Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Anouar Hallioui | -- | 4533 | 2023-09-14 01:50:07 | | | |

| 2 | Jessie Wu | + 19 word(s) | 4552 | 2023-09-14 03:25:00 | | | | |

| 3 | Jessie Wu | -1 word(s) | 4551 | 2023-09-18 10:33:45 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Hallioui, A.; Herrou, B.; Katina, P.F.; Santos, R.S.; Egbue, O.; Jasiulewicz-Kaczmarek, M.; Soares, J.M.; Marques, P.C. Sustainable Total Productive Maintenance. Encyclopedia. Available online: https://encyclopedia.pub/entry/49134 (accessed on 07 February 2026).

Hallioui A, Herrou B, Katina PF, Santos RS, Egbue O, Jasiulewicz-Kaczmarek M, et al. Sustainable Total Productive Maintenance. Encyclopedia. Available at: https://encyclopedia.pub/entry/49134. Accessed February 07, 2026.

Hallioui, Anouar, Brahim Herrou, Polinpapilinho F. Katina, Ricardo S. Santos, Ona Egbue, Małgorzata Jasiulewicz-Kaczmarek, Jose Miguel Soares, Pedro Carmona Marques. "Sustainable Total Productive Maintenance" Encyclopedia, https://encyclopedia.pub/entry/49134 (accessed February 07, 2026).

Hallioui, A., Herrou, B., Katina, P.F., Santos, R.S., Egbue, O., Jasiulewicz-Kaczmarek, M., Soares, J.M., & Marques, P.C. (2023, September 14). Sustainable Total Productive Maintenance. In Encyclopedia. https://encyclopedia.pub/entry/49134

Hallioui, Anouar, et al. "Sustainable Total Productive Maintenance." Encyclopedia. Web. 14 September, 2023.

Copy Citation

Sustainable Total Productive Maintenance (STPM) arose in 2021 as a promising, new concept to fill the lack of sustainability in Total Productive Maintenance (TPM) and allow companies to overcome its implementation barriers. It revolves around increasing the understanding of the systems approach and contributing to setting contemporary companies’ sustainable ideology by supporting orientation toward sustainability from a sustainable maintenance perspective. However, STPM is still in its infancy and is viewed as a complement to the traditional TPM approach and is based on its pillars.

sustainable total productive maintenance

sustainability

sustainable maintenance

re-engineered fourth generation management

1. Chronological Context of the Creation of Sustainable Total Productive Maintenance

1.1. Emergence of Total Productive Maintenance

Companies began to worry about offering higher quality products from World War II and the last decades of the mass production era (i.e., the second industrial revolution or pre-lean automation era) (Figure 1). Japanese industries were the pioneers in improving quality based on the ideas from the United States [1]. They transformed these ideas into successful practices to make products manufactured in Japan known for their superior quality and exported them to Western industrial countries in large quantities [2]. Japanese fathers of manufacturing and management systems (e.g., [2][3]) never denied their learning from the US manufacturing empire to import ideas and put them into practice in Japan, nor their struggles, successes, frustrations, and surprises to lead the transformation of Japanese industry. Moreover, the world wars during the 20th century played a centric role in creating energy transitions given the growth of oil as a significant energy source, which accelerated after the Second World War in North America and Europe [4]. Therefore, the improvement in the quality of products and the energy transition were the significant factors contributing to increased competitiveness among companies from the Second World War onwards. During the 1950s, the author of [5] introduced the systems approach to address the complexity of the interacting elements of systems.

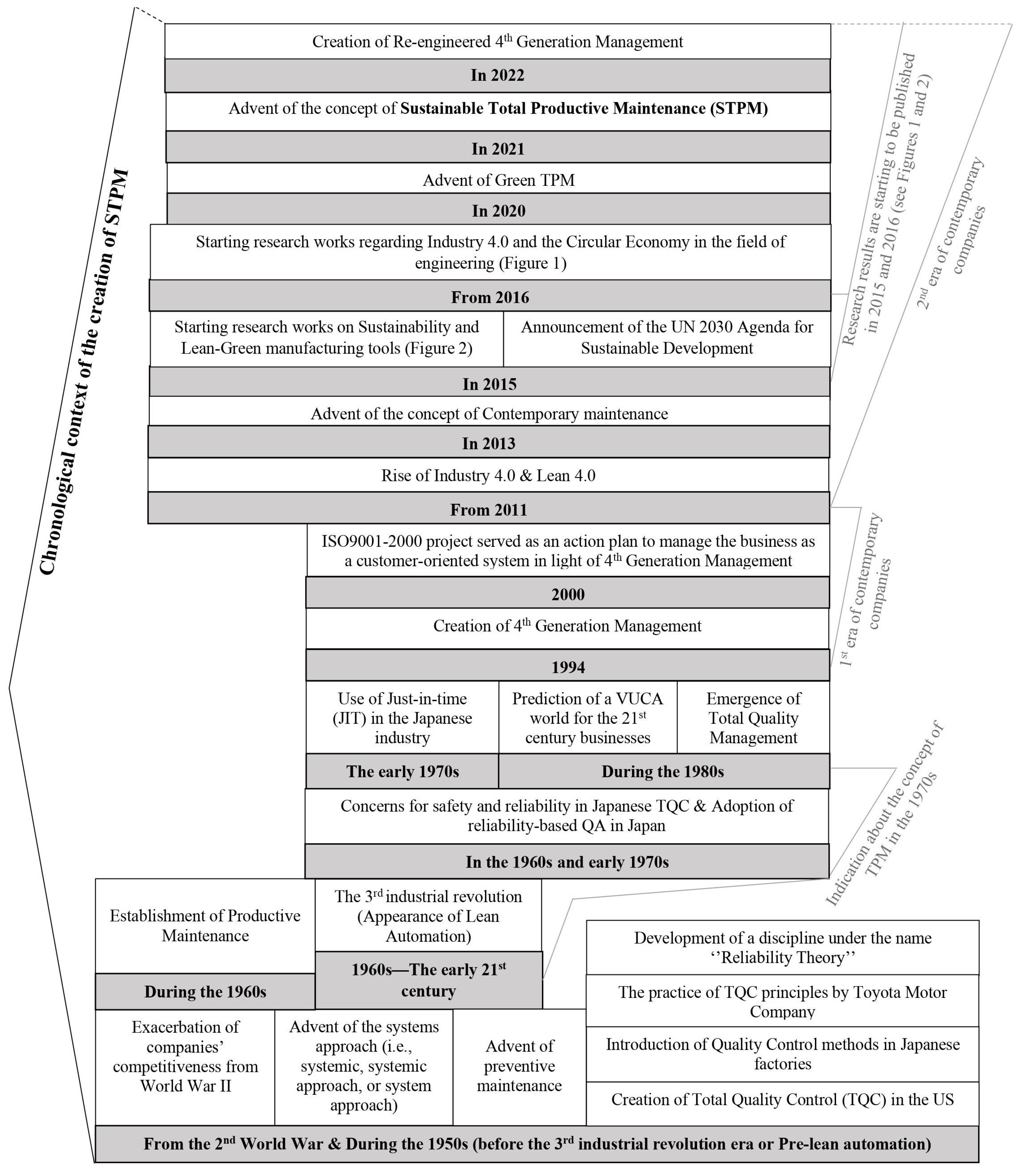

Figure 1. The chronological context of the creation of Sustainable Total Productive Maintenance.

During the second half of the 20th century, researchers (e.g., [6][7][8]) studied the systems approach and its tools, such as systems theory (i.e., general system theory), system analysis, and cybernetics [9]. These studies led to a better understanding among companies of the complexities of working within a system. It is crucial to indicate that the author of [10] and then the authors of [11] were the pioneers in emphasizing the concept of the systems approach to understand the complex meaning of classical Total Productive Maintenance (TPM).

While considering quality control as a classical quality management approach starting in the United States in the 1920s [12], which was based on statistical and mathematical techniques [13], the following factors should be taken into account: (i) the introduction of quality control methods (e.g., control charts, sampling inspection techniques, etc.) in Japanese factories in the early 1950s [12]; (ii) the appearance of the Japanese style of quality control as a thought revolution in management [14], which is termed Total Quality Control (TQC), though after Feigenbaum’s American TQC [15][16]; (iii) the development of a discipline under the name Reliability Theory from World War II [17] to analyze the failure of complex, multi-component engineered systems, which typically defines exceeded safety thresholds [18][19]; and (iv) the advent of preventive maintenance and productive maintenance during the 1950s and 1960s, respectively [2], all of which had crucial roles in creating TPM at the Japan Institute of Plant Maintenance in the 1970s, as an approach denoted to develop the preventive maintenance methodologies created by the Americans [10]. TPM’s creation came after the author of [2] studied American preventive maintenance in 1950 and after his first visit to the United States in 1962; every year after then, he visited Western (i.e., American and European) manufacturers to study their manufacturing facilities and learn more about preventive maintenance systems. Based on his observations, the author of [2] developed TPM and introduced it in Japan in 1971. Those were all historical processes, leading to the reason for one of the first and most famous definitions of TPM, which was given by the author of [2]: like TQC, which is company-wide total quality control, TPM is equipment maintenance performed on a company-wide basis. He considered TPM the fourth stage after the development of the first three stages, which include breakdown maintenance, preventive maintenance, and productive maintenance. In breakdown maintenance, an old maintenance strategy that characterized the period before the 1950s, the repair is performed after equipment stoppage, failure, or severe performance decline [20][21]. Preventive maintenance was introduced in 1951 to systematically intervene with equipment before anomalies to maintain and improve its working conditions and operational performance. Lastly, productive maintenance is the best economic maintenance that enhances the company’s productivity by lowering the overall cost of the equipment during the span of its life (i.e., during the stages of design, manufacture, operation, and maintenance) while also reducing the losses brought on by its degradation [20].

1.2. After the Appearance of Total Productive Maintenance and the Advent of Sustainable Total Productive Maintenance

According to [12], a remarkable increase in concerns for safety and reliability in Japanese TQC characterized the 1960s before TPM emerged. Japanese manufacturers regarded quality assurance based on reliability as one of the foundations of quality control education in the early 1970s. In the same decade, during the first oil crisis in the fall of 1973, the Toyota production system supported by the just-in-time system and autonomation (i.e., automation with a human touch) began attracting the Japanese industry’s attention after its design and implementation soon after World War II [3]. The Toyota production system and, ultimately, lean production was the Japanese substitute that led the Toyota Motor Company out of the American mass production model that was unworkable in Japan. Eiji Toyoda and his production genius Taiichi Ohno’s viewpoint believed in Japanese manufacturing’s values, culture, and unicity in the context of their company and the circumstances of the country’s crisis during the post-war era [22]. Just-in-time production, an innovation pioneered at Toyota in the 1950s, was first embraced by Western firms in the early 1980s [23]. In just-in-time production, only the necessary products at the required times in the essential quantities are produced while maintaining the stock on hand at a minimum [24]. Mr. Taiichi Ohno, a Toyota executive and the creator of Toyota’s just-in-time production system, also identified the first seven kinds of Muda—overproduction, waiting, transportation, processing itself, stock on hand, movement, and the creation of defective goods [23]. According to [23], the Japanese concept of Muda means waste, specifically any human activity that uses resources without creating value.

Independent organizations began developing standards in the last decades of the 20th century to support the rise of Quality Management Systems (QMS); at the time, the concept of Total Quality Management (TQM) originated as an American response to Japan’s quality revolution [25]. In the literature, TQM is often discussed with or without TPM or JIT in a framework of lean manufacturing or continuous improvement to achieve world-class manufacturing [26][27][28][29][30][31][32][33][34][35][36][37][38][39][40][41][42][43][44][45][46][47][48][49][50][51][52], and the literature is inaccurate in encapsulating TQM and its country of origin (i.e., US or Japan) [15][53]. TQM is a company culture in which all employees actively participate in quality improvement [54]. This TQM definition enabled the authors of [55] to show that there do not seem to be any contradictions between TQM and lean production objectives, which proves that the roots of TQM, born in the late 1980s, can be linked to the development of Japanese quality.

The early anticipation of a volatile, uncertain, complex, and ambiguous world (VUCA world) for 21st-century businesses in the 1980s [56] led company leaders to rethink how they tackled culture, management, quality, and technology-related concerns. Indeed, it was a solid sign to shift their leadership paradigm in order to survive in a more turbulent future. It has been proposed that companies should rethink their strategies and processes to consider a highly competitive and dynamic landscape [57][58]. Furthermore, in the last decades of the 20th century, business managers and workers needed to learn to trust each other and live with and embrace a system-oriented, data-based customer focus [57]. Nevertheless, the traditional character stayed predominant in business management; in other words, companies were not capable of transitioning from traditional to contemporary organizations at that time, and only became capable after the creation of the so-called fourth generation management style in the 1990s [59]. According to the authors of [59]’s own words, the key elements of fourth generation management are a dedication to quality as defined by the customer (i.e., customer focus), a scientific approach to rapid learning, and the creation of team-spirited relationships (i.e., all one team). These three elements (quality, scientific approach, and all one team) are known as Joiner’s triangle. It aims at filling the gap of the lack of a clear explanation of the basic principles that underlie and unify the seemingly diverse approaches existing before the 1990s, such as TQM, continuous improvement, re-engineering, time-based competition, and visionary leadership [59]. The ISO 9001-2000 project [60] was an action plan to enable companies to manage quality based on fourth generation management by suggesting the eight quality management principles, including the process approach applied in managing the organization as a customer-oriented system, customer focus, leadership, relationship management, continuous improvement, evidence-based decision making, and the engagement of people.

Looking back to [56]’s 1980s postulate that it is hard to think of any 21st-century industry or government agency that will not find itself heavily dependent on technology in its operations, products, or services, Industry 4.0 emerged in 2011 as a major catalyst for waste removal and productivity growth [61], which supports that early prediction. Industry 4.0 forges new industrial production by linking machines and people for a faster exchange of information and is supported by web technology and intelligent systems [62][63]. In other words, it looks to connect the physical and virtual worlds in industrial production and has acquired popularity, as well as several opportunities, strategies, and business models that can be strengthened using digitalization technology [64]. Industry 4.0 has gained significant attention in recent years due to its potential to transform manufacturing strategies substantially [65][66][67]. Besides Industry 4.0, the interaction between lean manufacturing and Industry 4.0 paradigms has created great debate among researchers. It can be materialized by a finalized two-way relationship, i.e., lean tools (TPM, TQM, JIT, etc.) enable Industry 4.0 implementation while Industry 4.0 advances lean manufacturing, and their combination results in the concept of Lean 4.0 [68][69]. Lean 4.0 is the fourth phase of lean manufacturing evolution and the successor of lean automation, which began with the third industrial revolution in the 1960s [70].

As shown in Figure 1, after the debut of Industry 4.0 in 2011, notably after (i) the advent of the concept of contemporary maintenance in 2013; (ii) the announcement of the UN 2030 Agenda for Sustainable Development in 2015; (iii) the striking increase in research works on “Sustainability and Lean–Green manufacturing tools” and “Industry 4.0 and the circular economy in the field of engineering” in 2015 and 2016, respectively; and (iv) the creation of the concept of Green TPM in 2020 by the authors of [71], Sustainable Total Productive Maintenance (STPM) was created in 2021 by the authors of [72], who first presented it as an innovative concept at an international conference in Italy. In 2022, the authors of [57] created R4thGM as a new management style to enable organizations to be oriented toward sustainability and customers in the context of Industry 4.0, the circular economy, competitiveness, and diverse stakeholders, which can serve as a basis for STPM and a prerequisite for its achievement.

2. Barriers to Total Productive Maintenance

Researchers have dedicated more than 50 years to determining the causes of resistance to change and how to deal with it because it can significantly impact whether improvements succeed or fail [73]. The attempts to change reality for an organization have never been easy to implement given the tough opposition (i.e., complex resistance) imposed by several resources and concerns. In line with the trends of the 21st century, it seems particularly difficult to introduce changes in enterprises from the manufacturing sector [74]. The authors of [75] stated that more than 70% of attempts to bring about change in organizations fail because of factors including a lack of focus on business processes, disregard for the values and beliefs of employees, organizational culture traits, ineffective attempts to promote change in specific locations, inadequate leadership, high employee resistance, inaccurate estimation of a temporary resource, etc. The case of the Toyota Motor Company before they created their production system is a good example. That complex resistance is the set of constraints originating from the mindset of personnel and diverse stakeholders, equipment technology, the methods used, and financial resources constituting the external and internal environments of the business as a system (i.e., whole).

Numerous manufacturing companies attempted TPM in the past, but they failed because of an insufficient understanding of the obstacles to its effective implementation [76]. The literature has long provided many works on worldwide TPM implementation barriers; [76][77][78][79][80][81][82][83][84][85] are the most recent and accurate research works analyzing the barriers to TPM implementation across manufacturing companies. These works emphasized and detailed the following ten critical barriers to TPM, which were ranked in order of criticality in [84] as follows: (1) lack of top management commitment and support; (2) lack of training and education; (3) lack of motivation; (4) employee resistance; (5) cultural resistance; (6) failure to allow sufficient time for the evolution; (7) poor relationship between the production and maintenance department; (8) lack of communication; (9) financial constraints; and (10) lack of understanding and knowledge of TPM. The most significant success factor in implementing TPM is the involvement and commitment of top management [79][80][82][84][85][86].

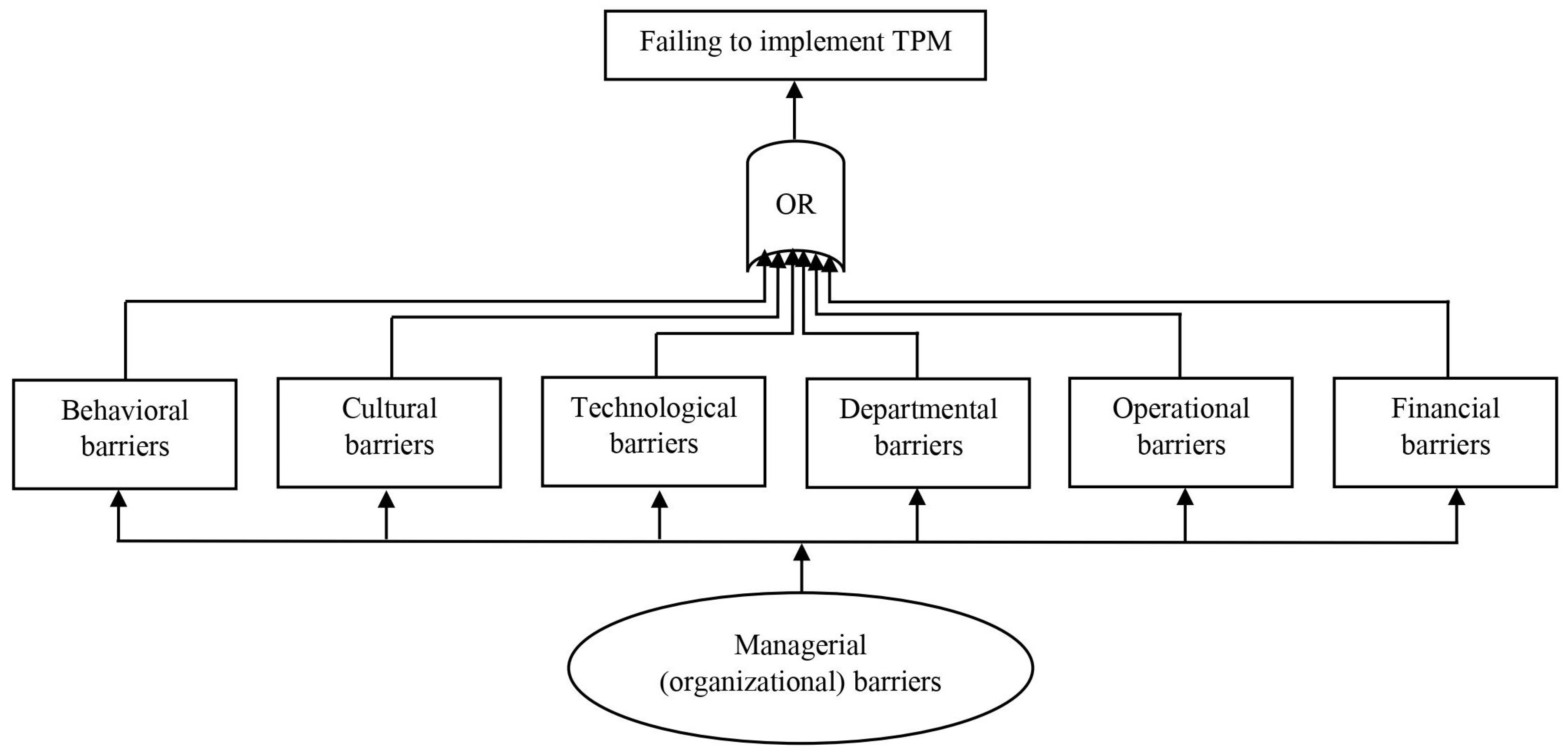

The literature categorizes these barriers into numerous families, such as cultural, organizational, behavioral, technological, financial, departmental, and operational barriers [50][78]. However, this categorization or understanding is reductionist (i.e., pragmatic in that it comes from analytical thinking that reduces the organization into its functions or departments), uncertain, and ineffective in overcoming TPM’s implementation barriers since it is confusing for companies. For instance, according to [78], a lack of training and education is regarded as an organizational, behavioral, cultural, and technological barrier. Still, employee resistance is considered a behavioral, cultural, operational, and organizational barrier.

All are managerial (i.e., organizational). On the one hand, management issues can generate behavioral, administrative, cultural, technological, departmental, operational, and financial problems, inhibiting company development and adaptation to the changing context of the business. On the other hand, through management, firms can eliminate all those categories of barriers. Figure 2 presents a fault tree of the failure to implement TPM as a philosophy across manufacturing businesses worldwide. It is a logic diagram that shows, through the recategorization of TPM’s barriers, the root causes of problems related to the deployment of TPM by companies over time, from its creation until today. TPM is still viewed from an operational point of view. In other words, the management style and its ideological implications do not matter yet for organizations implementing TPM.

Figure 2. Fault tree of the failure to implement TPM within manufacturing companies.

Barriers in the organization’s context mean that walls exist between its functions. Thus, their existence directly reflects management issues, such as organizational reductionism (i.e., bureaucracy) or an inadequate management style for the implementation of improvement projects such as TPM. Besides the findings of [84] regarding barrier rankings, it is important to add that top management can effectively contribute to manufacturing performance improvements by providing an effective structure for TPM implementation [87]. Moreover, two support practices (top management and leadership and human resource development) benefitted from adopting technological techniques such as TPM [79][88]. In other words, a high level of top management maturity is necessary to implement TPM successfully [85][89]. Thus, relating lean manufacturing tools such as TPM to the company’s management style (e.g., R4thGM) is necessary to implement them within the manufacturing business as a system in general and more contemporary business in particular (i.e., second-era contemporary business).

3. Lack of Sustainability in the Concept of Total Productive Maintenance

Businesses of the twenty-first century must prioritize sustainability [57]. The 2021 State of Green Business Report showed that, at last, sustainability has emerged from the shadows to become vital to corporate success. Many of the largest businesses in the world increasingly consider sustainability as essential to reducing risk, boosting resilience, strengthening competitiveness, and generating new opportunities. In terms of critical findings, in 2019, 90% of major US companies released a sustainability report, up from 86% in 2018 and 20% in 2011 [90]. Furthermore, sustainability is firmly ingrained in companies’ objectives and strategies based on the 2019 State of Sustainable Business Report [91]. The transition toward more sustainable business practices generally necessitates changes to an organizations’ products, services, processes, policies, and resources [92]. Today’s businesses must include sustainability in their strategies to ensure long-term survival, growth, and profitability in a competitive and constantly changing world [93]. Since its creation in Japan in the 1970s, TPM has known many definitions and several perspectives (Table 1). However, academics failed to introduce sustainability into the concept of TPM to forge STPM until 2021.

Table 1. Definitions of TPM and STPM in the period of 2020–2022. All chosen papers have undergone peer review and are indexed in Scopus/Web of Science/Science Direct.

| Year | Definition of TPM/STPM | STPM/Classical TPM | Source |

|---|---|---|---|

| 2022 | TPM is a lean manufacturing practice that can improve inventory turnover performance. | Classical TPM | [94] |

| TPM is a lean manufacturing tool that directly impacts social, economic, and environmental sustainability. | Classical TPM | [95] | |

| TPM is a lean manufacturing tool associated with machinery and equipment tools and directly and positively affects environmental sustainability. | Classical TPM | [96] | |

| TPM is an essential lean method without a significant relationship with firms’ sustainable performance. | Classical TPM | [97] | |

| TPM is among the critical green lean six sigma practices that allow organizations to manage waste effectively, conserve resources, control air emissions, and improve environmental and workplace safety. | Classical TPM | [98] | |

| TPM is a methodology that allows businesses to improve their productivity by focusing on occupational ergonomics. | Classical TPM | [99] | |

| TPM is a methodology that comprises all maintenance policies, such as predictive, preventive, and corrective maintenance, to reduce subsystem failures, reduce system downtime, and improve reliability and productivity. | Classical TPM | [100] | |

| TPM is a strategy that can potentially increase business machinery efficiency by minimizing downtime, speed, and quality losses. | Classical TPM | [101] | |

| TPM is a strategy to manage equipment, reduce waste and lead time, and enhance competitiveness. | Classical TPM | [102] | |

| TPM is a reliable maintenance strategy that has been incorporated into the work culture of many large industries. | Classical TPM | [76] | |

| TPM is a comprehensive strategy, provided the organization’s employees can participate in the operation and maintenance activities. | Classical TPM | [103] | |

| TPM is a philosophy that can be used as a long-term strategy to improve productivity in an organization. | Classical TPM | [86] | |

| TPM is a technique that can be incorporated into lean, smart manufacturing by combining it with Industry 4.0 technologies. | Classical TPM | [104] | |

| TPM is a problem-solving technique that contributes to improving manufacturing businesses through enhanced productivity and the cutting of costs. | Classical TPM | [105] | |

| TPM is a shop floor practice that can be digitalized through Industry 4.0 to lead a manufacturing firm toward sustainability. | Classical TPM | [106] | |

| TPM is a quality system that can improve the business’s overall performance. | Classical TPM | [107] | |

| TPM is an economical maintenance variant that ensures stability, quality, and the maximization of production efficiency. | Classical TPM | [108] | |

| TPM is company-wide preventive maintenance. | Classical TPM | [109] | |

| TPM is a dynamic capability that forges a new bundle with Industry 4.0 and the circular economy to ensure sustainable performance for manufacturing businesses. | Classical TPM | [110] | |

| STPM is a complement to TPM practices. It could become an essential tool for more sustainable manufacturing. | STPM | [111] | |

| 2021 | TPM is a lean manufacturing approach that can be combined with green manufacturing approaches (e.g., 6R techniques—Reduce, Reuse, Remanufacture, Recycle, Recover, and Redesign) and Industry 4.0 technologies to achieve optimized and cleaner production. | Classical TPM | [112] |

| TPM is a lean manufacturing tool that supports the industry’s economic sustainability. | Classical TPM | [113] | |

| TPM is among the lean–green and sustainability (LGS) tools that aim to achieve a superior triple bottom line (TBL) and positively impact the company’s economic and environmental pillars. | Classical TPM | [114] | |

| TPM is a methodology to improve the availability, productivity, and quality of manufacturing systems. | Classical TPM | [115] | |

| TPM is a methodology to maximize equipment effectiveness by actively involving all supporting departments. | Classical TPM | [116] | |

| TPM is a methodology aiming to increase equipment and machinery efficiency and longevity. | Classical TPM | [117] | |

| TPM is the most effective maintenance strategy to improve equipment availability and product quality while reducing waste. | Classical TPM | [118] | |

| TPM is a strategy to reduce equipment failure, minimize solid waste generation, and boost machine efficiency. | Classical TPM | [119] | |

| TPM is a maintenance philosophy that helps businesses improve their operational performance by acting on diverse dimensions such as productivity, quality, safety, flexibility, and costs. | Classical TPM | [120] | |

| TPM is a method that can be used to control operational performance and bring out improvements in production in the era of Industry 4.0. | Classical TPM | [121] | |

| TPM is a robust maintenance management approach grounded on lean principles. | Classical TPM | [122] | |

| TPM is a strategic management initiative that improves the machine lifecycle and productivity. | Classical TPM | [123] | |

| TPM is a high-effectiveness approach to maximize production in any industry. | Classical TPM | [62] | |

| TPM is a productivity improvement program for various manufacturing industries. | Classical TPM | [124] | |

| TPM is a system that maintains and improves business production and quality systems in terms of integrity by acting on equipment, processes, and people rather than making new investments. | Classical TPM | [125] | |

| TPM is an intellectual project that goes beyond the methodology or strategy of a firm to act on its ideology and anchor the manufacturing system sustainability mindset throughout the organization as a whole (concept of STPM). | STPM | [72] | |

| 2020 | TPM is a lean tool that improves business productivity by reducing waste to meet customer demand, which justifies its significant positive impact on green manufacturing. | Classical TPM | [126] |

| TPM is a lean tool that helps businesses reach economic and environmental gains and improve environmental management, which allows them to stand out from the competition and boost revenues. | Classical TPM | [127] | |

| TPM is a methodology to banish losses due to inefficiencies. | Classical TPM | [128] | |

| TPM is a methodology that prioritizes eliminating efficiency losses and uses some maintenance activities from preventive maintenance. | Classical TPM | [129] | |

| TPM is a methodology that aims to improve maintenance management and ensure the best operational performance for assets. | Classical TPM | [130] | |

| TPM is a cutting-edge maintenance strategy that will provide a comprehensive understanding of strategic maintenance. It can be scaled to Green TPM as an integrated approach covering elements like green training, maintenance, and six sigma, supporting higher manufacturing and environmental performance. | Green TPM and transition toward STPM | [71] | |

| TPM can be characterized as a manufacturing strategy to raise product quality and equipment productivity. | Classical TPM | [32] | |

| TPM is a systemic approach that emphasizes improving the efficiency of the manufacturing system; it constitutes one of the cornerstones of business management culture. | Classical TPM | [11] | |

| TPM is a vital tool for improving manufacturing firms’ productivity. | Classical TPM | [131] | |

| TPM is a modern maintenance practice that supports industrial production systems by reducing breakdowns, defects, accidents, and waste. | Classical TPM | [132] | |

| TPM is a technical practice; its adoption can be positively influenced by two support factors, top management involvement/leadership and human resource development within manufacturing firms. | Classical TPM | [88] | |

| TPM is among the performance improvement techniques widely deployed within manufacturing businesses and aims to achieve a competitive advantage, economic viability, customer fulfillment, dependability, and survival. | Classical TPM | [31] | |

| TPM is among the best waste management techniques. | Classical TPM | [133] | |

| TPM is a continuous improvement program that allows firms to enhance their performance and competitive advantage while achieving environmental sustainability. |

Table 2 shows that until the last three years, most researchers only knew of TPM and defined it in different ways as classical or Japanese TPM based on the eight pillars, thus lacking the concept of sustainability. Based on this table, in the period of 2020–2022, 94% of the selected papers studied classical TPM, and only 4% emphasized the new concept of STPM, which were carried out by the authors of [72][111] in 2021 and 2022; the remaining 2% is represented by [71], which led the transition from TPM to STPM in 2020 through the creation of Green TPM as a transitional concept toward STPM. Furthermore, until today, Morocco and the USA were the pioneering countries, with one paper each emphasizing the concept of STPM in the industrial literature.

4. Mechanisms of Sustainable Total Productive Maintenance

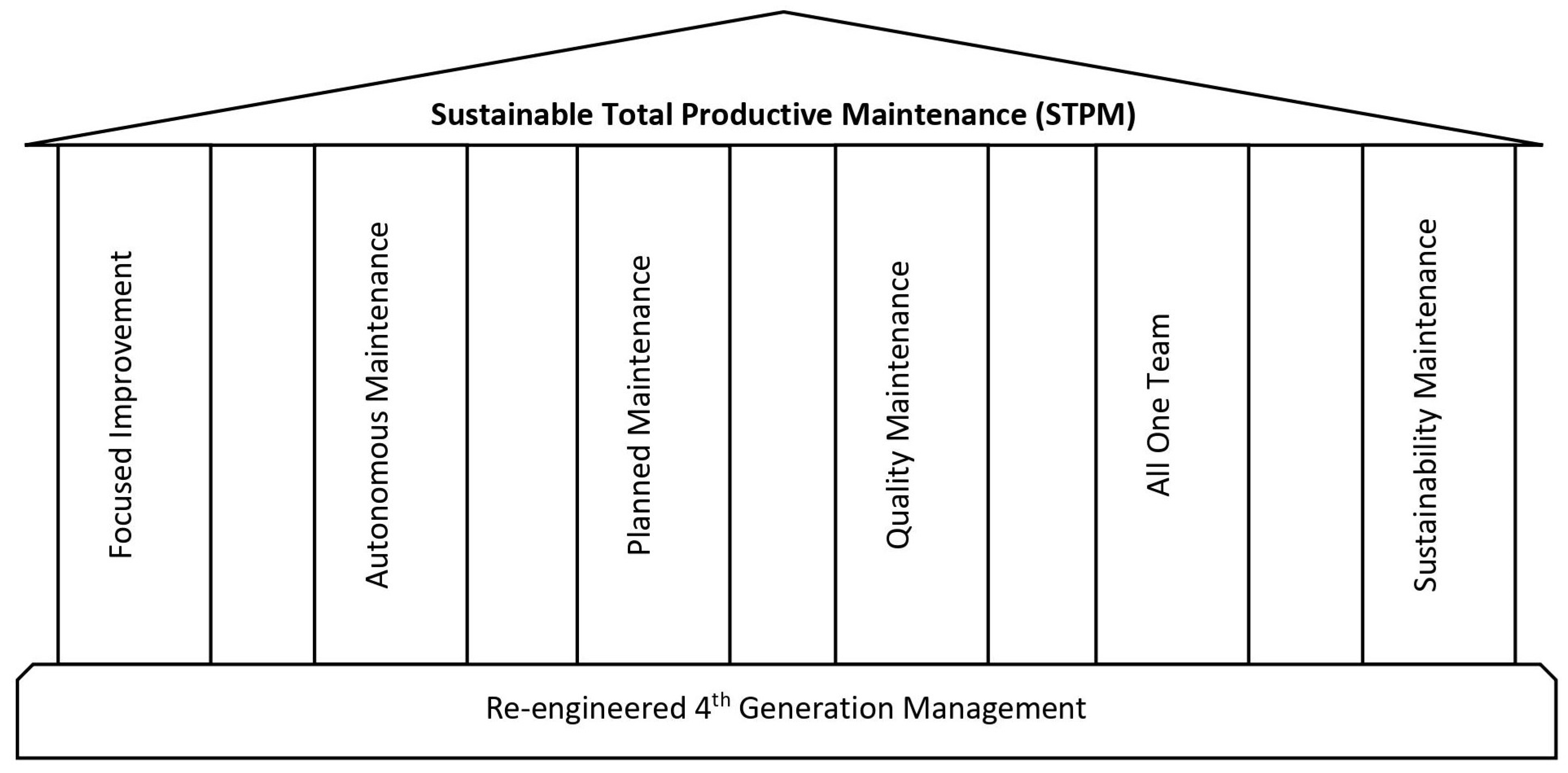

The eight pillars of TPM are focused improvement, autonomous maintenance, planned maintenance, training and education, early equipment maintenance, quality maintenance, TPM in administration, and safety, health, and environment [111]. They are dedicated to maximizing the effective production of any industry [62]. TPM shares only four pillars with STPM; the latter’s fifth and sixth pillars are all one team and sustainability maintenance, respectively (Figure 3).

Figure 3. The suggested unique architecture of Sustainable Total Productive Maintenance.

Starting with sustainability maintenance (i.e., the sixth pillar of STPM) as a sustainability pillar, it aims at improving the triple bottom line of sustainability by acting on the maintenance function in the context of R4thGM because it seems impossible to introduce a sustainable philosophy (e.g., STPM) into an organization without applying a sustainability-driven management paradigm. Sustainability maintenance targets the lack of sustainability in TPM. This new pillar includes and goes beyond the two pillars “training and education” and “safety, health, and environment,” for classical TPM to encompass sustainability’s economic, social, and environmental foundations. It allows for sustainable maintenance and fosters the company’s sustainability due to its alignment with the business orientation toward sustainability and customers. Sustainable maintenance, as one of the core aims of this pillar, should contribute to minimizing the environmental and social impacts of a manufacturing system, reducing life cycle costs, enhancing durability for equipment, and improving socio-economic well-being [134][135].

All one team (i.e., the fifth pillar of STPM) is a corner of Joiner’s triangle [59] that has recently been explained through Hallioui’s triangle as “engagement of people, including leadership” and “relationship management” [57]. In the scope of STPM (Figure 3), the engagement of people, including leadership, means the total involvement of all internal stakeholders of the company (i.e., all employees, including managers and non-managers, from all organizational classes and departments, shareholders, etc.) in achieving the goals of STPM. Relationship management is the dedication to managing relationships with internal and external stakeholders of the company to achieve and sustain STPM. This STPM pillar replaces the TPM in administration pillar from classical TPM since it considers administration and other departments independent from each other (i.e., without interactions). In other words, it proves bureaucracy has had a place among traditional companies with no openness to diverse stakeholders or sustainability awareness among them [57].

The four remaining pillars are well known in the lean manufacturing literature and common between TPM and STPM (Figure 3). This includes focused improvement, which relies on using problem-solving methods to encourage employee participation and suggestions (e.g., Kaizen) to ensure continuous improvement in equipment performance, thereby continuously reducing waste [26][111]. Moreover, this pillar aims to assess the operational effectiveness of equipment based on Overall Equipment Effectiveness (OEE). Autonomous maintenance is dedicated to including small maintenance tasks (i.e., first and second maintenance levels) into the duties of operators to make them more familiar with machines, encourage them to be more involved in the operational performance of their line, and improve their consciousness in terms of machine effectiveness and its impact on quality production, which enhances the focus and efficiency of maintenance personnel. Planned maintenance includes preventive maintenance (i.e., time-based maintenance) and even predictive maintenance as condition-based maintenance [20] to achieve zero failure. Quality maintenance aims at maintaining and continuously improving the quality of the products by mastering the machines, methods, materials, workforce, and environment; it requires the application of the tools necessary for continuous quality improvement (5M, statistical process control tools, etc.) to achieve zero quality defects.

References

- Díaz-Reza, J.R.; García-Alcaraz, J.L.; Martínez-Loya, V. TPM Background. In Impact Analysis of Total Productive Maintenance; Springer International Publishing: Cham, Switzerland, 2019; pp. 3–21.

- Nakajima, S. Introduction to TPM: Total Productive Maintenance; Productivity Press: New York, NY, USA, 1988; ISBN 0915299232.

- Ohno, T. Toyota Production System: Beyond Large-Scale Production, 1st ed.; Productivity Press: New York, NY, USA, 1988; ISBN 9780915299140.

- Johnstone, P.; McLeish, C. World Wars and the Age of Oil: Exploring Directionality in Deep Energy Transitions. Energy Res. Soc. Sci. 2020, 69, 101732.

- Von Bertalanffy, L. General System Theory. Gen. Syst. 1956, 1, 11–17.

- Le Moigne, J.-L. La Théorie Du Système Général: Théorie de La Modélisation, 1st ed.; Presses Universitaires de France-PUF: Paris, France, 1977.

- De Rosnay, J. Le Macroscope: Vers Une Vision Globale, French ed.; Seuil: Paris, France, 1975; ISBN 978-2020028189.

- Wiener, N. Cybernetics or Control and Communication in the Animal and the Machine, 2nd ed.; MIT Press: Cambridge, MA, USA, 1961; ISBN 978-0262730099.

- Hallioui, A.; Herrou, B. System Analysis: A Literature Review. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Detroit, Michigan, USA, 10–14 August 2020; IEOM Society: Southfield, MI, USA, 2020; pp. 2774–2785.

- Bufferne, J. Le Guide de La TPM: Total Productive Maintenance; Organisation: Paris, France, 2006; ISBN 2-7081-3723-9.

- Hallioui, A.; Herrou, B. System Approach of Production System Reliability and Maintainability. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Harare, Zimbabwe, 7–10 December 2020; IEOM Society: Southfield, MI, USA, 2020; pp. 72–86.

- Makabe, H. Quality Control and Quality Assurance—QC and QA Systems in Japan. IFAC Proc. Vol. 1991, 24, 93–97.

- Beltrami, G.; Maresca, E.S. From Quality Control to Total Quality Management. Microchem. J. 1992, 45, 310–317.

- Ishikawa, K. What Is Total Quality Control? The Japanese Way; Prentice Hall: Hoboken, NJ, USA, 1985; ISBN 0139524339.

- Pyzdek, T.; Keller, P. The Handbook for Quality Management: A Complete Guide to Operational Excellence, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2013; ISBN 9780071799249.

- Feigenbaum, A. Total Quality Control, 3rd ed.; McGraw Hill: Hoboken, NJ, USA, 1983; ISBN 0070203539.

- Leroy, A.; Signoret, J.-P. Le Risque Technologique; Presses Universitaires de France-PUF: Paris, France, 1992; ISBN 978-2130447580.

- Teklitz, A.; Nietch, C.; Riasi, M.S.; Yeghiazarian, L. Reliability Theory for Microbial Water Quality and Sustainability Assessment. J. Hydrol. 2021, 596, 125711.

- Høyland, A.; Rausand, M. System Reliability Theory: Models and Statistical Methods; John Wiley & Sons: New York, NY, USA, 2009; ISBN 978-0-470-31774-7.

- Ahuja, I.P.S.; Khamba, J.S. An Assessment of Maintenance Management Initiatives in the Indian Manufacturing Industry. Int. J. Technol. Policy Manag. 2008, 8, 250–278.

- Wireman, T. World Class Maintenance Management, 1st ed.; Industrial Press, Inc.: New York, NY, USA, 1990; ISBN 978-0831130251.

- Womack, J.P.; Jones, D.T.; Roos, D. ; Massachusetts Institute of Technology Machine That Changed the World; Simon and Schuster: New York, NY, USA, 1990; ISBN 0892563508.

- Womack, J.P.; Jones, D.T. Lean Thinking: Banish Waste and Create Wealth in Your Corporation, 2nd ed.; Free Press: Detroit, MI, USA, 2003; ISBN 978-0743249270.

- Sugimori, Y.; Kusunoki, K.; Cho, F.; Uchikawa, S. Toyota Production System and Kanban System Materialization of Just-in-Time and Respect-for-Human System. Int. J. Prod. Res. 1977, 15, 553–564.

- American Society for Quality. What Is a Quality Management System (QMS)? Available online: https://asq.org/quality-resources/quality-management-system (accessed on 13 July 2023).

- Al-Refaie, A.; Lepkova, N.; Camlibel, M.E. The Relationships between the Pillars of TPM and TQM and Manufacturing Performance Using Structural Equation Modeling. Sustainability 2022, 14, 1497.

- Adzrie, M.; Armi, M.A.S.M. The Awareness of Lean Manufacturing Implemented Practices in SME in Sabah State: TQM and TPM Practices Approach. J. Phys. Conf. Ser. 2021, 1878, 012002.

- Harris, M. An Investigation on Engine Mass Airflow Sensor Production via TQM, TPM, and Six Sigma Practices. Oper. Res. Forum 2021, 2, 61.

- Khalfallah, M.; Lakhal, L. The Relationships between TQM, TPM, JIT and Agile Manufacturing: An Empirical Study in Industrial Companies. Total Qual. Manag. J. 2021, 33, 1735–1752.

- Sahoo, S.; Yadav, S. Influences of TPM and TQM Practices on Performance of Engineering Product and Component Manufacturers. Procedia Manuf. 2020, 43, 728–735.

- Singh, K.; Ahuja, I.S. Structural Equation Modelling of Transfusion of TQM-TPM Model for Indian Manufacturing Industries. Int. J. Manag. Pract. 2020, 13, 47–73.

- Thorat, R.; Mahesha, G.T. Improvement in Productivity through TPM Implementation. Mater. Today Proc. 2018, 24, 1508–1517.

- Sahoo, S. Assessment of TPM and TQM Practices on Business Performance: A Multi-Sector Analysis. J. Qual. Maint. Eng. 2019, 25, 412–434.

- Hailu, H.; Mengstu, S.; Hailu, T. An Integrated Continuous Improvement Model of TPM, TPS and TQM for Boosting Profitability of Manufacturing Industries: An Innovative Model & Guideline. Manag. Sci. Lett. 2018, 8, 33–50.

- Sahoo, S. An Empirical Exploration of TQM, TPM and Their Integration from Indian Manufacturing Industry. J. Manuf. Technol. Manag. 2018, 29, 1188–1210.

- Tortorella, G.L.; da Silva, E.F.; Vargas, D.B. An Empirical Analysis of Total Quality Management and Total Productive Maintenance in Industry 4.0. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Pretoria/Johannesburg, South Africa, 28 October–1 November 2018; IEOM Society: Southfield, MI, USA, 2018; pp. 742–753.

- Singh, T.P.; Ahuja, I.S. Evaluating Manufacturing Performance through Strategic Total Productive Maintenance Implementation in a Food Processing Industry. Int. J. Product. Qual. Manag. 2017, 21, 429–442.

- Modgil, S.; Sharma, S. Total Productive Maintenance, Total Quality Management and Operational Performance an Empirical Study of Indian Pharmaceutical Industry. J. Qual. Maint. Eng. 2016, 22, 353–377.

- Kaur, M.; Singh, K.; Ahuja, I.S.; Singh, P. Justification of Synergistic Implementation of TQM-TPM Paradigms Using Analytical Hierarchy Process. Int. J. Process Manag. Benchmarking 2015, 5, 1–18.

- Gupta, P.; Vardhan, S.; Al Haque, M.S. Study of Success Factors of TPM Implementation in Indian Industry towards Operational Excellence: An Overview. In Proceedings of the 2015 International Conference on Industrial Engineering and Operations Management (IEOM), Dubai, United Arab Emirates, 3–5 March 2015; pp. 1–6.

- Ahmad, M.F.; Zakuan, N.; Rasi, R.Z.R.M.; Hisyamudin, M.N.N.; Takala, J. Mediator Effect of Total Productive Maintenance Between Total Quality Management and Business Performance: Survey Result in Malaysia Automotive Industry. Adv. Sci. Lett. 2015, 21, 3723–3725.

- Singh, K.; Ahuja, I.S. An Evaluation of Transfusion of TQM-TPM Implementation Initiative in an Indian Manufacturing Industry. J. Qual. Maint. Eng. 2015, 21, 134–153.

- Singh, K.; Ahuja, I.S. Synergising the Effects of Transfusion of TQM and TPM for Indian Manufacturing Industries: A Tactical TQM-TPM Model. Int. J. Process Manag. Benchmarking 2015, 5, 456–482.

- Singh, K.; Singh Ahuja, I. Effectiveness of TPM Implementation with and without Integration with TQM in Indian Manufacturing Industries. J. Qual. Maint. Eng. 2014, 20, 415–435.

- Al-Refaie, A.; Hanayneh, B. Influences of TPM, TQM, Six Sigma Practices on Firms Performance in Jordan. Int. J. Product. Qual. Manag. 2014, 13, 219–234.

- Ahmad, M.F.; Zakuan, N.; Jusoh, A.; Yusof, S.M.; Takala, J.; Arif, M.S.M. Comparative Study of TQM Practices between Japanese and Non-Japanese Companies: Proposed Conceptual Framework. Adv. Mater. Res. 2014, 903, 371–377.

- Wakchaure, V.D.; Nandurkar, K.N.; Kallurkar, S.P. Relationship Between Implementation of TQM, JIT, TPM and SCM and Manufacturing Performance: Empirical Evidences From Indian Context. In Proceedings of the International Manufacturing Science and Engineering Conference, Detroit, MI, USA, 9–13 June 2014.

- Singh, K.; Ahuja, I.S. Implementing TQM and TPM Paradigms in Indian Context: Critical Success Factors and Barriers. Int. J. Technol. Policy Manag. 2013, 13, 226–244.

- Wakchaure, V.D.; Nandurkar, K.N.; Kallurkar, S.P. Enhancing Manufacturing Excellence through Integrated Manufacturing Programme. Int. J. Integr. Supply Manag. 2010, 5, 376–400.

- Ahuja, I.P.S.; Khamba, J.S. Strategies and Success Factors for Overcoming Challenges in TPM Implementation in Indian Manufacturing Industry. J. Qual. Maint. Eng. 2008, 14, 123–147.

- Kedar, A.P.; Lakhe, R.R.; Deshpande, V.S.; Washimkar, P.V.; Wakhare, M.V. A Comparative Review of TQM, TPM and Related Organisational Performance Improvement Programs. In Proceedings of the 1st International Conference on Emerging Trends in Engineering and Technology, ICETET 2008, Nagpur, India, 16–18 July 2008; pp. 725–730.

- Ahmad, M.F.; Zakuan, N.; Jusoh, A.; Takala, J. Relationship of TQM and Business Performance with Mediators of SPC, Lean Production and TPM. Procedia. Soc. Behav. Sci. 2012, 65, 186–191.

- Martínez-Lorente, A.R.; Dewhurst, F.; Dale, B.G. Total Quality Management: Origins and Evolution of the Term. TQM Mag. 1998, 10, 378–386.

- Dahlgaard, J.J.; Kristensen, K.; Khanji, G.K. Fundamentals of Total Quality Management, 1st ed.; Routledge: Abingdon, UK, 1997; ISBN 9780748772933.

- Dahlgaard, J.J.; Mi Dahlgaard-Park, S. Lean Production, Six Sigma Quality, TQM and Company Culture. TQM Mag. 2006, 18, 263–281.

- Bennis, W.; Nanus, B. Leaders: The Strategies for Taking Charge, 1st ed.; Harper & Row: New York, NY, USA, 1985; ISBN 006015246X.

- Hallioui, A.; Herrou, B.; Santos, R.S.; Katina, P.F.; Egbue, O. Systems-Based Approach to Contemporary Business Management: An Enabler of Business Sustainability in a Context of Industry 4.0, Circular Economy, Competitiveness and Diverse Stakeholders. J. Clean. Prod. 2022, 373, 133819.

- Valamede, L.S.; Akkari, A.C.S. Lean 4.0: A New Holistic Approach for the Integration of Lean Manufacturing Tools and Digital Technologies. Int. J. Math. Eng. Manag. Sci. 2020, 5, 851–868.

- Joiner, B. Fourth Generation Management: The New Business Consciousness, 1st ed.; McGraw-Hill: New York, NY, USA, 1994; ISBN 0070327157.

- ISO 9001:2000; Quality Management Systems—Requirements, Multiple, 3rd ed. American National Standards Institute (ANSI): Washington, DC, USA, 2000.

- Elafri, N.; Tappert, J.; Rose, B.; Yassine, M. Lean 4.0: Synergies between Lean Management Tools and Industry 4.0 Technologies. IFAC-PapersOnLine 2022, 55, 2060–2066.

- Roosefert Mohan, T.; Preetha Roselyn, J.; Annie Uthra, R.; Devaraj, D.; Umachandran, K. Intelligent Machine Learning Based Total Productive Maintenance Approach for Achieving Zero Downtime in Industrial Machinery. Comput. Ind. Eng. 2021, 157, 107267.

- Rauch, E.; Linder, C.; Dallasega, P. Anthropocentric Perspective of Production before and within Industry 4.0. Comput. Ind. Eng. 2020, 139, 105644.

- Bittencourt, V.L.; Alves, A.C.; Leão, C.P. Lean Thinking Contributions for Industry 4.0: A Systematic Literature Review. IFAC-PapersOnLine 2019, 52, 904–909.

- Anosike, A.; Alafropatis, K.; Garza-Reyes, J.A.; Kumar, A.; Luthra, S.; Rocha-Lona, L. Lean Manufacturing and Internet of Things—A Synergetic or Antagonist Relationship? Comput. Ind. 2021, 129, 103464.

- Derakhti, A.; Santibanez Gonzalez, E.D.R.; Mardani, A. Industry 4.0 and Beyond: A Review of the Literature on the Challenges and Barriers Facing the Agri-Food Supply Chain. Sustainability 2023, 15, 5078.

- Yin, Y.; Stecke, K.E.; Li, D. The Evolution of Production Systems from Industry 2.0 through Industry 4.0. Int. J. Prod. Res. 2018, 56, 848–861.

- Marinelli, M.; Ali Deshmukh, A.; Janardhanan, M.; Nielsen, I. Lean Manufacturing and Industry 4.0 Combinative Application: Practices and Perceived Benefits. IFAC-PapersOnLine 2021, 54, 288–293.

- Mayr, A.; Weigelt, M.; Kühl, A.; Grimm, S.; Erll, A.; Potzel, M.; Franke, J. Lean 4.0-A Conceptual Conjunction of Lean Management and Industry 4.0. Procedia CIRP 2018, 72, 622–628.

- Abbadi, L.e.; Elrhanimi, S.; Manti, S.E. A Literature Review on the Evolution of Lean Manufacturing. J. Syst. Manag. Sci. 2020, 10, 13–30.

- Samadhiya, A.; Agrawal, R. Achieving Sustainability through Holistic Maintenance-Key for Competitiveness. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Dubai, United Arab Emirates, 10–12 March 2020; IEOM Society: Southfield, MI, USA, 2020; pp. 400–408.

- Hallioui, A.; Herrou, B. The Sustainable Total Productive Maintenance: An Evolved System Approach, from the Methodology to the Ideology of the Today’s Company. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Rome, Italy, 2–5 August 2021; IEOM Society: Southfield, MI, USA, 2021; pp. 568–569.

- Warrick, D.D. Revisiting Resistance to Change and How to Manage It: What Has Been Learned and What Organizations Need to Do. Bus. Horiz. 2023, 66, 433–441.

- Klimecka-Tatar, D.; Ingaldi, M. Digitization of Processes in Manufacturing SMEs—Value Stream Mapping and OEE Analysis. Procedia Comput. Sci. 2022, 200, 660–668.

- Hammer, M.; Champy, J. Reengineering the Corporation, Illustrated ed.; Harper Business: New York, NY, USA, 2006; ISBN 0060559535.

- Rathi, R.; Singh, M.; Sabique, M.; Al Amin, M.; Saha, S.; Krishnaa, M.H. Identification of Total Productive Maintenance Barriers in Indian Manufacturing Industries. In Materials Today: Proceedings, Proceedings of the 2nd International Conference on Functional Material, Manufacturing and Performances (ICFMMP-2021), Phagwara, India, 17–18 September 2021; Elsevier Ltd.: Amsterdam, The Netherlands, 2022; Volume 50, pp. 736–742.

- Chaurey, S.; Kalpande, S.D.; Gupta, R.C.; Toke, L.K. A Review on the Identification of Total Productive Maintenance Critical Success Factors for Effective Implementation in the Manufacturing Sector. J. Qual. Maint. Eng. 2023, 29, 114–135.

- Mishra, R.P.; Gupta, G.; Sharma, A. Development of a Model for Total Productive Maintenance Barriers to Enhance the Life Cycle of Productive Equipment. Procedia CIRP 2021, 98, 241–246.

- Prabowo, H.A.; Hilmy, I.; Triblas Adesta, E.Y. Total Productive Maintenance Implementation’s Barriers and Enablers in Indonesian Manufacturing Companies. In Proceedings of the 2020 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 4 February–9 April 2020; pp. 1–6.

- Prashanth Pai, M.; Ramachandra, C.G.; Srinivas, T.R.; Raghavendra, M.J. A Study on Usage of Total Productive Maintenance (TPM) in Selected SMEs. IOP Conf. Ser. Mater. Sci. Eng. 2018, 376, 1–8.

- Poduval, P.S.; Pramod, V.R.; Jagathy, R.V.P. Interpretive Structural Modeling (ISM) and Its Application in Analyzing Factors Inhibiting Implementation of Total Productive Maintenance (TPM). Int. J. Qual. Reliab. Manag. 2015, 32, 308–331.

- Singh, M.; Sachdeva, A.; Bhardwaj, A. An Interpretive Structural Modelling Approach for Analysing Barriers in Total Productive Maintenance Implementation. Int. J. Ind. Syst. Eng. 2014, 16, 433–450.

- Attri, R.; Grover, S.; Dev, N. A Graph Theoretic Approach to Evaluate the Intensity of Barriers in the Implementation of Total Productive Maintenance (TPM). Int. J. Prod. Res. 2014, 52, 3032–3051.

- Attri, R.; Grover, S.; Dev, N.; Kumar, D. Analysis of Barriers of Total Productive Maintenance (TPM). Int. J. Syst. Assur. Eng. Manag. 2013, 4, 365–377.

- Ng, K.C.; Goh, G.G.G.; Eze, U.C. Barriers in Total Productive Maintenance Implementation in a Semiconductor Manufacturing Firm: A Case Study. In Proceedings of the 2012 IEEE International Conference on Industrial Engineering and Engineering Management, Hong Kong, China, 10–13 December 2012; pp. 377–381.

- Singh, R.K.; Gurtu, A. Prioritizing Success Factors for Implementing Total Productive Maintenance (TPM). J. Qual. Maint. Eng. 2022, 28, 810–830.

- Ahuja, I.P.S.; Khamba, J.S. An Evaluation of TPM Initiatives in Indian Industry for Enhanced Manufacturing Performance. Int. J. Qual. Reliab. Manag. 2008, 25, 147–172.

- Sahoo, S. Exploring the Effectiveness of Maintenance and Quality Management Strategies in Indian Manufacturing Enterprises. Benchmarking Int. J. 2020, 27, 1399–1431.

- Jain, A.; Singh, H.; Bhatti, R.S. Identification of Key Enablers for Total Productive Maintenance (TPM) Implementation in Indian SMEs. Benchmarking Int. J. 2018, 25, 2611–2634.

- Makower, J. State of Green Business 2021. Available online: https://www.greenbiz.com/article/state-green-business-2021 (accessed on 11 August 2023).

- BSR. GlobeScan. The State of Sustainable Business 2019. Available online: https://www.bsr.org/en/reports/the-state-of-sustainable-business-in-2019 (accessed on 11 August 2023).

- Silvius, G.; Marnewick, C. Interlinking Sustainability in Organizational Strategy, Project Portfolio Management and Project Management A Conceptual Framework. Procedia Comput. Sci. 2021, 196, 938–947.

- Sanoran, K. (Lek) Corporate Sustainability and Sustainable Growth: The Role of Industry Sensitivity. Financ. Res. Lett. 2023, 53, 103596.

- Jayawardane, K.; Musthaffa, S.; Dias, M. Impact of Lean Manufacturing on Inventory Turnover Performances: Evidence From the Sri Lankan Apparel Industry. In Proceedings of the 2022 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 27–29 July 2022; IEEE: New York, NY, USA, 2022; pp. 1–6.

- García Alcaraz, J.L.; Morales García, A.S.; Díaz Reza, J.R.; Blanco Fernández, J.; Jiménez Macías, E.; Puig i Vidal, R. Machinery Lean Manufacturing Tools for Improved Sustainability: The Mexican Maquiladora Industry Experience. Mathematics 2022, 10, 1468.

- García-Alcaraz, J.L.; Morales García, A.S.; Díaz-Reza, J.R.; Jiménez Macías, E.; Javierre Lardies, C.; Blanco Fernández, J. Effect of Lean Manufacturing Tools on Sustainability: The Case of Mexican Maquiladoras. Environ. Sci. Pollut. Res. 2022, 29, 39622–39637.

- Zainal Abidin, M.H.; Leman, Z.; Mohd Yusof, Z.A.; Ismail, M.Y. Scrutinizing the Impact of Essential Lean Methods on Sustainable Performance in Malaysian Manufacturing Firms. J. Teknol. 2022, 84, 11–25.

- Farrukh, A.; Mathrani, S.; Sajjad, A. Managerial Perspectives on Green-Lean-Six Sigma Adoption in the Flexible Packaging Industry: Empirical Evidence from an Emerging Economy. J. Manuf. Technol. Manag. 2022, 33, 1232–1255.

- Chintada, A.; Umasankar, V. Improvement of Productivity by Implementing Occupational Ergonomics. J. Ind. Prod. Eng. 2022, 39, 59–72.

- Bhushan, K.; Chattopadhyaya, S.; Sharma, S.; Sharma, K.; Li, C.; Zhang, Y.; Eldin, E.M.T. Analyzing Reliability and Maintainability of Crawler Dozer BD155 Transmission Failure Using Markov Method and Total Productive Maintenance: A Novel Case Study for Improvement Productivity. Sustainability 2022, 14, 14534.

- Hung, Y.-H.; Li, L.Y.O.; Cheng, T.C.E. Uncovering Hidden Capacity in Overall Equipment Effectiveness Management. Int. J. Prod. Econ. 2022, 248, 108494.

- Ondra, P. The Impact of Single Minute Exchange of Die and Total Productive Maintenance on Overall Equipment Effectiveness. J. Compet. 2022, 14, 113–132.

- Au-Yong, C.P.; Azmi, N.F.; Myeda, N.E. Promoting Employee Participation in Operation and Maintenance of Green Office Building by Adopting the Total Productive Maintenance (TPM) Concept. J. Clean. Prod. 2022, 352, 131608.

- Tripathi, V.; Chattopadhyaya, S.; Mukhopadhyay, A.K.; Sharma, S.; Li, C.; Singh, S.; Hussan, W.U.; Salah, B.; Saleem, W.; Mohamed, A. A Sustainable Productive Method for Enhancing Operational Excellence in Shop Floor Management for Industry 4.0 Using Hybrid Integration of Lean and Smart Manufacturing: An Ingenious Case Study. Sustainability 2022, 14, 7452.

- Shandilya, S.; Arora, J.; Kalluri, V. To Study the Comparison and Effect of Six Sigma and Red Bin Analysis in Indian Manufacturing Industries. Total Qual. Manag. J. 2022. ahead-of-print.

- Samadhiya, A.; Agrawal, R.; Garza-Reyes, J.A. Integrating Industry 4.0 and Total Productive Maintenance for Global Sustainability. Total Qual. Manag. J. 2022. ahead-of-print.

- Singh, S.; Agrawal, A.; Sharma, D.; Saini, V.; Kumar, A.; Praveenkumar, S. Implementation of Total Productive Maintenance Approach: Improving Overall Equipment Efficiency of a Metal Industry. Inventions 2022, 7, 119.

- Drewniak, R.; Drewniak, Z. Improving Business Performance through TPM Method: The Evidence from the Production and Processing of Crude Oil. PLoS ONE 2022, 17, e0274393.

- Jiang, Y.; Dai, P.; Fang, P.; Zhong, R.Y.; Zhao, X.; Cao, X. A2-LSTM for Predictive Maintenance of Industrial Equipment Based on Machine Learning. Comput. Ind. Eng. 2022, 172, 108560.

- Samadhiya, A.; Agrawal, R.; Luthra, S.; Kumar, A.; Garza-Reyes, J.A.; Srivastava, D.K. Total Productive Maintenance and Industry 4.0 in a Sustainability Context: Exploring the Mediating Effect of Circular Economy. Int. J. Logist. Manag. 2022, 34, 818–846.

- Crosby, B.; Badurdeen, F. Integrating Lean and Sustainable Manufacturing Principles for Sustainable Total Productive Maintenance (Sus-TPM). Smart Sustain. Manuf. Syst. 2022, 6, 68–84.

- Amjad, M.S.; Rafique, M.Z.; Khan, M.A. Leveraging Optimized and Cleaner Production through Industry 4.0. Sustain. Prod. Consum. 2021, 26, 859–871.

- Reza, J.R.D.; García-Alcaraz, J.L.; Medina, M.A.R.; Vargas, A.R.; Soto, K.C.A.; Macias, E.G. Role of Lean Manufacturing Tools on Economic Sustainability in the Mexican Manufacturing Industry. In Proceedings of the 33rd European Modeling and Simulation Symposium, EMSS 2021, Krakow, Poland, 15–17 September 2021; Dime University of Genoa: Genoa, Italy, 2021; pp. 365–373.

- Teixeira, P.; Sá, J.C.; Silva, F.J.G.; Ferreira, L.P.; Santos, G.; Fontoura, P. Connecting Lean and Green with Sustainability towards a Conceptual Model. J. Clean. Prod. 2021, 322, 129047.

- Costa, R.; Lopes, I. Productivity Improvement in Manufacturing Systems through TPM, OEE and Collaboration between Maintenance and Production: A Case Study. In IFIP Advances in Information and Communication Technology, Proceedings of the Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems, Nantes, France, 5–9 September 2021; Springer: Cham, Switzerland, 2021; pp. 261–268.

- Hardt, F.; Kotyrba, M.; Volna, E.; Jarusek, R. Innovative Approach to Preventive Maintenance of Production Equipment Based on a Modified TPM Methodology for Industry 4.0. Appl. Sci. 2021, 11, 6953.

- Grajzova, L.; Janik, S.; Cambal, M.; Mlkva, M. Analysis of the Current Application of AR in the Context of TPM in Slovakia Organizations. In Proceedings of the 32nd DAAAM International Symposium on Intelligent Manufacturing and Automation, Vienna, Austria, 28–29 October 2021; DAAAM International Vienna: Vienna, Austria, 2021; Volume 32, pp. 546–554.

- Ait El Maalem, L.; Ech-Chhibat, E.H.; Ouajji, H. Performance Improvement by Total Productive Maintenance Implementation: Case of a Cable Company. Int. Rev. Mech. Eng. 2021, 15, 197–208.

- Aized, T. Analysis and Implementation of TPM in Plastic Industry. Pak. J. Eng. Appl. Sci. 2021, 29, 64–71.

- Vaz, E.; Vieira De Sá, J.C.; Santos, G.; Correia, F.; Ávila, P. The Value of TPM for Portuguese Companies. J. Qual. Maint. Eng. 2021, 29, 286–312.

- Tripathi, V.; Chattopadhyaya, S.; Bhadauria, A.; Sharma, S.; Li, C.; Pimenov, D.Y.; Giasin, K.; Singh, S.; Gautam, G.D. An Agile System to Enhance Productivity through a Modified Value Stream Mapping Approach in Industry 4.0: A Novel Approach. Sustainability 2021, 13, 11997.

- Tortorella, G.L.; Fogliatto, F.S.; Cauchick-Miguel, P.A.; Kurnia, S.; Jurburg, D. Integration of Industry 4.0 Technologies into Total Productive Maintenance Practices. Int. J. Prod. Econ. 2021, 240, 108224.

- Jusoh, M.S.; Ahmad, S.R.; Yusuf, D.H.M.; Salleh, S.S.M.M.; Din, M.S.H. Productivity Improvement in Food Manufacturing Company: Process Innovation Using Total Productive Maintenance. In Proceedings of the AIP Conference Proceedings, Langkawi, Malaysia, 26–27 November 2020; American Institute of Physics Inc.: College Park, MD, USA, 2021; Volume 2347.

- Pai, M.P.; Ramachandra, C.G.; Srinivas, T.R.; Raghavendra, M.J. Factors Influencing the Non-Implementation of TPM in the Selected Manufacturing Industries: A Statistical Approach. In Lecture Notes in Mechanical Engineering, Proceedings of the ICOFTIME 2020, Bengaluru, India, 24–25 April 2020; Springer: Singapore, 2021; pp. 153–166.

- Adithya, S.; Anantharaj, T. Enhancement of Overall Equipment Effectiveness in Automotive Parts Manufacturing Industry. Int. J. Mech. Eng. 2021, 6, 306–310.

- Logesh, B.; Balaji, M. Experimental Investigations to Deploy Green Manufacturing through Reduction of Waste Using Lean Tools in Electrical Components Manufacturing Company. Int. J. Precis. Eng. Manuf. Green Technol. 2020, 8, 365–374.

- Silva, S.; Sá, J.C.; Silva, F.J.G.; Ferreira, L.P.; Santos, G. Lean Green—The Importance of Integrating Environment into Lean Philosophy—A Case Study. In Lecture Notes in Networks and Systems, Proceedings of the 6th European Lean Educator Conference, Milan, Italy, 11–13 November 2019; Springer: Cham, Switzerland, 2020; pp. 211–219.

- Correia Pinto, G.F.; José Gomes da Silva, F.; Octávio Garcia Fernandes, N.; Carla Barros Casais, R.; Baptista da Silva, A.; Jorge Vale Carvalh, C. Implementing a Maintenance Strategic Plan Using TPM Methodology. Int. J. Ind. Eng. Manag. 2020, 11, 192–204.

- Pinto, G.; Silva, F.J.G.; Baptista, A.; Fernandes, N.O.; Casais, R.; Carvalho, C. TPM Implementation and Maintenance Strategic Plan—A Case Study. Procedia Manuf. 2020, 51, 1423–1430.

- Martins, L.; Silva, F.J.G.; Pimentel, C.; Casais, R.B.; Campilho, R.D.S.G. Improving Preventive Maintenance Management in an Energy Solutions Company. Procedia Manuf. 2021, 51, 1551–1558.

- Kumar Sharma, A.; Joshi, A.; Jurwall, V. Performance Measurement Metrics in TPM: A Contextual View to Training and Development. Mater. Today Proc. 2020, 28, 2476–2480.

- Manihalla, P.P.; Gopal, R.C.; Rao, S.T.R.; Jayaprakash, R. A Survey Approach to Study the Influence of Management Factor in Implementing TPM in Selected SMEs. In Proceedings of the AIP Conference Proceedings, Mangaluru, India, 9–10 August 2019; p. 050001.

- Leksic, I.; Stefanic, N.; Veza, I. The Impact of Using Different Lean Manufacturing Tools on Waste Reduction. Adv. Prod. Eng. Manag. 2020, 15, 81–92.

- Franciosi, C.; Iung, B.; Miranda, S.; Riemma, S. Maintenance for Sustainability in the Industry 4.0 Context: A Scoping Literature Review. IFAC-PapersOnLine 2018, 51, 903–908.

- Afrinaldi, F.; Taufik; Tasman, A.M.; Zhang, H.-C.; Hasan, A. Minimizing Economic and Environmental Impacts through an Optimal Preventive Replacement Schedule: Model and Application. J. Clean. Prod. 2017, 143, 882–893.

More

Information

Subjects:

Engineering, Manufacturing

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.4K

Revisions:

3 times

(View History)

Update Date:

18 Sep 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No