Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Alexander Kaulen | -- | 2555 | 2023-09-09 08:01:37 | | | |

| 2 | Rita Xu | Meta information modification | 2555 | 2023-09-11 03:20:40 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Kaulen, A.; Stopfer, L.; Lippert, K.; Purfürst, T. Tracing the Timber Supply Chain. Encyclopedia. Available online: https://encyclopedia.pub/entry/48988 (accessed on 01 March 2026).

Kaulen A, Stopfer L, Lippert K, Purfürst T. Tracing the Timber Supply Chain. Encyclopedia. Available at: https://encyclopedia.pub/entry/48988. Accessed March 01, 2026.

Kaulen, Alexander, Lukas Stopfer, Kai Lippert, Thomas Purfürst. "Tracing the Timber Supply Chain" Encyclopedia, https://encyclopedia.pub/entry/48988 (accessed March 01, 2026).

Kaulen, A., Stopfer, L., Lippert, K., & Purfürst, T. (2023, September 09). Tracing the Timber Supply Chain. In Encyclopedia. https://encyclopedia.pub/entry/48988

Kaulen, Alexander, et al. "Tracing the Timber Supply Chain." Encyclopedia. Web. 09 September, 2023.

Copy Citation

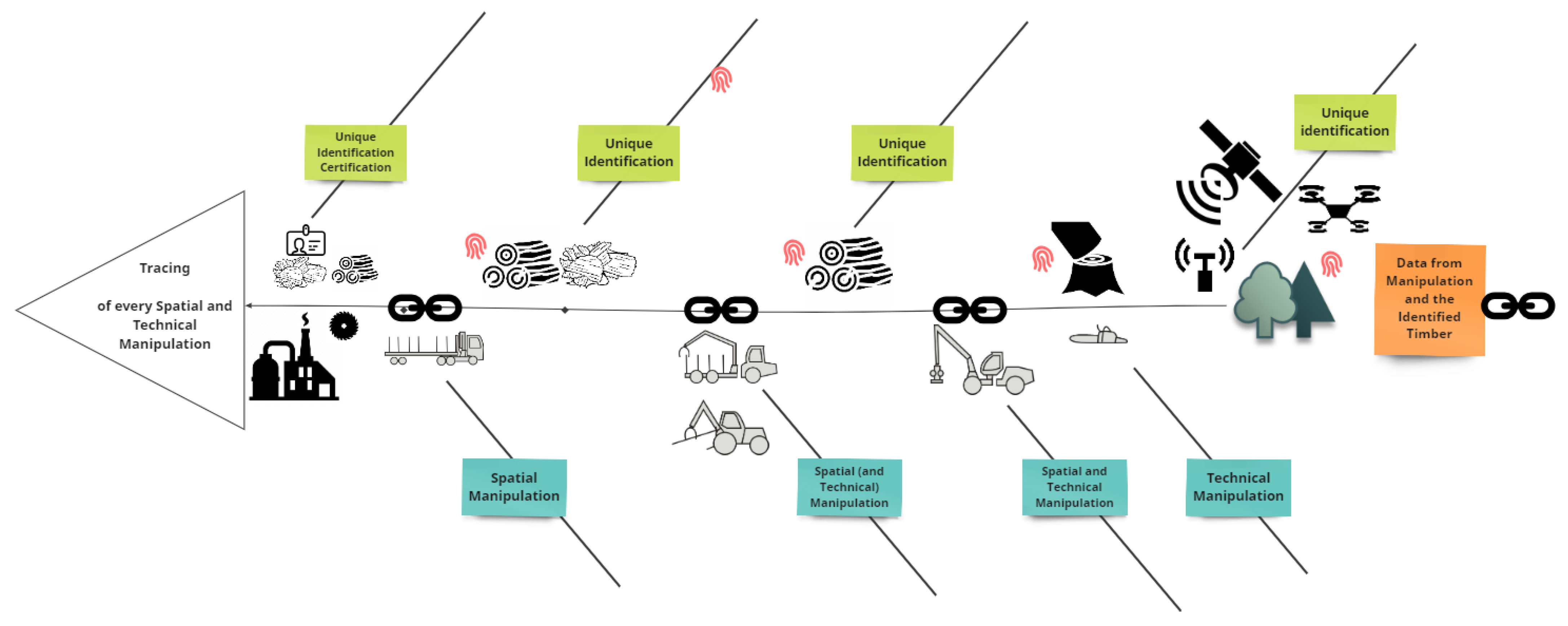

Traceability is the ability to follow the processes that a raw material or product goes through. For forestry, this means identifying the wood from the standing tree to the mill entrance and recording all information about the technical (production) and spatial (transportation) manipulation of the timber by linking it to the ID.

timber supply chain

traceability

timber identification

1. Introduction

Given the positive connotation of wood and wood-related products in society, forestry is gaining interest worldwide. Customer demand for sustainable products drives supply-chain tracing [1]. In forestry, the main driver is illegal logging and deforestation. In Europe, the European Timber Regulation (EUTR) and customer demand for sustainably harvested timber are prompting systems to trace timber flows [2]. Manual and paper-based systems, like branding, plastic tags, forest paint and certificates of origin from the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification Schemes (PEFC) still dominate the market [3][4][5]. With advances in digital technology and higher demands on supply-chain management, automated and digitalised systems are gaining importance [6].

The origin of wood as a raw material will become increasingly important in the near future. The political demands on the forests and the raw materials it provides are contradictory. On the one hand, society’s desire for more nature conservation and recreation increases in popularity, spawning demands for decommissioning. On the other hand, growing demands for raw materials conspire with requirements for wood products as CO2 sinks and substitutes for non-renewable substances to incentivize increased forestry productivity [7]. Digital technology, such as current traceability and data processing techniques, can balance sustainability and increased production by managing forests and downstream wood logistics more efficiently, thus ensuring climate-friendly extraction of wood products [8]. Consumers have more power over how products are produced than ever before. Climate-friendly, low-emission and socially sustainable products or raw materials can be marketed through meaningful brands and create so-called intangible capital through credibility, trust and relevance [9]. Especially since the Kyoto Protocol in 1997, public awareness of the sequestration potential in the Western world has been steadily increasing [10]. In addition to the presumed benefits for the environment, social as well as economic impacts are to be expected.

The newspaper The Guardian accuses the current certifications of inaccuracies. FSC and PEFC can only guarantee compliance with their guidelines in the forest. With media discontinuity along the forestry–timber chain, there are security gaps that need to be contained through the use of new technologies [11]. Technical solutions are needed to collect the data required to close these gaps.

Traceability of timber flows through the value chain means creating a link between the raw material and a system like Distributed Ledger Technology (DLT) or an Internet-of-Things (IOT) architecture that holds information about the raw material and the processes it undergoes.

Tracing timber can add value to the product by setting up an information system to detect and locate legal timber and timber products. “Traceability” means the ability to trace any product through all stages of production, processing and distribution [2][12][13]. In essence, a wood flow traceability system enables tracing the raw material one or more steps forward and back at any point in the value chain [14]. Tracing mechanisms are complex due to the composition of individual timber products and timber shipments, which contain a wide range of logs and processed products with different species and sizes. In addition to the traditional methods of stamping and varnishing logs, there are various digital information systems for identifying, tracing and monitoring logs. Automatic identification systems, such as barcodes, QR codes, RFID and microchips, and smart chips, which differ in their practicality and reliability, establish a link between the product, the product database and its process [4][15][16]. Innovative log tracing mechanisms such as DNA fingerprinting are usually very costly and difficult to apply [17]. Older and widely used methods such as colour marking, punching and barcoding still exist and are used effectively in the timber supply chain. Greater efforts towards international cooperation in sharing timber data as part of a global timber traceability information system with unique standards and features promise sustainable supply chains [4][18].

2. Limitations of Consideration

Timber provision includes felling planning and felling preparation, timber harvesting, timber sales and logistics. These are the limits of the technical and spatial framework to be considered. Silvicultural measures prior to wood supply and raw wood processing in the mill are not considered. In the following, researchers describe a generic wood supply chain for the German-speaking region. Processes vary in detail between regions because of cultural and regulatory differences resulting from the federally organized forest administrations [19]. An important prerequisite is the definition of the boundaries of consideration. The functional unit is the solid cubic metre of wood with bark (m3 over bark) or the batch, which is the selling unit [10][20][21]. The allocation of the functional units to the processes in the supply chain is crucial.

2.1. Tracking and Tracing

The spatial and technical manipulation of raw timber can be traced both to the customer and to the supplier of the timber. If it is the former—the tracking of the timber to the customer (downstream)—it is tracking. If it is the latter—the tracing of the supplier (upstream)—it is tracing [22][23].

2.2. Planning and Preparation of Felling

On the basis of the annual and natural planning of the forest enterprise, the district manager decides on the cutting sequence, which organises the stand treatment in terms of time and space. The forest manager determines the silvicultural procedure and whether the block formation of several contiguous stands appears to be sensible. Not only annual planning or silvicultural principles play a role, but also the current timber market situation. The forest manager must account for any contractually agreed provision of specific assortments. The marking process and the data collected on felling volume, qualities and assortments already provide important information for timber sales. The work plan contains the forestry operations, the number of forest workers and machines as well as important harvesting information.

2.3. Timber Harvesting

Prior to timber harvesting, the forestry enterprise instructs forest workers and machine operators by discussing the work order on site. During the felling, they control workers or are available as contact persons in case of issues. After the timber has been moved to the forest road, the district manager or a forest technician usually records the quantity and assortments of timber with a data recording device. Recording techniques should coincide with those used by the harvester, which serve as control for comparison with the dimensions recorded by the mill. All data flow into the timber list. The timber list contains pile-related timber data and is usually processed with the GPS/GNSS coordinates of the piles into a batch map, which is sent to the timber sales department in the forest enterprise. The batch maps are sent to the customer after the conclusion of a sales contract. In the case of an agreement for free mill delivery, it is sent directly to the timber customer; in the case of an agreement for free forest delivery, it is given to the haulage company.

2.4. Timber Sales

The timber data in the form of the timber lists are fractured into timber lots by telephone/written form, which concludes the negotiations. If contracts have not already been concluded, such as for long-term purchase of the timber, the contract is now concluded between the sales manager and the timber customer. The latter finally controls the settlement of the invoice. An important step is the timber data reconciliation between the logistic and control measurements taken by the forestry company and the sales measurement, which is usually the factory measurement. The forestry operation compares the measurement records. Discrepancies in quantity and assortment are investigated.

2.5. Timber Logistics

Free forest delivery is currently the most common method. In the “free forest method”, the timber customer commissions a haulage company to transport the timber to the mill. The “free forest method” means that the hauling company or mill takes over the organisation of the timber logistics. From the forestry enterprise’s point of view, the work steps are to instruct the driver, if necessary, and removal control.

All processes are depicted here in a highly simplified way and represent the limits of the object of consideration. All processes are meticulously documented, which may facilitate further technical innovations. Harvest planning, marking, harvest control, timber intake and timber transfer consume the majority of the time. These processes hold the greatest potential for optimisation (cf. on this section: [19][24][25]).

2.6. Functional Unit “Raw Wood”

In order to provide producers and consumers with relevant information, researchers need to trace the path of the wood from its place of extraction to the mill accurately and free of media breaks. In particular, the origin of the raw material wood and its sustainable and environmentally friendly production and extraction are of special interest to the buyer and customer [20]. Traceability systems (TSs) refer to the recording, storage and transmission of production routes and their underlying data. TSs consist of unique and unambiguously traceable units (TRU). These are clearly identifiable and are occupied with information [12][26]. In the case of the raw wood considered here—the individual log—the volume aggregation (for woodchips) or the pile is the TRU. The information can be quality, strength class, length, carbon storage, harvesting method, coordinates or any other attributes that arise during the manipulation of the wood [27]. Traceability requires a unique ID of the TRU, a data standard for the attached information and a database framework. The latter can be paper-based or electronic, with all information stored on the product ID [20][21]. Probably the best-known paper-based transfer of data along the value chain is certification according to PEFC or FSC. In this simple method, each company passes the certification of the manipulated product on to the next business partner (PEFC/04-01-01 and FSC-STD-40-004) [28]. While the origin of the wood and the presence of a certificate can easily be passed through the chain, the mapping of all relevant wood data is more complex. Here, every spatial and technical manipulation of the wood—be it the harvest itself, the transport, the debarking and/or the varnishing of the end product—is time-stamped so that the entire value chain of the raw wood can be traced at the factory entrance. Where and at what time data are generated during the manipulation of the wood is largely known. However, existing certificates do not adequately depict the traceability of individual processes in the value chain. In order to obtain this information for consumers and business partners, the following prerequisites must be met: (1) uniquely identifiable units (traceable units/TS); (2) hardware that identifies, recognises and assigns information to the units; (3) data transmission without media discontinuity; (4) secure and efficient systems for data storage and management; and (5) higher benefits than additional costs [12][29][30].

3. Forestry Technology and Traceability in Raw Wood Supply

The object of consideration is located in the field of forestry technology. Erler [31], following the definitions of the term "technology" by the Association of German Engineers, described forestry technology as material systems (artificially created entities) that are used for work in the forest, all facilities and actions in which the material systems are created, and all processes in which the material systems are used. Forestry technology thus includes not only the equipment used, but also the people and the effects of its use on people and the environment. The link between the environment, the people and the technology used is referred to as a process. This is distinct from the working method, which is defined from the perspective of the acting human being. Derived from the science of technology, two main functions of technology can be applied to the part of forestry technology discussed here: manufacturing and transport (Figure 1 and Figure 2). Production classically refers to joining and cutting. Relevant in this work is the cutting that takes place during felling, delimbing, ripping of the top, crosscutting and chipping. It is therefore a (forestry) technical manipulation of the functional unit of raw wood. Spatial manipulation takes place as part of the second main technical function: transport. Transport is the process of moving the functional unit—raw wood—from one place to another. In forestry, the transport of raw wood from the place of felling to the forest road is called “forwarding” if forwarders are used in the CTL system. “Primary transport” is a more general form, which refers to skidding, cable yarding and forwarding. Here, “primary transport” refers to the transport of the wood from the place of felling (and cutting to length, if done at the same place) to a defined place in the stand and to the transport of the timber from the skidding lane to the storage yard along a forest road that is accessible by truck. It is currently carried out exclusively using machines (and rarely by horses). At the storage yard, it is “piled”, i.e., stacked into “piles”, and separated according to assortment. This process is carried out as an integral part of the primary transport, both in terms of time and technology. Depending on the conditions, other technology may be used, e.g., excavators for clearing storm-drifts, skidders, or cable cranes up to helicopters, especially in the mountains.

Figure 1. In the process of timber supply, the timber goes through several processes. Researchers are talking here about spatial manipulation like transportation and technical manipulation like cutting, which the timber has to go through in order to be further processed in the mill. Here is an example of wood preparation in a highly mechanised timber harvesting system. The process starts with the standing tree, continues with the cutting of the timber in the stand and its advancement to the skid road by the harvester, advancement to the forest road and finally, hauling via truck.

Figure 2. In the highly mechanized timber harvesting process presented here as an exemplary case, the technical and spatial manipulation of the timber takes place in order to provide the raw material. During this manipulation, data are generated that contain information about the process but, above all, about the timber itself. In order to preserve this data for later use, they must be “stored” on the functional unit “timber”. This requires the identification of the timber at several points in the process: At the standing tree, during the assortment at the skid road, at the forest road and at the mill entrance. The data are therefore linked to the ID of the piece of wood.

At the timber storage site at the forest road, the presentation of the timber takes place in the course of the sale of timber. During the negotiations between the seller and the buyer, data are often changed (quality, dimensions, and sometimes also the tree species), and individual logs, log sections or piles may be re-sorted and may then have to be relocated. The relocated units are then either assigned to one or more existing lots/batches of the same forest owner or combined into one or more new lots/batches.

The “removal” of the raw wood from the forest to the mill or to another processor requires loading onto a truck. For longer distances, in addition, rail, barge and possibly ocean-going vessels are used [24][31].

The number and extent of manipulations not only generate data but also represent a potential source of error. This requires mechanisms to check and, if necessary, correct the data. In addition, they require dedicated regulations regarding authorizations and data security.

References

- Miller, T.P. Integrating Blockchain Technology within the Lowe’s Company Inc. to Enhance Traceability and Verify Wood Certification Along the Supply Chain. Ph.D. Thesis, College of Charleston, Charleston, SC, USA, 2020.

- Laporte, J.; Vandenhaute, M. Traceability: A management tool for business and governments. In FAO FLEFGT Programme. Technical Paper (FAO) eng no. 1; FAO: Rome, Italy, 2016.

- Dormontt, E.E.; Boner, M.; Braun, B.; Breulmann, G.; Degen, B.; Espinoza, E.; Gardner, S.; Guillery, P.; Hermanson, J.C.; Koch, G.; et al. Forensic Timber Identification: It’s Time to Integrate Disciplines to Combat Illegal Logging. Biol. Conserv. 2015, 191, 790–798.

- Fabing, M. Wood Identification Systems. Wtp-Proj Blog. 2021. Available online: https://wtp-project.com/blog/wood-identification-systems (accessed on 15 March 2022).

- Van der Ven, H.; Cashore, B. Forest certification: The challenge of measuring impacts. Curr. Opin. Environ. Sustain. 2018, 32, 104–111.

- Grant, J.; Freitas, B.; Wilson, T. Traceability Systems: Potential Tools to Deter Illegality and Corruption in the Timber and Fish Sectors? 2021. Available online: https://biodiversitylinks.org/projects/completed-projects/bridge/current-global-projects/tnrc/resources/topic-brief-traceability-systems-potential-tools-to-deter-illegality-and-corruption-in-the-timber-and-fish-sectors.pdf (accessed on 20 April 2022).

- Schier, F.; Iost, S.; Seintsch, B.; Weimar, H.; Dieter, M. Assessment of Possible Production Leakage from Implementing the EU Biodiversity Strategy on Forest Product Markets. Forests 2022, 13, 1225.

- Creutzburg, L.; Lieberherr, E. To Log or Not to Log? Actor Preferences and Networks in Swiss Forest Policy. For. Policy Econ. 2021, 125, 102395.

- Rehm, G.; Hildebrandt, A. Nachaltigkeit Braucht Markenkraft; Springer: Berlin/Heidelberg, Germany, 2020.

- Klein, D.; Wolf, C.; Schulz, C.; Weber-Blaschke, G. 20 Years of Life Cycle Assessment (LCA) in the Forestry Sector: State of the Art and a Methodical Proposal for the LCA of Forest Production. Int. J. Life Cycle Assess. 2015, 20, 556–575.

- The Guardian. Tracking Timber: Could New Technology Help Clean Up the Supply Chain? The Guardian, 14 August 2013. Available online: https://www.theguardian.com/sustainable-business/tracking-timber-new-technology-supply-chain(accessed on 10 March 2022).

- Olsen, P.; Borit, M. The components of a food traceability system. Trends Food Sci. Technol. 2018, 77, 143–149.

- Godbout, J.; Bomal, C.; Farr, K.; Williamson, M.; Isabel, N. Genomic Tools for Traceability: Opportunities, Challenges and Perspectives for the Canadian Forestry Sector. For. Chron. 2018, 94, 75–87.

- Figorilli, S.; Antonucci, F.; Costa, C.; Pallottino, F.; Raso, L.; Castiglione, M.; Pinci, E.; Del Vecchio, D.; Colle, G.; Proto, A.; et al. A Blockchain Implementation Prototype for the Electronic Open Source Traceability of Wood along the Whole Supply Chain. Sensors 2018, 18, 3133.

- Dykstra, D.P.; Kuru, G.; Taylor, R.; Nussbaum, R.; Magrath, W.B.; Story, J. Technologies for Wood Tracking: Verifying and Monitoring the Chain of Custody and Legal Compliance in the Timber Industry; World Bank: Washington, DC, USA, 2002.

- Fabing, M. QR Codes for Wood Identification. Wtp-Proj Blog. 2021. Available online: https://llanthu.com/blog/the-use-of-qr-codes-for-wood-identification.php (accessed on 19 August 2022).

- Schmitz, N.; Boner, M.; Cervera, M.; Chavesta, M.; Cronn, R.; Degen, B.; Deklerck, V.; Diaz-Sala, C.; Dormontt, E.; Ekué, M.; et al. General Sampling Guide for Timber Tracking; Global Timber Tracking Network, GTTN Secretariat, European Forest Institute and Thuenen Institute: Bonn, Germany, 2019; 46p.

- Keefe, R.F.; Zimbelman, E.G.; Picchi, G. Use of Individual Tree and Product Level Data to Improve Operational Forestry. Curr. For. Rep. 2022, 8, 148–165.

- Baumann, T. Analyse Logistischer Prozesse Und Deren Optimierungspotentiale Entlang Der Holzbereitstellungskette vom Wald zum Werk Unterstützt durch Spezielle Verfahren der Prozessmodellierung: Durchgeführt am Beispiel Verschiedener Forst-und Holzbetriebe in der Region Ostalb (Baden-Württemberg). Ph.D. Thesis, Albert-Ludwigs University, Freiburg, Germany, 2008.

- Appelhanz, S.; Osburg, V.S.; Toporowski, W.; Schumann, M. Traceability System for Capturing, Processing and Providing Consumer-Relevant Information about Wood Products: System Solution and Its Economic Feasibility. J. Clean. Prod. 2015, 110, 132–148.

- Lauri, L.; Roope, H.; Atsushi, T.; Tuovi, V.; Olli, D. Environmental product declaration of timber products: The impact of allocation method to the impact categories. J. Clean. Prod. 2020, 256, 120386.

- Eberhardt, J.; Tai, S. On or off the blockchain? Insights on off-chaining computation and data. In Service-Oriented and Cloud Computing, Proceedings of the 6th IFIP WG 2.14 European Conference, ESOCC 2017, Oslo, Norway, 27–29 September 2017, Proceedings 6; Springer: Berlin/Heidelberg, Germany, 2017; pp. 3–15.

- Dabbene, F.; Gay, P.; Tortia, C. Traceability issues in food supply chain management: A review. Biosyst. Eng. 2014, 120, 65–80.

- Erler, J.; Knobloch, C.; Faber, R.; Grüll, M.; Nimz, R. Forsttechnische Grundlagen, 10th ed.; Technikmanagement in der Forstwirtschaft; Ulmer: Baden-Wuerttemberg, Germany, 2020.

- Sohns, D.I.H. Moderne Holzernte; Ulmer: Baden-Wuerttemberg, Germany, 2012.

- Islam, S.; Cullen, J.M. Food traceability: A generic theoretical framework. Food Control 2021, 123, 107848.

- Zhang, X.; Zhang, W.; Xu, D. Life Cycle Assessment of Complex Forestry Enterprise: A Case Study of a Forest–Fiberboard Integrated Enterprise. Sustainability 2020, 12, 4147.

- PEFC Italy. Wood-Chain: The Technology for Strengthening Traceability and PEFC Certification; PEFC: Perugia, Italy, 2019.

- Appelhanz, S. Tracking&Tracing-systems in the Wood Supply Chain: Opportunities and Challenges. In Proceedings of the Nineteenth Americas Conference on Information Systems, Chicago, IL, USA, 15–17 August 2013; Volume 19, pp. 1–11.

- Mukkavaara, J.; Sandberg, M.; Sandberg, K.; Pousette, A.; Norén, J. Sustainability evaluation of timber dwellings in the north of Sweden based on environmental impact and optimization of energy and cost. Procedia Manuf. 2020, 44, 76–83.

- Erler, J. Forsttechnik: Verfahrensbewertung; Ulmer: Baden-Wuerttemberg, Germany, 2000.

More

Information

Subjects:

Forestry

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.2K

Revisions:

2 times

(View History)

Update Date:

11 Sep 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No