Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Ricardo Pereira | -- | 4653 | 2023-08-11 01:12:40 | | | |

| 2 | Catherine Yang | Meta information modification | 4653 | 2023-08-11 02:54:57 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Pereira, R.; Dos Santos, N. The Industry 5.0. Encyclopedia. Available online: https://encyclopedia.pub/entry/47926 (accessed on 07 February 2026).

Pereira R, Dos Santos N. The Industry 5.0. Encyclopedia. Available at: https://encyclopedia.pub/entry/47926. Accessed February 07, 2026.

Pereira, Ricardo, Neri Dos Santos. "The Industry 5.0" Encyclopedia, https://encyclopedia.pub/entry/47926 (accessed February 07, 2026).

Pereira, R., & Dos Santos, N. (2023, August 11). The Industry 5.0. In Encyclopedia. https://encyclopedia.pub/entry/47926

Pereira, Ricardo and Neri Dos Santos. "The Industry 5.0." Encyclopedia. Web. 11 August, 2023.

Copy Citation

The Industry 5.0 emerges as a new paradigm for the industry by considering sustainability, human-centered approaches, organizational resilience, and interaction between humans and machines as its core values. This new trend for the future of the industry is referred to as neoindustrialization.

Industry 5.0

scoping review

neoindustrialization

1. Introduction

Industry 4.0 has become the standard in the industry in recent years, with its technologies being implemented and positively impacting all sectors. However, these developments still fall short of achieving the desired results, neglecting the environment and prioritizing machines over humans [1][2][3].

This context has prompted research and discussions that have been undertaken since 2017. In 2021, the European Commission formalized the call for a new Industrial Revolution with the publication of a document titled “Industry 5.0: Towards a Sustainable, Human-centric, and Resilient European Industry”. This study resulted from two workshops held in 2020, which discussed the need to recognize the power of the industry in achieving social objectives, as well as jobs and growth, while considering the well-being of industrial workers, sustainability, resilience, and other issues related to productivity and efficiency in the supply chain [1][4][5].

Industry 5.0, referred to as Neoindustrialization in this study, emerges as an alternative to a set of challenges in the contemporary world (climate change, rapid consumption of non-renewable resources and energy, environmental pollution, and social injustice, among others) that have been amplified by the COVID-19 pandemic and the Russia-Ukraine conflict, elevating the complexity and dynamics of this context to levels not seen since World War II (1939–1945).

2. Industry 5.0 from a Quadridimensional Perspective: Advancing through a New View of Neoindustrialization

A set of advanced technologies, represented by the Internet of Things (IoT), artificial intelligence (AI), and robotics, enable the creation of flexible and highly efficient production systems, characterizing Industry 4.0 [6]. Its adoption has been gaining momentum, positively impacting various sectors, and becoming the standard in the industry in recent years. However, these developments still fall short of achieving the desired outcomes [1] and have faced significant challenges. These challenges include the need to adapt organizational structures and traditional business models, as well as the need to develop solutions to ensure data security and interoperability between systems. Additionally, there is a concern that the environment is being neglected and that machines are being prioritized over humans [1][6].

In 2021, the European Commission formalized the call for a new era in the industry when it published the article titled “Industry 5.0: Towards a sustainable, human-centric and resilient European industry” This work, resulting from two workshops held in 2020, lays the groundwork for what is now known as Industry 5.0. It represents a new paradigm that embraces sustainability, human-centered approaches, and organizational resilience as its core values [1][4][5]. Therefore, Industry 5.0 fills the gap left by the previous paradigm by prioritizing social and environmental issues alongside technological innovation [5].

As per the vision outlined by the European Commission, Industry 5.0 is based on three interconnected key principles: the importance of the individual, sustainability, and resilience. This human-centered approach positions their needs and interests at the heart of the production process, shifting the focus from a technological view to a strategy oriented towards the individual and society [4][7]. In this scenario, technology is seen as a means, being used to adapt to the diverse needs of industry workers and consumers [7]. Moreover, it’s imperative to create a work environment that is safe and inclusive, prioritizing physical and mental health, as well as well-being, and safeguarding the fundamental rights of workers, human dignity, and privacy. For the industry to respect the limits of our planet, it needs to be sustainable. This requires the development of circular processes that reuse and recycle natural resources, reduce waste and environmental impact, and drive a more efficient and effective circular economy. Organizational resilience, in turn, refers to the need to develop a more robust industrial production, able to protect against disruptions and ensure the supply and sustenance of critical infrastructures in times of crisis. The industry of the future must be resilient enough to quickly adjust to geopolitical changes and natural emergencies [4][5]. Industry 5.0 will allow the addressing of issues related to technology and human life not observed by Industry 4.0, in addition to providing greater scalability, flexibility, resilience, and efficiency in the industry [1][8].

Unlike the announcement made by the European Commission (2021), which indicates that Industry 5.0 should be human-centric, sustainable, and resilient, this study argues that this new approach to the industry should be envisioned from four perspectives of analysis. This additional perspective considers technology as an enabler of Industry 5.0, that is, a set of new technologies that will characterize this new industrial paradigm, fostering collaboration and interrelation between humans and machines [8][9]. In this new reality, where factories and devices are intelligent, humans work alongside machines and connect to them through smart devices [10]. Production undergoes a transformation, making way for mass personalization in the industry. In this context, robots will have significant importance, as advancements in artificial intelligence allow them to be connected to the human mind through brain interfaces [11] functioning as collaborators rather than competitors [12]. The advent of this new industrial revolution will drive the advancement of interfaces between humans and machines, utilizing artificial intelligence (AI) algorithms. This evolution will enable enhanced integration, allowing for more efficient and faster automation while harnessing the full potential of the human brain [13]. This also means that robots will not take over factories anytime soon, alleviating concerns from the era of Industry 4.0 [14]. The transition from Industry 4.0 to Industry 5.0 means combining the best features of humans and machines, which will result in increased productivity [3][15].

For proponents of this approach, the main characteristic of Industry 5.0 is “Personalization”, which can be described as “the design and production through various sensor data that will be directly linked, providing personalized products to users in real time” [3], p. 1, thus representing a neoindustrialization. In other words, this new reality allows customers to obtain products and services according to specific requirements, following a manufacturing process through the use of technologies that enable “design freedom”, making products more personalized and enhancing manufacturing capabilities by utilizing programmable machines and intelligent sensor networks [14][16][17]. In this context of a new revolution, the industry meets the individual demands of customers, made possible by a paradigm shift in manufacturing, transitioning from customization to mass personalization [14].

Despite the conceptual differences, there is a consensus that Industry 5.0 envisions an industry that goes beyond the goals of efficiency and productivity, emphasizing the role and impact of the industry on society [4].

It is essential to emphasize this point, as it justifies the need for a new paradigmatic approach based on neoindustrialization to address the challenges imposed on organizations, governments, and society as a whole. These challenges, such as climate change, rapid consumption of non-renewable resources and energy, environmental pollution, and social injustice, among others, largely impact the world today and have gradually gained prominence, particularly in the past two hundred years, which coincides with the industrial revolutions.

3. A New Stage for the Industry

The numeral that follows the term “industry” indicates a paradigmatic evolution known as an industrial revolution. What determines this evolution? In other words, what characterizes a new industrial revolution? Can Industry 5.0 be seen as a new revolution in the industry? Looking back at the past can help answer these questions, so it is important to establish a temporal demarcation of the evolutionary stages of the industry from the perspective of neoindustrialization.

Over the past two centuries, four industrial revolutions have occurred, “each producing a higher level of technology” [1], p. 1. The first industrial revolution, known as Industry 1.0, originated around 1760 through the generation of mechanical power from water, steam, and fossil fuels [1][12]. The steam engine allowed the transition from an agrarian and feudal society to a new manufacturing process. This transition included the use of coal as the primary source of energy while trains became the main mode of transportation. The textile and steel industries dominated in terms of employment, production value, and invested capital. It was followed by the second industrial revolution, Industry 2.0, which took place in the first half of the 19th century, around the 1840s. It was enabled by electric power and the invention of the internal combustion engine, leading to a period of rapid industrialization using oil and electricity, facilitating the advent of assembly line factories and enabling mass production [1][12].

In the 20th century, around the 1960s and 1970s, the era of computers, transistors, and later on, silicon chips, electronic devices, and information technology (IT) emerged, marking the Third Industrial Revolution (Industry 3.0) and introducing the industry to the concept of automation.

On the other hand, Industry 4.0 is an initiative by the German government that suggests the creation of smart factories with a simple and similar objective to previous revolutions: increasing productivity and achieving mass production with innovative technology [10]. It utilizes technologies such as artificial intelligence (AI), cloud computing, and the Internet of Things (IoT), enabling a real-time interface between the physical and virtual worlds (cyber-physical systems) [1][12]. Industry 4.0 is characterized by the integration of intelligent manufacturing systems and processes with advanced information and manufacturing technologies, enabling a flexible, intelligent, and reconfigurable production process [18].

In the technological search revolution of hyper-accumulation [19], evolutionary models of industrial dynamics based on the concepts of Industry 4.0, despite enabling several technological advancements, have limitations from an anthropocentric perspective in the industrial production process.

Industry 5.0 emerges as a complement to Industry 4.0, addressing the aspects that it does not fully cover, particularly issues related to social justice and sustainability. While still considering productivity and efficiency, Industry 5.0 brings the human-machine relationship to the forefront, placing the individual at the center of the production process [1][4][5].

The foundation for the construction of the principles of Industry 5.0 stemmed from society’s and governments’ concerns regarding the preference for machines over humans in the industry, along with the need to consider sustainable development and recognize the crucial role of humans in shaping the future of industrial development [20]. Moreover, even in conceptual terms, the excessive emphasis on technology and automation in Industry 4.0 distances it from the necessary paradigmatic alignment to serve as a solution to the challenges listed in the introduction of this paper [9]. This position has directed the search for a new paradigm that makes the industry (representing other organizations) more sustainable, human-centric, and resilient [4].

It is possible to identify common points regarding the industrial revolutions. A technological advent: steam power (Industry 1.0), electricity (Industry 2.0), computers (Industry 3.0), cyber-physical systems, and the Industrial Internet of Things (Industry 4.0). A specific phenomenon impacting the economy and society: the adoption of new agricultural techniques, leading to increased agricultural productivity and trade expansion (Industry 1.0); World War I, the Great Depression of 1929 (Industry 2.0); World War II (Industry 3.0); population aging, urbanization, growing demand for sustainability, and concerns about cybersecurity (Industry 4.0). According to [5], industrial revolutions are driven by transformative technological advancements that lead to fundamental changes in how the industry operates, with economic and social consequences. In other words, an industrial revolution is determined by a series of significant changes in the way production is carried out, accompanied by technological advancements, increased productivity, and changes in production methods and work organization. The transition from one industrial revolution to another is a complex and multifaceted process involving technological, economic, social, and political changes.

The absence of a technological advent fuels critics of Industry 5.0, who do not see it as a new paradigm for the industry. In this case, it can be observed that the technologies indicated as enablers of Industry 5.0 are similar to those of the previous paradigm. On the other hand, as seen in previous revolutions, phenomena can occur that impact markets and the global economy, demanding new approaches and differentiated actions from the industry (e.g., the two world wars, the 1929 crisis, the COVID-19 pandemic, which impacted the global supply chain).

Thus, drawing a parallel between Industry 4.0 and 5.0, it can be inferred that the former is technology-driven, while Industry 5.0 is propelled by values, with a focus on issues such as sustainability and social responsibility [5], configuring itself as a neoindustrialization.

4. Neoindustrialization and the Resurgence of Industry’s Protagonism: The Context of the Brazilian Industry

Industries are organizations that aim to transform raw materials into marketable goods and services. The industry originated with the industrial revolution and has evolved as mentioned in the previous subsection. From an economic point of view, the industry can be classified into four sectors: primary, secondary, tertiary, and quaternary. Industries in the primary sector are involved in raw material extraction. The secondary sector comprises industries engaged in processing, manufacturing, and construction using the raw materials extracted from the primary sector. The tertiary sector consists of service industries such as retailers, entertainment companies, and financial organizations. The quaternary sector encompasses innovative industries that use information and technology to improve processes and services, leading to societal improvements [21].

The Brazilian industrial sector is one of the largest job creators in Brazil and strengthens the entire productive sector. Research from the National Confederation of Industry (CNI) reveals that the sector employs 9.7 million Brazilians and accounts for 20.4% of the country’s formal employment. The participation of the Brazilian industry in the global industry represents 1.5%, with Brazil ranking 13th among the most industrialized countries. However, Figure 1 indicates that these numbers have been experiencing a downward trend. Importantly, it is also worth mentioning that these numbers are prior to the COVID-19 pandemic, which had a significant impact on the productive sector and disrupted the global supply chain.

Figure 1. Participation of the Brazilian industry in the global industry [21].

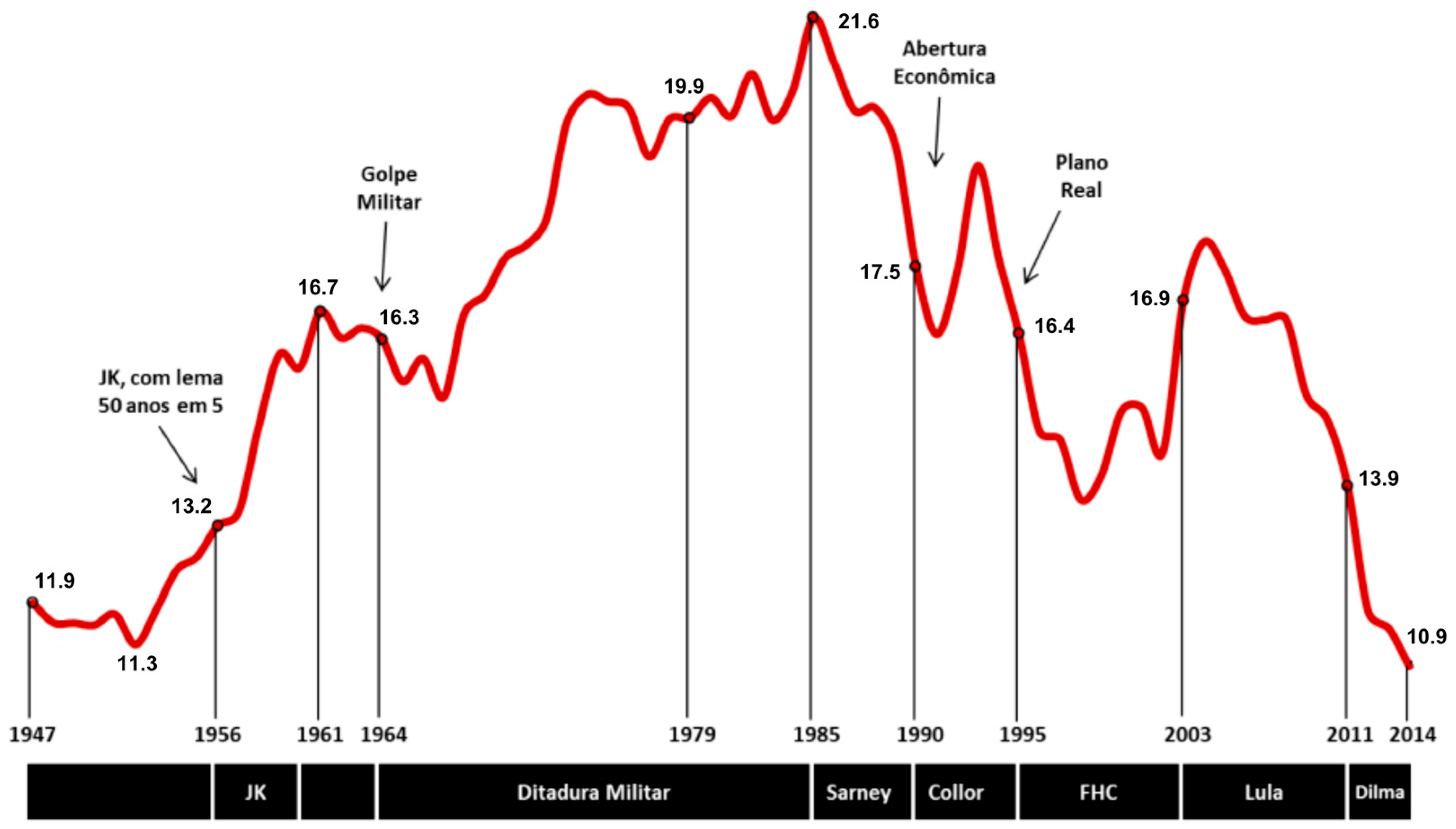

The participation of the manufacturing industry in the gross domestic product (GDP) can be evaluated in two distinct periods, between the years 1947 and 2018, as observed in the graph in Figure 2.

Figure 2. Participation of the Manufacturing Industry in the Brazilian GDP [22].

From the 1950s until 1985, the first period occurred, characterized by intense growth, diversification, and consolidation of the Brazilian industrial structure. During this period, the participation of the manufacturing industry in the GDP almost doubled, rising from 11.3% in 1952 to 21.6% in 1985. The second period, which began in 1986, is characterized by a significant loss of industry’s share in the country’s aggregate production [22].

The peak of the manufacturing industry in Brazil occurred in 1985, and since then, the industry’s importance has been gradually declining, with services gaining in significance [23]. According to data from the Brazilian Institute of Geography and Statistics (IBGE) and estimates from FIESP [22], the share of the Manufacturing Industry in the GDP declined by approximately 10 percentage points over the last period, reaching 10.9% in 2018. This phenomenon is known as deindustrialization [22][23]. This scenario is characterized by the decrease in employment opportunities in the industrial sector and its contribution to the composition of the GDP, caused by the loss of competitiveness and relative technological backwardness, the absence of public policies for the industrial sector, and an unfavorable economic environment, associated with dependence on foreign capital and technology.

Furthermore, a study conducted by the Federation of Industries of Rio de Janeiro [24] states that Brazilian industry is in transition between the second and third industrial revolutions [25]. A study conducted by the National Confederation of Industry [26], cited by [25], revealed that 43% of the 2225 surveyed companies were unaware of the technologies that could drive competitiveness in Industry 4.0. Furthermore, the lack of knowledge was more pronounced among small companies (57%) compared to large companies (32%). Additionally, 48% of the companies were using at least one new technology, with a focus on digital industrial automation (27%), collection and processing of large amounts of data (9%), operation of flexible autonomous lines (8%), cloud services (6%), and the Internet of Things (4%). According to the study, challenges for Industry 4.0 included implementation costs, lack of clarity in return on investment, organizational structure, national infrastructure, employee qualifications, and industrial policies/regulations [25].

Discussing Industry 5.0 after reading the previous paragraphs may seem presumptuous and ambitious, as it appears to be a distant scenario for Brazil. However, it is important to emphasize that the Brazilian industrial context is represented by diverse realities. For instance, the seven states comprising the South and Southeast regions of Brazil account for 73.9% of the country’s industrial GDP, despite Brazil having 27 federative units. This panorama not only demonstrates the disparity in the industry across Brazilian regions but also highlights the need for the Brazilian industry to reclaim its prominent role of decades past. To achieve this, a process of Neoindustrialization is necessary, which involves restructuring the industrial sector through the incorporation of new technologies, increased productivity, and a focus on higher value-added industries. This transition will entail shifting from traditional industries to advanced industries such as information technology, biotechnology, and renewable energy, among others. These actions will serve as a strategic response to contemporary economic challenges, including international competition, process automation, and the growing demand for sustainable and environmentally responsible solutions, aligning with the advent of Industry 5.0.

To achieve this, it is necessary to create an environment conducive to innovation and entrepreneurship that promotes the development of qualified human capital, investments in research and development, and strengthens partnerships between the public and private sectors. A successful neoindustrialization policy will generate high-quality jobs and foster economic growth.

The term Neoindustrialization is more suitable to describe this new phase of industrialization, in which companies in the industrial sector will need to combine technology with new strategies and organizational models, as well as undertake organizational changes that align their structure, operations, human resources, and new practices to meet the demands of society and all stakeholders involved in this process.

5. The Enabling Technologies of Industry 5.0: From Technocentrism to Mass Personalization

Technologies are also crucial in Industry 5.0. They enable the interaction between humans and robots, bringing humans back to the factory floor and presenting opportunities that position this new Industrial Revolution as the future of the industry.

Several technological trends are empowering the industry to increase production and deliver personalized products to their customers, while also enabling interaction between humans and machines [27]. Table 1 summarizes a range of technologies that are part of Industry 5.0.

| Technologies | Definition |

|---|---|

| Edge Computing |

Edge Computing (EC) is a data processing approach at the network edge that offers benefits such as low latency, increased energy efficiency, and enhanced security. Industries can access local data and minimize the volume sent to centralized servers, enabling proactive analytics and smarter decision-making. |

| Digital Twins |

Digital Twins (DT) are digital replicas that enable mass customization, and the seamless flow of data between the physical, digital, and cyber space is necessary for their application. In Industry 5.0, DT enables analysis, monitoring, and prevention of issues before they occur in the real world, offering significant value for the development of personalized products and innovative business models. With IoT and advancements in AI, ML, and big data analytics, DT reduces maintenance costs, improves system performance, and helps prevent major financial losses. |

| Collaborative Robots | Cobots are robots designed to work alongside humans, providing increased efficiency and safety in the work environment. They have the ability to detect unforeseen impacts and immediately stop when they detect objects in their path. While efficient in large-scale production, managing human connections remains important in tasks that require critical thinking and customization. |

| Internet of Everything | Internet of Everything (IoE) connects people, processes, information, and objects, offering benefits for Industry 5.0 such as enhancing customer experience and reducing operational costs. IoE can optimize the supply chain, reduce waste, and improve production processes. Wireless technology and sensors are used for information exchange, such as in the Internet of Medical Things. |

| Big Data | Big Data is a technology that stores large amounts of complex data using IoT devices and provides significant services to manufacturers and service providers. Big Data Analytics enables the analysis of large volumes of data, allowing for mass customization and a better understanding of consumer behavior in Industry 5.0. With the integration of Big Data and IoT, real-time information can be collected to optimize production, reduce costs, and make more informed decisions. |

| Blockchain | Blockchain is a secure and decentralized technology that protects customer data against deletion, tampering, and revision, making it suitable for handling data privacy and traceability. It can be used to create distributed management platforms, providing transparency and immutability for significant event records in Industry 5.0. Additionally, it enables the execution of smart contracts to enforce security measures and automate processes. |

| 6G | The 6G technology can offer valuable services for Industry 5.0, with dense infrastructure, reduced latency, and integrated AI capabilities. 6G networks can enhance the performance of Industry 5.0 applications, but energy efficiency needs to be ensured. Quantum and free-space optical communication can help address high data rate challenges. |

| Artificial Intelligence | Artificial intelligence provides human-like capabilities to perform tasks in the manufacturing field, enabling the solution of complex problems in a faster and more cost-effective manner. Additionally, AI is capable of understanding the functioning of the human brain and efficiently executing high-level tasks, enhancing the thinking process and directing the system towards powerful and predictive intelligence. |

With greater manufacturing flexibility, this neoindustrialization can meet and even exceed customer satisfaction requirements, personalization, enhanced productivity, efficiency, and product quality. Raw material waste is reduced as products are manufactured according to customer demand. Industry 5.0 utilizes devices, systems, automation, and intelligent and innovative materials [14].

In addition to the mentioned technologies, software, applications, and platforms play a crucial role in enhancing experiences and implementing intelligent manufacturing, from the perspective of Industry 5.0. These technologies enable control and monitoring of manufacturing processes, facilitating efficient and high-quality production. Regarding the design and manufacturing of complex-shaped products, the mentioned technologies are essential. They allow for 3D modeling and simulation of products before physical production, reducing the need for storing large quantities of finished products. Instead, designs can be stored digitally and produced on-demand, reducing inventory costs and minimizing waste [14]. To make the above a reality, technology will have a crucial role in operationalizing Industry 5.0.

6. The Human-Machine Relationship in the Industry

The relationship between humans and machines is referred to in the literature as Human-Machine Interaction (HMI) and can be characterized as “a form of communication and interaction between human users and machines in a dynamic environment through various interfaces” [28], p. 23. Throughout successive industrial revolutions and changes in manufacturing paradigms, this relationship has undergone significant transformations, influenced by human needs and the technologies available in each period [29].

As technology advances, machines acquire new functions, capabilities, and even skills that were once exclusive to humans, such as vision, inference, and classification [29]. This interaction has been present since humans began to build tools [28]. With the emergence of new revolutions and changes in manufacturing paradigms, the relationship between humans and machines becomes increasingly relevant and complex [29].

The next industrial evolution is characterized by leveraging the creativity and innovative potential of human experts in collaboration with efficient, intelligent, and precise machines in order to achieve resource efficiency and user/consumer-driven custom manufacturing solutions [27][30][31].

Humans have a limit to their cognitive capacity, which can affect their performance in certain tasks. On the other hand, machines have the ability to process massive amounts of information. By utilizing machines, which have greater processing capacity, it is possible to reduce the cognitive load on humans. This allows humans to focus on activities that require uniquely human skills, while machines handle the task of information processing. This task distribution aims to optimize overall performance and improve efficiency by leveraging the complementary abilities of humans and machines [32]. The adoption of Industry 5.0 technologies, therefore, will not undermine human value; on the contrary, it will enable the integration of human intelligence and machine intelligence in a collaborative environment [3].

In this context, dedicated manufacturing systems are being replaced by intelligent and flexible manufacturing systems with the introduction of collaborative machines driven by artificial intelligence, transforming the way work is performed on the factory floor [7]. The focus shifts to the role of humans in this technological transition, with attention to the collaboration between humans and robots in Industry 5.0 [31], aiming to enhance human capabilities and well-being [7].

To achieve this, it is necessary to develop a human-centered manufacturing system that optimizes its benefits for humans. Based on this premise, Lu et al. [7] propose a framework that seeks the symbiosis between humans and machines, where both form intelligent teams to collectively perceive, reason, and act in response to manufacturing tasks and contingencies.

The human-centric approach focuses on satisfying needs and promoting the well-being of individuals, taking into consideration their capacity to learn and adapt. These characteristics well define the new concept of neoindustrialization, highlighting the importance of placing humans at the center of the industrial processes and considering their well-being and adaptability as essential factors.

By adopting this approach, as artificial intelligence technologies advance, Industry 5.0 will transform production systems worldwide, allowing repetitive tasks to be performed by machines, freeing human workers for more creative and challenging activities [30]. Empathetic machines and high-performing human colleagues in dynamically coexisting environments will make manufacturing more resilient, flexible, and sustainable [7].

The collaborative relationship between humans and machines, referred to as human-machine symbiosis by [7], can enable the following benefits: (a) human well-being: reduction of stressful and repetitive operations that can expose the worker to potential health and safety risks; (b) flexibility in manufacturing: manufacturing systems and processes can be instantly reconfigured to respond to product dynamics, human behavior, and production systems; (c) development of human and machine capability: with intelligent AI-based algorithms, humans and machines can learn and develop their capabilities through joint work experiences; (d) increased efficiency and productivity: machines can help automate repetitive tasks and production processes, allowing workers to focus on more complex tasks that require unique human skills; (e) improved product quality: machines can perform tasks with greater precision and consistency than humans, which can lead to an improvement in the quality of the final product; (f) enhanced workplace safety: machines can handle hazardous or repetitive tasks that pose risks to worker safety, reducing the risk of injuries or workplace accidents; (g) higher worker satisfaction: by automating repetitive tasks, workers can focus on tasks that require human skills such as creativity and critical thinking, making the work more challenging and interesting; (h) cost reduction: automation can reduce the time and cost associated with production, as well as reduce material waste; (i) better decision-making: machines can provide real-time data analytics and insights, enabling workers to make more informed and effective decisions [7][31][33]

Despite the technological advancements and digitalization driving Industry 5.0, there are still challenges to be faced, including: (a) lack of skills and training: the introduction of advanced technology will require skills and training that workers currently lack. In this regard, according to [34], the future workforce should be prepared to discern and understand the different production systems in order to make relevant decisions regarding the various approaches to work: whether through exclusive human effort, exclusive technological effort, or a harmonious collaboration between both. It is essential for professionals to have the experience and knowledge required to make informed choices, aiming to optimize production processes and achieve superior results. The lack of proper skills and training can lead to errors and reduce overall production efficiency; (b) resistance to change: some workers may resist the adoption of new technologies, concerned about job loss or changes in their roles. This can create a climate of mistrust and resistance that hinders the adoption of new technologies; (c) privacy and security concerns: the introduction of advanced technology can increase the risk of privacy breaches and data security, especially if sensitive worker information is collected and stored by machines; (d) liability in case of failures: Automation may reduce the need for workers in certain tasks, but it can also increase liability in case of failures or errors made by the machines; (e) high cost: the introduction of advanced technology can be expensive and may require significant investment in hardware and software, as well as ongoing updates and maintenance; (f) excessive dependency: excessive reliance on advanced technology can make production vulnerable to technical failures or disruptions in power supply or connectivity [7][31][33].

In the context of the neoindustrialization of Industry 5.0, the human-machine interaction represents one of its key characteristics and challenges. This new stage of industrial evolution is not just about automation and digitalization, but rather the harmonious and collaborative integration between humans and intelligent systems. It seeks to combine the best of both worlds: the unique capacity of humans for creativity, complex problem-solving, and understanding social and emotional nuances, with the efficiency, precision, and data processing capability of machines.

References

- Sindhwani, R.; Afridi, S.; Kumar, A.; Banaitis, A.; Luthra, S.; Singh, P.L. Can industry 5.0 revolutionize the wave of resilience and social value creation? A multi-criteria framework to analyze enablers. Technol. Soc. 2022, 68, 101887.

- Longo, F.; Padovano, A.; Umbrello, S. Value-oriented and ethical technology engineering in industry 5.0: A human-centric perspective for the design of the factory of the future. Appl. Sci. 2020, 10, 4182.

- Di Nardo, M.; Yu, H. Special Issue. Industry 5.0: The prelude to the sixth industrial revolution. Appl. Syst. Innov. 2021, 4, 45.

- European Commission. Industry 5.0: Towards a Sustainable, Human-Centric and Resilient European Industry; European Commission, Directorate-General for Research and Innovation: Luxembourg, 2021.

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0: Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535.

- Müller, J.M.; Kiel, D.; Voigt, K.-I. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247.

- Lu, Y.; Adrados, J.S.; Chand, S.S.; Wang, L. Humans are not machines—Anthropocentric human–machine symbiosis for ultra-flexible smart manufacturing. Engineering 2021, 7, 734–737.

- Paschek, D.; Mocan, A.; Draghici, A. Industry 5.0—The expected impact of next industrial revolution. In Proceedings of the Make Learn and TIIM International Conference, Piran, Slovenia, 15–17 May 2019; Thriving on Future Education, Industry, Business and Society. Dermol, V., Ed.; ToKnowPress: Piran, Slovenia, 2019; pp. 125–132.

- Madsen, D.; Berg, T. An Exploratory Bibliometric Analysis of the Birth and Emergence of Industry 5.0. Appl. Syst. Innov. 2021, 4, 87.

- Demir, K.A.; Döven, G.; Sezen, B. Industry 5.0 and human-robot Co-working. Proc. Comput. Sci. 2019, 158, 688–695.

- Welfare, K.S.; Hallowell, M.R.; Shah, J.A.; Riek, L.D. Consider the Human Work Experience When Integrating Robotics in the Workplace. In Proceedings of the 2019 14th ACM/IEEE International Conference on Human-Robot Interaction (HRI), Daegu, Republic of Korea, 11–14 March 2019; pp. 75–84.

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371.

- Aslam, F.; Aimin, W.; Li, M.; Rehman, K.U. Innovation in the Era of IoT and Industry 5.0: Absolute Innovation Management (AIM) Framework. Information 2020, 11, 124.

- Javaid, M.; Haleem, A. Critical components of Industry 5.0 towards a successful adoption in the field of manufacturing. J. Ind. Integr. Manag. 2020, 5, 327–348.

- Nelles, J.; Kuz, S.; Mertens, A.; Schlick, C.M. Human-centered design of assistance systems for production planning and control: The role of the human in Industry 4.0. In Proceedings of the 2016 IEEE International Conference on Industrial Technology (ICIT), Taipei, Taiwan, 14–17 March 2016; pp. 2099–2104.

- Özdemir, V.; Hekim, N. Birth of industry 5.0: Making sense of big data with artificial intelligence. The Internet of things and next-generation technology policy. OMICS J. Integr. Biol. 2018, 22, 65–76.

- Reinhardt, D.; Haeusler, M.H.; London, K.; Loke, L.; Feng, Y.; De Oliveira Barata, E.; Firth, C.; Dunn, K.; Khean, N.; Fabbri, A.; et al. CoBuilt 4.0: Investigating the potential of collaborative robotics for subject matter experts. Int. J. Archit. Comput. 2020, 18, 353–370.

- Zhong, R.; Xu, X.; Klotz, E.; Newman, S. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630.

- Sousa, S.A. Um modelo evolucionário de busca tecnológica em condições de hipercumulatividade. Rev. Bras. Econ. 2005, 59, 335–380.

- Saniuk, S.; Grabowska, S.; Straka, M. Identification of Social and Economic Expectations: Contextual Reasons for the Transformation Process of Industry 4.0 into the Industry 5.0 Concept. Sustainability 2022, 14, 1391.

- Available online: https://industriabrasileira.portaldaindustria.com.br/grafico/transformacao/mundo/#/industria-total (accessed on 13 April 2023).

- Departamento de Pesquisas e Estudos Econômicos. Panorama da Indústria Brasileira. FIESP. 2017. Available online: http://www.fiesp.com.br/arquivo-download/?id=236253 (accessed on 13 April 2023).

- Bacha, E. O Futuro da indústria no Brasil: Desindustrialização em Debate; Editora José Olympio: Rio de Janeiro, Brazil, 2015.

- Federação das Indústrias do Rio de Janeiro—FIRJAN. Panorama da Inovação—Indústria 4.0; FIRJAN: Rio de Janeiro, Brazil, 2016.

- Firmino, A.S.; Perles, G.X.; Mendes, J.V.; Silva, J.E.A.R.D.; Silva, D.A.L. Towards Industry 4.0: A SWOT-based analysis for companies located in the Sorocaba Metropolitan Region (São Paulo State, Brazil). Gestão Produção 2020, 27, e5622.

- Confederação Nacional de Indústria—C.N.I. Desafios para Indústria 4.0 no Brasil; CNI: Brasília, Brazil, 2016.

- Maddikunta, P.K.R.; Pham, Q.-V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Liyanage, M. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 2022, 26, 100257.

- Nardo, M.; Forino, D.; Murino, T. The evolution of man–machine interaction: The role of human in Industry 4.0 paradigm. Prod. Manuf. Res. 2020, 8, 20–34.

- Pizón, J.; Gola, A. Human–Machine Relationship—Perspective and Future Roadmap for Industry 5.0 Solutions. Machines 2023, 11, 203.

- Adel, A. Future of industry 5.0 in society: Human-centric solutions, challenges and prospective research areas. J. Cloud. Comp. 2022, 11, 40.

- Jafari, N.; Azarian, M.; Yu, H. Moving from Industry 4.0 to Industry 5.0: What Are the Implications for Smart Logistics? Logistics 2022, 6, 26.

- Villalba-Diez, J.; Ordieres-Meré, J. Human–Machine Integration in Processes within Industry 4.0 Management. Sensors 2021, 21, 5928.

- Alves, J.; Lima, T.M.; Gaspar, P.D. Is Industry 5.0 a Human-Centred Approach? A Systematic Review. Processes 2023, 11, 193.

- Broo, D.G.; Kaynak, O.; Sait, S.M. Rethinking engineering education at the age of industry 5.0. J. Ind. Inf. Integr. 2022, 25, 100311.

More

Information

Subjects:

Operations Research & Management Science

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.8K

Revisions:

2 times

(View History)

Update Date:

11 Aug 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No