Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Benay Gursoy | -- | 3727 | 2023-09-04 04:06:23 | | | |

| 2 | Rita Xu | -9 word(s) | 3718 | 2023-09-04 04:47:39 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Mohseni, A.; Vieira, F.R.; Pecchia, J.A.; Gürsoy, B. Three-Dimensional Printing of Living Mycelium-Based Composites. Encyclopedia. Available online: https://encyclopedia.pub/entry/48778 (accessed on 07 February 2026).

Mohseni A, Vieira FR, Pecchia JA, Gürsoy B. Three-Dimensional Printing of Living Mycelium-Based Composites. Encyclopedia. Available at: https://encyclopedia.pub/entry/48778. Accessed February 07, 2026.

Mohseni, Alale, Fabricio Rocha Vieira, John A. Pecchia, Benay Gürsoy. "Three-Dimensional Printing of Living Mycelium-Based Composites" Encyclopedia, https://encyclopedia.pub/entry/48778 (accessed February 07, 2026).

Mohseni, A., Vieira, F.R., Pecchia, J.A., & Gürsoy, B. (2023, September 04). Three-Dimensional Printing of Living Mycelium-Based Composites. In Encyclopedia. https://encyclopedia.pub/entry/48778

Mohseni, Alale, et al. "Three-Dimensional Printing of Living Mycelium-Based Composites." Encyclopedia. Web. 04 September, 2023.

Copy Citation

The construction industry makes a significant contribution to global CO2 emissions. Material extraction, processing, and demolition account for most of its environmental impact. As a response, there is an increasing interest in developing and implementing innovative biomaterials that support a circular economy, such as mycelium-based composites. The mycelium is the network of hyphae of fungi. Mycelium-based composites are renewable and biodegradable biomaterials obtained by ceasing mycelial growth on organic substrates, including agricultural waste.

mycelium

3D printing

mycelium-based composites

1. Introduction

The world is currently facing the threat of a major environmental disaster, and the construction industry plays an important role in the current conditions. The construction industry must undertake considerable change to achieve sustainable practices and a circular economy. The consumption of non-renewable building materials should be minimized [1]. According to the United Nations, the construction industry is responsible for 38% of global CO2 emissions due to energy consumption, and material extraction, processing, and discharge have the greatest environmental impacts in this industry [2]. There is an increasing need for sustainable building materials, and the focus is now shifting toward the development and implementation of novel biomaterials that support the concept of a circular economy over their life cycle [3]. Biomaterials are abundant on both local and global scales, have a low carbon footprint, and are biodegradable. Designers and architects, in collaboration with material scientists and biologists, have explored how to design and fabricate using biomaterials [4]. The mycelium is fungi’s hyphal system, and its inadequate growth forms mycelium-based composites [5]. These composites have the ability to transform bio-waste into high-end goods. When the adaptive growing nature of mycelial networks is combined with the potential to shape matter in three dimensions, complex living materials that meet particular engineering needs can be produced. Mycelium-based biomaterials need to be carefully managed and grown in a controlled environment to form functional structures. This requires transforming biomaterials’ shape or adding substances that enhance their characteristics. To develop the appropriate structures, their growth and development must be monitored and regulated as living organisms [6]. Mycelium-based composites provide good heat and sound insulation, are hydrophobic, have compression resistance, are 100% biodegradable, and have low density. Furthermore, the raw ingredients for such composites are low cost, locally available, renewable, and capable of capturing and storing CO2 [7]. Cultivating mycelium-based composites utilizing the molding technique is a common approach [8]. However, molds limit the geometric complexity and scale of mycelium-based composites. Furthermore, if molds are not reusable, the process is often wasteful.

Three-dimensional printing methods, as an alternative to molding techniques, can be used to form mycelium-based composites, allowing unique shapes to be manufactured without the need for unique molds [9]. In addition, this can minimize waste from the manufacturing process and make it possible to create complex shapes that can support the growth of mycelia that would otherwise be impossible to produce [10]. The integration of the livingness characteristic of mycelium-based biomaterials and the shaping potential of 3D printing technology opens up the possibility of developing living materials with unprecedented adaptive features [6].

2. Mycelium-Based Composites

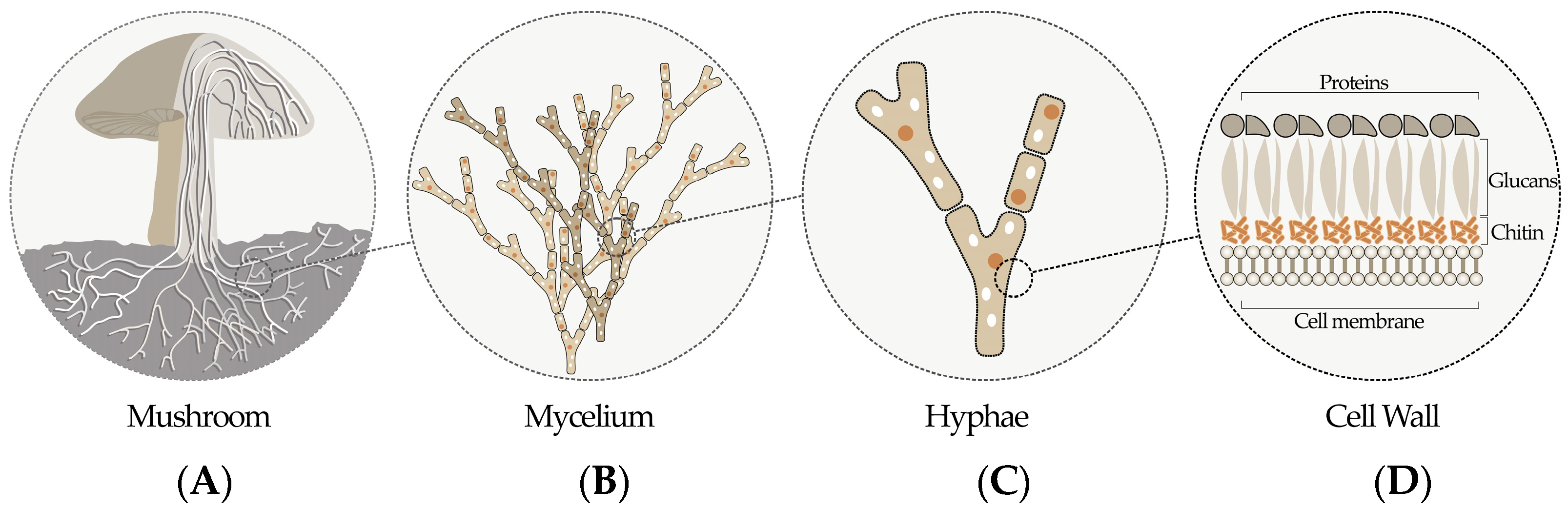

Mycelium-based composites are biomaterials that are formed when living fungi grow onto organic substrates, which also act as nutrition sources for the fungi [11]. The mycelium, a network of fungal hyphae, is composed of a network of “fine fibers” of 1–30 μm in diameter [8][12]. Chitin, glucans, and proteins are the main components of the hyphal wall, as illustrated in Figure 1. In particular, chitin is an intricate polysaccharide that consists of modified glucose chains and is primarily responsible for the material properties of mycelium-based composites [13]. A fungus takes nutrition from its environment using its mycelium. In order to break down the biological polymers of organic materials into simpler molecules, the hyphae first discharge enzymes into the organic substrates and subsequently absorb the resulting monomers. When the mycelial branches combine the organic substrates in this manner, the result is a lightweight and foam-like substance, called mycelium-based composite [5]. With the development of their mycelial network, fungi can integrate various types of organic waste into composite materials without requiring extra energy or creating additional waste [8]. Mycelial cells have evolved in nature to maneuver through and develop within the hollow spaces of porous structures. This metabolic activity gives them the strength to self-regenerate and repair the broken or empty spots in mycelium-based composites [6].

Figure 1. On various scales, a schematic representation of the mycelium is shown: (A) mushroom structure, (B) hyphae, (C) several cells of hyphae, and (D) single hyphal cell wall.

As living organisms, fungi react to environmental influences by rebuilding their hyphal network to optimize nutrient intake. They transform continuously, resulting in different properties across the mycelial structure. In the presence of appropriate substrates, the mycelial structure can self-replicate to generate seemingly limitless composites [14]. Mycelium-based composites are foam-like, light-weight materials formed by drying or heating the mycelial colony, which ultimately results in the hibernation or death of the fungal mycelium [5]. According to [6], the relationship between exploration and exportation implemented by different fungal species can explain the different growing patterns of mycelial networks. There are two different growing strategies based on the availability of nutrients, known as phalanx and guerilla. When a large, easily available nutrition source is available, the mycelium uses an exploitative growing strategy, also known as phalanx, by progressing slowly in a continuous line, which results in a thick hyphal mat with many branches. On the contrary, when the nutrition source is limited, the mycelium changes the growing pattern to an exploratory mode, known as guerilla, resulting in long, branchless hyphae [6].

Although frequently referred to as mycelium-based composites, these biomaterials are also called myco-materials, fungi-based materials, mycelium materials, mycelium composites, and mycelium-bonded composites in the literature.

Multiple factors affect the mycelial growth and the material properties of the resulting composites. These include the species of fungi utilized for inoculation, the substrates and additives used, the growing conditions, the cultivation period, and the method of processing and formation [15]. By altering these determining factors, researchers attempt to enhance the mechanical and durability characteristics of mycelium-based composites [16].

Recently, there has been a growing interest in using mycelium-based materials in architecture. Architects working on digital and computational design analyze and decode molecular structures, such as the hyphal network of mycelia, to learn about the geometric, structural, and behavioral motions [3]. Mycelium-based composites can be formed using a variety of methods and are used to construct a wide range of architectural elements [4].

3. Three-Dimensional Printing of Mycelium-Based Composites

One of the distinctive qualities of mycelium-based composites is the ability of mycelia to grow in molds, which enables designers to directly cultivate composites in the final, desired form. This has been the preferred method to construct architectural prototypes so far [17]. The molding process proceeds with the following stages: the substrate and fungal inoculum (spawn) are mixed, placed in a sterilized mold, and allowed to develop until mycelial growth is ceased using heating or drying [11]. While this method is rather straightforward, it is well suited for industrial-scale production. However, molding techniques limit the product’s customization and geometrical complexity [18]. Furthermore, molds can produce waste, especially if they are not reused or recycled. Recently, there have been efforts to use additive manufacturing techniques to form mycelium-based composites.

The 3D printing of mycelium-based materials can facilitate the fabrication of more intricate forms without the need for unique molds and provides new applications for mycelium-based composites [7]. According to Soh et al. [11], extrusion is one of the least energy-intensive manufacturing techniques, making it a promising option for the low-cost and low-energy manufacture of mycelium-based products.

In order to 3D-print mycelium-based composites, it is important to first develop an extrudable paste that has form stabilization qualities and is workable and buildable. To improve workability and buildability, additives, such as fibers and binders, are commonly used. Altering the water content and using modifiers to change the mixture’s viscosity is also an option [11].

4. Three-Dimensional Printing Workflow for Mycelium-Based Composites

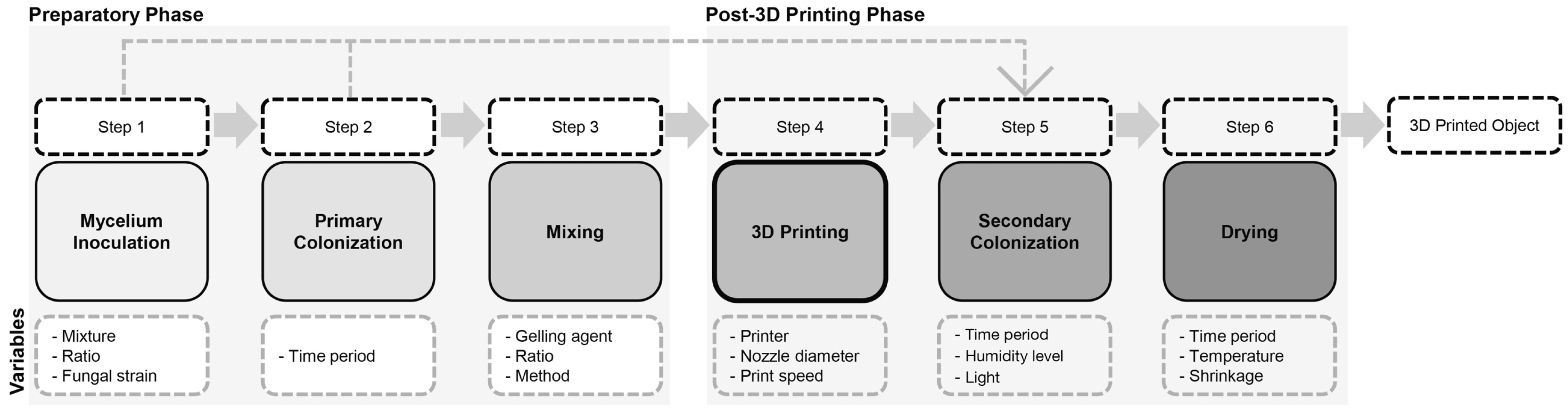

Mycelium-based composites for architectural use can be grown on a variety of substances and under a variety of conditions. There are three main stages of mycelium-based composite cultivation: inoculation, growth, and ceasing. Based on studies in which extrusion techniques have been already developed for mycelium-based composites, the steps for 3D printing mycelium-based composites can be divided into two primary stages, before and after 3D printing [7][11]. The entire 3D printing workflow can be divided into six steps: mycelium inoculation, primary colonization, mixing, 3D printing, secondary colonization, and drying [7][19], as shown in Figure 2.

Figure 2. Six steps of the 3D printing of mycelium-based bio-composite material.

4.1. Step 1: Mycelium Inoculation of Agricultural Feedstock

Inoculation is the first step in the cultivation of mycelium-based materials. It starts with the preparation of the substrate mixture. Mycelium-based composites have two main parts: a filler, that is, a bio-substrate, and a binding agent, that is, a mycelium. Mycelium-based composites can be compared to concrete that has aggregates and cement, but the main difference is that in mycelium-based composites, the substrate works as a source of nutrients for the fungi for the next stages of development [20]. Mycelium-based composites may be cultivated on a wide range of organic matter. Based on the literature, the most common substrates for developing mycelium-based composites are straw, woodchip, and hemp [16]. On the other hand, cardboard, paper, and newspaper have a high content of plant materials, such as cellulose, hemicellulose, and lignin, which can easily be degraded and used as carbon sources by primary decomposer fungi [21].

To eliminate any possible microbial contaminators, the mixture must be sterilized [22]. Sterilization should be performed before the substrate is inoculated with the fungal mycelium. There are several methods, such as cold sterilization with chemicals, scalding, using peroxide, cold fermentation, and sterilizing in bags in an autoclave. The most common approach is using autoclavable bags filled with the prepared mixture and sterilizing in an autoclave for 30–45 min at 121 °C or at lower temperatures, such as 90 °C, for a longer period [22]. The fungal spawn is added after the mixture has been sterilized and cooled to eliminate any microbial competitors. The fungal species is a determining factor of mycelial behavior during growth as a binding agent. It is critical to choose the appropriate fungal species to achieve the desired material quality in the end [23].

4.2. Step 2: Primary Colonization

Fungi grow in the form of colonies on primary substrates or host materials, which is why this step is called primary colonization [7]. Colonization is the second step of the cultivation process, during which the mycelium goes through different development phases. In most cases, this initial step of mycelial formation occurs in the sterilization bags. The colonization procedure takes approximately between 5 and 15 days, depending on the substrate type, fungal species, and growing conditions [16]. During the first stage of development, little branches of hyphae form in the bags, mostly on the surface of the mixture [5]. Once colonization is visible, the mixture is ready to be taken out of the bags for the next steps. If there is enough and equal growth in the mixture, it is possible to proceed to the next steps of the cultivation, which include molding the mixture into the desired forms or adding some admixtures to make it extrudable for the 3D printing method. This step results in a dense mixture [7], the characteristics of which can be altered by changing the environmental factors, such as temperature, humidity, and light, throughout the cultivation process [5].

4.3. Step 3: Mixing

Before extruding mycelium-based composites, it is necessary to develop a paste or mixture that is extrudable and has certain characteristics, such as flowability, rheology, and buildability [11]. Flowability is one of the key measurements for ensuring that the paste is successfully delivered from the container to the nozzle during 3D printing. Rheology is linked to material flow and deformation, which, in the case of printable materials, is the examination of printability, buildability, and segregation resistance. Buildability, on the other hand, is the capability of a material to hold its printed shape and the durability of an extruded wet material against distortion under its self-load [24].

The primary colonized material is initially too thick for passing through the print nozzle. To convert the thick colonizing-mycelium-based composite into an extrudable mixture that is flowable and buildable, more water and a gelling agent must be added [7]. The ingredients can be mixed using a mixer to enhance their printing quality and integrity.

4.4. Step 4: Three-Dimensional Printing

The determining factors of 3D-printed mycelium-based composites can be divided into two main categories: (1) factors associated with the material itself, including material particle size, viscosity, and ingredient concentration; (2) factors associated with the printing environment and printing equipment, such as extrusion pressure, extrusion speed, nozzle diameter, toolpath geometry, and the 3D printer [25].

4.5. Step 5: Secondary Colonization

The living mycelium existing in the mixture must expand its growth to solidify the composite after 3D printing [11]. According to Bhardwaj et al. [7], secondary colonization refers to this second stage of mycelial growth, where the fungi begin to proliferate again. This period varies based on the fungal species used for the first colonization step. The 3D-printed objects must be maintained in sterilized containers away from direct sunlight to support further fungal development.

4.6. Step 6: Drying/Heating

To stop the growth process of mycelium-based composites, it is necessary to either dry or heat the composites [26]. This step takes place after secondary colonization. Drying hibernates the fungus; if the material is exposed to the desirable humidity conditions again, it may restart growing. Adequate heating, on the other hand, kills the fungus and terminates further colonization by the mycelium.

5. 3D Printing of Mycelium-Based Composites

Previous experiments on the 3D printing of mycelium-based materials can be divided into two groups, large-scale and small-scale prototypes. There are currently two large-scale projects to date built by 3D-printing mycelium-based composites, where both of them are column-like vertical structures: Pulp Faction and the column by Blast Studio. Both projects were developed using a reaction–diffusion algorithm for form finding [27]. After the completion of the first phase of growth in bags, the manufacturing process of both projects consisted in 3D-printing individual components that were then vertically stacked. Because of the size constraints of the 3D printers, as well as the limited number of layers that could be supported, the columns were created in sections [28][29]. The additive manufacturing technique used in the production of both columns made it possible to fabricate complex and unique forms that could not be fabricated with conventional molding techniques. The biologically active process, however, introduces new challenges, such as additional sterilization needs for the processing of the materials. In order to overcome these challenges, the designers explored novel manufacturing techniques and tested various material compositions [28]. The manufacturing method used by Blast Studio starts with shredding waste paper coffee cups to generate organic substrates, which are then inoculated with fungal spawn. The generated biomass paste is pushed through an extruder layer by layer to create ten separate modules. These modules are then piled into a column of 2.1 m in height and bio-welded together using more biomass paste [29].

As part of the first study published on the 3D printing of mycelium-based materials on a small scale, Bhardwaj et al. (2020) combined biomass paste with additives after the first growing phase to produce an extrudable mixture [7]. After 3D printing, the printed item was placed in a sterile container for five days for the second stage of growth. Finally, a heater was used to stop the fungus’ growth. The results showed that similar to the results of the molding technique, the majority of mycelial growth occurred in the outer parts [7]. The same group of researchers published a follow-up study in which they investigated the effects of the composition of the mixture, particularly the addition of psyllium husk powder, on the 3D printing quality and the rheological properties of the mixture [19]. In another study, chitosan and shredded bamboo fibers were used for preparing a mycelium mixture. Chitosan is a biopolymer derived from chitin. When dissolved in a moderately acidic liquid medium, it generated a gel that served as a physical stabilizer and facilitated the extrusion of the mycelium paste [11].

In the MyCera project [30], a unique form of 3D printable material was developed using a mixture of clay and mycelium-based composites. Two distinct 3D-printed versions of the composite material were created. “Node” elements were developed using mycelium-based composites to deal with tension and shear forces, and “bar” elements were developed with fired clay. Both samples were made up of a combination of sawdust and clay that was inoculated with the fungal spawn.

In “multi-material fabrication” research, researchers investigated a two-phase multi-material manufacturing method to fabricate mycelium-based composites with enhanced porosity and intricacy [31]. The suggested technique bypasses existing 3D printing restrictions by adding a secondary material to act as structural support in order to create the complicated structure for this study. The basic inoculated pulp that makes up the form is extruded, and a fabrication setup is created to deposit the secondary material that supports and forms it.

In another study, several characteristics that determine the 3D printability of mycelium-based composite materials were systematically studied [27]. The viscosity of the mixture, extrusion parameters, and printer hardware settings were the three primary categories of 3D printing parameters that were analyzed. By outlining several substrate compositions, material processing, 3D printing settings, the development of extruders, and sterile printing techniques for living extrudable materials, this work provided clear workflows for the 3D printing of mycelium-based composites.

In the Tilted Arch project, the main purpose was to explore the mechanical characteristics of 3D-printed mycelium-based components by 3D-printing a funicular form that only worked under compressive forces [4]. Their findings demonstrated the possibility of creating compression-only forms that can bear loads by 3D printing and bio-welding mycelium-based composite components.

Table 1 provides an overview of the projects mentioned above and reviews all of the variables related to the 3D printing of mycelium-based composites and the six steps of cultivation outlined above in Figure 2.

Table 1. Existing 3D printing experiments with mycelium-based materials.

| Pulp Faction [28] | Tilted Arch [4] | Mycelium Matters [27] | Mycelium-Bound Composite [11] | MyCera [30] |

Multi-Material Fabrication [31] | 3D Printing of Biomass-Fungi Composite Material [7] |

3D Printing of Biomass-Fungi Composite Material II [19] |

|

|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

| Sequence of steps |

1-2-3-4-5-6 | 1-2-3-4-5-6 | 1-2-3-4-5-6 | 1-2-3-4-5-6 | 3-4-1-2-5-6 | 1-2-3-4-5-6 | 1-2-3-4-5-6 | 1-2-3-4-5-6 |

| Step 1: Mycelium Inoculation of Agricultural Feedstock | ||||||||

| Mixture | Fine woodchips + paper pulp + kaolin clay | Shredded paper + wheat bran | Beechwood + paper cellulose | Bamboo fibers (500 μm) | Sawdust (<2 mm) + bleached and unbleached cellulose |

Paper pulp + secondary material: sand (0.02–0.05 mm) and gravel (4–8 mm) |

Ecovative GIY mixture [32] | Ecovative GIY mixture ([32] |

| Ratio | N/A | 65–70 wt% water + 7% wheat bran (dry weight) | 64 wt% water | 175 g of bamboo fibers + 175 mL of water + 50 g of spawn + sawdust | N/A | N/A | 400 g of Ecovative mixture + 700 mL water + 32 g flour | 400 g of Ecovative mixture + 700 mL water + 32 g flour |

| Fungal strains | Byssomerulius corium + Gloeophyllum | Pleurotus ostreatus (10% of dry weight content) | Trametes versicolor + Ganoderma resinaceum | Ganoderma lucidum | Pleurotus ostreatus | Ganoderma Lucidum | N/A | N/A |

| Step 2: Primary Colonization | ||||||||

| First incubation period | 7 days | 14 days | 14 days | 1 to 4 weeks | N/A | N/A | 3–5 days | 3–5 days |

| Step 3: Mixing | ||||||||

| Gelling agent | Kaolin Clay | Guar gum | Xanthan gum (3 wt%) |

Chitosan | Clay | Xanthan gum | Psyllium husk powder | Psyllium husk powder |

| Ratio | N/A | 3:50 Guar gum:water | 10–80 wt% fiber-water /5–85 wt% fiber-water |

60:40 and 70:30 fiber ratios + 3 wt% chitosan solution at pH~6 | 7:1 clay: sawdust + 35 wt% water |

11% spawn, 56% paper pulp, 1% xanthan gum, and 32% water (by weight) | 100 g of primary material + 400 g of water + psyllium husk (20 g) |

100 g of primary material + 400 g of water + psyllium husk (0, 10 g, 20 g, or 30 g) |

| Method | N/A | N/A | 20 min at 400 rpm | Pounded with pestle and mortar | Mixing machine | N/A | Commercial mixer for 30 s | Commercial mixer for 15 s |

| Step 4: 3D Printing | ||||||||

| Printer | Vormvrij Lutum v4 | Custom extruder | KUKA KR 15/2 6-axis industrial robot | Manually with serological syringes |

Delta WASP 40100 | N/A | Delta WASP 2040 |

Delta WASP 2040 |

| Nozzle diameter | 3.5 mm | 9 mm | N/A | 6 mm | 4 mm | N/A | 4 mm | N/A |

| Layer height | 1.5 mm | N/A | 3 mm | N/A | N/A | N/A | N/A | N/A |

| Print speed | N/A | N/A | N/A | N/A | N/A | N/A | 15 mm/s + air pressure of 3.5 bar | 30 mm/s |

| Step 5: Secondary Colonization | ||||||||

| Second incubation period |

N/A | 5 weeks + 7 days of biowelding | 7 days at 26 °C | 20 days | 2 weeks at 24 °C | 14 days | 3–5 days | N/A |

| Step 6: Drying/Heating | ||||||||

| Drying period | N/A | N/A | N/A | Overnight at 40 °C | 6 h at 600 °C + 2.5 h at 960 °C | N/A | 4 h at 95 °C | N/A |

| Shrinkage | 40% | N/A | N/A | 3–6% | N/A | N/A | N/A | N/A |

Similar to molding or other building techniques with mycelium-based materials, it is necessary to first inoculate the primary substrate, let it colonize for a while, and then mix it with other additives to obtain workable extrusion pulp. According to Lim and Thomsen (2021), there are two main criteria to obtain workable extrusion pulp: its ability to sustain fungal growth and development, and its suitability for fabrication, which involves both extrudability and material stability during the 3D printing and growth stages [31].

6. Contamination and Its Effect on Mycelial Growth

P. ostreatus (oyster mushroom) was the fungal species chosen to generate grain-based spawn that followed substrate inoculation under axenic conditions (i.e., sterile substrate and aseptic environmental conditions). However, during the second stage of fungal growth, after 3D printing, if the mycelium-based paste is exposed to the environment, it becomes susceptible to microbial contamination. For example, a previous report shows that contamination with the fungus Trichoderma sp. (green mold disease) can significantly affect mycelium composites’ growth [33]. It is difficult to distinguish Trichoderma growth from mushroom growth during the first days of colonization, since it first develops a thick, pure, white mycelium layer that is similar to a mushroom mycelium. During the reproductive stage, Trichoderma produces green structures (spores), which are a clear indicator of this infection, often during the secondary colonization step [34]. Because of the high sporulation of the causative agent, which results in a recognizable infection symptom, the mycelial mat on the covering layer of the mycelium-based composite gradually takes on a green color [35]. Because of the high sporulation of the causative agent, which results in a recognizable infection symptom, the mycelial mat on the covering layer of the mycelium-based composite gradually takes on a green color [36].

The management of this infection is very difficult, since both P. ostreatus and Trichoderma are fungi. Enzymes produced by Trichoderma are antagonistic to many microorganisms, which allows it to inhibit the development of P. ostreatus mycelia. Due to the green mold fungi attack, the oyster mushroom mycelium does not grow as expected [37].

References

- Girometta, C.; Picco, A.M.; Baiguera, R.M.; Dondi, D.; Babbini, S.; Cartabia, M.; Pellegrini, M.; Savino, E. Physico-Mechanical and Thermodynamic Properties of Mycelium-Based Biocomposites: A Review. Sustainability 2019, 11, 281.

- United Nations Environment Programme. 2020 Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. 2022. Available online: https://globalabc.org/sites/default/files/inline-files/2020%20Buildings%20GSR_FULL%20REPORT.pdf (accessed on 14 March 2022).

- Almpani-Lekka, D.; Pfeiffer, S.; Schmidts, C.; Seo, S. A review on architecture with fungal biomaterials: The desired and the feasible. Fungal Biol. Biotechnol. 2021, 8, 17.

- Modanloo, B.; Ghazvinian, A.; Matini, M.; Andaroodi, E. Tilted Arch; Implementation of Additive Manufacturing and Bio-Welding of Mycelium-Based Composites. Biomimetics 2021, 6, 68.

- Appels, F.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.M.B.; Dijksterhuis, J.; Krijgsheld, P.; Wosten, H. Fabrication factors influencing mechanical, moisture- and water-related properties of mycelium-based composites. Mater. Des. 2018, 161, 64–71.

- Gantenbein, S.; Colucci, E.; Käch, J.; Trachsel, E.; Coulter, F.; Rühs, P.A.; Masania, K.; Studart, A. Three-dimensional Printing of Mycelium Hydrogels into Living Complex Materials. Nat. Mater. 2023, 22, 128–134.

- Bhardwaj, A.; Vasselli, J.; Lucht, M.; Pei, Z.; Shaw, B.; Grasley, Z.; Wei, X.; Zou, N. 3D Printing of Biomass-Fungi Composite Material: A Preliminary Study. Manuf. Lett. 2020, 24, 96–99.

- Yang, L.; Park, D.; Qin, Z. Material Function of Mycelium-Based Bio-Composite: A Review. Front. Mater. 2021, 8, 737377.

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196.

- Block, P.; Mele, T.; Liew, A.; DeJong, M.; Escobedo, D.; Ochsendorf, J. Structural design, fabrication and construction of the Armadillo vault. Struct. Eng. 2018, 96, 10–20.

- Soh, E.; Chew, Z.Y.; Saeidi, N.; Javadian, A.; Hebel, D.; Ferrand, H.L. Development of an extrudable paste to build mycelium-bound composites. Mater. Des. 2020, 195, 109058.

- Islam, M.R.; Tudryn, G.; Bucinell, R.; Schadler, L.; Picu, R.C. Morphology and mechanics of fungal mycelium. Sci. Rep. 2017, 7, 13070.

- Jones, M.P.; Huynh, T.; Dekiwadia, C.; Daver, F.; John, S. Mycelium Composites: A Review of Engineering Characteristics and Growth Kinetics. J. Bionanosci. 2017, 11, 241–257.

- Jambaro, A.; Neri, K.; Alvarez, L. Utilization of Selected Urban Wastes as Substrate Solutions in the Growth and Yield Performance of Pleurotus sajor-caju Fr. (Singer) (Gray Oyster mushroom). PUP J. Sci. Technol. 2014, 7, 28–44.

- Ghazvinian, A.; Farrokhsiar, P.; Rocha Vieira, F.; Pecchia, J.; Gursoy, B. Mycelium-Based Bio-Composites for Architecture: Assessing the Effects of Cultivation Factors on Compressive Strength. Mater. Res. Innov. 2019, 2, 505–514.

- Attias, N.; Danai, O.; Abitbol, T.; Tarazi, E.; Ezov, N.; Pereman, I.; Grobman, Y.J. Mycelium bio-composites in industrial design and architecture: Comparative review and experimental analysis. J. Clean. Prod. 2020, 246, 119037.

- Grünewald, J.; Parlevliet, P.; Altstädt, V. Manufacturing of thermoplastic composite sandwich structures: A review of literature. J. Thermoplast. Compos. Mater. 2017, 30, 437–464.

- Yang, Z.; Zhang, F.; Still, B.; White, M.; Amstislavski, P. Physical and Mechanical Properties of Fungal Mycelium-Based Biofoam. J. Mater. Civ. Eng. 2017, 29, 04017030.

- Bhardwaj, A.; Rahman, A.M.; Wei, X.; Pei, Z.J.; Truong, D.; Lucht, M.; Zou, N. 3D Printing of Biomass–Fungi Composite Material: Effects of Mixture Composition on Print Quality. J. Manuf. Mater. Process. 2021, 5, 112.

- Ghazvinian, A. A Sustainable Alternative to Architectural Materials: Mycelium-based Bio-Composites. In Proceedings of the Divergence in Architectural Research, Atlanta, GA, USA, 15 February 2021; Georgia Institute of Technology: Atlanta, GA, USA, 2021; pp. 159–167.

- Grimm, A.; Eilertsen, L.; Chen, F.; Huang, R.; Atterhem, L.; Xiong, S. Cultivation of Pleurotus ostreatus Mushroom on Substrates Made of Cellulose Fibre Rejects: Product Quality and Spent Substrate Fuel Properties. Waste Biomass Valorization 2021, 12, 4331–4340.

- Abhijith, R.; Ashok, A.; Rejeesh, C.R. Sustainable packaging applications from mycelium to substitute polystyrene: A review. Mater. Today Proc. 2018, 5, 2139–2145.

- Jones, M.P.; Huynh, T.; John, S. Inherent species characteristic influence and growth performance assessment for mycelium composite applications. Adv. Mater. Lett. 2018, 9, 71–80.

- Long, W.-J.; Tao, J.-L.; Lin, C.; Gu, Y.; Mei, L.; Duan, H.-B.; Xing, F. Rheology and buildability of sustainable cement-based composites containing micro-crystalline cellulose for 3D-printing. J. Clean. Prod. 2019, 239, 118054.

- Elsacker, E. Mycelium Matters—An Interdisciplinary Exploration of the Fabrication and Properties of Mycelium-Based Materials. Ph.D. Thesis, Vrije Universiteit Brussel, Brussel, Belgium, 2021.

- Ghazvinian, A.; Khalilbeigi Khameneh, A.; Mottaghi, E.; Gursoy, B. A Computational Framework for the Design and Fabrication of Spatial Structures with Mycelium-based Composites. In Proceedings of the IASS Annual Symposia, Guildford, UK, 23–27 August 2021.

- Elsacker, E.; Peeters, E.; De Laet, L. Large-scale robotic extrusion-based additive manufacturing with living mycelium materials. Sustain. Futur. 2022, 4, 100085.

- Goidea, A.; Andreen, D.; Floudas, D. Pulp Faction: 3D Printed Material Assemblies through Microbial Biotransformation; UCL Press: London, UK, 2020.

- Hahn, J. Blast Studio 3D Prints Column from Mycelium to Make “Architecture That Could Feed People”. 2022. Available online: https://www.dezeen.com/2022/01/18/blast-studio-tree-column-mycelium-design/ (accessed on 6 August 2022).

- Jauk, J.; Vašatko, H.; Gosch, L.; Christian, I.; Klaus, A.; Stavric, M. Digital Fabrication of Growth Combining digital manufacturing of clay with natural growth of mycelium. In Proceedings of the 26th International Conference of the Association for Computer-Aided, Hong Kong, China, 29 March–1 April 2021.

- Lim, A.C.S.; Thomsen, M.R. Multi-material Fabrication for Biodegradable Structures: Enabling the printing of porous mycelium composite structures. In Proceedings of the eCAADe 2021: Towards a New, Configurable Architecture, Novi Sad, Serbia, 8 September–10 September 2021; pp. 85–94. Available online: http://www.ecaade2021.ftn.uns.ac.rs/ (accessed on 3 May 2023).

- Grow It YourselfTM Material. Grow.bio. Available online: https://grow.bio/products/grow-it-yourself-material (accessed on 3 May 2023).

- Innocenti, G.; Montanari, M.; Righini, H.; Roberti, R. Trichoderma species associated with green mould disease of Pleurotus ostreatus and their sensitivity to prochloraz. Plant Pathol. 2019, 68, 392–398.

- Park, M.S.; Bae, K.S.; Yu, S.H. Two New Species of Trichoderma Associated with Green Mold of Oyster Mushroom Cultivation in Korea. Mycobiology 2006, 34, 111–113.

- Danesh, Y.R.; Goltapeh, E.M.; Rohani, H. Identification of Trichoderma species causing green mould in button mushroom farms, distribution and their relative abundance. Sci. Cultiv. Edible Fungi 2000, 2, 653–659.

- Cao, Z.-J.; Qin, W.-T.; Zhao, J.; Liu, Y.; Wang, S.-X.; Zheng, S.-Y. Three New Trichoderma Species in Harzianum Clade Associated with the Contaminated Substrates of Edible Fungi. J. Fungi 2022, 8, 1154.

- Pakeerthan, K. Eco-Friendly Management Common Lab Contaminant Trichoderma spp. in Oyster mushroom Production Using Agrobased Industry’s by-Products. In Proceedings of the International Conference on Climate Change, Virtual, 18–19 February 2021; Available online: https://tiikmpublishing.com/proceedings/index.php/iccc/article/view/733 (accessed on 23 February 2023).

More

Information

Subjects:

Biotechnology & Applied Microbiology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

3.8K

Revisions:

2 times

(View History)

Update Date:

04 Sep 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No