Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Duygu AĞAGÜNDÜZ | -- | 2088 | 2023-08-08 08:44:28 | | | |

| 2 | Catherine Yang | Meta information modification | 2088 | 2023-08-08 08:50:56 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Icer, M.A.; Özbay, S.; Ağagündüz, D.; Kelle, B.; Bartkiene, E.; Rocha, J.M.F.; Ozogul, F. Acidophilic Lactic Acid Bacteria in Foods and Health. Encyclopedia. Available online: https://encyclopedia.pub/entry/47771 (accessed on 07 February 2026).

Icer MA, Özbay S, Ağagündüz D, Kelle B, Bartkiene E, Rocha JMF, et al. Acidophilic Lactic Acid Bacteria in Foods and Health. Encyclopedia. Available at: https://encyclopedia.pub/entry/47771. Accessed February 07, 2026.

Icer, Mehmet Arif, Sena Özbay, Duygu Ağagündüz, Bayram Kelle, Elena Bartkiene, João Miguel F. Rocha, Fatih Ozogul. "Acidophilic Lactic Acid Bacteria in Foods and Health" Encyclopedia, https://encyclopedia.pub/entry/47771 (accessed February 07, 2026).

Icer, M.A., Özbay, S., Ağagündüz, D., Kelle, B., Bartkiene, E., Rocha, J.M.F., & Ozogul, F. (2023, August 08). Acidophilic Lactic Acid Bacteria in Foods and Health. In Encyclopedia. https://encyclopedia.pub/entry/47771

Icer, Mehmet Arif, et al. "Acidophilic Lactic Acid Bacteria in Foods and Health." Encyclopedia. Web. 08 August, 2023.

Copy Citation

Acidophilic lactic acid bacteria (LAB) are the most commonly used low-pH microorganisms in the healthcare, pharmaceutical, and food industries.

lactic acid bacteria

probiotics

beneficial compounds

toxic compounds

1. Their Utilization in Fermentation Technology as Starter Cultures

The preservation of foods by fermentation is an ancient, widely practiced method. Fermentation increases the shelf life and microbiological safety of a food [1]. Fermentation also yields new products.

The production of these foods in the past was traditional and secretive due to the long history of fermented foods. Today, fermentation is carried out under controlled conditions with strains that have been carefully chosen [2]. Traditionally, fermentation was carried out by inoculation from the previous batch. However, at present, there are starter cultures for fermentation, thus standardizing the process and product quality.

LAB play a role in the fermentation processes of milk, meat, grains and vegetables owing to their metabolic properties [1]. However, the optimum pH for the growth of most LAB is close to neutral. Therefore, it should be noted that most LAB are neutrophilic. However, some bacterial species, such as Lactobacillus and Oenococcus, show more acidophilic behavior [3]. Lactobacilli are usually aciduric or acidophilic. These microorganisms are also strictly fermentative, oxygen-tolerant or anaerobic and have complex nutritional requirements, including carbohydrates, amino acids, peptides, fatty acid esters, salts, nucleic acid derivatives and vitamins [4].

LAB are also significant in animal foods. In the past, straw was used to store grass for use as animal feed. At present, animal feed preserves more nutrients when converted into silage. This process was only made possible when the fermentation of lactic acid bacteria was understood [2]. In this way, acidophilic LAB are used as a starter culture in the production of food.

Lactobacillus delbrueckii subsp. Bulgaricus, used as a starter culture, is an important Lactobacilli. This microorganism is a Gram-positive rod, non-motile, and does not form spores. It is considered either aciduric or acidophilic. It requires a low pH (approximately 5.4–4.6) to grow effectively in the optimum temperature range from 43 to 46 °C [5]. Lactobacillus delbrueckii subsp. bulgaricus is widely used together with Streptococcus thermophilus as a starter culture in yogurt production [6]. However, studies have shown that a wide variety of LAB have been isolated. Aslam and Qazi (2010) isolated Lactobacillus delbrueckii subsp. bulgaricus, Lacticaseibacillus casei, Lactobacillus acidophilus and Ligilactobacillus salivarius from local yogurts in their study and reported that they have high acid tolerance properties [7]. Similarly, Latilactobacillus sakei is a species of microorganism from the same family, which is a facultative heterofermentative that can produce alcohol or lactic acid from sugars. It is used as a starter culture in meat products [8]. For instance, the genus Lactobacillus, which is frequently found in meat and processed food, as well as different fermented food products, includes the species Lactiplantibacillus plantarum. Sauerkraut, pickles, pickled olives, Korean kimchi, Nigerian ogis, sourdough and some cheeses, fermented sausages, and pickled olives contain Lactiplantibacillus plantarum. A homofermentative genus of LAB is called Lactococcus. They can be modified by changing environmental factors such as pH, glucose concentration, and nutrient limitations due to their homofermentative nature. They are a Gram-positive, catalase-negative, dormant cocci in single, double or chain forms [5]. These organisms are widely used in the dairy industry in the production of fermented milk products such as cheese. They can be used in starter cultures with single strains or mixed strains with other LAB, such as Lactobacillus and Streptococcus. Lactococcus lactis and its subspecies lactis and cremoris are important starter cultures in industrial dairy fermentation [9].

Another LAB, the Weissella species, has been isolated from a wide range of habitats, including milk, vegetables, and different fermented foods such as European sourdoughs and traditional Asian and African fermented foods [5]. Important species of acidophilic and aciduric LAB, along with the food sources from which they were obtained, are shown in Table 1.

Table 1. Important species of acidophilic and aciduric LAB with the food sources (adapted from the references [10][11]).

| Microorganism | Food in Which İt İs İsolated/Used |

|---|---|

| Lactobacillus delbrueckii subsp. bulgaricus | Dairy products |

| Ligilactobacillus acidipiscis | |

| Lactobacillus acidophilus | |

| Lactobacillus delbrueckii subsp. lactis | |

| Levilactobacillus brevis | |

| Lacticaseibacillus casei | |

| Lactiplantibacillus plantarum | |

| Loigolactobacillus coryniformis subsp. coryniformis | |

| Lactobacillus helveticus | |

| Levilactobacillus parabrevis | |

| Lacticaseibacillus paracasei subsp. paracasei | |

| Lactiplantibacillus pentosus | |

| Lactiplantibacillus plantarum subsp. plantarum | |

| Weissella hellenica | |

| Weisella paramesenteroides | |

| Weisella confusa | |

| Lactobacillus helveticus | Probiotic Dairy Products |

| Lacticaseibacillus casei | |

| Lacticaseibacillus rhamnosus | |

| Limosilactobacillus reuteri | |

| Lactiplantibacillus plantarum | Sauerkraut |

| Lactiplantibacillus plantarum | Meat, Meat Products |

| Companilactobacillus alimentarius | |

| Latilactobacillus curvatus subps. curvatus | |

| Lapidilactobacillus dextrinicus | |

| Lacticaseibacillus paracasei subsp. paracasei | |

| Lactiplantibacillus plantarum subsp. plantarum | |

| Latilactobacillus sakei subsp. sakei | |

| Weisella hellenica | |

| Weisella viridescens | |

| Weisella paramesenteroides | |

| Weisella confusa | |

| Lactobacillus acetotolerans | Vegetables |

| Levilactobacillus brevis | |

| Lactobacillus acidophilus | |

| Schleiferilactobacillus harbinensis | |

| Lactobacillus helveticus | |

| Companilactobacillus kimchii | |

| Lentilactobacillus kisonensis | |

| Levilactobacillus parabrevis | |

| Lactiplantibacillus plantarum subsp. plantarum | |

| Weisella paramesenteroides | |

| Weisella confusa | |

| Levilactobacillus acidifarinae | Sourdough |

| Lactobacillus amylolyticus | |

| Lactobacillus amylovorus | |

| Lentilactobacillus parabuchneri | |

| Lactobacillus crispatus | |

| Limosilactobacillus fermentum | |

| Companilactobacillus crustorum | |

| Lactobacillus gasseri | |

| Levilactobacillus hammesii | |

| Fructilactobacillus fructivorans | |

| Lactobacillus jensenii | |

| Lactobacillus johnsonii | |

| Lacticaseibacillus manihotivorans | |

| Companilactobacillus mindensis | |

| Limosilactobacillus mucosae | |

| Weisella cibaria | |

| Weisella confusa | |

| Ligilactobacillus acidipiscis | Fish |

| Companilactobacillus alimentarius | |

| Companilactobacillus farciminis | |

| Weisella thailandensis | |

| Lentilactobacillus parabuchneri | Wine |

| Lentilactobacillus hilgardii | |

| Liquorilactobacillus oeni | |

| Lactiplantibacillus pentosus | |

| Liquorilactobacillus cacaonum | Cocoa |

| Lactiplantibacillus fabifermentans | |

| Liquorilactobacillus ghanensis | |

| Liquorilactobacillus nagelii | |

| Secundilactobacillus collinoides | Fruits |

| Liquorilactobacillus mali | |

| Lactiplantibacillus pentosus | |

| Paucilactobacillus suebicus | |

| Agrilactobacillus composti | Beverages |

| Fructilactobacillus fructivorans | |

| Liquorilactobacillus hordei | |

| Latilactobacillus sakei subsp. sakeii | |

| Liquorilactobacillus mali | |

| Lentilactobacillus diolivorans | Cereals |

| Limosilactobacillus frumenti | |

| Companilactobacillus farciminis | Soy |

2. Food Safety and Stability Issues

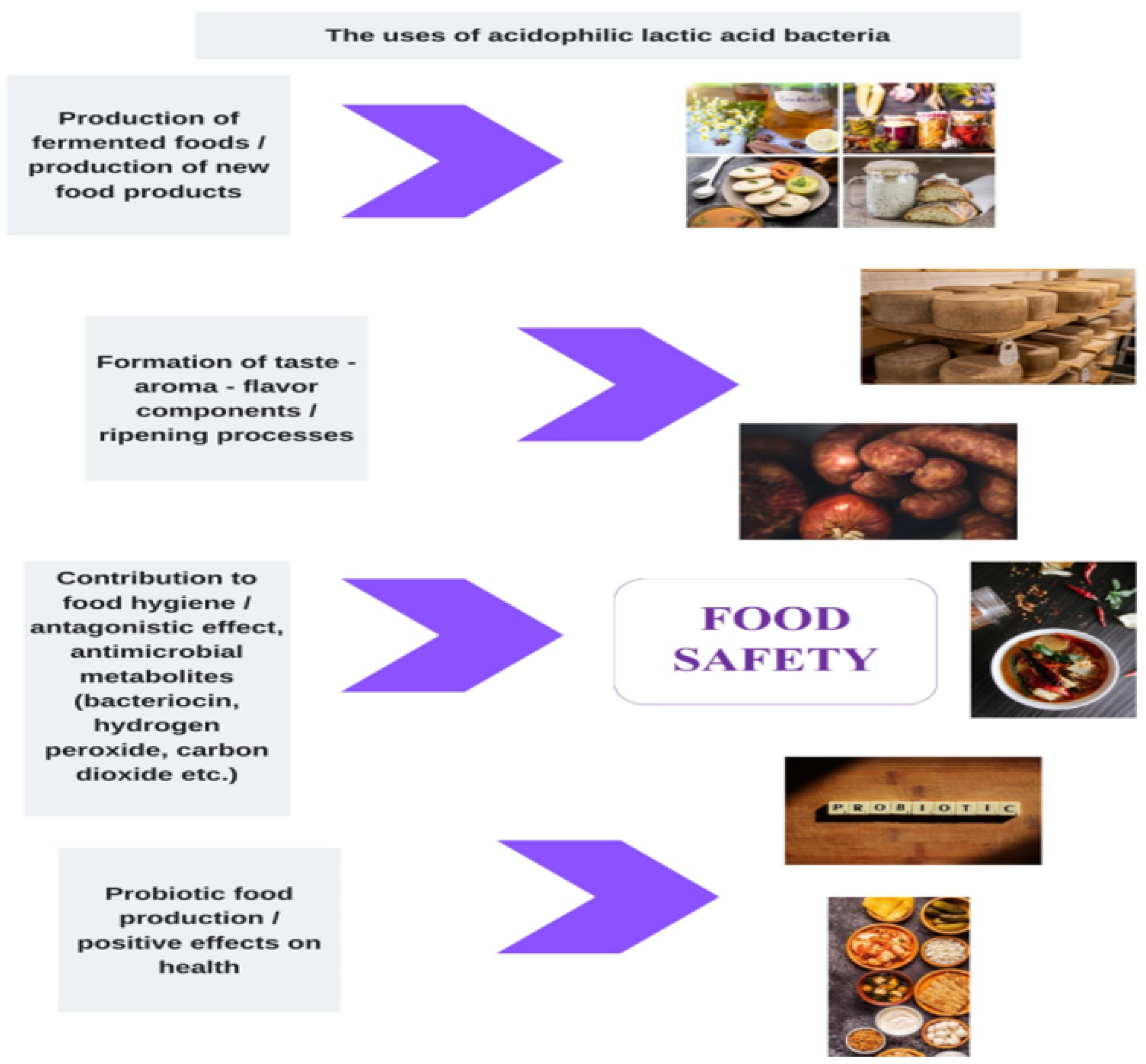

In traditional fermented food production, the food is produced by inoculating the fermented food that is produced beforehand. However, this situation is mostly valid for home-type food production at present. One of the important steps to ensure food safety and stabilization in large-scale, standard fermented food production is the use of starter cultures. Acidophilic–aciduric microorganisms are also involved in various production processes for fermented foods. In this situation, acidophilic LAB are used as a starter culture for several purposes. Producing fermented dairy products such as meat, fish, fruit, vegetable, and cereal products is the major objective of the usage of acidophilic LAB. Another objective is to enhance the nutritional value, flavor, and texture of fermented foods by producing flavor compounds. In this regard, the maturation process is very significant. The most prevalent acidophilic LAB identified in ripened cheeses are Pediococcus acidilactici and Pediococcus pentosaceus [12]. Despite not being a starter, acidophilic LAB can be isolated from many foods. For example, nonstarter Lacticaseibacillus casei, which has a wide pH and temperature range, can be found in ripe cheddar cheese and Sicilian green olives [5].

In addition, another purpose of the use of acidophilic LAB, which is used as a starter culture, is the support of food hygiene. The majority of acidophilic LAB live independently of any host species, are not pathogenic, and produce no products that are toxic or unpleasant to humans. Therefore, people can consume fermented foods formed by the growth of acidophilic LAB. The reducing conditions provided by these bacteria and low-pH habitats with high concentrations of fermented acids can inhibit the growth of many bacteria [2][13]. For example, they have been reported to inhibit the growth of Listeria monocytogenes and Escherichia coli O157:H7 in the processed meat products from which Latilactobacillus sakei is isolated [8].

It is clear that the fermentation process used by acidophilic LAB improves food flavor, aroma, and hygiene. It should be noted that some acidophilic and aciduric microorganisms contribute to food spoilage. Bacillus coagulans, a microaerophilic, slightly acidophilic, and heat-tolerant species, was isolated from spoiled canned milk and first described in 1915. This microorganism is highly suitable for development in acidic food due to its acidophilic nature. Moreover, it has been isolated from this type of food and is usually identified as the cause of spoilage in dairy products, vegetables, and fruits. High levels of lactic acid are produced as a result of this type of degradation [14]. Bacillus coagulans is also a thermophile, but differs from Geobacillus stearothermophilus (previously Bacillus stearothermophilus) as it can grow at pH values below 4.0 [15]. During deterioration, it causes the product to become tasteless and sour. Generally speaking, Bacillus coagulans has caused significant economic losses for the food industry due to flat-sour spoilage in canned foods [16]. Similarly, Alicyclobacillus acidoterrestris is an obligate acidophilic that grows optimally at pH 3.5–4.0 and has a pH of 2.5–5.5 for growth. Alicyclobacillus is the only spore-producing acidophilic genus that has been described as a cause of spoilage at these pH values to date [5]. Alicyclobacillus acidoterrestris spores are generally more heat resistant than other acidophilic spore formers and cause the spoilage of processed fruit and vegetable juices and concentrates [17][18]. Some species in the genus Alicyclobacillus have greater perishability as they can produce large amounts of guaiacol, which negatively affects the odor of the product [18]. In addition, butyric anaerobes, Clostridium butyricum, Clostridium beijerinckii and Clostridium pasteurianum, which cause spoilage in low-acid canned foods, are generally associated with the spoilage of products with pH values between 3.9 and 4.5 [5].

In conclusion, acidophilic microorganisms can often result in losses, food deterioration, and changes in food stability. These different acidophilic and aciduric microorganism states occupy different places on the benefit–harm axis. The importance of using acidophilic LAB as a starter culture in the production of fermented foods, in the development of new foods, and in the formation of the texture, taste, aroma and odor of products, is indisputable. Moreover, they improve food hygiene by limiting other microbial species’ ability to reproduce by balancing the pH of the food. In acidic food production lines, where production hygiene and processes are taken into consideration, the hazards produced by acidophilic LAB can be minimized, ensuring that the negative impacts of these microorganisms on food safety and stability do not occur.

3. Effects of Acidophilic Lactic Acid Bacteria on the Nutritional Value of Foods

It is known that acidophilic LAB are generally used in the production of fermented products. In this regard, the expected benefits and effects of the fermentation process can often be evaluated as the benefits provided by acidophilic LAB.

The most important output of the fermentation process is the production of organic acids. These organic acids (lactic acid, acetic acid, formic acid, propionic acid) are important food preservatives [19]. The antagonistic activity of acidophilic LAB against other microorganisms is due to the metabolites they produce, such as bacteriocin [20]. Thus, acidophilic LAB provide hygienic conditions by preventing and even eliminating food pathogens [11], since acidophilic LAB are used as bioprotective cultures [21]. Acidophilic LAB provide hygienic and organoleptic benefits, especially in fermented foods such as yogurt, wine and cheese [22]. In addition to its known benefits, acidophilic LAB can bind heavy metals in the water and environmental matrix. This is especially useful in the aquaculture industry [19].

Moreover, acidophilic LAB are used in the production of probiotic foods, which plays a critical role in maintaining human health. Due to their potential benefits as probiotics, the acidophilic Lactobacillus species are the most commonly used group of microorganisms within the LAB group [23]. Acidophilic LAB are also important because of the antimicrobial and antifungal substances they produce. Thus, they also reduce the formation of mycotoxins. In addition, it is possible to increase the bioavailability of grain-based products by fermentation with the fermentation activities of LAB [24]. It is possible to obtain healthier, more delicious and innovative products with the lactic acid fermentation of legumes [25]. The benefits of the fermented product produced by acidophilic LAB fermentation of soy milk, whose consumption has increased in recent years, are also emphasized. Various enhanced health benefits of this fermented product have also been reported, including bioactive compounds, enhanced nutritional values, and antihypertensive, antioxidant, antidiabetic, anticancer, and hypocholesterolemic effects [26]. It was also reported that the soluble dietary fiber, total polyphenol content and organic acid levels of potatoes increased at the end of the fermentation process of sweet potatoes using acidophilic LAB [27]. It is also known that many intestinal and urinary pathogenic bacteria are inhibited by the antagonistic activity of these microorganisms [7]. Furthermore, certain strains of the important acidophilus Lactobacillus acidophilus have been found to absorb cholesterol in the intestines [23]. It has also been reported that LAB’s dominance in the gut microbiota may be one of the ways to treat obesity [28].

In general, acidophilic–aciduric microorganisms affect the nutritional value of foods, both by preserving the food and its positive effects on human health. Specifically, with the use of acidophilic LAB as a starter culture in foods, it is stated that aroma, taste, texture, odor, and beneficial microorganism growth increase, while preservatives, artificial sweeteners, sucrose, lactose, oil and contaminants decrease in food [10]. Although many food-preserving processes and substances have been developed in advanced food production techniques, the conditions provided by fermentation are essential for ensuring the shelf life and microbiological safety of products [1]. Figure 1 shows the effects of low-pH microorganisms on the nutritional values and safety of foods.

Figure 1. The effects of low-pH microorganisms on the nutritional value and safety of foods.

References

- Mannaa, M.; Han, G.; Seo, Y.S.; Park, I. Evolution of Food Fermentation Processes and the Use of Multi-Omics in Deciphering the Roles of the Microbiota. Foods 2021, 10, 2861.

- Garvie, E.I. Bacterial lactate dehydrogenases. Microbiol. Rev. 1980, 44, 106–139.

- du Toit, M.; Engelbrecht, L.; Lerm, E.; Krieger-Weber, S. Lactobacillus: The next generation of malolactic fermentation starter cultures—An overview. Food Bioprocess Technol. 2011, 4, 876–906.

- Gürsoy, O.; kınık, Ö. Lactobacıllı and theır usage potentıal ın probıotıc cheese productıon. J. Eng. Sci. 2005, 11, 361–371.

- Lorenzo, J.M.; Munekata, P.E.; Dominguez, R.; Pateiro, M.; Saraiva, J.A.; Franco, D. Main groups of microorganisms of relevance for food safety and stability: General aspects and overall description. In Innovative Technologies for Food Preservation; Academic Press: Cambridge, MA, USA, 2018; pp. 53–107.

- Courtin, P.; Rul, F. Interactions between microorganisms in a simple ecosystem: Yogurt bacteria as a study model. Le Lait 2004, 84, 125–134.

- Aslam, S.; Qazi, J.I. Isolation of acidophilic lactic acid bacteria antagonistic to microbial contaminants. Pak. J. Zool. 2010, 42, 567–573.

- Laranjo, M.; Potes, M.E.; Elias, M. Role of Starter Cultures on the Safety of Fermented Meat Products. Front. Microbiol. 2019, 10, 853.

- Kleerebezem, M.; Bachmann, H.; van Pelt-KleinJan, E.; Douwenga, S.; Smid, E.J.; Teusink, B.; van Mastrigt, O. Lifestyle, metabolism and environmental adaptation in Lactococcus lactis. FEMS Microbiol. Rev. 2020, 44, 804–820.

- Johansen, E. Use of natural selection and evolution to develop new starter cultures for fermented foods. Annu. Rev. Food Sci. Technol. 2018, 9, 411–428.

- Bourdichon, F.; Boyaval, P.; Casaregola, S.; Dupont, J.; Farrokh, C.; Frisvad, J.; Hammes, W.; Huys, G.; Jany, J.; Laulund, S. 3 The 2012 Inventory of Microbial Species with technological beneficial role in fermented food products. Bull. Int. Dairy Fed. 2012, 455, 22–61.

- Tzora, A.; Nelli, A.; Voidarou, C.; Fthenakis, G.; Rozos, G.; Theodorides, G.; Bonos, E.; Skoufos, I. Microbiota “Fingerprint” of Greek Feta Cheese through Ripening. Appl. Sci. 2021, 11, 5631.

- Russell, J.B.; Diez-Gonzalez, F. The effects of fermentation acids on bacterial growth. Adv. Microb. Physiol. 1997, 39, 205–234.

- De Clerck, E.; Rodriguez-Diaz, M.; Forsyth, G.; Lebbe, L.; Logan, N.A.; DeVos, P. Polyphasic characterization of Bacillus coagulans strains, illustrating heterogeneity within this species, and emended description of the species. Syst. Appl. Microbiol. 2004, 27, 50–60.

- Haberbeck, L.U.; da Silva Riehl, C.A.; Salomão, B.d.C.M.; De Aragao, G.M.F. Bacillus coagulans spore inactivation through the application of oregano essential oil and heat. LWT-Food Sci. Technol. 2012, 46, 267–273.

- Lucas, R.; Grande, M.J.; Abriouel, H.; Maqueda, M.; Omar, N.B.; Valdivia, E.; Martínez-Cañamero, M.; Gálvez, A. Application of the broad-spectrum bacteriocin enterocin AS-48 to inhibit Bacillus coagulans in canned fruit and vegetable foods. Food Chem. Toxicol. 2006, 44, 1774–1781.

- Silva, F.V.; Gibbs, P. Target selection in designing pasteurization processes for shelf-stable high-acid fruit products. Crit. Rev. Food Sci. Nutr. 2004, 44, 353–360.

- Danyluk, M.D.; Friedrich, L.M.; Jouquand, C.; Goodrich-Schneider, R.; Parish, M.E.; Rouseff, R. Prevalence, concentration, spoilage, and mitigation of Alicyclobacillus spp. in tropical and subtropical fruit juice concentrates. Food Microbiol. 2011, 28, 472–477.

- Chizhayeva, A.; Amangeldi, A.; Oleinikova, Y.; Alybaeva, A.; Sadanov, A. Lactic acid bacteria as probiotics in sustainable development of aquaculture. Aquat. Living Resour. 2022, 35, 10.

- Sharma, H.; Ozogul, F.; Bartkiene, E.; Rocha, J.M. Impact of lactic acid bacteria and their metabolites on the techno-functional properties and health benefits of fermented dairy products. Crit. Rev. Food Sci. Nutr. 2023, 63, 4819–4841.

- Grattepanche, F.; Miescher-Schwenninger, S.; Meile, L.; Lacroix, C. Recent developments in cheese cultures with protective and probiotic functionalities. Dairy Sci. Technol. 2008, 88, 421–444.

- Xu, J.; Guo, L.; Zhao, N.; Meng, X.; Zhang, J.; Wang, T.; Wei, X.; Fan, M. Response mechanisms to acid stress of acid-resistant bacteria and biotechnological applications in the food industry. Crit. Rev. Biotechnol. 2022, 43, 258–274.

- Hammes, W.P.; Tichaczek, P.S. The potential of lactic acid bacteria for the production of safe and wholesome food. Z. Lebensm.-Unters. Und-Forsch. 1994, 198, 193–201.

- Wafula, E.N.; Muhonja, C.N.; Kuja, J.O.; Owaga, E.E.; Makonde, H.M.; Mathara, J.M.; Kimani, V.W. Lactic Acid Bacteria from African Fermented Cereal-Based Products: Potential Biological Control Agents for Mycotoxins in Kenya. J. Toxicol. 2022, 2022, 2397767.

- Emkani, M.; Oliete, B.; Saurel, R. Effect of Lactic Acid Fermentation on Legume Protein Properties, a Review. Fermentation 2022, 8, 244.

- Kumari, M.; Kokkiligadda, A.; Dasriya, V.; Naithani, H. Functional relevance and health benefits of soymilk fermented by lactic acid bacteria. J. Appl. Microbiol. 2022, 133, 104–119.

- Zhu, L.; Mu, T.; Ma, M.; Sun, H.; Zhao, G. Nutritional composition, antioxidant activity, volatile compounds, and stability properties of sweet potato residues fermented with selected lactic acid bacteria and bifidobacteria. Food Chem. 2022, 374, 131500.

- Burakova, I.; Smirnova, Y.; Gryaznova, M.; Syromyatnikov, M.; Chizhkov, P.; Popov, E.; Popov, V. The Effect of Short-Term Consumption of Lactic Acid Bacteria on the Gut Microbiota in Obese People. Nutrients 2022, 14, 3384.

More

Information

Subjects:

Nutrition & Dietetics

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.5K

Revisions:

2 times

(View History)

Update Date:

08 Aug 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No