitland, G.C. The role of CO2 capture and utilization in mitigating climate change. Nat. Clim. Chang. 2017, 7, 243–249.

- Rashid, M.I.; Benhelal, E.; Rafiq, S. Reduction of Greenhouse Gas Emissions from Gas, Oil, and Coal Power Plants in Pakistan by Carbon Capture and Storage (CCS): A Review. Chem. Eng. Technol. 2020, 43, 2140–2148.

- Allinson, K.; Burt, D.; Campbell, L.; Constable, L.; Crombie, M.; Lee, A.; Lima, V.; Lloyd, T.; Solsbey, L. Best Practice for Transitioning from Carbon Dioxide (CO2) Enhanced Oil Recovery EOR to CO2 Storage. Energy Procedia 2017, 114, 6950–6956.

- Manisalidis, I.; Stavropoulou, E.; Stavropoulos, A.; Bezirtzoglou, E. Environmental and Health Impacts of Air Pollution: A Review. Front. Public Health 2020, 8, 14.

- Hu, Y.; Cheng, H.; Tao, S. Environmental and human health challenges of industrial livestock and poultry farming in China and their mitigation. Environ. Int. 2017, 107, 111–130.

- Gholami, R.; Raza, A.; Iglauer, S. Leakage risk assessment of a CO2 storage site: A review. Earth-Science Rev. 2021, 223, 103849.

- Roefs, P.; Moretti, M.; Welkenhuysen, K.; Piessens, K.; Compernolle, T. CO2-enhanced oil recovery and CO2 capture and storage: An environmental economic trade-off analysis. J. Environ. Manag. 2019, 239, 167–177.

- Ko, K.; Lee, J.-Y.; Chung, H. Highly efficient colorimetric CO2 sensors for monitoring CO2 leakage from carbon capture and storage sites. Sci. Total. Environ. 2020, 729, 138786.

- Jana, A.; Snyder, S.W.; Crumlin, E.J.; Qian, J. Integrated carbon capture and conversion: A review on C2+ product mechanisms and mechanism-guided strategies. Front. Chem. 2023, 11, 1135829.

- Størset, S.; Tangen, G.; Berstad, D.; Eliasson, P.; Hoff, K.A.; Langørgen, Ø.; Munkejord, S.T.; Roussanaly, S.; Torsæter, M. Profiting from CCS innovations: A study to measure potential value creation from CCS research and development. Int. J. Greenh. Gas Control. 2019, 83, 208–215.

- Julien, M.; Colas, B.; Muller, S.; Schatz, B. Dataset of costs of the mitigation hierarchy and plant translocations in France. Data Brief 2022, 40, 107722.

- Heesh, N. Low carbon policy and market mechanisms to enable carbon capture and storage and decarbonisation in Australia. Int. J. Greenh. Gas Control. 2021, 105, 103236.

- Da Fonseca, R.S.; Veloso, A.P. The practice and future of financing science, technology, and innovation. Φopcaйm 2018, 12, 6–22.

- Piñeiro, V.; Arias, J.; Dürr, J.; Elverdin, P.; Ibáñez, A.M.; Kinengyere, A.; Opazo, C.M.; Owoo, N.; Page, J.R.; Prager, S.D.; et al. A scoping review on incentives for adoption of sustainable agricultural practices and their outcomes. Nat. Sustain. 2020, 3, 809–820.

- Perona, J.J. Biodiesel for the 21st century renewable energy economy. Energy LJ 2017, 38, 165.

- Pihkola, H.; Tsupari, E.; Kojo, M.; Kujanpää, L.; Nissilä, M.; Sokka, L.; Behm, K. Integrated Sustainability Assessment of CCS—Identifying Non-technical Barriers and Drivers for CCS Implementation in Finland. Energy Procedia 2017, 114, 7625–7637.

- Harkin, T.; Filby, I.; Sick, H.; Manderson, D.; Ashton, R. Development of a CO2 Specification for a CCS Hub Network. Energy Procedia 2017, 114, 6708–6720.

- Dai, Z.; Viswanathan, H.; Middleton, R.; Pan, F.; Ampomah, W.; Yang, C.; Jia, W.; Xiao, T.; Lee, S.; McPherson, B.; et al. CO2 accounting and risk analysis for CO2 sequestration at enhanced oil recovery sites. Environ. Sci. Technol. 2016, 50, 7546–7554.

- Ilinova, A.; Cherepovitsyn, A.; Evseeva, O. Stakeholder Management: An Approach in CCS Projects. Resources 2018, 7, 83.

- Herepovitsyn, A.E.; Ilinova, A.A.; Evseeva, O.O. Stakeholders management of carbon sequestration project in the state–business–society system. Записки Гoрнoгo Института 2019, 240, 731–742.

- Chiarini, A. Industry 4.0 technologies in the manufacturing sector: Are we sure they are all relevant for environmental per-formance? Bus. Strategy Environ. 2021, 30, 3194–3207.

- Leiss, W.; Larkin, P. Risk communication and public engagement in CCS projects: The foundations of public acceptability. Int. J. Risk Assess. Manag. 2019, 22, 384.

- Sahoo, B.; Behera, D.K.; Rahut, D. Decarbonization: Examining the role of environmental innovation versus renewable energy use. Environ. Sci. Pollut. Res. 2022, 29, 48704–48719.

- Wang, J.; Zhang, Y.; Xie, J. Influencing factors and application prospects of CO2 flooding in heterogeneous glutenite reservoirs. Sci. Rep. 2020, 10, 1839.

- Soltanzadeh, A.; Mahdinia, M.; Golmohammadpour, H.; Pourbabaki, R.; Mohammad-Ghasemi, M.; Sadeghi-Yarandi, M. Evaluating the potential severity of biogas toxic release, fire and explosion: Consequence modeling of biogas dispersion in a large urban treatment plant. Int. J. Occup. Saf. Ergon. 2022, 29, 335–346.

- Driga, A.M.; Drigas, A.S. Climate Change 101: How Everyday Activities Contribute to the Ever-Growing Issue. Int. J. Recent Contrib. Eng. Sci. IT 2019, 7, 22–31.

- Shahbazi, A.; Nasab, B.R. Carbon Capture and Storage (CCS) and its Impacts on Climate Change and Global Warming. J. Pet. Environ. Biotechnol. 2016, 7.

- Mustafa, M.; Alshare, M.; Bhargava, D.; Neware, R.; Singh, B.; Ngulube, P. Perceived Security Risk Based on Moderating Factors for Blockchain Technology Applications in Cloud Storage to Achieve Secure Healthcare Systems. Comput. Math. Methods Med. 2022, 2022, 6112815.

- Roberts, J.J.; Gilfillan, S.M.; Stalker, L.; Naylor, M. Geochemical tracers for monitoring offshore CO2 stores. Int. J. Greenh. Gas Control. 2017, 65, 218–234.

- Chen, Y.; Guerschman, J.P.; Cheng, Z.; Guo, L. Remote sensing for vegetation monitoring in carbon capture storage regions: A review. Appl. Energy 2019, 240, 312–326.

- Janik-Karpinska, E.; Brancaleoni, R.; Niemcewicz, M.; Wojtas, W.; Foco, M.; Podogrocki, M.; Bijak, M. Healthcare Waste—A Serious Problem for Global Health. Healthcare 2023, 11, 242.

- Wulayatu, M. Policies on Sustainable Remediation of Contaminated Soil in the Us and Eu. Bachelor’s Thesis, South-Eastern Finland University of Applied Sciences, Kouvola, Finland, 2022.

- Kang, J.-N.; Wei, Y.-M.; Liu, L.-C.; Yu, B.-Y.; Liao, H. A social learning approach to carbon capture and storage demonstration project management: An empirical analysis. Appl. Energy 2021, 299, 117336.

- Razvarz, S.; Jafari, R.; Gegov, A. Flow Modelling and Control in Pipeline Systems. Stud. Syst. Decis. Control. 2021, 321, 25–57.

- Rahman, F.A.; Aziz, M.M.A.; Saidur, R.; Abu Bakar, W.A.W.; Hainin, M.R.; Putrajaya, R.; Hassan, N.A. Pollution to solution: Capture and sequestration of carbon dioxide (CO2) and its utilization as a renewable energy source for a sustainable future. Renew. Sustain. Energy Rev. 2017, 71, 112–126.

- Gough, C.; Cunningham, R.; Mander, S. Understanding key elements in establishing a social license for CCS: An empirical ap-proach. Int. J. Greenh. Gas Control. 2018, 68, 16–25.

- Crawford, B.A.; Katz, R.A.; McKay, S.K. Engaging Stakeholders in Natural Resource Decision-Making; Engineer Research and Development Center: Saint Louis, MO, USA, 2017.

- Fedoseev, S.V.; Tcvetkov, P.S. Key factors of public perception of carbon dioxide capture and storage projects. Записки Гoрнoгo Института 2019, 237, 361–368.

- Murdoch, L.C.; Germanovich, L.N.; Slack, W.W.; Carbajales-Dale, M.; Knight, D.; Moak, R.; Laffaille, C.; DeWolf, S.; Roudini, S. Shallow Geologic Storage of Carbon to Remove Atmospheric CO2 and Reduce Flood Risk. Environ. Sci. Technol. 2023, 57, 8536–8547.

- Zheng, X.; Junfeng, S.H.I.; Gang, C.A.O.; Nengyu, Y.; Mingyue, C.U.I.; Deli, J.I.A.; He, L.I.U. Progress and Prospects of Oil and Gas Production Engineering Technology in China. Pet. Explor. Dev. 2022, 49, 644–659.

- Cuéllar-Franca, R.M.; Azapagic, A. Carbon capture, storage and utilisation technologies: A critical analysis and comparison of their life cycle environmental impacts. J. CO2 Util. 2015, 9, 82–102.

- Yu, W.; Lashgari, H.R.; Wu, K.; Sepehrnoori, K. CO2 injection for enhanced oil recovery in Bakken tight oil reservoirs. Fuel 2015, 159, 354–363.

- Burrows, L.C.; Haeri, F.; Cvetic, P.; Sanguinito, S.; Shi, F.; Tapriyal, D.; Goodman, A.L.; Enick, R.M. A Literature Review of CO2, Natural Gas, and Water-Based Fluids for Enhanced Oil Recovery in Unconventional Reservoirs. Energy Fuels 2020, 34, 5331–5380.

- Tarkowski, R.; Uliasz-Misiak, B.; Tarkowski, P. Storage of hydrogen, natural gas, and carbon dioxide–Geological and legal con-ditions. Int. J. Hydrog. Energy 2021, 46, 20010–20022.

- Sedlar, D.K.; Vulin, D.; Krajačić, G.; Jukić, L. Offshore gas production infrastructure reutilisation for blue energy production. Renew. Sustain. Energy Rev. 2019, 108, 159–174.

- Xinhua, M.; Zheng, D.; Ruichen, S.; Chunyan, W.; Jinheng, L.; Junchang, S. Key technologies and practice for gas field storage facility construction of complex geological conditions in China. Pet. Explor. Dev. 2018, 45, 507–520.

- Ciotta, M.; Peyerl, D.; Zacharias, L.G.L.; Fontenelle, A.L.; Tassinari, C.; Moretto, E.M. CO2 storage potential of offshore oil and gas fields in Brazil. Int. J. Greenh. Gas Control. 2021, 112, 103492.

- Eide, L.I.; Batum, M.; Dixon, T.; Elamin, Z.; Graue, A.; Hagen, S.; Hovorka, S.; Nazarian, B.; Nøkleby, P.H.; Olsen, G.I.; et al. Enabling Large-Scale Carbon Capture, Utilisation, and Storage (CCUS) Using Offshore Carbon Dioxide (CO2) Infrastructure Developments—A Review. Energies 2019, 12, 1945.

- Bera, A.; Vij, R.K.; Shah, S. Impact of newly implemented enhanced oil and gas recovery screening policy on current oil production and future energy supply in India. J. Pet. Sci. Eng. 2021, 207, 109196.

- Moshari, A.; Aslani, A.; Zolfaghari, Z.; Malekli, M.; Zahedi, R. Forecasting and gap analysis of renewable energy integration in zero energy-carbon buildings: A comprehensive bibliometric and machine learning approach. Environ. Sci. Pollut. Res. 2023, 30, 91729–91745.

- Zhang, Z.; Pan, S.-Y.; Li, H.; Cai, J.; Olabi, A.G.; Anthony, E.J.; Manovic, V. Recent Advances in Carbon Dioxide Utilization. Renew. Sustain. Energy Rev. 2020, 125, 109799.

- Razmjoo, A.; Kaigutha, L.G.; Rad, M.V.; Marzband, M.; Davarpanah, A.; Denai, M. A Technical analysis investigating energy sus-tainability utilizing reliable renewable energy sources to reduce CO2 emissions in a high potential area. Renew. Energy 2021, 164, 46–57.

- Verma, M.K. Fundamentals of Carbon Dioxide-Enhanced Oil Recovery (CO2-EOR): A Supporting Document of the Assessment Methodology for Hydrocarbon Recovery Using CO2-EOR Associated with Carbon Sequestration; U.S. Geological Survey Open-File Report; US Geological Survey: Tucson, AZ, USA, 2015.

- González-González, L.M.; Correa, D.F.; Ryan, S.; Jensen, P.D.; Pratt, S.; Schenk, P.M. Integrated biodiesel and biogas production from microalgae: Towards a sustainable closed loop through nutrient recycling. Renew. Sustain. Energy Rev. 2017, 82, 1137–1148.

- Fan, J.-L.; Yu, P.; Li, K.; Xu, M.; Zhang, X. A levelized cost of hydrogen (LCOH) comparison of coal-to-hydrogen with CCS and water electrolysis powered by renewable energy in China. Energy 2021, 242, 123003.

- Psarras, P.; He, J.; Pilorgé, H.; McQueen, N.; Jensen-Fellows, A.; Kian, K.; Wilcox, J. Cost Analysis of Carbon Capture and Sequestration from U.S. Natural Gas-Fired Power Plants. Environ. Sci. Technol. 2020, 54, 6272–6280.

- Kazemifar, F. A review of technologies for carbon capture, sequestration, and utilization: Cost, capacity, and technology readiness. Greenh. Gases Sci. Technol. 2022, 12, 200–230.

- Alsarhan, L.M.; Alayyar, A.S.; Alqahtani, N.B.; Khdary, N.H. Circular carbon economy (CCE): A way to invest CO2 and protect the environment, a review. Sustainability 2021, 13, 11625.

- Gils, H.C.; Scholz, Y.; Pregger, T.; de Tena, D.L.; Heide, D. Integrated modelling of variable renewable energy-based power supply in Europe. Energy 2017, 123, 173–188.

- Al-Shetwi, A.Q. Sustainable development of renewable energy integrated power sector: Trends, environmental impacts, and recent challenges. Sci. Total. Environ. 2022, 822, 153645.