You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Lilia Sabantina | -- | 1112 | 2023-08-01 11:51:37 | | | |

| 2 | Peter Tang | Meta information modification | 1112 | 2023-08-02 05:54:04 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Marterer, L.; Torst, N.; Haddar, O.A.; Sabantina, L. Sustainable Engineering of an Outdoor Jacket from Waste. Encyclopedia. Available online: https://encyclopedia.pub/entry/47486 (accessed on 26 December 2025).

Marterer L, Torst N, Haddar OA, Sabantina L. Sustainable Engineering of an Outdoor Jacket from Waste. Encyclopedia. Available at: https://encyclopedia.pub/entry/47486. Accessed December 26, 2025.

Marterer, Laura, Nora Torst, Oussema Ahmed Haddar, Lilia Sabantina. "Sustainable Engineering of an Outdoor Jacket from Waste" Encyclopedia, https://encyclopedia.pub/entry/47486 (accessed December 26, 2025).

Marterer, L., Torst, N., Haddar, O.A., & Sabantina, L. (2023, August 01). Sustainable Engineering of an Outdoor Jacket from Waste. In Encyclopedia. https://encyclopedia.pub/entry/47486

Marterer, Laura, et al. "Sustainable Engineering of an Outdoor Jacket from Waste." Encyclopedia. Web. 01 August, 2023.

Copy Citation

Due to the almost linear textile chain, large amounts of non-renewable resources are consumed to produce cheap clothes that are only worn a few times. Particularly problematic are the fiber waste and the enormous water consumption of the textile industry.

sustainability

textile waste

recycling

textile manufacturing

renewable sources

zero-waste

transformable design

1. Introduction

The McKinsey study predicts large-scale fiber-to-fiber recycling by 2030, creating a sustainable circular economy in Europe [1]. The European Commission envisions durable, repairable, recyclable textile products made from recycled fibers, free from hazardous substances, and produced with respect for social rights by 2030 [2]. The garment manufacturing process produces a lot of waste, which includes not only fabric waste but also residual fibers and yarns, dyes, and chemicals used in the dyeing process of fibers and textile surfaces, which pollute the environment [3]. Waste, in particular, is a major problem in the textile industry. Each European consumes almost 30 kg of clothing per year, of which 11 kg is thrown away.

2. Fibers from Waste

There are ample opportunities to recover fibers from agricultural, food, and cutting wastes in the textile production and recycling processes, but these methods often receive insufficient attention. For instance, in paper production, wood is commonly used to obtain cellulose, while the discarded tree bark is typically incinerated or discarded. Similarly, in pineapple or banana harvesting, the leaves and fruit contents contain valuable fibers that could be utilized as a sustainable alternative for pulp recovery, but they are often overlooked [4]. Despite their suitability for casein fibers, valuable by-products generated during milk production are often discarded and wasted. These by-products could be utilized to create sustainable casein fibers, thereby reducing waste and maximizing resource efficiency in the milk production process [5].

The casein protein utilized in creating the fabric is sourced from discarded milk that would otherwise go to waste, making it an eco-friendly option. Cellulosic fibers from sources like bast or stem fibers in the inner bark of dicotyledonous plants, leaf fibers in monocotyledonous plants, and fibers from seeds and fruits can be used for fiber production. Bio-based fibers like ramie, flax, hemp, jute, sisal, and coir are commonly used for technical purposes due to their rough texture and strong mechanical properties. These fibers can be obtained through isolation processes involving bacteria, fungi, as well as chemical and mechanical methods. Chitin, found in the cell wall of many fungi, can be extracted from fungal biomass through alkali treatment [6]. This presents a sustainable and eco-friendly resource for the production of textile fabrics with potential applications in sustainability-driven industries.

3. Sustainable Finishing

Chitin and chitosan, which can be obtained from tons of shell waste from the processing of crustaceans and fungi, are versatile materials used for the surface modification of textiles [7]. Their incorporation into textile finishing processes can improve properties such as dyeability and color strength [8]. In addition, chitosan applications in textile finishing can impart antimicrobial, anti-odor, anticoagulant, antistatic, and crease-resistant finishes, providing further functional benefits to textiles. These multifunctional properties make chitin and chitosan valuable resources for textile innovation and sustainability [9]. Other sustainable alternatives to petroleum-based wax systems for textile finishing include natural animal waxes such as beeswax and vegetable waxes (e.g., palm wax, soy wax, castor wax, sunflower wax). The bio-based waxes form a protective layer that repels water and prevents the sun’s UV rays from drying out the plant [10].

4. Multifunctional Design

Design plays a significant role in the environmental impact a garment will have throughout its life cycle. The design stage sets the roadmap for the further production of a garment, so it is at this stage that sustainable practices need to be implemented to ensure a more sustainable garment production process. Today’s fashion industry is based on rapid cycles of changing styles, creating a culture where psychological obsolescence becomes the norm. Consumers are under pressure to own the latest trends, so clothes go out of fashion at an increasingly rapid rate [11]. Nes and Cramer’s theory suggests that by delaying product replacement, a consumer’s period of use and lifetime is extended. By designing garments with multifunctional and adjustable features, the consumer’s need for the new can be minimized. Designing for longevity means that the product can evolve with the owner, with the adaptability of transformable design increasing the chances of wearing the garment more and for longer [12]. Because the garment can be changed to suit different occasions and seasons, the wearer’s needs and desires are met, which in turn leads to greater product satisfaction [13]. Ultimately, transformable design actively involves the consumer in the design process, as they are the ones who decide which transformation stage they want to wear the garment in each time they wear it. This strengthens the emotional connection between the wearer and the garment, which directly leads to better care of the garment and, therefore, longer use.

5. Modular Transformable Design

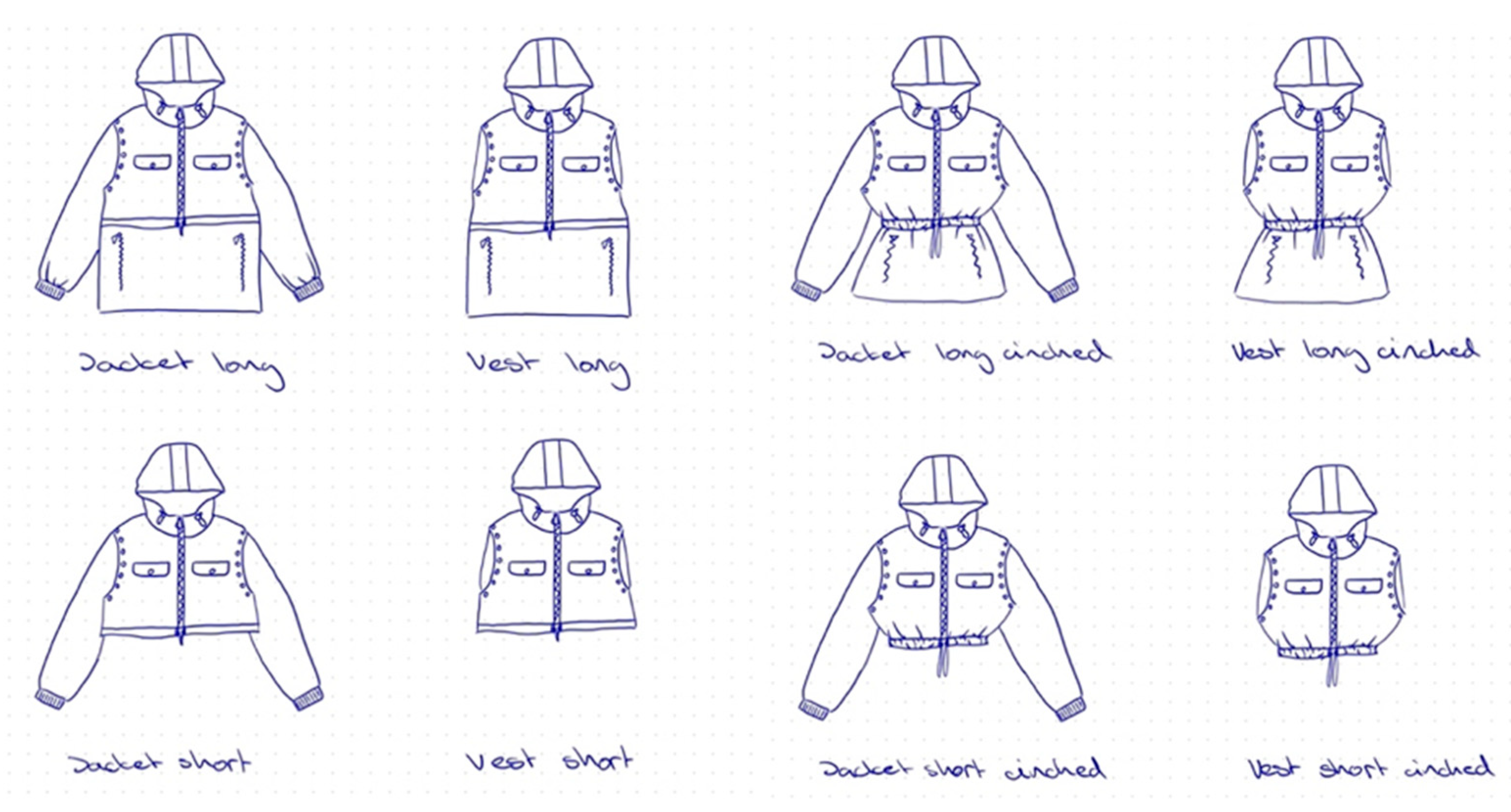

The outdoor jacket was designed with the capability to transform itself into different pieces of clothing that showcase different styles and are wearable in different seasons, making this jacket not only wearable all through the year within different weather conditions, but also a fashionable piece that can be styled in a number of different ways. The design of this jacket aims to achieve multiple functional and/or aesthetic transformations achieved by different techniques, as shown in Figure 1.

Figure 1. Sketches showing the eight variations in which the jacket can be worn. (Top row: jacket long, vest long, jacket long cinched, vest long cinched; upper row: jacker short, vest short, jacket short cinched, vest short cinched).

6. Zero-Waste Pattern Making

Therefore, a zero-waste pattern-making approach is used to construct the jacket, ensuring a waste-free production. There are many techniques for making zero-waste patterns used by designers worldwide. For this jacket, the jigsaw approach is used. This approach produces patterns that are the closest to traditional patterns in terms of other zero-waste techniques [14]. Traditional pattern-making techniques, such as the Müller and Sohn technique, construct patterns based on body measurements, where the pattern is fitted to individually measured and calculated sizes. The result is complex, two-dimensional pattern pieces that stand alone but come together to form a complete garment when sewn [15].

In zero-waste pattern making, the approach to the pattern-making process is different because the individual pieces of the pattern are not considered as individual working parts, but are constructed to fit together like a jigsaw puzzle. Therefore, the pieces need to be made in relation to each other, as the finished pattern needs to fit into a perfect rectangle. Zero-waste pattern making aims to use the entire area of the available fabric in its specific length and width. This is the only way to ensure that a true zero-waste pattern-making approach will be successful in its implementation [16].

References

- McKinsey & Company. Scaling Textile Recycling in Europe—Turning Waste into Value. 2022. Available online: https://www.nweurope.eu/media/19019/2207-scaling-textile-recycling-in-europe-turning-waste-into-value.pdf (accessed on 1 March 2023).

- Publications Office of the European Union. © European Union. 2022. Available online: https://www.interregeurope.eu/sites/default/files/2022-05/Textiles_Factsheet_EC.pdf (accessed on 1 March 2023).

- Juanga-Labayen, J.P.; Labayen, I.V.; Yuan, Q. A Review on Textile Recycling Practices and Challenges. Textiles 2022, 2, 174–188.

- Stenton, M.; Houghton, J.A.; Kapsali, V.; Blackburn, R.S. The Potential for Regenerated Protein Fibres within a Circular Economy: Lessons from the Past Can Inform Sustainable Innovation in the Textiles Industry. Sustainability 2021, 13, 2328.

- Flores-Nieves, M.M.; Castellanos-Espinoza, R.; Estevez, M.; Baldenegro-Pérez, L.A.; García Trejo, J.F.; García, M.E.; Martínez Cano, B.; Soto-Zarazúa, G.M.; España-Sánchez, B.L. Electrospun Casein fibers obtained from revalued milk with mechanical and antibacterial properties. Arab. J. Chem. 2022, 15, 104201.

- Zainol Abidin, N.A.; Kormin, F.; Zainol Abidin, N.A.; Mohamed Anuar, N.A.F.; Abu Bakar, M.F. The Potential of Insects as Alternative Sources of Chitin: An Overview on the Chemical Method of Extraction from Various Sources. Int. J. Mol. Sci. 2020, 21, 4978.

- Shahid-Ul-Islam, B.B.S. Recent advances in chitosan polysaccharide and its derivatives in antimicrobial modification of textile materials. Int. J. Biol. Macromol. 2019, 121, 905–912.

- Svensson, S.E.; Ferreira, J.A.; Hakkarainen, M.; Adolfsson, K.H.; Zamani, A. Fungal textiles: Wet spinning of fungal microfibers to produce monofilament yarns. Sustain. Mater. Technol. 2021, 28, e00256.

- Shirvan, A.R.; Shakeri, M.; Bashari, A. Recent advances in application of chitosan and its derivatives in functional finishing of textiles. In The Textile Institute Book Series, The Impact and Prospects of Green Chemistry for Textile Technology; Shahid-ul-Islam, B.S.B., Ed.; Woodhead Publishing: Sawston, UK, 2019; pp. 107–133.

- Collet, C. Chapter 8—Biotextiles: Making Textiles in a Context of Climate and Biodiversity Emergency; Pedgley, O., Rognoli, V., Karana, E., Eds.; Materials Experience 2; Butterworth-Heinemann: Oxford, UK, 2021; pp. 207–226.

- van Nes, N.; Cramer, J. Product lifetime optimization: A challenging strategy towards more sustainable consumption patterns. J. Clean. Prod. 2006, 14, 1307–1318.

- Koo, H.S.; Dunne, L.; Bye, E. Design functions in transformable garments for sustainability. J. Fash. Des. Technol. Educ. 2013, 7, 10–20.

- Hethorn, J.U. Sustainable Fashion: Why now? A Conversation Exploring Issues, Practices, and Possibilities; Fairchild Books: New York, NY, USA, 2008.

- McQuillan, H. Zero-Waste Design Practice: Strategies and Risk Taking for Gament Design; Earthscan: London, UK, 2011.

- Valenzuela-Fernández, L.; Escobar-Farfán, M. Zero-Waste Management and Sustainable Consumption: A Comprehensive Bibliometric Mapping Analysis. Sustainability 2022, 14, 16269.

- Ramkalaon, S.; Sayem, A.S.M. Zero-Waste Pattern Cutting (ZWPC) to tackle over sixty billion square metres of fabric wastage during mass production of apparel. J. Text. Inst. 2021, 112, 809–819.

More

Information

Subjects:

Engineering, Manufacturing

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

918

Revisions:

2 times

(View History)

Update Date:

02 Aug 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No