Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Hilal El-Hassan | -- | 2571 | 2023-08-03 08:42:53 | | | |

| 2 | Jason Zhu | Meta information modification | 2571 | 2023-08-07 04:58:17 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Hwalla, J.; Bawab, J.; El-Hassan, H.; Abu Obaida, F.; El-Maaddawy, T. Research Trends of Geopolymer Composites in Construction. Encyclopedia. Available online: https://encyclopedia.pub/entry/47593 (accessed on 07 February 2026).

Hwalla J, Bawab J, El-Hassan H, Abu Obaida F, El-Maaddawy T. Research Trends of Geopolymer Composites in Construction. Encyclopedia. Available at: https://encyclopedia.pub/entry/47593. Accessed February 07, 2026.

Hwalla, Joud, Jad Bawab, Hilal El-Hassan, Feras Abu Obaida, Tamer El-Maaddawy. "Research Trends of Geopolymer Composites in Construction" Encyclopedia, https://encyclopedia.pub/entry/47593 (accessed February 07, 2026).

Hwalla, J., Bawab, J., El-Hassan, H., Abu Obaida, F., & El-Maaddawy, T. (2023, August 03). Research Trends of Geopolymer Composites in Construction. In Encyclopedia. https://encyclopedia.pub/entry/47593

Hwalla, Joud, et al. "Research Trends of Geopolymer Composites in Construction." Encyclopedia. Web. 03 August, 2023.

Copy Citation

Conventional cement-based composites, such as concrete and mortar, are ranked as the most used construction materials in the world. Concrete and mortar are mainly produced with ordinary Portland cement (OPC), coarse and fine aggregates, water, and additives. The widespread use of OPC by the construction industry is attributed to its impressive performance, affordability, availability, standardization, and compatibility with different types of materials and admixtures.

scientometric analysis

geopolymer

mortar

composites

1. Introduction

Conventional cement-based composites, such as concrete and mortar, are ranked as the most used construction materials in the world [1][2]. Concrete and mortar are mainly produced with ordinary Portland cement (OPC), coarse and fine aggregates, water, and additives. The widespread use of OPC by the construction industry is attributed to its impressive performance, affordability, availability, standardization, and compatibility with different types of materials and admixtures. Due to the increase in human population and the exponential increase in construction work, it is predicted that the OPC demand will reach 3.7–4.4 billion tons in 2050 [3]. In addition to the need for a large number of natural resources for the manufacture of OPC, it is estimated that this process emits around 6 to 9% of the total greenhouse gas emissions globally, which mainly result from the combustion of fossil fuels for the kiln, the heating limestone, and the consumption of electrical power [4]. Accordingly, the production of 1 ton of OPC emits 1 ton of CO2 and consumes 1.5 tons of natural resources [5]. In addition, OPC is ranked as the third most energy-intensive material, after steel and aluminum, with a percentage of global energy consumption of 7% [5][6][7]. These environmental concerns created a need to find alternative materials to partially or fully replace it.

Geopolymers and alkali-activated materials are cement-free composites formulated by activating alumino-silicate materials, such as fly ash, metakaolin, and silica fume, and calcium-rich materials, such as blast furnace slag or ladle slag, respectively, with a sodium, potassium, or carbonate hydroxide-based alkaline solution. In 1978, Prof. Joseph Davidovits introduced geopolymer materials in construction [8]. During the geopolymerization reaction, the dissolution of silicate and aluminate compounds creates oligomers that condensate to form an amorphous and partially crystalline structure of polymers [9][10]. In the last two decades, the performance of geopolymers has been extensively studied [11][12][13][14][15][16]. Since then, these cement-free materials have shown superior mechanical performance and a higher ability to maintain their properties under harsh environments to cement-based materials, such as high temperatures, salt and acid attacks [17][18][19][20][21]. Furthermore, the use of geopolymer mortar in various construction applications has been examined, such as corrosion-resistant materials [22][23][24], fire protection materials [17][18][25], repairing, strengthening, and retrofitting old structures [26][27][28][29][30][31][32], grouting [33][34], bonding [27][35], coating [22][24], masonry materials [36], and for underwater placing [15][37].

The number of scientific publications has been exponentially increasing. As such, it is becoming nearly unfeasible to cover all studies within a specific topic. Nowadays, scholars are using different approaches for conducting quantitative and qualitative literature reviews. The scientometric study has been introduced as an essential tool that gives an objective, reliable, transparent, and systematic review that covers scientific activities and publications describing a specific topic [38]. Based on the data extracted from publications (authors, total publications and citations, affiliations, countries, etc.), a scientometric analysis can display a structure analysis for a large number of data, show trends of paper publications and keywords over time, detect the most productive authors, countries, affiliations, and journals, infer gaps or shifts within a specific topic, and analyze the connections of the extracted data plotted in the form of mapping and clustering networks [39][40][41]. The scientometric analysis was described by Boquera et al. [42] as “a way to elucidate the past, present, and future within the different areas of knowledge, reporting the main research interest and future trends”. The deep analysis of keywords used by scholars to describe and summarize their research content is crucial to describe the current trending topics and their evolutions and to highlight gaps that can be covered in future work [39][41][43].

Lately, scientometric reviews have been used in different areas, such as cryptocurrency and stock markets [44], concrete as a thermal energy storage material [42], self-healing concrete [41], construction demolition waste management [45], biological water treatment [46], business and management [47], and sports [48], among others. Similarly, geopolymer and alkali-activated composites have been introduced in scientometric studies in recent years. Yang et al. [2] have found that the acceptance of geopolymer concrete by the industry is not achieved yet due to the lack of long-term performance testing. In addition, future work was suggested to examine the microstructure of the geopolymer matrix. Another study performed by Tian et al. [49] on fly ash-based geopolymers highlighted the high contribution and impact of China and Professor Davidovits as a prolific reference in the investigation and the development of fly ash-based geopolymer properties. According to Elmesalami and Celik [50], more studies should be carried out to evaluate the effect of steel polyethylene, glass basalt polypropylene, and natural microfibers on the properties of the engineered geopolymer composites. In addition, Ji and Pei [51] highlighted the efficiency of geopolymer composites in immobilizing heavy metals. Based on the literature, numerous articles have been published to investigate the use of geopolymers in different applications. Hence, there is a pressing need to determine the research trends and gaps for the use of geopolymers and alkali-activated materials in various construction applications.

2. Keyword Analysis

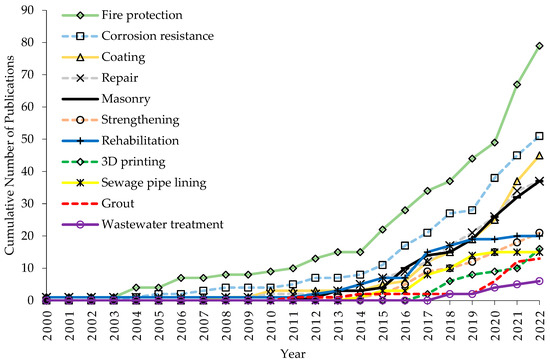

Figure 1 illustrates the evolution of investigating different types of applications of geopolymer mortars and composites between 2000 and 2022. Fire protection, corrosion resistance, coating, repair, and masonry were the top five applications with a cumulative number of publications of 79, 51, 45, 37, and 37 in 2022, respectively. Generally, the trend of this graph is similar to that of the total publications, where most applications have been investigated since 2013, except fire protection and corrosion resistance, which have been studies since 2003 and 2004, respectively.

Figure 1. Number of publications related to the top applications over time.

The early investigation of using geopolymer composites for fire protection can be related to their impressive ability to maintain their weight and strength under high-temperature exposure [25]. In addition, the paper published in 1997 by Lyon et al. [18] was used as a benchmark to advance the comprehension of geopolymers prepared with different precursors under high-temperature exposure. Similarly, the ability of geopolymer mortars and composites to protect steel reinforcement against corrosion has been assessed extensively. With a decrease in the matrix permeability caused by the formation of the dense N-A-S-H and C-A-S-H gels, lower amounts of chloride or carbon dioxide accessed the steel reinforcement [23][52].

Furthermore, over the last few years, several articles investigated the use of geopolymer composites in repair, strengthening, and rehabilitation applications, owing to their excellent bonding behavior [5][6][23][53][54]. Meanwhile, it was difficult to differentiate the use of geopolymers in masonry blocks and plastering applications. Thus, the term masonry in Figure 1 refers to both applications. Similar to repair, strengthening, and rehabilitation, geopolymer materials were only assessed in masonry production from 2013. Using geopolymer mortars is particularly beneficial for masonry applications to accelerate construction operations and eliminate water curing that is generally required for the strength gain of cement-based masonry materials [36][55][56].

New applications for geopolymer mortars have been explored in the last 5 years, including sewage lining, wastewater treatment, 3D printing, and grouting. The performance of geopolymer mortars in a sewage environment has been assessed in past studies [57][58][59][60]. A fly ash geopolymer mortar could be a sustainable alternative for a sulfate-resistant Portland cement-based mortar, owing to its superior ability to maintain its mass and greater depth of neutralization under a sewage environment [57][58]. In other work, Bogdan et al. suggested a geopolymer material for wastewater treatment applications. Results showed that geopolymer mortars limited the growth of microorganisms on the surfaces of concrete samples to a better extent than their plain Portland cement and calcium aluminate cement-based counterparts [61]. Lately, there has been an increasing interest in developing the thixotropic, mechanical, and bonding properties of fly ash and slag geopolymer mortars reinforced with different types of reinforcement for 3D printing applications [54][62][63][64][65]. Research findings noted that 3D printing parameters and material strength development mostly affected the interlayer bond strength [54][62]. Meanwhile, the addition of slag to a fly ash-based geopolymer 3D printed mortar required a faster printing time to counter the fast setting of slag-based geopolymers and to ensure proper bonding between the 3D-printed layers [63]. Furthermore, reinforcing 3D geopolymer composites with steel cables achieved 290% higher flexural strength than their plain counterparts [65]. For the production of geopolymer mortar as a grouting material, Gullu et al. [66] produced a fly ash-based geopolymer mortar with feasible rheological properties compared to a native cement grouting material.

Research gaps could be highlighted through the analysis of the trend of applications identified in Figure 1. Geopolymer mortars and composites have displayed impressive performances when used as fire and corrosion protection materials, coating and masonry materials, or for repair, strengthening, and rehabilitation applications. Yet, their adoption in such construction applications requires further assessment in terms of serviceability. Thus, future research entails focusing on examining the lifecycle and economic impact of geopolymer mortar and composites in such applications. Other construction applications for geopolymer mortars are yet to receive adequate attention, such as tunnel and pipe lining or underwater placing. Also, despite their aptitude to adsorb and immobilize heavy metals, as highlighted in [11], limited studies have been carried out in research field. Similarly, more work is needed in the recently explored applications, including 3D printing, wastewater treatment, sewage and tunnel lining, and as grouting materials. Such a demand for more research is to provide critical scientific evidence that could promote the adoption of geopolymer composites by relevant industries.

3. Keyword Co-Occurrence

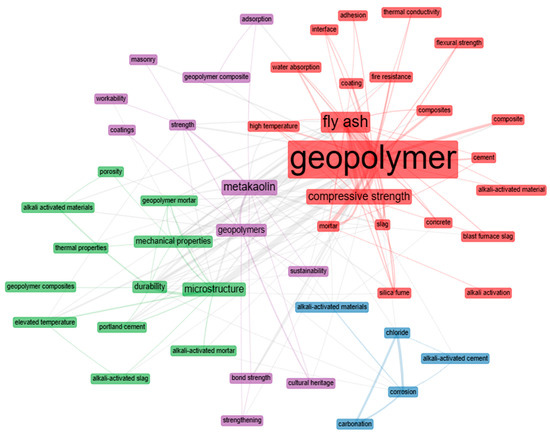

Bibliometrix was used to produce the authors’ keyword co-occurrence network. A threshold value of fifty nodes and minimum edges equal to two were set to include the keywords most repeatedly used. Figure 2 shows the cluster map of the authors’ keywords. The box size represents the keyword occurrence by the authors in their research works, while the thickness of the connecting lines signifies the intensity of the interconnection between the nodes. The word “geopolymer” is noted to be the most commonly used keyword. In turn, “fly ash”, “metakaolin”, “silica fume”, and “slag” are the primary aluminosilicate precursors employed in producing geopolymer composites. In addition, keywords such as “elevated temperature”, “high temperature”, “fire resistance”, and “thermal conductivity” show that geopolymer composites were mostly assessed for fire and high-temperature resistance applications.

Figure 2. Co-occurrence network for the author’s keywords.

Furthermore, the co-occurrence network shown in Figure 2 was divided into four clusters. The red cluster is related to the main precursors used in the production of geopolymer composites while focusing on the main properties that have been tested. The green cluster represents the correlation between durability testing, especially thermal and high-temperature resistance, and each of mechanical properties and microstructure analysis. While the purple cluster highlights the applications related to bonding, strengthening, and protection of old and damaged structural elements, and the blue cluster is related to corrosion. The red cluster was represented by one primary keyword, “geopolymer”. Conversely, the other clusters were characterized by a group of keywords. The red cluster mainly highlighted the precursors used in the production of geopolymer mortars and the main properties that have been evaluated, such as compressive strength, water absorption, and flexural strength. However, terms related to the fresh mortar properties, such as flow, setting time, plastic viscosity, and yield stress, were not found in the network. This indicates that more work should be carried out to assess the fresh properties of geopolymer materials. Moreover, for the green cluster, the main keywords were microstructure, durability, and mechanical properties, providing evidence to the need to conduct microstructure analysis when mechanical and durability testing were performed in the research work. Other keywords have also been found to be interconnected. For instance, the keyword porosity was connected to mechanical properties. This may be due to the direct relationship between the porosity, i.e., volume of pores in the mortar matrix, and the mechanical properties of geopolymer composites [26][67]. In the meantime, the purple cluster highlighted the keywords geopolymers, metakaolin, masonry, cultural heritage, coating, and strengthening. This cluster seemed to be focused on the use of geopolymers in specific construction applications. Lastly, the blue cluster was characterized by different keywords, including corrosion, chloride, and carbonation. Therefore, it is inferred that the blue cluster is primarily associated with the use of geopolymer composites as a protective layer for steel against corrosion. In fact, chloride ingress and carbonation are the two main reasons for corrosion initiation and rust creation [24][52][68][69].

4. Word Cloud

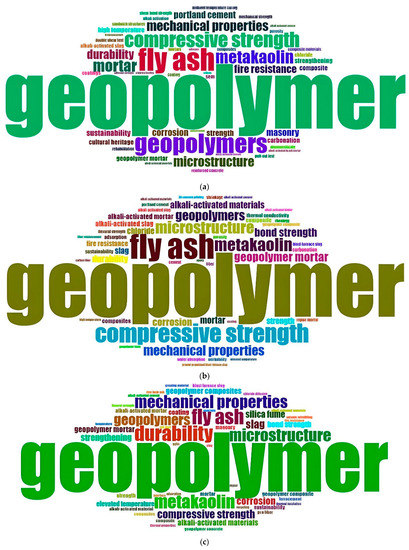

A word cloud is another tool to highlight research interests and trend developments. Figure 3 presents word clouds illustrating the most used author keywords within three time intervals: 1996–2017, 2018–2020, and 2021–2023, corresponding to 237, 261, and 291 articles, respectively. The time intervals were divided in a way to obtain a similar number of publications in each to facilitate the comparison. As anticipated, “geopolymer” was the most occurring keyword in all time slots, with a total occurrence of 244. Meanwhile, other terms, such as alkali-activated material, alkali-activated fly ash, and alkali-activated mortar were not as frequently used. As for the precursor binders, fly ash and metakaolin were mostly employed in past research. Yet, slag (also referred to as blast furnace slag and GGBS) became more prominently utilized after 2018. This could be due to the superior performance of blended geopolymer mortars made with fly ash and slag compared to counterparts comprising one of the two binders. Other materials, such as red mud and silica fume, also became more apparent in the latest time interval, indicating the exploration of new alternative materials in the past few years. Nevertheless, while geopolymer mortar is cement-free, cement was a commonly used keyword between 2018 and 2023. This is probably owed to the comparison of geopolymer mortar with cement-based mortar in terms of performance and microstructure. Indeed, the evidence emerging in the last five years on the superiority of geopolymers has been promoting its adoption by the construction industry.

Figure 3. Word cloud of most frequent author’s keywords between (a) 1996–2017 (237 articles), (b) 2018–2020 (261 articles), and (c) 2021–2023 (291 articles).

The word clouds also highlight several material properties. For example, a focus on the compressive strength and mechanical properties of the geopolymer mortar was evident, while less attention to durability and microstructure was observed. Though no significant differences were noted in the second time period, more properties were addressed, including bond strength, shrinkage, and water absorption. Bond strength is significant to several applications of geopolymer mortar, such as repair and strengthening. As these two applications became more prominent in this time period, their corresponding characterization tests were more frequently employed. In the last time period, greater attention was paid to durability and microstructure than compressive strength and mechanical properties. This indicates a more profound knowledge of the material under study, with a need to develop a better understanding of its durability performance and microstructure.

Based on the word cloud analysis, several research gaps can be depicted. Despite the introduction of new aluminosilicate binding materials in the production of geopolymer composites, fly ash has remained the most used precursor. However, owing to the depletion in its quantities over the past years, researchers are required to search for other industrial materials that possess similar chemical compositions to fly ash to serve as a suitable replacement. Another reason to find other alternatives to fly ash is that the level of toxicity varies between one region and another, where Russian fly ash showed less toxicity level with a pH near neutral compared to fly ash exported from other countries [70]. In addition, the complete or partial replacement of natural fine aggregates with recycled counterparts in producing geopolymer mortars has not received adequate attention [71]. Also, it seems that, other than workability, the fresh properties and rheology of geopolymers have not been investigated thoroughly.

References

- Alex, J.; Dhanalakshmi, J.; Ambedkar, B. Experimental Investigation on Rice Husk Ash as Cement Replacement on Concrete Production. Constr. Build. Mater. 2016, 127, 353–362.

- Yang, H.; Liu, L.; Yang, W.; Liu, H.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A Comprehensive Overview of Geopolymer Composites: A Bibliometric Analysis and Literature Review. Case Stud. Constr. Mater. 2022, 16, e00830.

- Akashi, O.; Hanaoka, T.; Matsuoka, Y.; Kainuma, M. A Projection for Global CO2 Emissions from the Industrial Sector through 2030 Based on Activity Level and Technology Changes. Energy 2011, 36, 1855–1867.

- Xie, J.-F.; Huang, Y.-X.; Li, W.-W.; Song, X.-N.; Xiong, L.; Yu, H.-Q. Efficient Electrochemical CO2 Reduction on a Unique Chrysanthemum-like Cu Nanoflower Electrode and Direct Observation of Carbon Deposite. Electrochim. Acta 2014, 139, 137–144.

- Wei, J.; Cen, K. Empirical Assessing Cement CO2 Emissions Based on China’s Economic and Social Development during 2001–2030. Sci. Total Environ. 2019, 653, 200–211.

- Gopalakrishnan, R.; Kaveri, R. Using Graphene Oxide to Improve the Mechanical and Electrical Properties of Fiber-Reinforced High-Volume Sugarcane Bagasse Ash Cement Mortar. Eur. Phys. J. Plus 2021, 136, 202.

- Bawab, J.; Khatib, J.; Kenai, S.; Sonebi, M. A Review on Cementitious Materials Including Municipal Solid Waste Incineration Bottom Ash (MSWI-BA) as Aggregates. Buildings 2021, 11, 179.

- Davidovits, J. Geopolymers Inorganic Polymerie New Materials. J. Therm. Anal. Calorim. 1991, 37, 1633–1656.

- Bakri, A.M.A.; Kamarudin, H.; Bnhussain, M.; Nizar, I.K.; Mastura, W.I.W. Mechanism and Chemical Reaction of Fly Ash Geopolymer Cement—A Review. J. Asian Sci. Res. 2011, 1, 247–253.

- Ismail, I.; Bernal, S.A.; Provis, J.L.; San Nicolas, R.; Hamdan, S.; van Deventer, J.S.J. Modification of Phase Evolution in Alkali-Activated Blast Furnace Slag by the Incorporation of Fly Ash. Cem. Concr. Compos. 2014, 45, 125–135.

- Komnitsas, K.; Zaharaki, D. Geopolymerisation: A Review and Prospects for the Minerals Industry. Miner. Eng. 2007, 20, 1261–1277.

- Yan, L.; Kasal, B.; Huang, L. A Review of Recent Research on the Use of Cellulosic Fibres, Their Fibre Fabric Reinforced Cementitious, Geo-Polymer and Polymer Composites in Civil Engineering. Compos. Part B Eng. 2016, 92, 94–132.

- Fahim Huseien, G.; Mirza, J.; Ismail, M.; Ghoshal, S.K.; Abdulameer Hussein, A. Geopolymer Mortars as Sustainable Repair Material: A Comprehensive Review. Renew. Sustain. Energy Rev. 2017, 80, 54–74.

- Najm, O.; El-Hassan, H.; El-Dieb, A. Ladle Slag Characteristics and Use in Mortar and Concrete: A Comprehensive Review. J. Clean. Prod. 2021, 288, 125584.

- Ahmad Zaidi, F.H.; Ahmad, R.; Al Bakri Abdullah, M.M.; Abd Rahim, S.Z.; Yahya, Z.; Li, L.Y.; Ediati, R. Geopolymer as Underwater Concreting Material: A Review. Constr. Build. Mater. 2021, 291, 123276.

- Arulmoly, B.; Konthesingha, C. Pertinence of Alternative Fine Aggregates for Concrete and Mortar: A Brief Review on River Sand Substitutions. Aust. J. Civ. Eng. 2021, 20, 272–307.

- Kong, D.L.Y.; Sanjayan, J.G. Effect of Elevated Temperatures on Geopolymer Paste, Mortar and Concrete. Cem. Concr. Res. 2010, 40, 334–339.

- Lyon, R.E.; Balaguru, P.N.; Foden, A.; Sorathia, U.; Davidovits, J.; Davidovics, M. Fire-Resistant Aluminosilicate Composites. Fire Mater. 1997, 21, 67–73.

- Ariffin, M.A.M.; Bhutta, M.A.R.; Hussin, M.W.; Mohd Tahir, M.; Aziah, N. Sulfuric Acid Resistance of Blended Ash Geopolymer Concrete. Constr. Build. Mater. 2013, 43, 80–86.

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.-B. Resistance of Alkali-Activated Slag Concrete to Acid Attack. Cem. Concr. Res. 2003, 33, 1607–1611.

- Kuri, J.C.; Sarker, P.K.; Shaikh, F.U.A. Sulphuric Acid Resistance of Ground Ferronickel Slag Blended Fly Ash Geopolymer Mortar. Constr. Build. Mater. 2021, 313, 125505.

- Zhang, Z.; Yao, X.; Zhu, H. Potential Application of Geopolymers as Protection Coatings for Marine ConcreteI. Basic Properties. Appl. Clay Sci. 2010, 49, 1–6.

- Zhang, Z.; Yao, X.; Zhu, H. Potential Application of Geopolymers as Protection Coatings for Marine ConcreteII. Microstructure and Anticorrosion Mechanism. Appl. Clay Sci. 2010, 49, 7–12.

- Aguirre-Guerrero, A.M.; Robayo-Salazar, R.A.; de Gutiérrez, R.M. A Novel Geopolymer Application: Coatings to Protect Reinforced Concrete against Corrosion. Appl. Clay Sci. 2017, 135, 437–446.

- Saxena, S.K.; Kumar, M.; Singh, N.B. Fire Resistant Properties of Alumino Silicate Geopolymer Cement Mortars. Mater. Today Proc. 2017, 4, 5605–5612.

- Bhutta, A.; Farooq, M.; Banthia, N. Performance Characteristics of Micro Fiber-Reinforced Geopolymer Mortars for Repair. Constr. Build. Mater. 2019, 215, 605–612.

- Wang, Y.-S.; Peng, K.-D.; Alrefaei, Y.; Dai, J.-G. The Bond between Geopolymer Repair Mortars and OPC Concrete Substrate: Strength and Microscopic Interactions. Cem. Concr. Compos. 2021, 119, 103991.

- Bencardino, F.; Condello, A.; Ashour, A.F. Single-Lap Shear Bond Tests on Steel Reinforced Geopolymeric Matrix-Concrete Joints. Compos. Part B Eng. 2017, 110, 62–71.

- Menna, C.; Asprone, D.; Ferone, C.; Colangelo, F.; Balsamo, A.; Prota, A.; Cioffi, R.; Manfredi, G. Use of Geopolymers for Composite External Reinforcement of RC Members. Compos. Part B Eng. 2013, 45, 1667–1676.

- Tamburini, S.; Natali, M.; Garbin, E.; Panizza, M.; Favaro, M.; Valluzzi, M.R. Geopolymer Matrix for Fibre Reinforced Composites Aimed at Strengthening Masonry Structures. Constr. Build. Mater. 2017, 141, 542–552.

- Longo, F.; Cascardi, A.; Lassandro, P.; Aiello, M.A. A Novel Composite Reinforced Mortar for the Structural and Energy Retrofitting of Masonry Panels. Key Eng. Mater. 2022, 916, 377–384.

- Longo, F.; Lassandro, P.; Moshiri, A.; Phatak, T.; Aiello, M.A.; Krakowiak, K.J. Lightweight Geopolymer-Based Mortars for the Structural and Energy Retrofit of Buildings. Energy Build. 2020, 225, 110352.

- Guo, L.; Zhou, M.; Wang, X.; Li, C.; Jia, H. Preparation of Coal Gangue-Slag-Fly Ash Geopolymer Grouting Materials. Constr. Build. Mater. 2022, 328, 126997.

- Bai, T.; Liang, Y.; Li, C.; Jiang, X.; Li, Y.; Chen, A.; Wang, H.; Xu, F.; Peng, C. Application and Validation of Fly Ash Based Geopolymer Mortar as Grouting Material in Porous Asphalt Concrete. Constr. Build. Mater. 2022, 332, 127154.

- Gouny, F.; Fouchal, F.; Maillard, P.; Rossignol, S. A Geopolymer Mortar for Wood and Earth Structures. Constr. Build. Mater. 2012, 36, 188–195.

- Assaad, J.J.; Saba, M. Suitability of Metakaolin-Based Geopolymers for Masonry Plastering. ACI Mater. J. 2020, 117.

- Hwalla, J.; Saba, M.; Assaad, J.J. Suitability of Metakaolin-Based Geopolymers for Underwater Applications. Mater. Struct. 2020, 53, 119.

- Sarquah, K.; Narra, S.; Beck, G.; Awafo, E.A.; Antwi, E. Bibliometric Analysis; Characteristics and Trends of Refuse Derived Fuel Research. Sustainability 2022, 14, 1994.

- de Sousa, F.D.B. A Simplified Bibliometric Mapping and Analysis about Sustainable Polymers. Mater. Today Proc. 2022, 49, 2025–2033.

- Montalván-Burbano, N.; Pérez-Valls, M.; Plaza-Úbeda, J. Analysis of Scientific Production on Organizational Innovation. Cogent Bus. Manag. 2020, 7, 1745043.

- Alzard, M.H.; El-Hassan, H.; El-Maaddawy, T.; Alsalami, M.; Abdulrahman, F.; Hassan, A.A. A Bibliometric Analysis of the Studies on Self-Healing Concrete Published between 1974 and 2021. Sustainability 2022, 14, 11646.

- Boquera, L.; Castro, J.R.; Pisello, A.L.; Cabeza, L.F. Research Progress and Trends on the Use of Concrete as Thermal Energy Storage Material through Bibliometric Analysis. J. Energy Storage 2021, 38, 102562.

- Zhou, M.; Wang, R.; Cheng, S.; Xu, Y.; Luo, S.; Zhang, Y.; Kong, L. Bibliometrics and Visualization Analysis Regarding Research on the Development of Microplastics. Environ. Sci. Pollut. Res. 2021, 28, 8953–8967.

- Jeris, S.S.; Ur Rahman Chowdhury, A.S.M.N.; Akter, T.; Frances, S.; Roy, M.H. Cryptocurrency and Stock Market: Bibliometric and Content Analysis. Heliyon 2022, 8, e10514.

- Li, Y.; Li, M.; Sang, P. A Bibliometric Review of Studies on Construction and Demolition Waste Management by Using CiteSpace. Energy Build. 2022, 258, 111822.

- Jin, L.; Sun, X.; Ren, H.; Huang, H. Hotspots and Trends of Biological Water Treatment Based on Bibliometric Review and Patents Analysis. J. Environ. Sci. 2023, 125, 774–785.

- Anugerah, A.R.; Muttaqin, P.S.; Trinarningsih, W. Social Network Analysis in Business and Management Research: A Bibliometric Analysis of the Research Trend and Performance from 2001 to 2020. Heliyon 2022, 8, e09270.

- Mat Daud, N.I.; Mohd, F.; Che Nawi, N.; Ibrahim, M.A.H.; Tan, W.H.; Zainuddin, Z.F.; Mohd Yussoff, N.H. Bibliometric Analysis of Optimization in Sports from 2011 to 2020 Using Scopus Database. Lect. Notes Netw. Syst. 2023, 487, 689–701.

- Tian, Q.; Pan, Y.; Bai, Y.; Yao, S.; Sun, S. A Bibliometric Analysis of Research Progress and Trends on Fly Ash-Based Geopolymer. Materials 2022, 15, 4777.

- Elmesalami, N.; Celik, K. A Critical Review of Engineered Geopolymer Composite: A Low-Carbon Ultra-High-Performance Concrete. Constr. Build. Mater. 2022, 346, 128491.

- Ji, Z.; Pei, Y. Bibliographic and Visualized Analysis of Geopolymer Research and Its Application in Heavy Metal Immobilization: A Review. J. Environ. Manag. 2019, 231, 256–267.

- Shaikh, F.U.A. Effects of Alkali Solutions on Corrosion Durability of Geopolymer Concrete. Adv. Concr. Constr. 2014, 2, 109–123.

- Hwalla, J.; El-Hassan, H.; Assaad, J.J.; El-Maaddawy, T. Performance of Cementitious and Slag-Fly Ash Blended Geopolymer Screed Composites: A Comparative Study. Case Stud. Constr. Mater. 2023, 18, e02037.

- Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tay, Y.W.D.; Tan, M.J. Measurement of Tensile Bond Strength of 3D Printed Geopolymer Mortar. Measurement 2018, 113, 108–116.

- Saba, M.; Assaad, J.J. Effect of Recycled Fine Aggregates on Performance of Geopolymer Masonry Mortars. Constr. Build. Mater. 2021, 279, 122461.

- Branavan, A.; Konthesingha, K.M.C. Fine Aggregate Usage in Concrete and Masonry Mortar by Local Construction Industries. In Proceedings of the 10th International Conference on Structural Engineering and Construction Management (ICSECM), Kandy, Sri Lanka, 12–14 December 2019.

- Khan, H.A.; Castel, A.; Sunarho, J. Neutralization and Corrosion of Geopolymer Mortar in an Aggressive Sewer Environment. In Proceedings of the Corrosion & Prevention, Adelaide, Australia, 11-14 November 2018.

- Khan, H.A.; Castel, A.; Khan, M.S.H. Corrosion Investigation of Fly Ash Based Geopolymer Mortar in Natural Sewer Environment and Sulphuric Acid Solution. Corros. Sci. 2020, 168, 108586.

- Khan, H.A.; Khan, M.S.H.; Castel, A.; Sunarho, J. Deterioration of Alkali-Activated Mortars Exposed to Natural Aggressive Sewer Environment. Constr. Build. Mater. 2018, 186, 577–597.

- Khan, H.A.; Yasir, M.; Castel, A. Performance of Cementitious and Alkali-Activated Mortars Exposed to Laboratory Simulated Microbially Induced Corrosion Test. Cem. Concr. Compos. 2022, 128, 104445.

- Drugă, B.; Ukrainczyk, N.; Weise, K.; Koenders, E.; Lackner, S. Interaction between Wastewater Microorganisms and Geopolymer or Cementitious Materials: Biofilm Characterization and Deterioration Characteristics of Mortars. Int. Biodeterior. Biodegrad. 2018, 134, 58–67.

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay, Y.W.D.; Tan, M.J. Additive Manufacturing of Geopolymer for Sustainable Built Environment. J. Clean. Prod. 2017, 167, 281–288.

- Panda, B.; Noor Mohamed, N.A.; Tay, Y.W.D.; He, L.; Tan, M.J. Effects of Slag Addition on Bond Strength of 3D Printed Geopolymer Mortar: An Experimental Investigation. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing (Pro-AM 2018), Singapore, 14–17 May 2018; pp. 62–67.

- Panda, B.; Noor Mohamed, N.A.; Tay, Y.W.D.; Tan, M.J. Bond Strength in 3D Printed Geopolymer Mortar. In RILEM Bookseries; Springer: Cham, Switzerland, 2019; Volume 19, pp. 200–206.

- Lim, J.H.; Panda, B.; Pham, Q.-C. Improving Flexural Characteristics of 3D Printed Geopolymer Composites with in-Process Steel Cable Reinforcement. Constr. Build. Mater. 2018, 178, 32–41.

- Güllü, H.; Cevik, A.; Al-Ezzi, K.M.A.; Gülsan, M.E. On the Rheology of Using Geopolymer for Grouting: A Comparative Study with Cement-Based Grout Included Fly Ash and Cold Bonded Fly Ash. Constr. Build. Mater. 2019, 196, 594–610.

- Alexander, A.E.; Shashikala, A.P. Studies on the Microstructure and Durability Characteristics of Ambient Cured FA-GGBS Based Geopolymer Mortar. Constr. Build. Mater. 2022, 347, 128538.

- Liu, Z.; Meng, W. Fundamental Understanding of Carbonation Curing and Durability of Carbonation-Cured Cement-Based Composites: A Review. J. CO2 Util. 2021, 44, 101428.

- Rostami, V.; Shao, Y.; Boyd, A.J. Durability of Concrete Pipes Subjected to Combined Steam and Carbonation Curing. Constr. Build. Mater. 2011, 25, 3345–3355.

- Kozhukhova, N.I.; Lebedev, M.S.; Vasilenko, M.I.; Goncharova, E.N. Fly Ash Impact from Thermal Power Stations on the Environment. J. Phys. Conf. Ser. 2018, 1066, 012010.

- Bawab, J.; Khatib, J.; El-Hassan, H.; Assi, L.; Kırgız, M.S. Properties of Cement-Based Materials Containing Cathode-Ray Tube (CRT) Glass Waste as Fine Aggregates—A Review. Sustainability 2021, 13, 11529.

More

Information

Subjects:

Construction & Building Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

794

Revisions:

2 times

(View History)

Update Date:

07 Aug 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No