| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Hongxing Dai | -- | 4797 | 2023-09-07 13:01:53 | | | |

| 2 | Peter Tang | -1 word(s) | 4796 | 2023-09-08 04:28:29 | | |

Video Upload Options

The emission of methane leads to the increase in the methane concentration in the atmosphere, which not only wastes resources but also intensifies the greenhouse effect and brings about serious environmental problems. Catalytic combustion can completely convert methane into carbon dioxide and water at low temperatures. However, the catalytic activities of the conventional supported palladium catalysts (e.g., Pd/Al2O3 and Pd/ZrO2) are easy to decrease or the two catalysts can even be deactivated under actual harsh reaction conditions (high temperatures, steam- and sulfur dioxide-containing atmospheres, etc.). Noble metal catalysts supported on zeolites with ordered pores and good thermal stability have attracted much attention.

1. Introduction

|

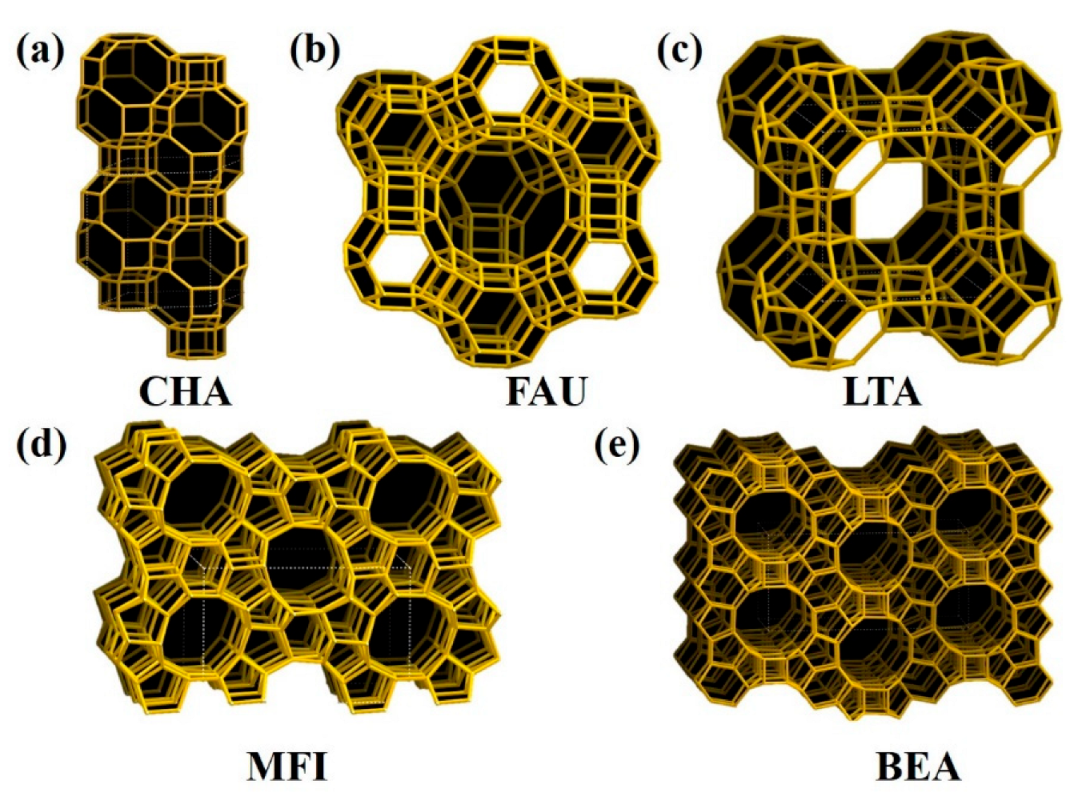

Framework Type |

Material Name |

Dimensionality |

Ring Type (Pore Type) |

Limiting Pore Size (nm) |

|---|---|---|---|---|

|

CHA |

SSZ-13 |

3D |

8/6/4 (micropore) |

0.38 × 0.38 |

|

LTA |

LTA |

3D |

8/6/4 (micropore) |

0.41 × 0.41 |

|

MFI |

ZSM-5 |

3D |

10/6/5/4 (micropore) |

0.53 × 0.56 |

|

BEA |

Beta |

3D |

12/6/5/4 (micropore) |

0.66 × 0.67 |

|

FAU |

X, Y |

3D |

12/6/4 (micropore) |

0.33 × 0.33 |

|

SBA-15 |

- |

1D |

-/-/- (mesopore) |

4.6–10.0 [42] |

|

MCM-41 |

- |

1D |

-/-/- (mesopore) |

10.0 [43] |

|

KIT-6 |

- |

3D |

-/-/- (mesopore) |

4.0–12.0 [44] |

Note: The information for the microporous zeolites is obtained from the “Database of zeolite structures” by the Structure Commission of the International Zeolite Association (IZA-SC), whereas the information for the mesoporous zeolites is cited from the references as noted.

2. Small-Pore Zeolites with 8 Member Rings

3. Medium-Pore Zeolites with 10 Member Rings

4. Large-Pore Zeolites with 12 Member Rings

5. Mesoporous Zeolite and Mesoporous Silicas Catalysts

6. Other Noble Metal-Based Zeolite Catalysts

References

- Ai, X.Y.; Hu, C.; Yang, Y.R.; Zhang, L.Y.; Liu, H.L.; Zhang, J.Q.; Chen, X.; Bai, G.Q.; Xiao, W. Quantification of Central and Eastern China’s atmospheric CH4 enhancement changes and its contributions based on machine learning approach. J. Environ. Sci. 2023, 138, 236–248.

- Francoeur, C.B.; McDonald, B.C.; Gilman, J.B.; Zarzana, K.J.; Dix, B.; Brown, S.S.; de Gouw, J.A.; Frost, G.J.; Li, M.; McKeen, S.A.; et al. Quantifying methane and ozone precursor emissions from oil and gas production regions across the contiguous US. Environ. Sci. Technol. 2021, 55, 9129–9139.

- Feng, X.B.; Jiang, L.; Li, D.Y.; Tian, S.P.; Zhu, X.; Wang, H.; He, C.; Li, K.Z. Progress and key challenges in catalytic combustion of lean methane. J. Energy Chem. 2022, 75, 173–215.

- Zhang, Y.Z.; Fang, S.X.; Chen, J.M.; Lin, Y.; Chen, Y.Y.; Liang, R.S.; Jiang, K.; Parker, R.J.; Boesch, H.; Steinbacher, M.; et al. Observed changes in China’s methane emissions linked to policy drivers. Proc. Natl. Acad. Sci. USA 2022, 119, e2202742119.

- He, L.; Fan, Y.L.; Bellettre, J.; Yue, J.; Luo, L.G. A review on catalytic methane combustion at low temperatures: Catalysts, mechanisms, reaction conditions and reactor designs. Renew. Sustain. Energy Rev. 2020, 119, 109589.

- Farrauto, R.J. Low-temperature oxidation of methane. Science 2012, 337, 659–660.

- Chen, J.H.; Arandiyan, H.; Gao, X.; Li, J.H. Recent advances in catalysts for methane combustion. Catal. Surv. Asia 2015, 19, 140–171.

- Chen, J.J.; Zhong, J.W.; Wu, Y.; Hu, W.; Qu, P.F.; Xiao, X.; Zhang, G.C.; Liu, X.; Jiao, Y.; Zhong, L.; et al. Particle size effects in stoichiometric methane combustion: Structure-activity relationship of Pd catalyst supported on gamma-alumina. ACS Catal. 2020, 10, 10339–10349.

- Wang, Y.; Arandiyan, H.; Scott, J.; Akia, M.; Dai, H.X.; Deng, J.G.; Aguey-Zinsou, K.; Amal, R. High performance Au–Pd supported on 3D hybrid strontium-substituted lanthanum manganite perovskite catalyst for methane combustion. ACS Catal. 2016, 6, 6935–6947.

- Xiong, H.F.; Kunwar, D.; Jiang, D.; García-Vargas, C.E.; Li, H.; Du, C.; Canning, G.; Pereira-Hernandez, X.I.; Wan, Q.; Lin, S.; et al. Engineering catalyst supports to stabilize PdOx two-dimensional rafts for water-tolerant methane oxidation. Nat. Catal. 2021, 4, 830–839.

- Xu, P.; Zhang, X.; Zhao, X.T.; Yang, J.; Hou, Z.Q.; Bai, L.; Chang, H.Q.; Liu, Y.X.; Deng, J.G.; Guo, G.S.; et al. Preparation, characterization, and catalytic performance of PdPt/3DOM LaMnAl11O19 for the combustion of methane. Appl. Catal. A 2018, 562, 284–293.

- Yang, J.; Hu, S.Y.; Shi, L.M.; Hoang, S.; Yang, W.W.; Fang, Y.R.; Liang, Z.F.; Pan, C.Q.; Zhu, Y.H.; Li, L.; et al. Oxygen vacancies and Lewis acid sites synergistically promoted catalytic methane combustion over perovskite oxides. Environ. Sci. Technol. 2021, 55, 9243–9254.

- Zhao, X.T.; Zhang, R.; Liu, Y.X.; Deng, J.G.; Xu, P.; Yang, J.; Han, Z.; Hou, Z.Q.; Dai, H.X.; Au, C.T. In-situ reduction-derived Pd/3DOM La0.6Sr0.4MnO3: Good catalytic stability in methane combustion. Appl. Catal. A 2018, 568, 202–212.

- Gélin, P.; Primet, M. Complete oxidation of methane at low temperature over noble metal based catalysts: A review. Appl. Catal. B 2002, 39, 1–37.

- Park, J.; Ahn, J.; Sim, H.; Seo, G.; Han, H.S.; Shin, C. Low-temperature combustion of methane using PdO/Al2O3 catalyst: Influence of crystalline phase of Al2O3 support. Catal. Commun. 2014, 56, 157–163.

- Beck, I.E.; Bukhtiyarov, V.I.; Pakharukov, I.Y.; Zaikovsky, V.I.; Kriventsov, V.V.; Parmon, V.N. Platinum nanoparticles on Al2O3: Correlation between the particle size and activity in total methane oxidation. J. Catal. 2009, 268, 60–67.

- Shi, W.; Xu, G.Y.; Han, X.W.; Wang, Y.J.; Liu, Z.; Xue, S.; Sun, N.N.; Shi, X.Y.; Yu, Y.B.; He, H. Nano-sized alumina supported palladium catalysts for methane combustion with excellent thermal stability. J. Environ. Sci. 2023, 126, 333–347.

- Hou, Z.Q.; Dai, L.Y.; Deng, J.G.; Zhao, G.F.; Jing, L.; Wang, Y.; Yu, X.H.; Gao, R.Y.; Tian, X.R.; Dai, H.X.; et al. Electronically engineering water resistance in methane combustion with an atomically dispersed tungsten on PdO catalyst. Angew. Chem. Int. Ed. 2022, 61, e202201655.

- Hou, Z.Q.; Liu, Y.X.; Deng, J.G.; Lu, Y.; Xie, S.H.; Fang, X.; Dai, H.X. Highly active and stable Pd–GaOx/Al2O3 catalysts derived from intermetallic Pd5Ga3 nanocrystals for methane combustion. ChemCatChem 2018, 10, 5637–5648.

- Liu, Z.; Xu, G.Y.; Zeng, L.Y.; Shi, W.; Wang, Y.J.; Sun, Y.W.; Yu, Y.B.; He, H. Anchoring Pt-doped PdO nanoparticles on γ-Al2O3 with highly dispersed La sites to create a methane oxidation catalyst. Appl. Catal. B 2023, 324, 122259.

- Ma, X.Y.; Xu, H.; Liu, Z.; Liu, Y.F.; Wang, C.; Shen, M.Q.; Du, C.; Shan, B. Durable PdNi/Al2O3 catalysts with PdO–NiO and PdO–NiAl2O4 dual interfaces for methane combustion. ACS ES&T Eng. 2023, 3, 349–359.

- Poznyak, A.A.; Knörnschild, G.H.; Pligovka, A.N.; Larin, T.D. Anodic alumina prepared in aqueous solutions of chelating complex zinc and cobalt compounds. Tech. Phys. 2022, 67, 411–422.

- Poznyak, A.; Knörnschild, G.; Karoza, A.; Norek, M.; Pligovka, A. Peculiar porous aluminum oxide films produced via electrochemical anodizing in malonic acid solution with arsenazo-I additive. Materials 2021, 14, 5118.

- Chen, S.Y.; Li, S.D.; You, R.Y.; Guo, Z.Y.; Wang, F.; Li, G.X.; Yuan, W.T.; Zhu, B.; Gao, Y.; Zhang, Z.; et al. Elucidation of active sites for CH4 catalytic oxidation over Pd/CeO2 via tailoring metal-support interactions. ACS Catal. 2021, 11, 5666–5677.

- Colussi, S.; Gayen, A.; Farnesi Camellone, M.; Boaro, M.; Llorca, J.; Fabris, S.; Trovarelli, A. Nanofaceted Pd-O sites in Pd-Ce surface superstructures: Enhanced activity in catalytic combustion of methane. Angew. Chem. Int. Ed. 2009, 48, 8481–8484.

- Xie, S.H.; Liu, Y.X.; Deng, J.G.; Zhao, X.; Yang, J.; Zhang, K.F.; Han, Z.; Dai, H.X. Three-dimensionally ordered macroporous CeO2-supported Pd@Co nanoparticles: Highly active catalysts for methane oxidation. J. Catal. 2016, 342, 17–26.

- Yang, W.W.; Polo-Garzon, F.; Zhou, H.; Huang, Z.N.; Chi, M.F.; Meyer, H., III; Yu, X.B.; Li, Y.Y.; Wu, Z.L. Boosting the activity of Pd single atoms by tuning their local environment on ceria for methane combustion. Angew. Chem. Int. Ed. 2023, 62, e202217323.

- Ding, Y.Q.; Jia, Y.Y.; Jiang, M.X.; Guo, Y.; Guo, Y.; Wang, L.; Ke, Q.P.; Ngoc Ha, M.; Dai, S.; Zhan, W.C. Superior catalytic activity of Pd-based catalysts upon tuning the structure of the ceria-zirconia support for methane combustion. Chem. Eng. J. 2021, 416, 129150.

- Ding, Y.Q.; Wu, Q.Q.; Lin, B.; Guo, Y.L.; Guo, Y.; Wang, Y.S.; Wang, L.; Zhan, W.C. Superior catalytic activity of a Pd catalyst in methane combustion by fine-tuning the phase of ceria-zirconia support. Appl. Catal. B 2020, 266, 118631.

- 2Yang, W.W.; Kim, M.Y.; Polo-Garzon, F.; Gong, J.; Jiang, X.; Huang, Z.N.; Chi, M.F.; Yu, X.B.; Wang, X.; Guo, Y.B.; et al. CH4 combustion over a commercial Pd/CeO2–ZrO2 three-way catalyst: Impact of thermal aging and sulfur exposure. Chem. Eng. J. 2023, 451, 138930.

- Huang, J.L.; Lin, J.; Chen, X.H.; Zheng, Y.; Xiao, Y.H.; Zheng, Y. Optimizing the microstructure of SnO2–CeO2 binary oxide supported palladium catalysts for efficient and stable methane combustion. ACS Appl. Mater. Interfaces 2022, 14, 16233–16244.

- Takeguchi, T.; Takeoh, O.; Aoyama, S.; Ueda, J.; Kikuchi, R.; Eguchi, K. Strong chemical interaction between PdO and SnO2 and the influence on catalytic combustion of methane. Appl. Catal. A 2003, 252, 205–214.

- Wang, Y.; Liu, C.W.; Liao, X.M.; Liu, Y.M.; Hou, J.D.; Pham-Huu, C. Enhancing oxygen activation on high surface area Pd–SnO2 solid solution with isolated metal site catalysts for catalytic CH4 combustion. Appl. Surf. Sci. 2021, 564, 150368.

- Zhao, Z.Y.; Wang, B.W.; Ma, J.; Zhan, W.C.; Wang, L.; Guo, Y.L.; Guo, Y.; Lu, G.Z. Catalytic combustion of methane over Pd/SnO2 catalysts. Chin. J. Catal. 2017, 38, 1322–1329.

- Willis, J.J.; Gallo, A.; Sokaras, D.; Aljama, H.; Nowak, S.H.; Goodman, E.D.; Wu, L.; Tassone, C.J.; Jaramillo, T.F.; Abild-Pedersen, F.; et al. Systematic structure-property relationship studies in palladium-catalyzed methane complete combustion. ACS Catal. 2017, 7, 7810–7821.

- Garbowski, E.; Feumi-Jantou, C.; Mouaddib, N.; Primet, M. Catalytic combustion of methane over palladium supported on alumina catalysts: Evidence for reconstruction of particles. Appl. Catal. A 1994, 109, 277–291.

- Wang, Y.L.; Hu, P.; Yang, J.; Zhu, Y.A.; Chen, D. C–H bond activation in light alkanes: A theoretical perspective. Chem. Soc. Rev. 2021, 50, 4299–4358.

- Murata, K.; Mahara, Y.; Ohyama, J.; Yamamoto, Y.; Arai, S.; Satsuma, A. The metal–support -interaction concerning the particle size effect of Pd/Al2O3 on methane combustion. Angew. Chem. Int. Ed. 2017, 56, 15993–15997.

- Hong, E.; Kim, C.; Lim, D.; Cho, H.; Shin, C. Catalytic methane combustion over Pd/ZrO2 catalysts: Effects of crystalline structure and textural properties. Appl. Catal. B 2018, 232, 544–552.

- Schwartz, W.R.; Ciuparu, D.; Pfefferle, L.D. Combustion of methane over palladium-based catalysts: Catalytic deactivation and role of the support. J. Phys. Chem. C 2012, 116, 8587–8593.

- Smit, B. Molecular simulations of zeolites: Adsorption, diffusion, and shape selectivity. Chem. Rev. 2008, 108, 4125–4184.

- Zhao, D.Y.; Feng, J.L.; Huo, Q.S.; Melosh, N.; Fredrickson, G.H.; Chmelka, B.F.; Stucky, G.D. Triblock copolymer syntheses of mesoporous silica with periodic 50 to 300 angstrom pores. Science 1998, 279, 548–552.

- Kresge, A.C.; Leonowicz, M.E.; Roth, W.J.; Vartuli, J.C.; Beck, J.S. Ordered mesoporous molecular sieves synthesized by a liquid-crystal template mechanism. Nature 1992, 359, 710–712.

- Kleitz, F.; Hei Choi, S.; Ryoo, R. Cubic Ia3d large mesoporous silica: Synthesis and replication to platinum nanowires, carbon nanorods and carbon nanotubes. Chem. Commun. 2003, 2136–2137.

- Cui, Y.R.; Chen, J.Z.; Peng, B.; Kovarik, L.; Devaraj, A.; Li, Z.; Ma, T.; Wang, Y.L.; Szanyi, J.; Miller, J.T.; et al. Onset of high methane combustion rates over supported palladium catalysts: From isolated Pd cations to PdO nanoparticles. JACS Au 2021, 1, 396–408.

- Friberg, I.; Clark, A.H.; Ho, P.H.; Sadokhina, N.; Smales, G.J.; Woo, J.; Auvray, X.; Ferri, D.; Nachtegaal, M.; Kröcher, O.; et al. Structure and performance of zeolite supported Pd for complete methane oxidation. Catal. Today 2021, 382, 3–12.

- Leistner, K.; Kumar, A.; Kamasamudram, K.; Olsson, L. Mechanistic study of hydrothermally aged Cu/SSZ-13 catalysts for ammonia-SCR. Catal. Today 2018, 307, 55–64.

- Friberg, I.; Wang, A.; Olsson, L. Hydrothermal aging of Pd/LTA monolithic catalyst for complete CH4 oxidation. Catalysts 2020, 10, 517.

- Argauer, R.J.; Landolt, G.R. Crystalline Zeolite ZSM-5 and Method of Preparing the Same. U.S. Patent 3702886DA, 14 November 1972.

- Li, Y.; Armor, J.N. Catalytic combustion of methane over palladium exchanged zeolites. Appl. Catal. B 1994, 3, 275–282.

- Liu, C.; Yu, K.; Zhang, Y.; Zhu, X.; He, F.; Eliasson, B. Remarkable improvement in the activity and stability of Pd/HZSM-5 catalyst for methane combustion. Catal. Commun. 2003, 4, 303–307.

- Hosseiniamoli, H.; Setiawan, A.; Adesina, A.A.; Kennedy, E.M.; Stockenhuber, M. The stability of Pd/TS-1 and Pd/silicalite-1 for catalytic oxidation of methane-understanding the role of titanium. Catal. Sci. Technol. 2020, 10, 1193–1204.

- Wang, W.Y.; Zhou, W.; Li, W.; Xiong, X.W.; Wang, Y.H.; Cheng, K.J.; Kang, J.; Zhang, Q.H.; Wang, Y. In-situ confinement of ultrasmall palladium nanoparticles in silicalite-1 for methane combustion with excellent activity and hydrothermal stability. Appl. Catal. B 2020, 276, 119142.

- Zhang, Z.S.; Sun, L.W.; Hu, X.F.; Zhang, Y.B.; Tian, H.Y.; Yang, X.G. Anti-sintering Pd@silicalite-1 for methane combustion: Effects of the moisture and SO2. Appl. Surf. Sci. 2019, 494, 1044–1054.

- Zhang, L.L.; Chen, J.F.; Guo, X.M.; Yin, S.M.; Zhang, M.; Rui, Z.B. Combination of reduction-deposition Pd loading and zeolite dealumination as an effective route for promoting methane combustion over Pd/Beta. Catal. Today 2021, 376, 119–125.

- Zhang, L.L.; Chen, J.F.; Yang, H.; Wang, X.; Rui, Z.B. In situ mercaptosilane-assisted confinement of Pd nanoparticles in Beta for high-efficient methane oxidation. Catal. Today 2022, 400, 124–131.

- Petrov, A.W.; Ferri, D.; Krumeich, F.; Nachtegaal, M.; van Bokhoven, J.A.; Kröcher, O. Stable complete methane oxidation over palladium based zeolite catalysts. Nat. Commun. 2018, 9, 2545.

- Zina, M.S.; Ghorbel, A. Preparation and characterization of bimetallic PdMo/Y-zeolite: Catalytic properties in methane combustion. Solid State Sci. 2004, 6, 973–980.

- Song, H.; Rioux, R.M.; Hoefelmeyer, J.D.; Komor, R.; Niesz, K.; Grass, M.; Yang, P.; Somorjai, G.A. Hydrothermal growth of mesoporous SBA-15 silica in the presence of PVP-stabilized Pt nanoparticles: Synthesis, characterization, and catalytic properties. J. Am. Chem. Soc. 2006, 128, 3027–3037.

- Hussain, M.; Deorsola, F.A.; Russo, N.; Fino, D.; Pirone, R. Abatement of CH4 emitted by CNG vehicles using Pd-SBA-15 and Pd-KIT-6 catalysts. Fuel 2015, 149, 2–7.

- Yuranov, I.; Moeckli, P.; Suvorova, E.; Buffat, P.; Kiwi-Minsker, L.; Renken, A. Pd/SiO2 catalysts: Synthesis of Pd nanoparticles with the controlled size in mesoporous silicas. J. Mol. Catal. A 2003, 192, 239–251.

- Murthy, P.R.; Zhang, J.; Li, W. Exceptionally stable sol-immobilization derived Pd/SBA-15 catalysts for methane combustion. Catal. Sci. Technol. 2021, 11, 3609–3618.

- Li, C.S.; Tang, B.Y.; Li, W.Z.; Lu, Q.; Yuan, L. Palladium nanoparticles encapsulated in surface-defected SBA-15 for lean methane oxidation. ACS Appl. Nano Mater. 2022, 5, 13055–13068.

- Zribi, S.; Albela, B.; Bonneviot, L.; Zina, M.S. Surface engineering and palladium dispersion in MCM-41 for methane oxidation. Appl. Catal. A 2015, 502, 195–203.

- Liotta, L.F.; Di Carlo, G.; Pantaleo, G.; Hernandez Garrido, J.C.; Venezia, A.M. Pd (1 wt%)/LaMn0.4Fe0.6O3 catalysts supported over silica SBA-15: Effect of perovskite loading and support morphology on methane oxidation activity and SO2 tolerance. Top. Catal. 2012, 55, 782–791.

- Yin, F.X.; Ji, S.F.; Wu, P.Y.; Zhao, F.Z.; Li, C.Y. Deactivation behavior of Pd-based SBA-15 mesoporous silica catalysts for the catalytic combustion of methane. J. Catal. 2008, 257, 108–116.

- Ruiz, J.A.; Fraga, M.A.; Pastore, H.O. Methane combustion over Pd supported on MCM-41. Appl. Catal. B 2007, 76, 115–122.

- Peng, H.G.; Dong, T.; Yang, S.; Chen, H.; Yang, Z.Z.; Liu, W.M.; He, C.; Wu, P.; Tian, J.; Peng, Y.; et al. Intra-crystalline mesoporous zeolite encapsulation-derived thermally robust metal nanocatalyst in deep oxidation of light alkanes. Nat. Commun. 2022, 13, 295.

- Zhang, Y.; Glarborg, P.; Andersson, M.P.; Johansen, K.; Torp, T.K.; Jensen, A.D.; Christensen, J.M. Sulfur poisoning and regeneration of Rh-ZSM-5 catalysts for total oxidation of methane. Appl. Catal. B 2020, 277, 119176.

- Zhang, Y.; Glarborg, P.; Johansen, K.; Andersson, M.P.; Torp, T.K.; Jensen, A.D.; Christensen, J.M. A rhodium-based methane oxidation catalyst with high tolerance to H2O and SO2. ACS Catal. 2020, 10, 1821–1827.

- Nomura, K.; Noro, K.; Nakamura, Y.; Yazawa, Y.; Yoshida, H.; Satsuma, A.; Hattori, T. Pd-Pt bimetallic catalyst supported on SAPO-5 for catalytic combustion of diluted methane in the presence of water vapor. Catal. Lett. 1998, 53, 167–169.

- Osman, A.I.; Abu-Dahrieh, J.K.; Laffir, F.; Curtin, T.; Thompson, J.M.; Rooney, D.W. A bimetallic catalyst on a dual component support for low temperature total methane oxidation. Appl. Catal. B 2016, 187, 408–418.

- Dai, Q.G.; Bai, S.; Lou, Y.; Wang, X.; Guo, Y.; Lu, G.Z. Sandwich-like PdO/CeO2 nanosheet@HZSM-5 membrane hybrid composite for methane combustion: Self-redispersion, sintering-resistance and oxygen, water-tolerance. Nanoscale 2016, 8, 9621–9628.