Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Kyriaki KISKIRA | -- | 3725 | 2023-08-01 10:04:29 | | | |

| 2 | Camila Xu | Meta information modification | 3725 | 2023-08-01 10:12:56 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Plakantonaki, S.; Kiskira, K.; Zacharopoulos, N.; Chronis, I.; Coelho, F.; Togiani, A.; Kalkanis, K.; Priniotakis, G. Sustainability Standards and Ecolabeling in the Textile Industry. Encyclopedia. Available online: https://encyclopedia.pub/entry/47478 (accessed on 08 February 2026).

Plakantonaki S, Kiskira K, Zacharopoulos N, Chronis I, Coelho F, Togiani A, et al. Sustainability Standards and Ecolabeling in the Textile Industry. Encyclopedia. Available at: https://encyclopedia.pub/entry/47478. Accessed February 08, 2026.

Plakantonaki, Sofia, Kyriaki Kiskira, Nikolaos Zacharopoulos, Ioannis Chronis, Fernando Coelho, Amir Togiani, Konstantinos Kalkanis, Georgios Priniotakis. "Sustainability Standards and Ecolabeling in the Textile Industry" Encyclopedia, https://encyclopedia.pub/entry/47478 (accessed February 08, 2026).

Plakantonaki, S., Kiskira, K., Zacharopoulos, N., Chronis, I., Coelho, F., Togiani, A., Kalkanis, K., & Priniotakis, G. (2023, August 01). Sustainability Standards and Ecolabeling in the Textile Industry. In Encyclopedia. https://encyclopedia.pub/entry/47478

Plakantonaki, Sofia, et al. "Sustainability Standards and Ecolabeling in the Textile Industry." Encyclopedia. Web. 01 August, 2023.

Copy Citation

The textile and fashion industry is a major polluter, contributing significantly to the pollution of water and air and producing solid waste. Textile manufacturing occurs in many steps, such as pretreatment, dyeing, and finishing; involves the use of several harmful chemicals that generate a significant amount of toxic waste and greenhouse gases; and consumes a large amount of water.

textile industry

ecotextiles

ecofriendly textile fibers

ecolabels

sustainability

1. Introduction

As the world’s population grows at an exponential rate, the demand for energy, food, and resources increases dramatically [1][2]. As a result, pollution to the environment increases, and nonrenewable resources such as water, land, and fossil fuels are depleted [3][4]. Global warming is the result of environmental pollution. The textile and fashion industry is a major polluter, contributing significantly to the pollution of water and air and producing solid waste [5]. Textile manufacturing occurs in many steps, such as pretreatment, dyeing, and finishing; involves the use of several harmful chemicals that generate a significant amount of toxic waste and greenhouse gases; and consumes a large amount of water [6][7][8]. For that reason, textiles are characterized as unsustainable products from raw material cultivation to manufacturing [5][9]. It is important to make the product non-toxic, but it is also essential to control pollution [10].

The introduction of new production equipment, together with a number of breakthroughs in the domains of textile technology and textile chemistry, signaled the beginning of substantial changes in the textile industry towards the end of the 18th century [11]. At the start of the 20th century, several industries reached their development peak. Due to the difficulty of manufacturing natural fiber at the time, several investigations on synthetic chemical products were conducted in an effort to significantly improve both the quality of life and the availability of goods for consumption [12]. Because the textile industry at the time was considerably smaller, the pollution it produced did not constitute a significant danger to the environment. Aside from that, the chemicals in use at the time were natural and biodegradable [11]. Synthetic fiber production and usage, however, have significantly expanded worldwide in recent decades [13]. The idea of rapid fashion has changed consumers’ shopping habits in addition to population increase [14].

With increased water consumption and pollution from synthetic textile displays introducing plastic or microplastic buildup on human bodies and the Earth [11][14], the cycle between water use and waste management is becoming shorter nowadays. One kilogram of cotton, which is equal to one t-shirt and a pair of trousers, is produced by cotton farming globally, using 20,000 L of water with 24% insecticides and 11% pesticides [5][15]. In 2020, global fiber production was 109 million tonnes and is growing year by year, compared to 95.6 million tonnes in 2015 [13]. Numerous novel dyes and auxiliaries were created and accumulated in the environment throughout the past century [16]. Consumers have become more cautious regarding greenhouse gas (GHG) emissions and environmental effects, and the fact that several chemicals have been proven to be potentially dangerous [6][7]. Legislation was thus passed to restrict or outlaw the use of certain drugs [7][17].

For sustainability, renewable resources might be considered. All items, including textiles, must be evaluated for sustainability [18]. The ecologically advantageous sustainability movement has recently gained support from almost every business. Sustainability refers to the persistence of the social, economic, and environmental facets of human civilization [19]. Synthetic fibers (such as polyester and nylon) depend on readily available fossil fuels, increasing GHG. Regenerated fibers are a good alternative to this fiber [10]. There is a transition taking place from petrochemistry to green chemistry [12]. By carefully managing raw resources, energy, trash, and products, the green notion seeks to minimize the environmental effect of industrial operations.

Governments promote ecolabels and sustainability standards that encourage the “ecofriendliness” of textiles. According to these legislations, textile manufacturers and product designers must pay special attention to these standards. In order for a product to be deemed “green,” it must be ecologically responsible at all stages of manufacturing, usage, and maintenance, as well as after its useful life has passed. Ecological, social, and economic concerns must coexist in product design [20]. Products that are safe for human health and the environment are given specific certifications by independent organizations.

There is a lack of consumer awareness regarding ecofriendly products and their life cycle. Undoubtedly, the first step is to increase consumer awareness and openness to change by choosing clothing made in countries with more stringent environmental regulations for textile factories and selecting products made from organic, ecofriendly fibers without the use of harmful and toxic chemicals. The term “Ecotextiles” refers to apparel and products made from natural fibers such as organic cotton, hemp, and bamboo, regenerated fibers, and organically dyed materials with natural dyes using a small amount of water, energy, and non-harmful chemicals. Currently, clothing includes ecolabels to help consumers identify environmentally friendly products.

Despite the fact that there are numerous ecolabeling schemes available around the globe that can be applied to the textile sector, there are no systematic techniques for determining which ecolabeling scheme is best for a certain clothing product. The ‘‘Ecolabel Index’’ is the world’s largest global registry of ecolabels, tracking more than 456 ecolabels in 199 countries representing 25 business sectors [21]. Around 100 ecolabels are used in the textile industry on both an international and national basis, spanning different stages of the manufacturing life cycle. Up to now, there has been no standardized method for a textile manufacturing company to choose an appropriate ecolabel. It is also clear that ecolabels produced in different parts of the world have given different impact criteria. There are currently no systematic assessments of textile ecolabeling and its criteria, making it difficult for textile sustainability practitioners to evaluate the current ecolabels and choose the optimal options for their industry.

2. Sustainable Product Design and Manufacturing—Ecological Requirements

A product’s final use, regular use, and maintenance must all be taken into account by the designer while creating the product [22][23][24]. Environmental acceptability may be impacted by the choice of raw materials [25][26]. Combining recyclable fabrics with non-recyclable textiles is not appropriate [27]. Some clothing components, such as coatings and zippers, could not be ecofriendly. Despite the high expense of doing so, a manufacturer that strives for ecological manufacturing will think about replacing such components with ecologically acceptable and environmentally friendly items [28].

Additionally, textiles that are produced using traditional methods may have residual chemicals and volatile or skin-absorbable dyes. Some can result in allergic responses or cancer [6]. In an effort to stop these negative consequences, as well as in response to new facts and growing ecological consciousness, ever-increasing limitations and prohibitions have been placed on the use of specific chemicals and dyestuffs [29]. Regulations governing the maximum permissible concentration of a chemical compound on textile treatment, or that is allowed to stay on a particular textile substrate, may—in certain situations—place restrictions on their usage [30]. Additionally, regulations for worker health and environmental protection are being tightened.

The duty for a product continues past the point of creation and lasts at least as long as the product is in use. It is vital that textile products do not release volatile organic compounds or other dangerous chemicals (e.g., heavy metals) while being used and cared for. The environmental impact of textile maintenance is greater and more severe than that of the manufacturing process itself [31][32]. When frequently washing worn fabrics, excessive volumes of water are typically utilized [33]. As a result, textile products should be created to require the least amount of washing and dry cleaning. Moreover, washing at a lower temperature is more cost-effective.

The product’s design should minimize dirt accumulation, and the colors should remain vibrant in most textiles all the way to the end of their useful life. Colorfastness is the ability of any colored textile material to retain its original color without fading, altering, or running when washed, wetted, cleaned, or exposed to light, heat, or other factors [34]. However, colorfastness is a major parameter for the use of harmful chemicals in textile dyeing and printing [35]. The textile industry should shift to more sustainable manufacturing by using sustainable natural dyes and low-impact fibers. However, despite significant advances in natural dye applications, bio-based colorants have a long way to go before they can be regarded as viable alternatives to synthetic colorants [36]. These disadvantages of natural dyes can be overcome by using environmentally friendly mordants, which are permitted at certain amounts for textile dyeing [37]. Low-impact fibers contain no dangerous chemicals and, ideally, are OEKO-TEX Standard 100 certified free of toxic substances. They require less rinsing, the absorption rate is higher, and they use less water.

Another issue caused by textile washing is the release of microplastics. Microplastics have recently been identified as a new and concerning source of marine contamination [38]. Microplastics are difficult to detect with the naked eye and biodegrade in marine environments, posing a problem because they can be ingested by organisms and infiltrate the food chain [39]. A significant source of microplastics appears to be synthetic fibers from washing clothes that contaminate wastewater [40]. De Falco et al. [40] demonstrated that the washing of woven polyester resulted in the greatest discharge of microplastics compared to knitted polyester and woven polypropylene, which was correlated with the fabric’s properties.

Additionally, odors that may arise from use and wear can be removed to increase the product’s functional life. Hanging tags and sewn-in labels should normally be used to identify textile products when they are first introduced to a store [41]. How and under what circumstances a particular product should be maintained should be covered in the care instructions. The need for antimicrobial treatment on particular fabrics, such as athletic clothing, is related to the fact that microbes break down human perspiration, and the resulting byproducts commonly release unpleasant scents [42].

The disposal of textiles, once their useful life is through, should also be the responsibility of textile product designers and producers [43]. The final alternative is to dispose of a product in a landfill; nevertheless, burning a product might provide certain amounts of energy [1][3]. However, recycling textiles and reusing them as fillers for other textile goods or as new products is the best approach [43][44].

The principle causes of environmental issues in this sector are the finishing procedures, which range from initial scouring and bleaching, through mercerization and dyeing, to the final finishing processes and coatings applied to fabrics [45]. Consequently, in order to reduce the adverse consequences of the aforementioned processes, it is crucial to monitor and manage wastewater pollution as well as exhaust air pollution.

Toxic and hazardous chemicals are replaced with ecologically preferred goods that have less detrimental impacts on the environment and human health [23]. Maximum energy, water, and chemical savings are targeted. The right choice of dyestuffs and chemicals combined with the best process management may significantly reduce the use of natural resources such as water and energy while also reducing environmental pollution.

Textile items must be long-lasting since ecodesign enables consumers to use them for a longer time. Three design elements make up this overall idea: design for disassembly, design for long-lasting style, and design for durability [46]. It is crucial that durable, high-quality materials be used, along with other components, and that seams be constructed in a way that prevents tearing out. The second idea takes into account the fashion sensibility of the customers and shifting fashion trends. By carefully selecting colors and designs that are thought to be timeless and appealing to a wide audience, designers prevent products from being rejected because they are thought to be out of trend. Longer usage and reuse are also encouraged by the increased resale value of timeless objects. Finally, how a textile product is put together affects whether and how simple it is to dismantle for repair, maintenance, component reuse, and/or recycling. Many fashion houses and retailers are thinking about ways to make their items “green”. Designers should start with more ethical or sustainable textile fibers and low-impact dyes and chemicals in order to produce more ethical or sustainable clothing.

3. Ecofriendly Textile Fibers—Classification and Ecofiber Market

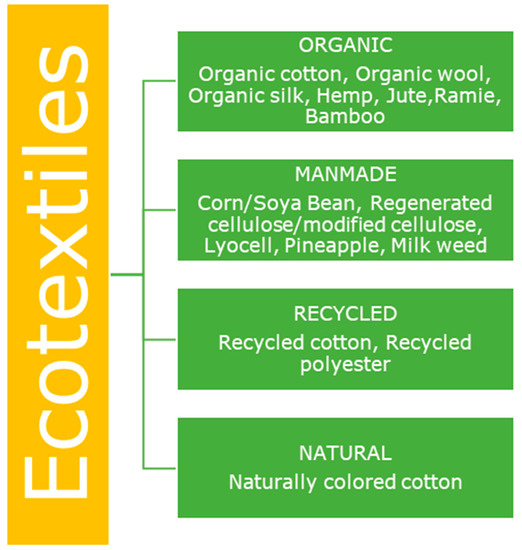

Ecofriendly fibers might be natural or synthetic, but their manufacturing and processing must have a lower environmental impact than conventional fibers [12]. Figure 1 shows the classification of the most common ecofriendly fibers. There are fewer risks for people, especially farmers, when pesticides and synthetic fertilizers are excluded from or reduced during production [47]. Biopesticides can be used in place of synthetic chemical pesticides since they are less harmful to the environment and human health [48]. Many organic farms utilize Integrated Pest Management (IPM) instead of insecticides [49]. Overall pesticide handling optimization by adherence to existing standards may lead to a reduction in pesticide-related harmful effects on human health and the environment. Long used in the textile sectors, organic fibers (cotton, wool, silk), recycled cotton, naturally colored cotton, lyocell, maize, soya bean, recycled polyester, and others have recently gained prominence owing to their favorable effects on the environment.

Figure 1. Classification of the most common ecofriendly fibers.

Processors satisfy the RSLs requirements by carefully choosing dyes and chemicals based on accurate and trustworthy information provided by reputable suppliers. A number of myths regarding dyestuffs have developed as a result of a lack of clear information and the absence of universally accepted criteria for identifying ecofriendly dyes.

-

Minimal chemical consumption;

-

Minimal use of energy and water;

-

Minimal pollution production;

-

Removal of hazardous chemicals from the supply chain.

As a result, sustainable textiles or apparel: (a) are made from renewable materials, (b) should be safe for humans and the environment, (c) are manufactured by workers in a safe environment, (d) are produced with the most efficient use of resources (e.g., water, energy), (e) are capable of being washed at low temperatures using environmentally friendly laundering agents, and (f) are capable of being returned safely to the environment at the end of their useful life.

Textiles are essential materials of daily living, and the fashion business is an important component of the worldwide economy. Due to the growth of the human population, global fiber production and consumption are increasing. The EUR 1.1 trillion garment business employs over 300 million people throughout the value chain [9]. In recent years, there has been a revolution in sustainable apparel due to increased awareness of ethically manufactured materials. It not only provides an extra source of economic benefit, but it also creates a new market for additional job opportunities and reduces the use of virgin resources and raw materials. These trends are also expected to play a key role in encouraging the organic fibers sector during the forecast period.

According to a recent market analysis report of Grand View Research [51], the worldwide ecofiber market is predicted to reach USD 77.17 billion by 2030, growing at a compound annual growth rate (CAGR) of 7.6% from 2023 to 2030. This increase can be ascribed to an increase in concern about the adverse environmental effects of utilizing synthetic fibers, which has been a major factor leading to the growing demand for organic ecofiber in recent years. The increased reliance on chemicals and pesticides to improve crop yield has resulted in widespread environmental deterioration. As a result, governments and other regulatory agencies have been forced to comply with countless restrictions. These laws apply to both the manufacture and disposal of synthetic sources of fiber production.

This trend has also resulted in a desire for bio-based alternatives such as organic cotton, hemp, and other ecofiber sources.

Global fiber output has nearly quadrupled in the last two decades, rising from 58 million tons in 2000 to 109 million tons in 2020. While it is unclear how the pandemic and other variables will affect future development, worldwide fiber production is predicted to expand by 34% to 146 million tons in 2030, assuming the industry returns to normal operations. Virgin fossil-based fibers grew in absolute terms from 55.7 million tons in 2016 to 59.7 million tons in 2020 [13].

The Organic Content Standard (OCS) and the Global Organic Textile Standard (GOTS) are the primary organic textile standards. The Organic Content Standard (OCS) is a voluntary international standard that establishes criteria for third-party certification of organic input and chain of custody. The OCS aims to increase organic agriculture production. In April 2020, Textile Exchange announced OCS 3.0. Manuals have been revised, as has traceability between farm and first processor, GMO testing standards, and non-mulesing for organic wool. From 6181 in 2019 to 8680 in 2020, the number of OCS-certified locations grew [13].

4. Restricted Substances in Textiles

Due to the fact that different countries have varying environmental regulations (or none at all), the transfer of production owing to globalization has added levels of complication to sustainable textile manufacture [52]. The RSL is used by manufacturers, traders, and brands all across the world to ensure clean production. Consumers who expect transparent value chains, high-quality, safe, and environmentally friendly products are increasingly becoming more numerous and demanding [13][15]. Companies that are forward-thinking must acknowledge this issue. For the foreseeable future, the textile sector will continue to play a significant role in the industrial sector [13][51]. Having a finished product that is just safe for people is no longer adequate; the product must be ecologically safe for the duration of its existence and even beyond. Clean/green technology uses green chemistry and environmental science to protect the environment and natural resources while reducing the negative consequences of human activity [53][54].

The textile industry uses many chemicals that can be harmful to humans and the environment. Over 8000 synthetic chemicals are estimated to be utilized in the clothing manufacturing process, including carcinogens and hormone disruptors [54]. Flame retardants, AZO dyes, chromium, and formaldehydes are also on this list. As a result, customers may be exposed to dangerous compounds in textiles via skin contact, inhalation, or unintentional ingestion of dust generated by the materials [55]. The most sensitive to these compounds’ exposure are generally children and pregnant women, who may suffer more serious health consequences [55].

RSLs can be different for each country or industry. Unsurprisingly, governments and industries prioritize harmful substances that are essential to them in terms of causing serious health or environmental concerns. Nonetheless, certain chemicals are regularly found in RSLs.

The three major Chemical Regulations in the Textile and Fashion Industry are:

-

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): REACH is a European Union law that was created in 2006 to govern the impact of chemical substances on society and the environment [56].

-

The United Nations Basel Convention Treaty: This was signed in 1989 and bans the movement of hazardous waste between countries. It was designed to reduce the total toxicity of waste produced for environmental management purposes [57].

-

The MRSL (Manufactures Restricted Substance List): This list contains forbidden textile and fashion materials such as leather, rubber, foam, adhesives, and trim elements in textiles, garments, and footwear. It is significant because it restricts ingredients not just in the completed product but also throughout the supply chain. The Zero Discharge of Hazardous Chemicals (ZDHC) initiative created the list [58].

Chemicals are a useful tool for textile manufacturing, but they require cautious handling and application. Consequently, it is essential to be able to identify chemicals of grave concern and restrict their use, but the greater challenge is to find appropriate substitutes that are safe, efficient, and cost-effective. As a result, textile processing has become increasingly difficult; as individual firms develop their own specifications, the manufacturer faces an even greater challenge. In terms of efficacy, color range, fastness, evenness of shade, color yield, and consistency, a number of ostensibly ecofriendly products, such as natural dyes in lieu of synthetic colors, have proven to be less effective.

5. Ecolabeling in the Textile Industry

Ecocertification’s goal is to gain market access to environmentally friendly products [59]. The certification process should help since the information gathered may be very useful for market planning, development, and research. In addition, it enhances the product’s image and increases its credibility and visibility.

Ecolabels are hallmarks of approval granted to products deemed to have fewer negative effects on the environment. The primary purpose of ecolabeling is to encourage the manufacturing of environmentally friendly and sustainable products and to inform consumers to look for these labels before making purchases. The presence of ecolabels on the garments ensures that the products adhere to social, ecological, and environmental standards. In the textile industry, more than 100 labels are available for certification, and over 9000 textile manufacturers have been certified, according to available data [11][21].

The main issues with ecolabeling include deceptive or false claims, as well as protectionism and unfair competition, as well as a lack of standards or strictness in the ecolabeling process or processes [60]. Ecolabeling educates the customer, separates the product from the target market, implies sustainability for the producer or seller, and alters or elevates the perception of the product along the whole supply chain [61]. While a global, transparent ecolabeling system encourages markets, regional ecolabeling can restrict market access and lessen global competitiveness [60][62]. Ecolabeling can also be used to construct market-based trade barriers.

Ecolabels are normally optional but, in some cases, are mandatory [63]. Three typologies of optional labeling are categorized in ISO 14020, the International Standard Organization [64]. Type I is optional and is determined by several factors. It is given out by independent programs that award a license allowing the use of environmental labels on products. Based on lifecycle considerations, these marks reflect an environmental choice within a category. The environmental claims made on the Type II labels are informative self-declarations. These are self-declarations based on linguistically widespread terminology, concepts, and symbols. Type III labels are optional, give quantitative environmental information in accordance with predetermined categories, and are created and confirmed by certified third parties. When it has been established that the applicant’s product satisfies the requirements, ecolabels are frequently given out by publicly funded or privately-run organizations. In circumstances where an industry’s voluntary participation in an ecolabeling system is deemed insufficient, governments may decide to compel enterprises to take actions to decrease environmental consequences, adopt specified technological modifications, or implement mandatory (national) labeling regulations [65]. Governments, for example, may require warning labels to enhance health and environmental safety. In some cases, producers that do not meet national criteria are denied access to domestic markets.

Greenwashing is a form of propaganda in which green marketing is ostensibly used to convey the idea that a company’s goods, objectives, or policies are environmentally advantageous [66]. Disparities in expenditure, or when considerably more money or effort is spent on “green” advertising than is really spent on ecologically friendly operations, are sometimes used to illustrate greenwashing [66]. A product containing harmful chemicals may have its name or label changed to invoke the natural world, while polluting energy companies may have their advertising campaigns spend millions of dollars to appear ecologically friendly [66][67].

References

- Kalkanis, K.; Alexakis, D.E.; Kyriakis, E.; Kiskira, K.; Lorenzo-Llanes, J.; Themelis, N.J.; Psomopoulos, C.S. Transforming Waste to Wealth, Achieving Circular Economy. Circ. Econ. Sustain. 2022, 2, 1541–1559.

- Hatzilyberis, K.; Tsakanika, L.A.; Lymperopoulou, T.; Georgiou, P.; Kiskira, K.; Tsopelas, F.; Ochsenkühn, K.M.; Ochsenkühn-Petropoulou, M. Design of an advanced hydrometallurgy process for the intensified and optimized industrial recovery of scandium from bauxite residue. Chem. Eng. Process. Process Intensif. 2020, 155, 108015.

- Psomopoulos, C.S.; Kiskira, K.; Kalkanis, K.; Leligou, H.C.; Themelis, N.J. The role of energy recovery from wastes in the decarbonization efforts of the EU power sector. IET Renew. Power Gener. 2022, 16, 48–64.

- Kiskira, K.; Papirio, S.; Pechaud, Y.; Matassa, S.; van Hullebusch, E.D.; Esposito, G. Evaluation of Fe (II)-driven autotrophic denitrification in packed-bed reactors at different nitrate loading rates. Process Saf. Environ. Prot. 2020, 142, 317–324.

- Vercalsteren, A.; Nicolau, M.; Lafond, E. Textiles and the Environment in a Circular Economy. Eionet Report 2019- ETC/WMGE 2019/6. Available online: https://www.eionet.europa.eu/etcs/etc-wmge/products/etc-wmge-reports/textiles-and-the-environment-in-a-circular-economy (accessed on 10 January 2023).

- Sivaramakrishnan, C.N. Pollution in textile industry. Colourage 2009, 16, 66–68.

- Huang, B.; Zhao, J.; Geng, Y.; Tian, Y.; Jiang, P. Energy-related GHG emissions of the textile industry in China. Resour. Conserv. Recycl. 2017, 119, 69–77.

- WWF. Cotton Facts. Available online: https://www.worldwildlife.org/industries/cotton (accessed on 15 December 2022).

- ten Wolde, A.; Korneeva, P. Circular Fashion Advocacy, A Strategy towards a Circular Fashion Industry in Europe. Report 2019, Ecopreneur.eu. Available online: https://ecopreneur.eu/wp-content/uploads/2019/03/EcoP-Circular-Fashion-Advocacy-Report-28-3-19.pdf (accessed on 15 January 2023).

- Plakantonaki, S.; Stergiou, M.; Panagiotatos, G.; Kiskira, K.; Priniotakis, G. Regenerated cellulosic fibers from agricultural waste. AIP Conf. Proc. 2022, 2430, 080006.

- Choudhury, R.A.K. Development of eco-labels for sustainable textiles. In Roadmap to Sustainable Textile and Clothing: Regulatory Aspects and Sustainability Standards of Textiles and the Clothing Supply Chain, 1st ed.; Muthu, S.S., Ed.; Springer: Cham, Switzerland, 2015; pp. 137–174.

- Periyasamy, A.P.; Militky, J. Sustainability in Regenerated Textile Fibers. In Sustainability in the Textile and Apparel Industries, 1st ed.; Muthu, S.S., Gardetti, M.A., Eds.; Springer: Cham, Switzerland, 2020; pp. 63–95.

- Pepper, L.R.; Truscott, L. Preferred Fiber & Materials Market Report 2021. Textile Exchange. Available online: https://textileexchange.org/app/uploads/2021/08/Textile-Exchange_Preferred-Fiber-and-Materials-Market-Report_2021.pdf (accessed on 11 November 2022).

- Buchel, S.; Roorda, C.; Schipper, K.; Loorbach, D.; Janssen, R. The Transition to Good Fashion. DRIFT Report 2018. Rotterdam: Erasmus University Rotterdam. Available online: https://drift.eur.nl/wp-content/uploads/2018/11/FINAL_report.pdf (accessed on 8 October 2022).

- UNECE. Fashion Is an Environmental and Social Emergency, But Can also Drive Progress towards the Sustainable Development Goals. Available online: https://unece.org/forestry/news/fashion-environmental-and-social-emergency-can-also-drive-progress-towards (accessed on 18 December 2022).

- Baaka, N.; Khiari, R.; Haji, A. Ecofriendly Dyeing of Textile Materials with Natural Colorants from Date Palm Fiber Fibrillium. Sustainability 2023, 15, 1688.

- EUR-Lex. Access to European Law. Regulation 1007/2011 on Fibre Names and Related Marking of the Fibre Composition of Textile Products. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32011R1007&from=EN (accessed on 11 January 2023).

- Shirvanimoghaddam, K.; Motamed, B.; Ramakrishna, S.; Naebe, M. Death by waste: Fashion and textile circular economy case. Sci. Total Environ. 2020, 718, 137317.

- Ben-Eli, M.U. Sustainability: Definition and five core principles, a systems perspective. Sustain. Sci. 2018, 13, 1337–1343.

- Thiry, M.C. Following the Fabric lifecycle. AATCC Rev. 2009, 9, 22–29.

- Ecolabel Index. Available online: https://www.ecolabelindex.com/ecolabels/?st=category,textiles (accessed on 25 February 2023).

- Angelova, R.A.; Sofronova, D. Sustainable Textiles: Design of New Weave Patterns Based on Texts. Sustainability 2023, 15, 1614.

- Kalkanis, K.; Kiskira, K.; Papageorgas, P.; Kaminaris, S.D.; Piromalis, D.; Banis, G.; Mpelesis, D.; Batagiannis, A. Advanced Manufacturing Design of an Emergency Mechanical Ventilator via 3D Printing—Effective Crisis Response. Sustainability 2023, 15, 2857.

- Psomopoulos, C.S.; Kalkanis, K.; Chatzistamou, E.D.; Kiskira, K.; Ioannidis, G.C.; Kaminaris, S.D. End of life treatment of photovoltaic panels. Expected volumes up to 2045 in EU. AIP Conf. Proc. 2022, 2437, 20084–20098.

- Fernández, V.; Laborda, E.; Del-Busto, F.; Bartolomé, C. Social Perspectives towards Biobased Products and Textiles. Sustainability 2023, 15, 2284.

- Toghyani, A.E.; Matthews, S.; Varis, J. Feasibility assessment of a wood-plastic composite post-production process: Cuttability. Procedia Manuf. 2018, 25, 271–278.

- Lee, H.W. Development of Sustainable Creative Three-Dimensional Virtual Woven Textiles Using Clothing Waste. Sustainability 2023, 15, 2263.

- Bourtsalas, A.C.; Papadatos, P.E.; Kiskira, K.; Kalkanis, K.; Psomopoulos, C.S. Ecodesign for Industrial Furnaces and Ovens: A Review of the Current Environmental Legislation. Sustainability 2023, 15, 9436.

- Patra, A.K.; Pariti, S.R.K. Restricted substances for textiles. Text. Prog. 2022, 54, 1–101.

- Dulo, B.; De Somer, T.; Phan, K.; Roosen, M.; Githaiga, J.; Raes, K.; De Meester, S. Evaluating the potential of natural dyes from nutshell wastes: Sustainable colouration and functional finishing of wool fabric. Sustain. Mater. Technol. 2022, 34, 518–531.

- Lant, N.J.; Hayward, A.S.; Peththawadu, M.M.; Sheridan, K.J.; Dean, J.R. Microfiber release from real soiled consumer laundry and the impact of fabric care products and washing conditions. PLoS ONE 2020, 15, 233332–233350.

- Yun, C.; Patwary, S.; LeHew, M.L.; Kim, J. Sustainable care of textile products and its environmental impact: Tumble-drying and ironing processes. Fibers Polym. 2017, 18, 590–596.

- Rotzler, S.; Krshiwoblozki, M.V.; Schneider-Ramelow, M. Washability of e-textiles: Current testing practices and the need for standardization. Text. Res. J. 2021, 91, 2401–2417.

- Iqbal, S.; Ansari, T.N. Extraction and application of natural dyes. In Sustainable Practices in the Textile Industry, 1st ed.; Rather, L.J., Shabbir, M., Haji, A., Eds.; Scrivener Publishing LLC: Beverly, MA, USA, 2021; pp. 1–40.

- Uddin, F. Environmental hazard in textile dyeing wastewater from local textile industry. Cellulose 2021, 28, 10715–10739.

- Mandal, S.; Venkatramani, J. A review of plant-based natural dyes in leather application with a special focus on color fastness characteristics. Environ. Sci. Pollut. Res. 2023, 30, 48769–48777.

- Choudhury, A.K.R. Eco-friendly dyes and dyeing. Adv. Mater. Technol. Environ. 2018, 2, 145–176.

- Gross, M. Oceans of plastic waste. Curr. Biol. 2015, 25, 93–96.

- Rochman, C.M.; Tahir, A.; Williams, S.L.; Baxa, D.V.; Lam, R.; Miller, J.T.; Teh, F.C.; Werorilangi, S.; Teh, S.J. Anthropogenic debris in seafood: Plastic debris and fibers from textiles in fish and bivalves sold for human consumption. Sci. Rep. 2015, 5, 14340.

- De Falco, F.; Gullo, M.P.; Gentile, G.; Di Pace, E.; Cocca, M.; Gelabert, L.; Brouta-Agnésa, M.; Rovira, A.; Escudero, R.; Villalba, R.; et al. Evaluation of microplastic release caused by textile washing processes of synthetic fabrics. Environ. Pollut. 2018, 236, 916–925.

- Byrd, K.; Su, J. Investigating consumer behaviour for environmental, sustainable and social apparel. Int. J. Cloth. Sci. Technol. 2021, 33, 336–352.

- Lou, L.; Yu, W.; Ramkumar, S. Wearable and smart responsive textiles. In High Performance Technical Textiles, 1st ed.; Paul, P., Ed.; John Wiley & Sons, Ltd.: West Sussex, UK, 2019; pp. 439–473.

- Pandit, P.; Nadathur, G.T.; Jose, S. Upcycled and low-cost sustainable business for value-added textiles and fashion. In Circular Economy in Textiles and Apparel, 1st ed.; Muthu, S.S., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; pp. 95–122.

- Pandey, R.; Pandit, P.; Pandey, S.; Mishra, S. Solutions for sustainable fashion and textile industry. In Recycling from Waste in Fashion and Textiles: A Sustainable and Circular Economic Approach, 1st ed.; Pandit, P., Ahmed, S., Singha, K., Shrivastava, S., Eds.; John Wiley & Sons, Ltd.: West Sussex, UK, 2020; pp. 33–72.

- Madhav, S.; Ahamad, A.; Singh, P.; Mishra, P.K. A review of textile industry: Wet processing, environmental impacts, and effluent treatment methods. Environ. Qual. Manag. 2018, 27, 31–41.

- Dissanayake, D.G.K.; Weerasinghe, D. Towards circular economy in fashion: Review of strategies, barriers and enablers. Circ. Econ. Sustain. 2021, 2, 25–45.

- Durham, T.C.; Mizik, T. Comparative economics of conventional, organic, and alternative agricultural production systems. Economies 2021, 9, 64–84.

- Srijita, D. Biopesticides: An ecofriendly approach for pest control. World J. Pharm. Pharm. Sci. 2015, 4, 250–265.

- Beyond Pesticides. Defining a Strong IPM or EPM Program. Available online: https://www.beyondpesticides.org/resources/safety-source-on-pesticide-providers/what-is-integrated-pest-management (accessed on 26 June 2023).

- Harsanto, B.; Primiana, I.; Sarasi, V.; Satyakti, Y. Sustainability Innovation in the Textile Industry: A Systematic Review. Sustainability 2023, 15, 1549.

- Grand View Research. Market Analysis Report 2021. Available online: https://www.grandviewresearch.com/industry-analysis/eco-fiber-market# (accessed on 10 April 2023).

- Jia, F.; Yin, S.; Chen, L.; Chen, X. The circular economy in the textile and apparel industry: A systematic literature review. J. Clean. Prod. 2020, 259, 120728–120748.

- Kiskira, K.; Lymperopoulou, T.; Lourentzatos, I.; Tsakanika, L.A.; Pavlopoulos, C.; Papadopoulou, K.; Ochsenkühn, K.M.; Tsopelas, F.; Chatzitheodoridis, E.; Lyberatos, G.; et al. Bioleaching of Scandium from Bauxite Residue using Fungus Aspergillus Niger. Waste Biomass Valorization 2023, 1, 1–14.

- Nabil, I.; Chaudhery, M. Green Chemistry for Sustainable Textiles: Modern Design and Approaches, 1st ed.; Woodhead Publishing: Duxford, UK, 2021; pp. 1–491.

- Rovira, J.; Domingo, J.L. Human health risks due to exposure to inorganic and organic chemicals from textiles: A review. Environ. Res. 2019, 168, 62–69.

- ECHA, EU. Available online: https://echa.europa.eu/regulations/reach/understanding-reach (accessed on 15 January 2023).

- UN, Environmnet Programme. Available online: http://www.basel.int/TheConvention/Overview/tabid/1271/Default.aspx (accessed on 15 March 2023).

- ZDHC Manufacturing Restricted Substance List. Available online: https://www.roadmaptozero.com/?locale=en (accessed on 20 April 2023).

- Henninger, C.E. Traceability the new eco-label in the slow-fashion industry?—Consumer perceptions and micro-organisations responses. Sustainability 2015, 7, 6011–6032.

- Diekel, F.; Mikosch, N.; Bach, V.; Finkbeiner, M. Life cycle based comparison of textile ecolabels. Sustainability 2021, 13, 1751.

- Wojnarowska, M.; Sołtysik, M.; Prusak, A. Impact of eco-labelling on the implementation of sustainable production and consumption. Environ. Impact Assess. Rev. 2021, 86, 106505.

- Singer, A.A.; van der Ven, H. Beyond market, firm, and state: Mapping the ethics of global value chains. Bus. Soc. Rev. 2019, 124, 325–343.

- Ranasinghe, L.; Jayasooriya, V. Ecolabelling in textile industry: A review. Resour. Environ. Sustain. 2021, 6, 100037.

- ISO 14020:2022. Environmental Statements and Programmes for Products—Principles and General Requirements. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14020:ed-3:v1:en (accessed on 20 April 2023).

- Ibanez, L. Ecolabels: Are They Environmental-Friendly? In Encyclopedia of Law and Economics, 1st ed.; Marciano, A., Ramello, G., Eds.; Springer: New York, NY, USA, 2016; pp. 1–9.

- de Freitas Netto, S.V.; Sobral, M.F.F.; Ribeiro, A.R.B.; Soares, G.R.D.L. Concepts and forms of greenwashing: A systematic review. Environ. Sci. Eur. 2020, 32, 19.

- Nemes, N.; Scanlan, S.J.; Smith, P.; Smith, T.; Aronczyk, M.; Hill, S.; Lewis, S.L.; Montgomery, A.W.; Tubiello, F.N.; Stabinsky, D. An integrated framework to assess greenwashing. Sustainability 2022, 14, 4431.

More

Information

Subjects:

Green & Sustainable Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.1K

Revisions:

2 times

(View History)

Update Date:

01 Aug 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No